Automatic coating device

A paint and equipment technology, applied in the field of automatic paint equipment, can solve the problems of paint spilling on the ground, low work efficiency, uneven application, etc., and achieve the effects of reducing labor, improving work efficiency, and brushing parts uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

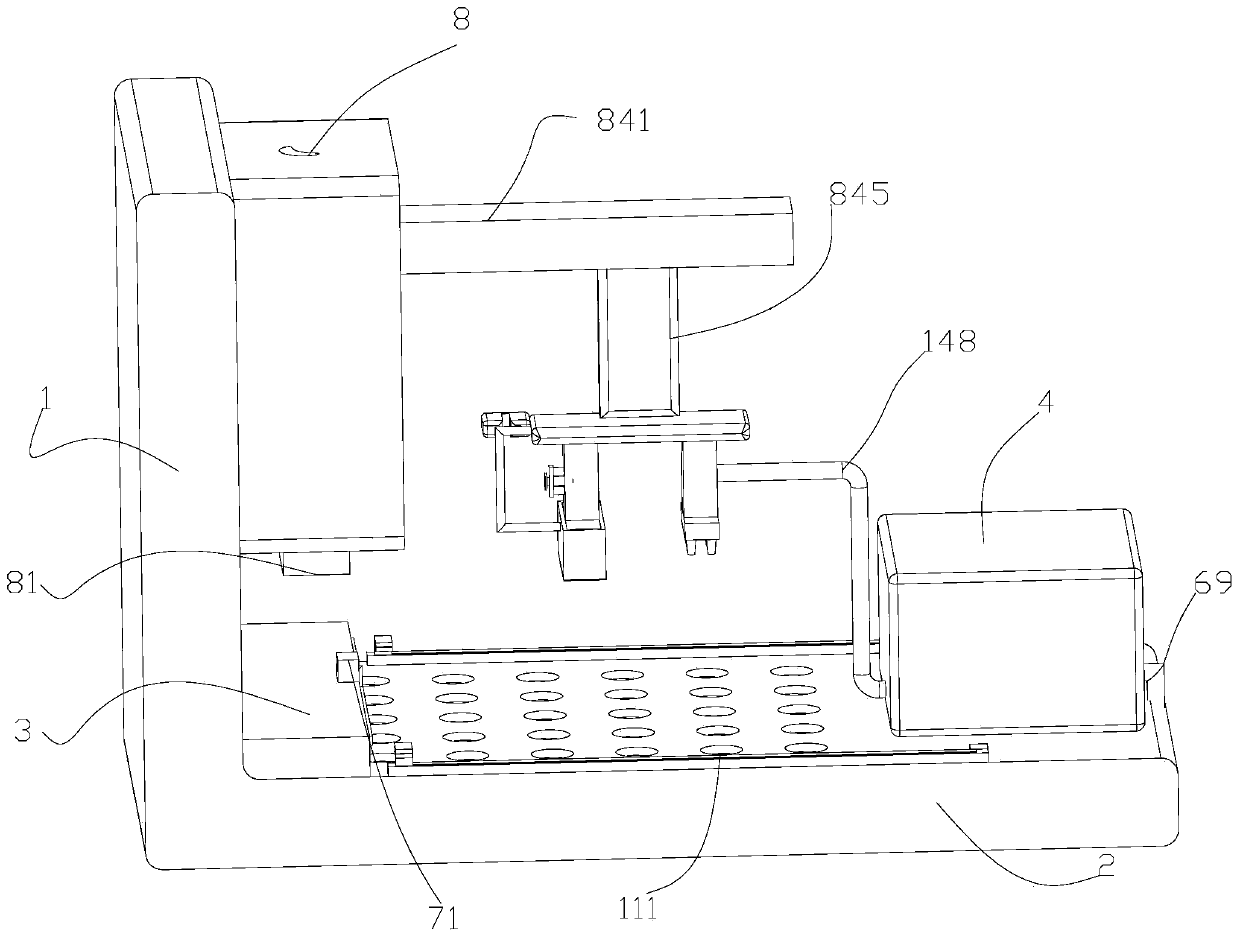

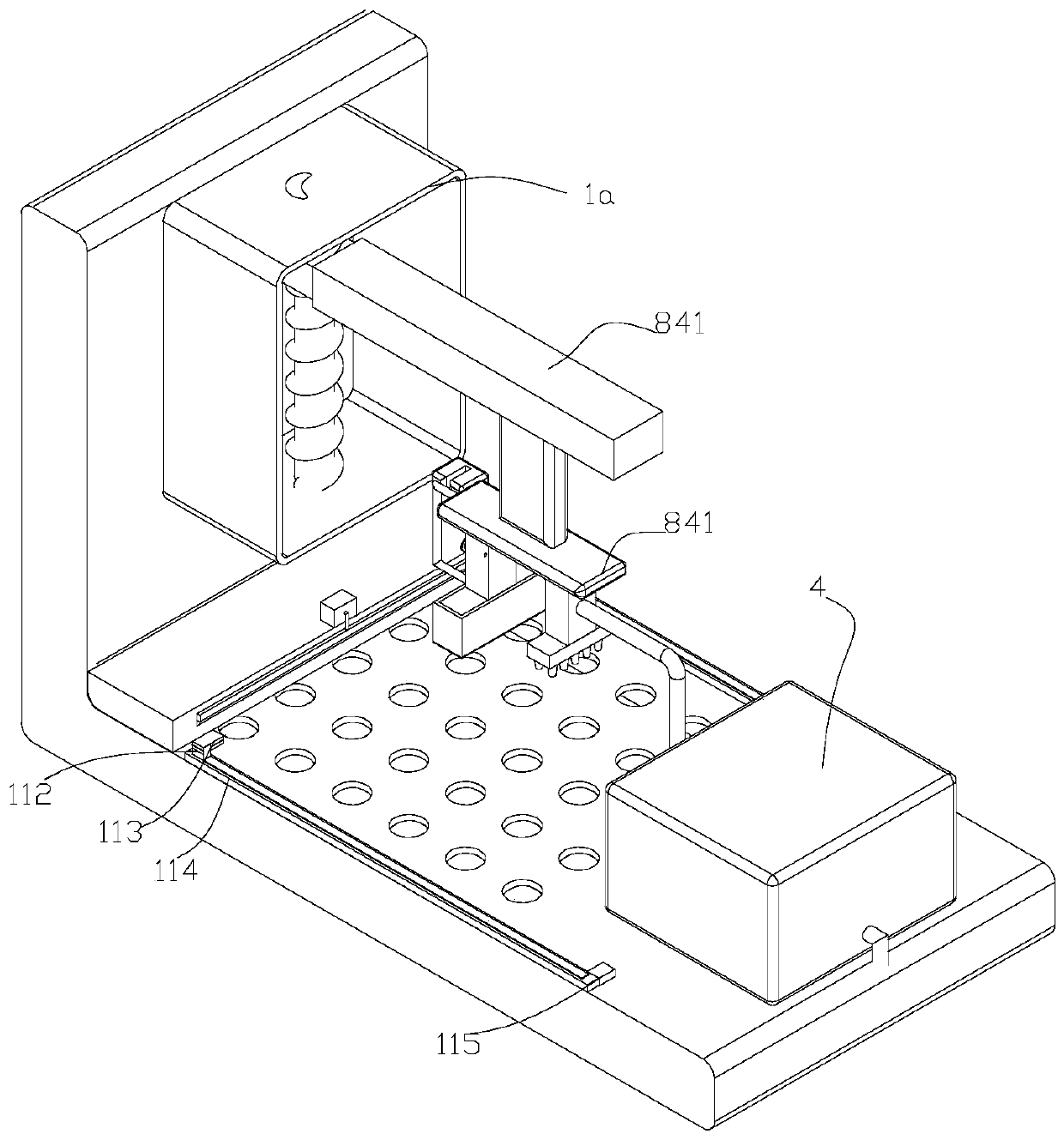

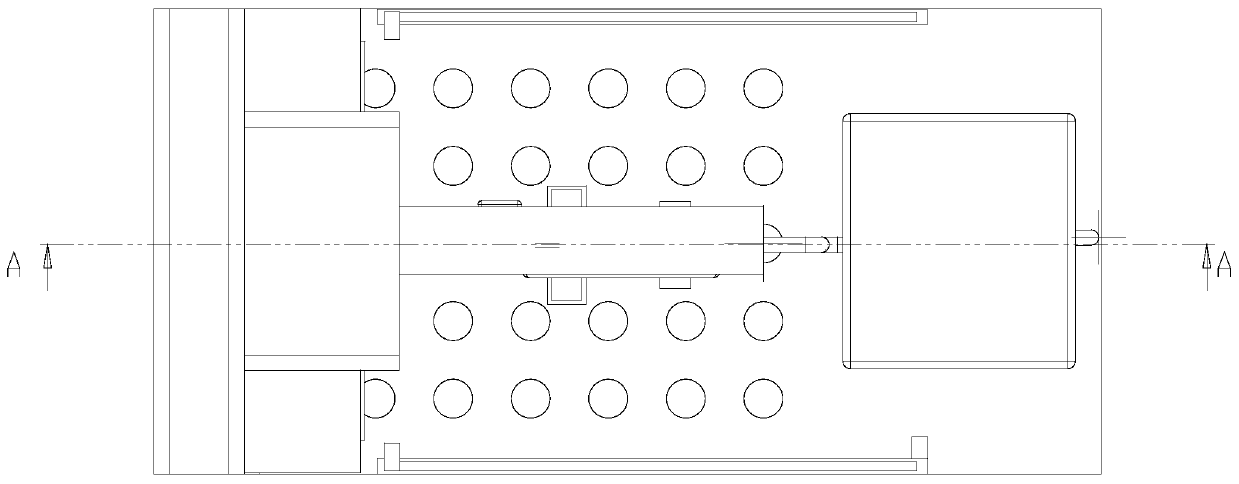

[0030]As shown in the figure, a kind of automatic coating equipment comprises vertical plate 1, base plate 2, distribution box 3, paint box 4, paint recovery box 5, paint mechanism 6, cutting mechanism 7, moving mechanism 8 and moving box 1a; The bottom plate 2 is fixedly connected to the upper part of the vertical plate 1, and a plurality of mesh holes are opened on the bottom plate 2; the distribution box 3 is fixedly connected at the angle between the vertical plate 1 and the bottom plate 2; The right side; the paint recovery box 5 is located inside the base plate 2; the mobile box 1a is fixedly connected to the upper right side of the vertical plate 1; the paint mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com