Composite of engine lubricant and preparation method thereof

A lubricating oil composition and engine technology, applied in the field of lubricating oil, can solve the problems of inconvenience and benefit, difficult to cure, and high cost, and achieve the effects of extending the oil change period and the service life of the engine, improving the power performance and improving the emission performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A full-component lubricating oil composition was prepared, named "Guanxiubao" 10W-40, and the existing Longpan lubricating oil Jingwei SJ 15W-40 was used as a comparison.

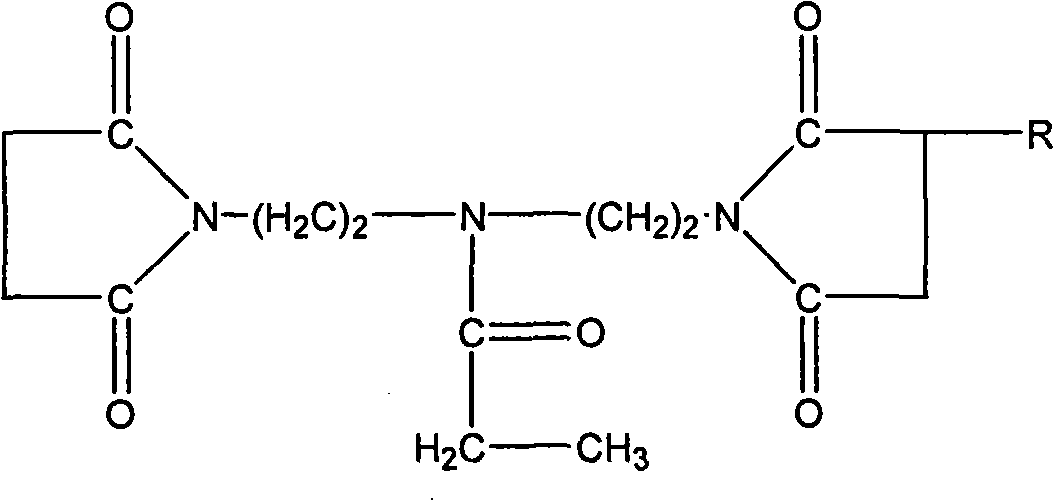

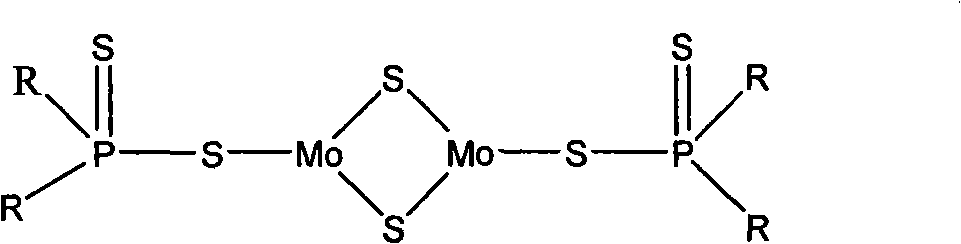

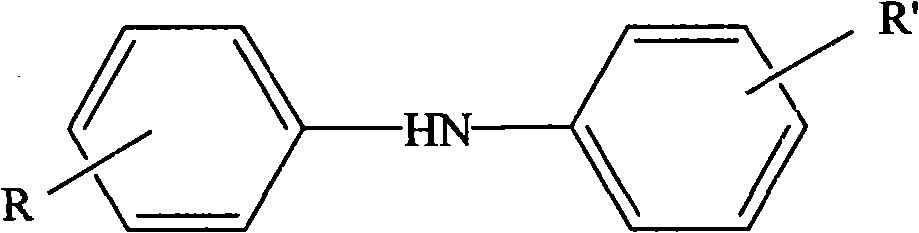

[0047] The preparation method is as follows: put the base oil (hydrogenated base oil, high-pressure hydrogenated bright stock, alkyl naphthalene) into the blending kettle in proportion, raise the temperature to 75°C, and then add the viscosity index improver (SV-261) and Pour point depressant (1-248), stir for 30 minutes; cool down to 65°C, add detergent and dispersant (boronated succinimide ashless dispersant, sulfurized alkylphenol calcium, synthetic calcium sulfonate, synthetic magnesium sulfonate ), anti-oxidation and anti-wear agent (nitrogen-containing molybdenum thiophosphate, zinc dialkyldithiophosphate, amine antioxidant, phenolic antioxidant), add antifoaming agent (T901) after stirring for 30 minutes; The product was produced after stirring for 15 minutes.

[0048] Its data are shown in T...

Embodiment 2

[0052] Prepare a full-component lubricating oil composition, named "Guanxiubao" 10W-40, the preparation method is the same as in Example 1, and the existing Longpan lubricating oil Jingwei SJ 15W-40 is used as a comparison, and its data are shown in Table 2:

[0053] Table 2

[0054]

Embodiment 3

[0056] A full-component lubricating oil composition was prepared, named "Guanxiubao" 10W-40, the preparation method was the same as in Example 1, and the existing Longpan lubricating oil Jingwei SJ 15W-40 was used as a comparison. The data are shown in Table 3:

[0057] table 3

[0058]

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com