Direct injection type gas/liquid fuel supply system of rotary engine and control method of direct injection type gas/liquid fuel supply system

A technology of fuel supply system and rotary engine, which is applied in engine control, electrical control, engine components, etc., can solve the problems of substandard emissions and low efficiency of rotary engines, and achieve the solution of substandard emissions, expand multi-fuel characteristics, and solve efficiency low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

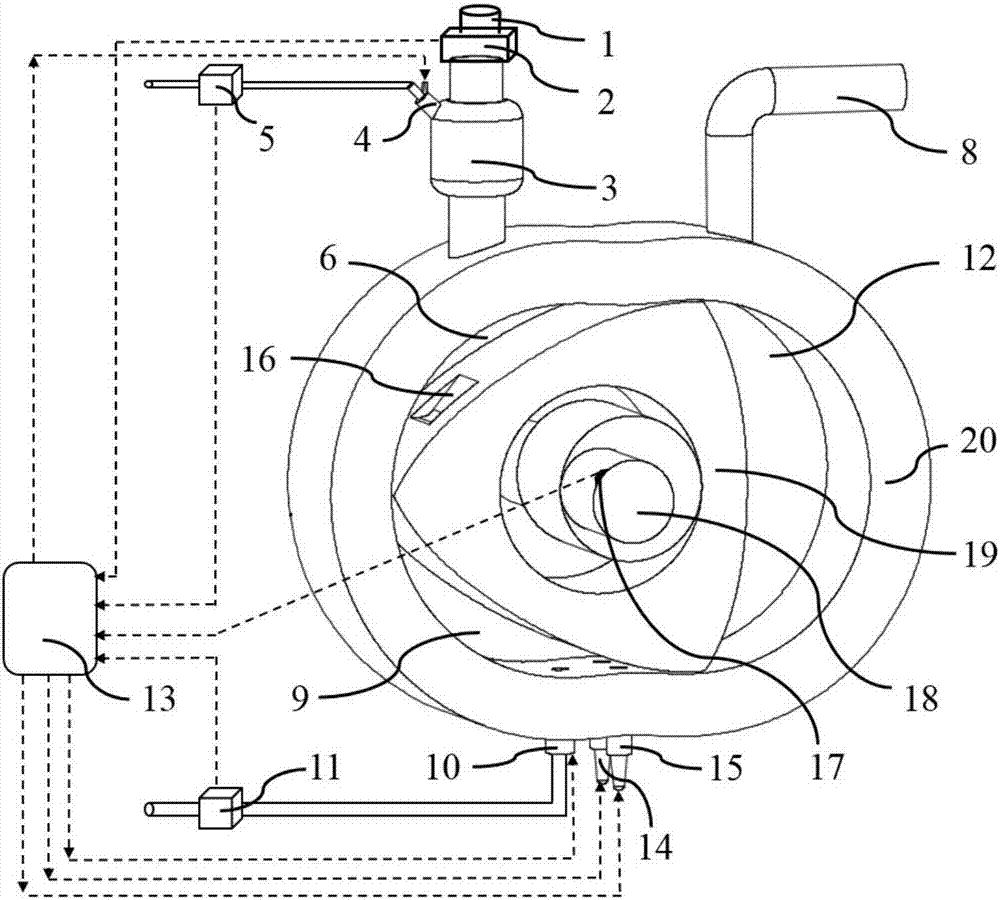

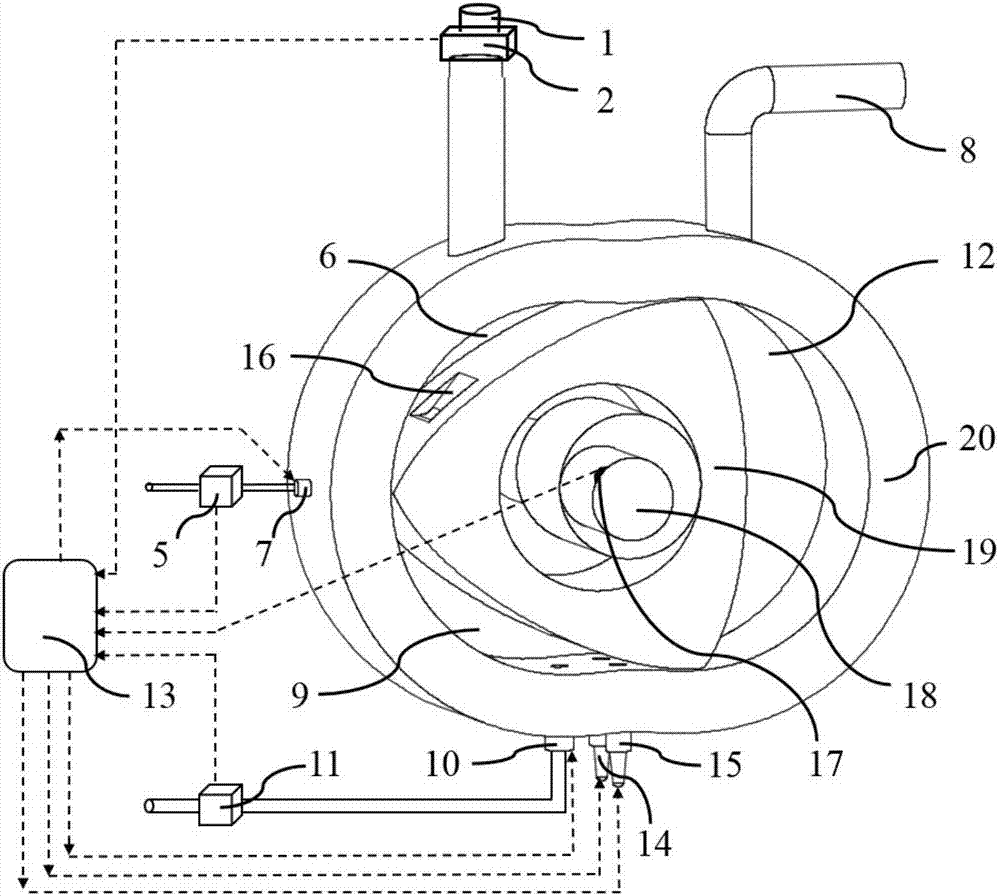

Embodiment 1

[0043] In Embodiment 1 and Embodiment 2, the gas ejected from the first gas fuel nozzle 4 or the second gas fuel nozzle 7 is biogas or natural gas or hydrogen or petroleum gas; the liquid gasoline ejected from the liquid fuel nozzle 10 or Diesel or kerosene or jet fuel or biodiesel or heavy fuel oil.

