Light source and method for producing the light source

A technology of light source and light emitting diode, applied in the field of light source, can solve the problems of poor volume and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

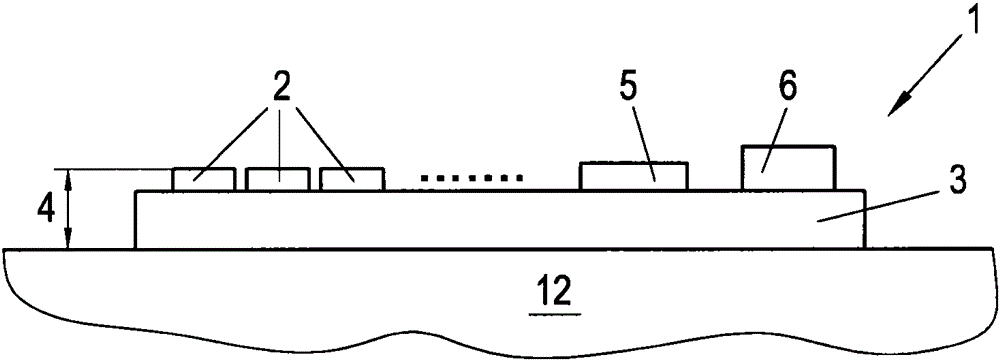

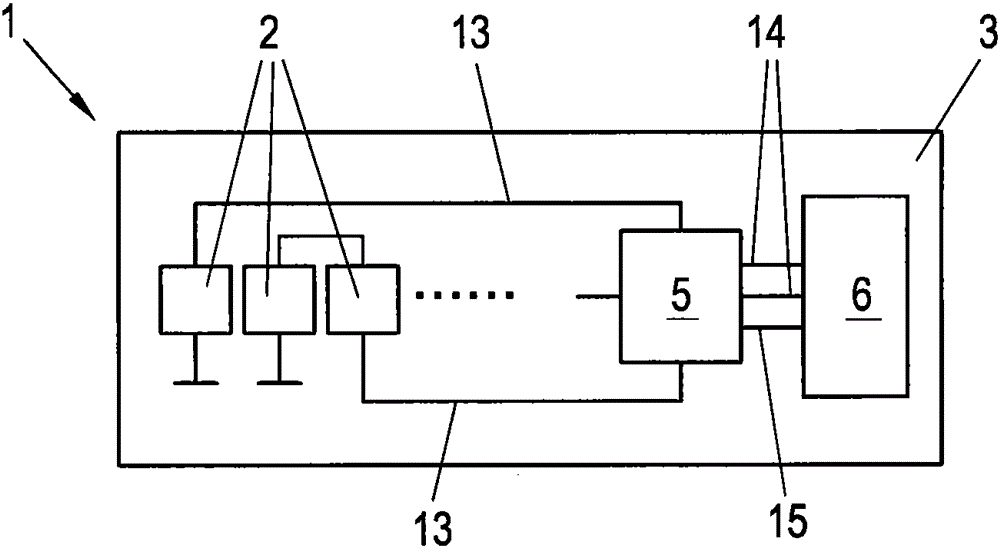

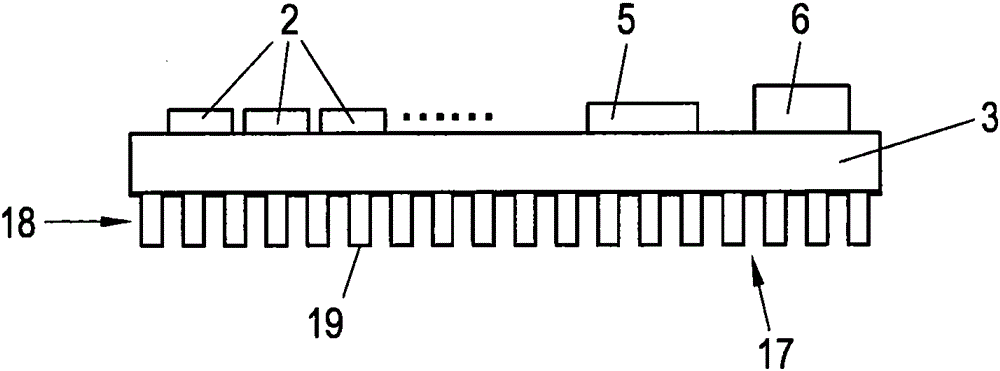

[0029] exist figure 1A side view of a light source 1 with a plurality of LEDs 2 is shown in . The LED 2 is an SMD component which is arranged on or connected to the circuit board 3 . The structural height 4 of the light source 1 in the area of the LED 2 is approximately 4 mm in the present example. Furthermore, the printed circuit board 3 has a converter unit 5 , which is likewise assembled by means of SMD technology, and has a connector 6 for the electrical connection of the light source 1 to the vehicle electrical system or the headlight cable harness. The converter unit 5 is implemented as an integrated kit or system-in-package (SiP) and integrates at least one, preferably a plurality of buck converters 7 (see FIG. 5 ). The step-down converter 7 is provided for voltage conversion from the typical vehicle electrical system range of 6 to 18 V into the forward voltage of the LEDs, so that for example (in each case) two LEDs 2 connected in series can be supplied with a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com