Metal part melting, extruding and quick-forming system and implementing method thereof

A metal forming and melt extrusion technology, applied in the field of rapid prototyping, can solve problems such as hindering the widespread popularization of metal material rapid prototyping technology, expensive laser system systems, and increased raw material costs, and achieves multiple heating and melting methods and controllable feeding speed. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

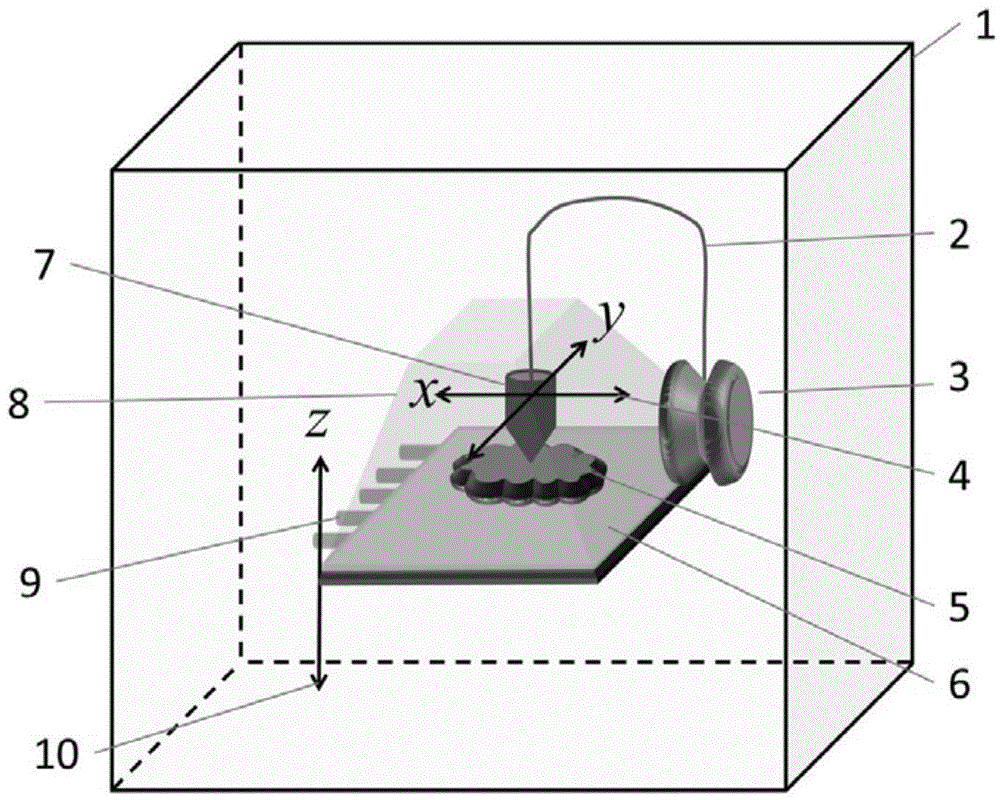

[0024] The entire forming system is protected with a vacuum box 1, and the aluminum wire is put into the system. The diameter of the aluminum wire is 2mm, and it is hung on an automatically controlled spool 3. Before the system works, vacuumize to below 5Pa, and then fill it with argon to an atmospheric pressure; rotate the spool 3, and at the same time cooperate with the wire feeding system to push the aluminum wire into the crucible, heat the crucible to 900°C, and melt the aluminum in the middle and lower parts of the crucible , while the upper part of the crucible is kept below 500°C; continue to press the aluminum wire into the crucible, use the aluminum wire itself to apply pressure to the aluminum melt and extrude the melt from the extrusion nozzle; the bottom plate is heated and kept at 500°C. The extrusion nozzle scans the substrate according to a pre-planned path, filling out a device layer map. The base plate is then lowered one layer thick, and the nozzle continues...

Embodiment 2

[0026] Protect the entire forming system with a vacuum box 1, put the magnesium alloy strip into the system, the cross-sectional area of the magnesium alloy strip is 9mm 2 , hang on a spool 3 that can be automatically controlled. Vacuum the system to 10 before working -2 Below Pa and keep in a vacuum state; rotate the bobbin 3, and at the same time cooperate with the wire feeding system, push the magnesium alloy strip into the crucible, heat the crucible to 750°C, melt the magnesium alloy in the middle and lower part of the crucible, and keep the upper part of the crucible below 400°C Continue to press the magnesium alloy strip into the crucible, use the magnesium alloy strip itself to exert pressure on the magnesium alloy melt and make the melt extrude from the extrusion nozzle; the bottom plate is heated and kept at 400°C. The extrusion nozzle scans the substrate according to a pre-planned path, filling out a device layer map. The base plate is then lowered one layer thi...

Embodiment 3

[0028]The whole molding system is protected with a vacuum box 1, and the iron wire is put into the system. The diameter of the iron wire is 1mm, and is hung on an automatically controllable spool 3. Before the system starts to work, first evacuate to below 5 Pa, and maintain this vacuum state; rotate the spool 3, and at the same time cooperate with the wire feeding system, push the iron wire into the crucible, heat the crucible to 1750°C, and melt the iron in the middle and lower parts of the crucible, and the crucible Keep the upper part below 1000°C; continue to press the iron wire into the crucible, and apply a gas pressure to the crucible to push the iron melt to be extruded from the extrusion nozzle; the bottom plate is heated and kept at 1000-1300°C; the extrusion nozzle is on the bottom plate Scanning according to the pre-planned path fills out a device layer map. The base plate is then lowered one layer thick, and the nozzle continues to fill the current layer profile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com