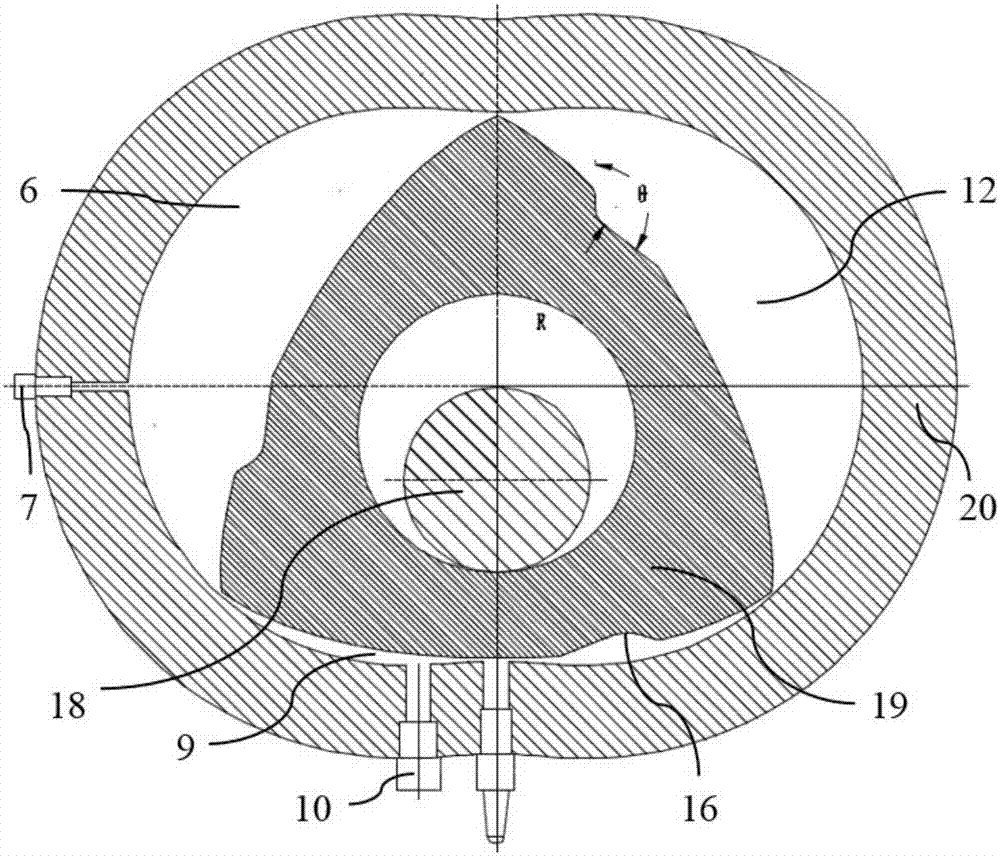

[0044] Such as image 3 As shown, the outer surface of the triangular rotor 19 is provided with dimples 16; the cross-section of the dimples 16 is approximately triangular. The pit 16 and the outer surface of the triangular rotor 19 have a circular arc transition with a radius of 8-10mm; the included angle θ of the outline of the pit 16 is 120°-128°. The purpose is to ensure that the high-speed injected fuel collides and diffuses at the pit 16, so that the fuel is mostly concentrated in the middle and front of the combustion chamber, which is beneficial to subsequent combustion work and power output. The angle between the injection direction of the first gas fuel nozzle 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com