Variable intake tumble adjusting mechanism for gasoline engine

A gasoline engine and regulating mechanism technology, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems of cumbersome layout, large number of parts, and high requirements for the whole machine, so as to improve general performance, smooth gas flow, reduce The effect of small airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

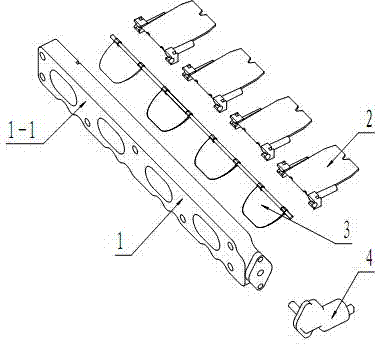

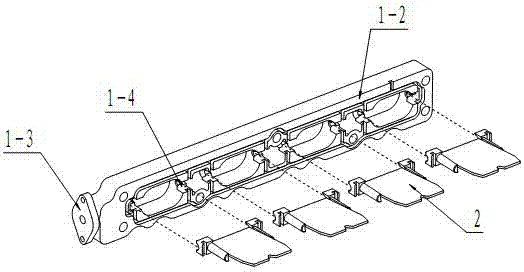

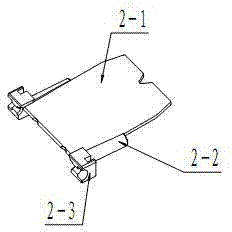

[0020] See Figure 1, figure 2 , Figure 5 , the present invention includes a support body 1, a tumble regulating valve assembly 3, a deflector assembly 2 and an electric actuator 4, and the support body 1 is arranged between the intake manifold air passage 5 and the engine cylinder head intake passage 6 , the tumble regulating valve assembly 3 is assembled with the support body 1, the front end of the deflector assembly 2 is assembled with the support body 1, and the rear end goes deep into the engine cylinder head intake passage 6, and the electric actuator 4 Installed on the support body 1.

[0021] see Figure 1 to Figure 6 , the present invention is installed between gasoline engine cylinder head air passage 6 and intake manifold air passage 5, and the thickness of support body 1 is very little, hardly has influence on intake passage length; Rotating shaft 3-2 of the present invention and tumble flow The valve plate 3-1 is injection molded into one body, and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com