1-polyolefin halogenation production method

A production method and polyolefin technology, applied in the field of halogenated polymer preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

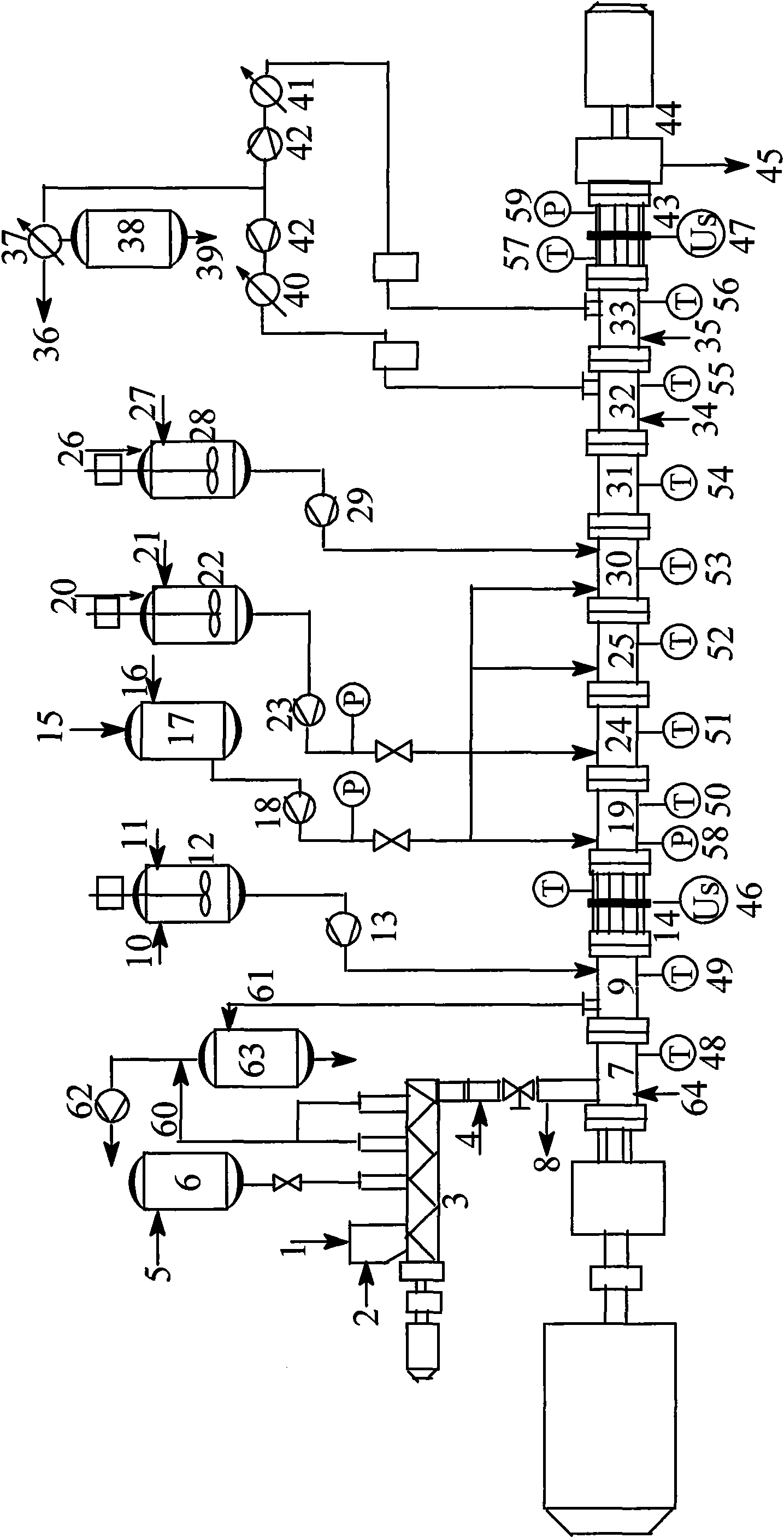

[0052] 1- The main equipment of the polyolefin halogenation plant is as follows: figure 1 In the shown reactor device of a reverse twin-screw extruder, the diameter of the screw is Ф36mm, and the ratio of length to diameter is L / D=60. Except for the metering and discharging section, which is meshed, the rest of the sections are non-meshed. The cylinder body is divided into 10 sections for temperature control, the internal cooling medium of the cylinder is 0 ℃ white oil, and the outer cylinder is heated by an electric heating copper tile heating jacket. High-density polyethylene pellets (density 0.95g / m 3 ) into the hopper of feeder-screw crushing plasticizer 3, with a weight of 30kg. Into the lower part of the hopper into 0.01MPa pressure nitrogen, the flow rate is about 0.2NM 3 / h, the temperature of the screw crushing plasticizer is controlled at 60-100°C. Through the liquid raw material tank 6, 20 kg of carbon tetrachloride dissolved with 60 g of azobisisobutyronitrile i...

Embodiment 2

[0054] The same reaction device system as in Example 1 was used. Present embodiment adopts low-density polyethylene pellets (density 0.92g / m 3 ) into the hopper of feeder-screw crushing plasticizer 3, with a weight of 30kg. Into the lower part of the hopper into 0.01MPa pressure nitrogen, the flow rate is about 0.2NM 3 / h. The temperature of the screw crushing plasticizer is controlled at 60-80°C. Through the liquid raw material tank 6, 20 kg of carbon tetrachloride dissolved in 60 g of azobisisobutyronitrile is metered into, and the low-density polyethylene is softened, shredded and extruded into a porous soft material, which is sent into a twin-screw extruder reactor plastic After the degassing section, the solvent and a small amount of water are evaporated and recovered to obtain a viscous liquid with a solid content of more than 70%, which is then subjected to ultrasonic viscosity reduction and enters the halogenation reaction system. Twin-screw extruder reactor diamet...

Embodiment 3

[0056]The same reactor setup system as in Example 1 was used. In this embodiment, polypropylene pellets are added to the hopper of the feeder-screw crushing plasticizer 3 with a weight of 30 kg. Into the lower part of the hopper into 0.01MPa pressure nitrogen, the flow rate is about 0.2NM 3 / h. The temperature of the screw crushing plasticizer is controlled at 80-100°C. Through the liquid raw material tank 6, 20 kg of toluene dissolved with 40 g of azobisisobutyronitrile is metered in, and the polypropylene is softened, shredded and extruded into a porous soft material, which is then sent into the plasticizing and degassing section of the twin-screw extruder reactor. , the solvent and a small amount of water are evaporated and recovered to obtain a viscous liquid with a solid content of more than 70%, which is then subjected to ultrasonic viscosity reduction and enters the halogenation reaction system. Twin-screw extruder reactor diameter Ф100mm, L / D=10 asynchronous co-rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com