Titanium and titanium alloy low-cost continuous casting technology and equipment

A titanium alloy, low-cost technology, applied in the field of metal material preparation and processing, can solve problems such as low thermal strength, achieve the effect of speeding up melting, avoiding oxidation problems, and ensuring metallurgical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

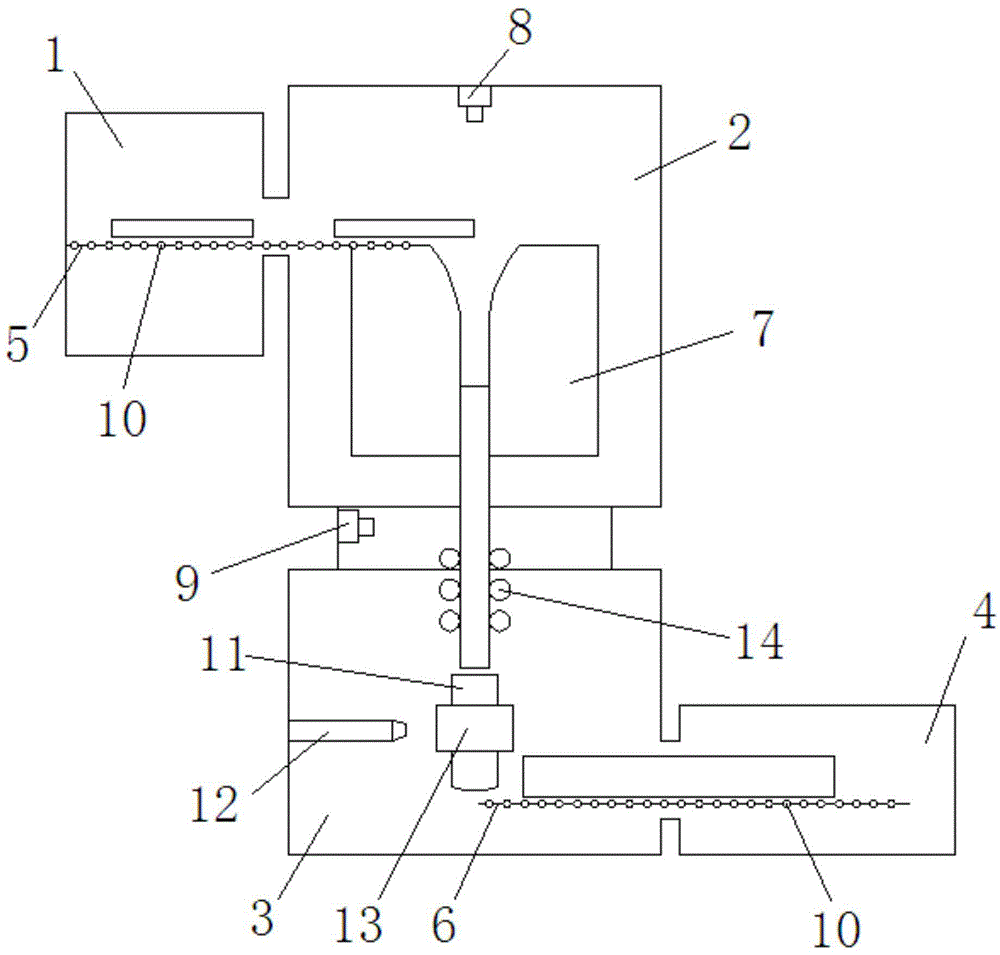

[0024] The invention provides a low-cost continuous casting technology for titanium and titanium alloys, comprising the following steps:

[0025] a. Feeding: The titanium or titanium alloy blank is transported from the feeding chamber into the melting chamber along the feeding track under the action of the feeding driving roller;

[0026] b. Melting: After the titanium or titanium alloy billet enters the melting chamber, it is transported to the first plasma gun under the continuous action of the driving roller, and the billet is melted by the ion arc generated by the first plasma gun;

[0027] c. Cooling and pulling down: the molten titanium or titanium alloy solution will drop into the crystallizer for slow cooling to form an ingot, and then use the pull-down mechanism set under the crystallizer to pull down;

[0028] d. Cutting off: start the second plasma gun arranged on the side every time the pull-down mechanism pulls down one meter, and cut off the ingot by using the io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com