Electricity-auxiliary two-stage supercharging system capable of reusing exhaust gas

A supercharging system and electric auxiliary technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of turbocharging hysteresis and low utilization rate of exhaust gas, etc., achieve high temperature load reduction, easy implementation, and improved power and emission performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better illustrate the purpose and advantages of the present invention, further introduction will be made below in conjunction with the accompanying drawings and embodiments.

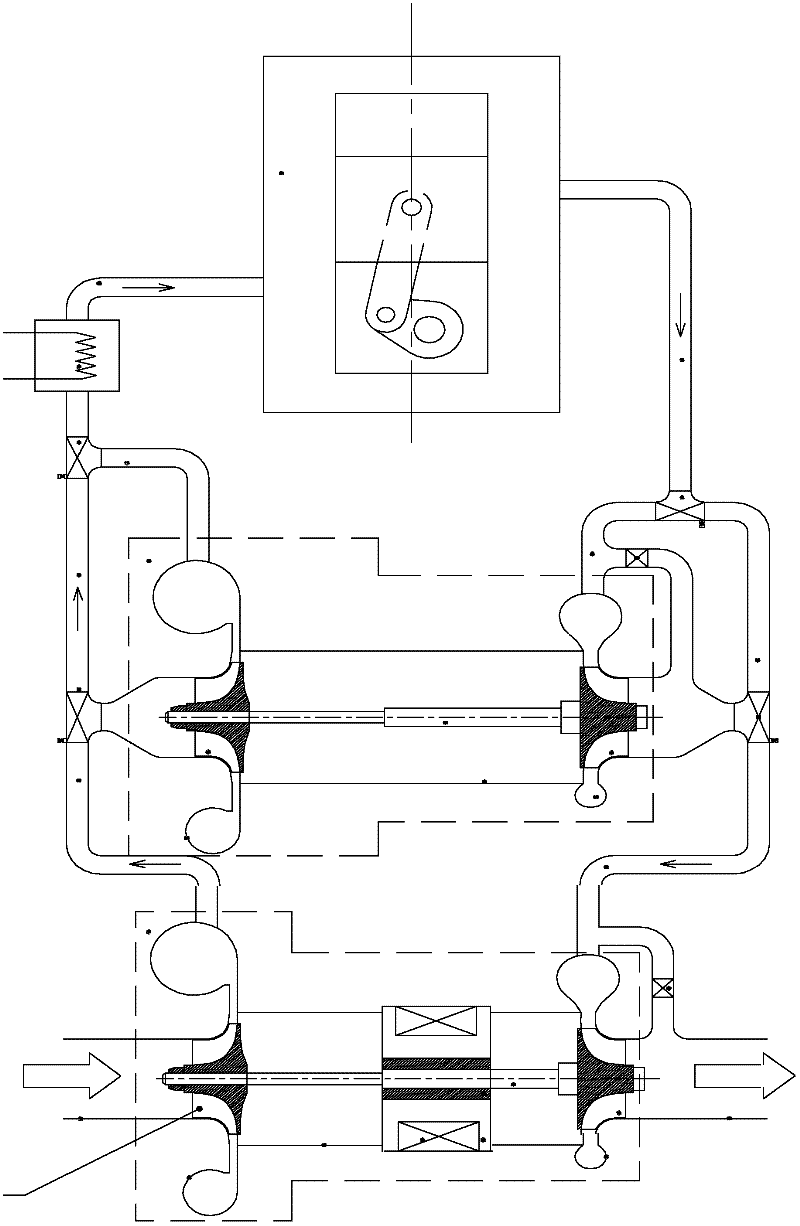

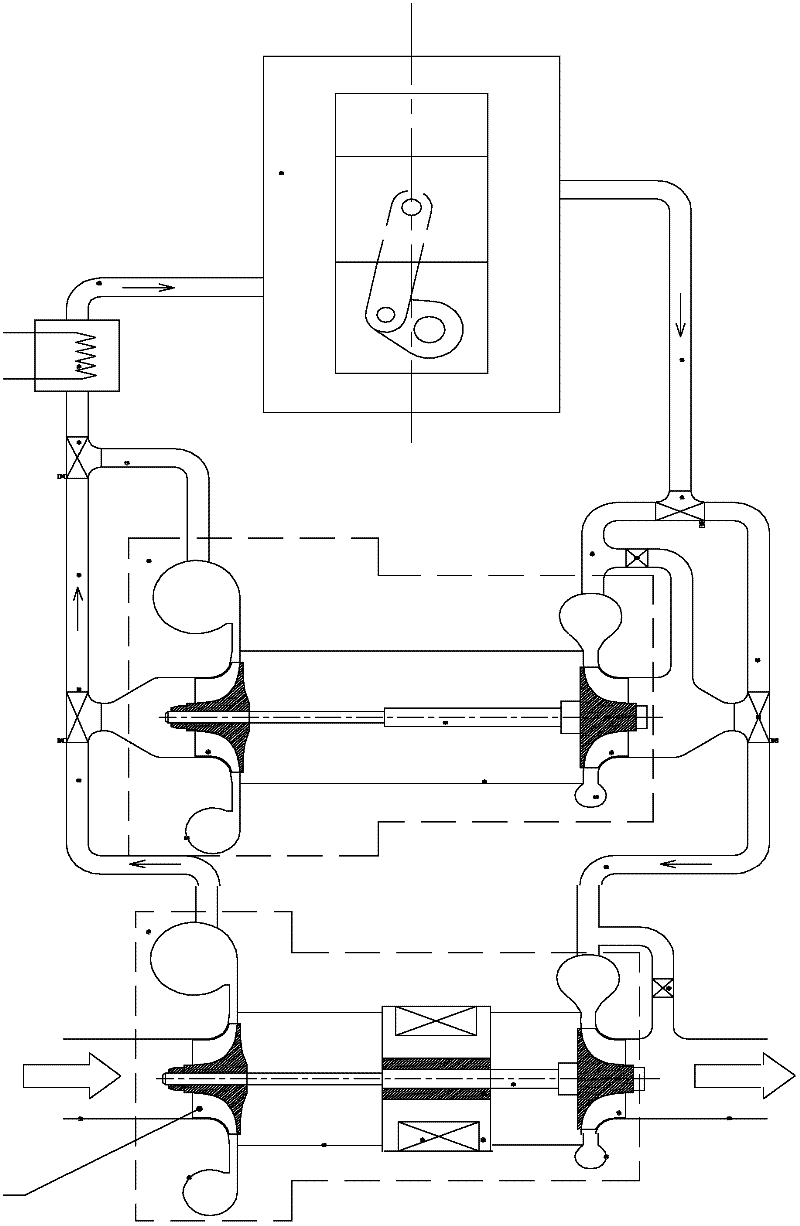

[0036] Such as figure 1 As shown, the exhaust gas reuse electric auxiliary two-stage supercharging system of the present invention includes the following parts:

[0037] 1. Electrically assisted turbine primary supercharger A: including primary supercharger compressor volute 1, primary supercharger compressor impeller 2, primary supercharger turbine 26, and primary supercharger turbine box 27 , first-stage supercharger wastegate valve 24, one-stage supercharger rotor 28, one-stage supercharger intermediate 31, motor system M (motor rotor 29 and motor stator 30);

[0038] Wherein the first-stage supercharger compressor volute 1 and the first-stage supercharger compressor impeller 2 form the first-stage supercharger compressor end, and the first-stage supercharger turbine 26 and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com