Hydrogen gas natural gas mixed fuel engine optimizing method

A technology of mixed fuel and optimization method, which is applied in the direction of combustion engine, internal combustion piston engine, gaseous engine fuel, etc., can solve the problems of unobtainable control parameters, large amount of experiments, etc., and achieve economic optimization, emission performance optimization, and comprehensive performance improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

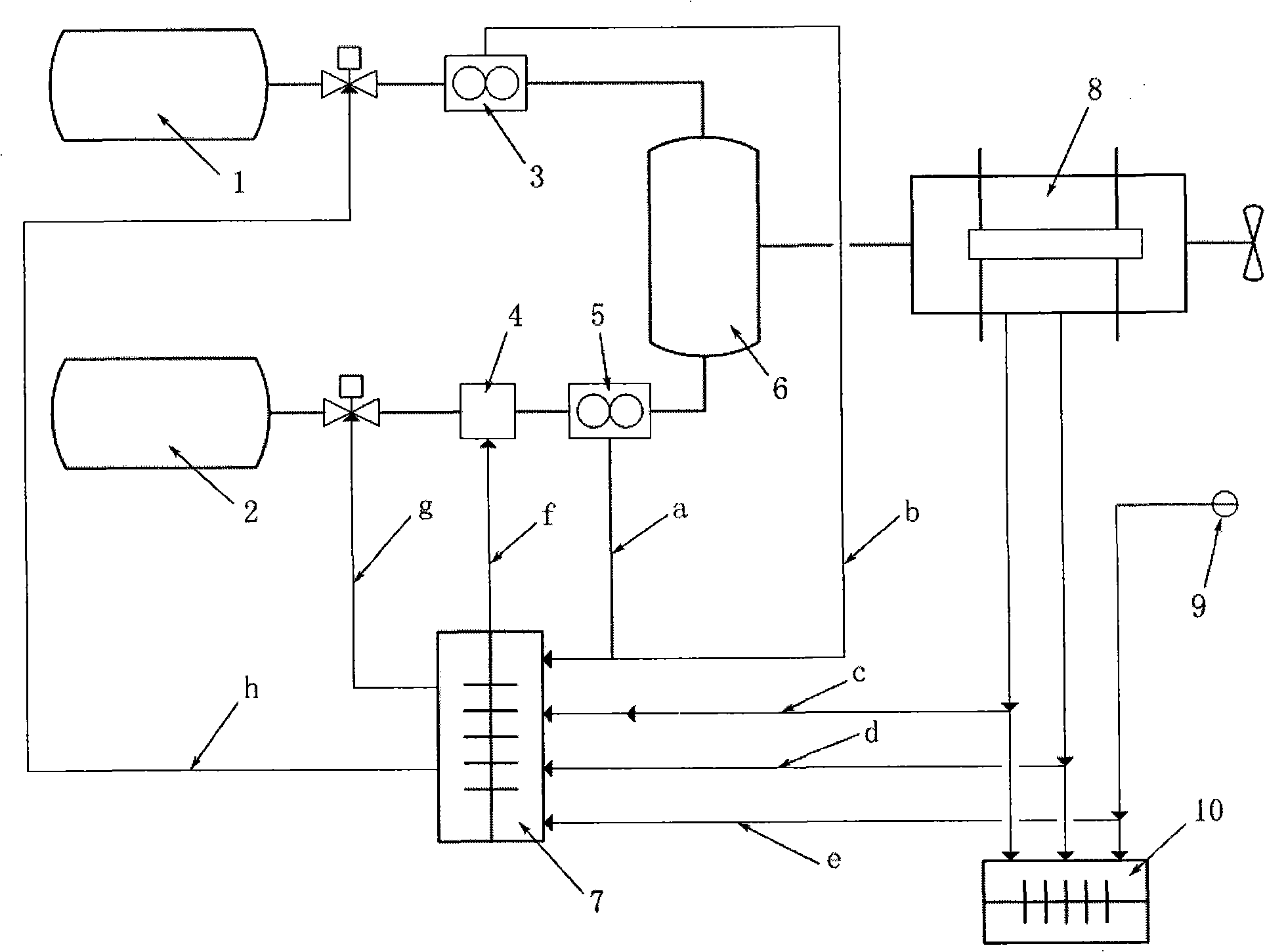

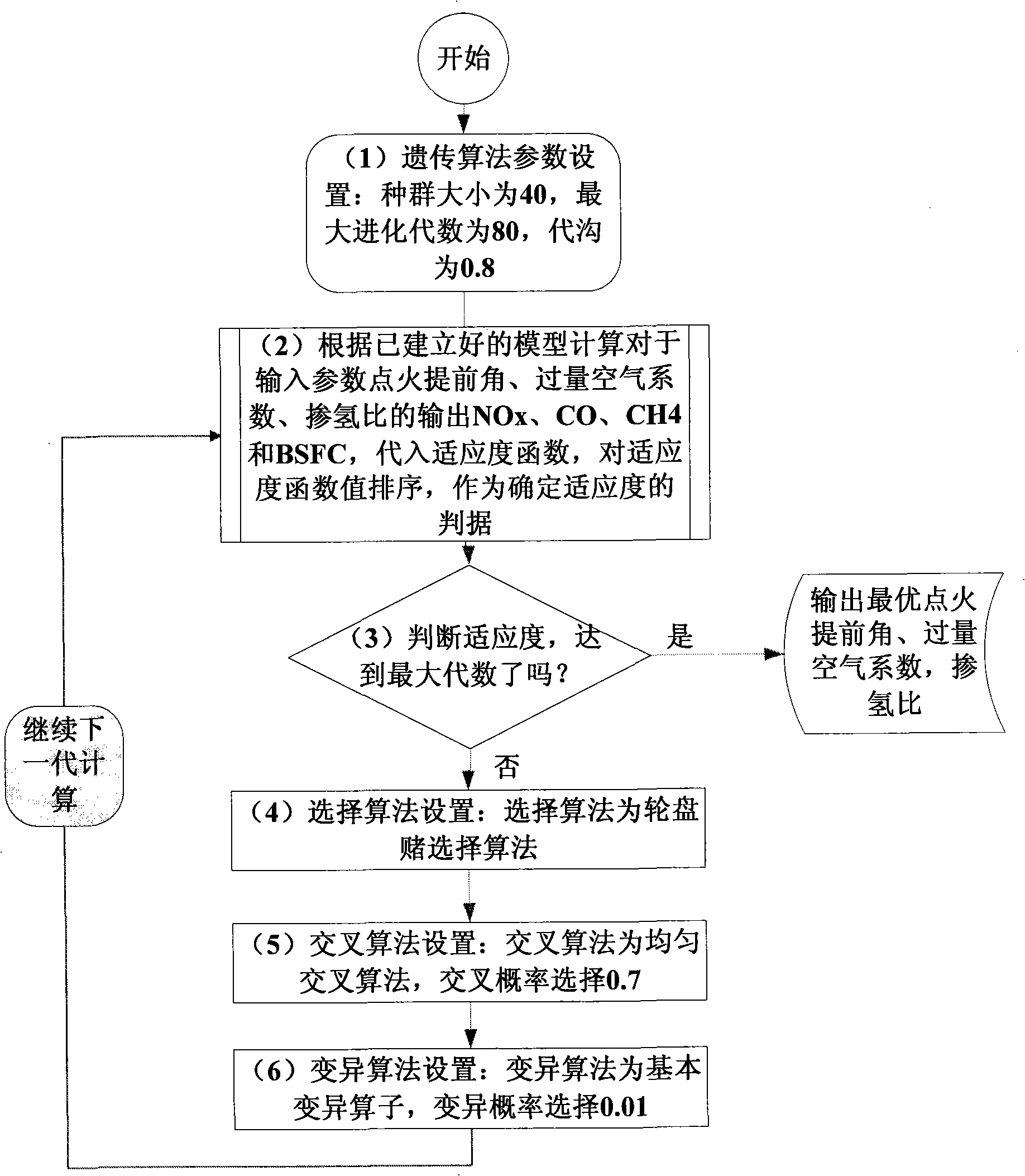

[0030] The principle and working process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. In the embodiment, the selected operating point is the speed of 1200r / min, the torque of 200N.M, the range of ignition advance angle is 20-40 degrees, the adjustment range of excess air coefficient is 1.1-1.6, and the adjustment range of hydrogen doping ratio is 0-40%. The overall flow of the optimization control method is as follows: figure 1 Shown:

[0031] 1) Experimental design

[0032] The main purpose of using experimental design is to obtain the most important information with the least number of experiments. From the point of view of hydrogen doping ratio, ignition advance angle, excess air coefficient adjustment range and each adjustment amount, if all experiments are done at all experimental points, 330 experiments need to be done. This is only the experimental amount required for one speed and torque oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com