Preparation method of loaded zinc oxide photocatalyst

A photocatalyst and zinc oxide technology, applied in the field of photocatalytic materials, can solve the problems of long grinding time, poor grinding effect and low grinding efficiency of ball mills, and achieve the goal of increasing grinding and crushing efficiency, improving grinding and crushing efficiency, and increasing collision probability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

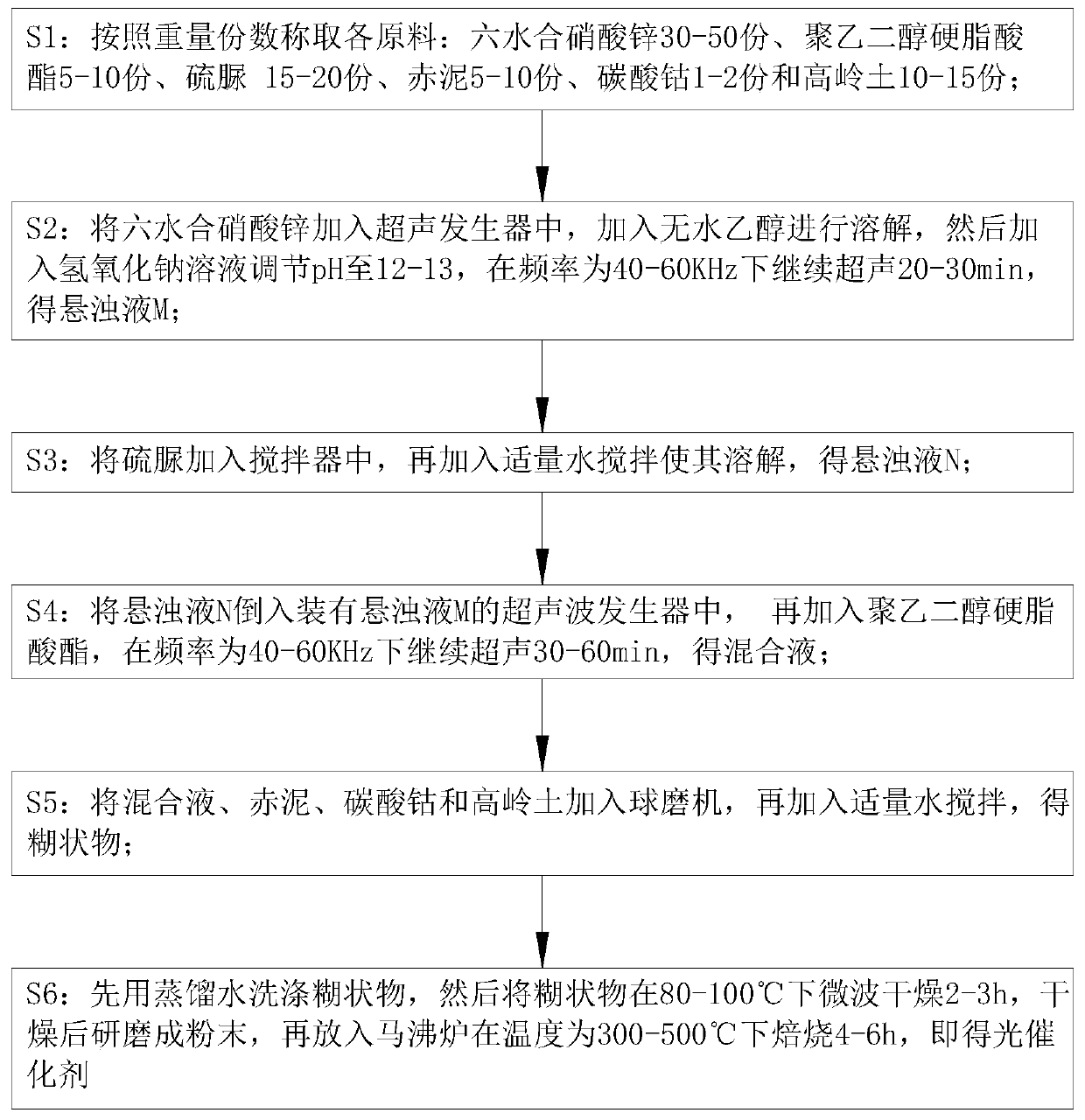

[0030] like Figure 1 to Figure 6Shown, the preparation method of a kind of supported zinc oxide photocatalyst of the present invention, this preparation method comprises the following steps:

[0031] S1: Weigh each raw material according to parts by weight: 30-50 parts of zinc nitrate hexahydrate, 5-10 parts of polyethylene glycol stearate, 15-20 parts of thiourea, 5-10 parts of red mud, 1 part of cobalt carbonate -2 parts and 10-15 parts of kaolin;

[0032] S2: Add zinc nitrate hexahydrate into the ultrasonic generator, add absolute ethanol to dissolve, then add sodium hydroxide solution to adjust the pH to 12-13, and continue ultrasonication at a frequency of 40-60KHz for 20-30min to obtain a suspension M;

[0033] S3: add thiourea into the stirrer, then add an appropriate amount of water and stir to dissolve it, and obtain a suspension N;

[0034] S4: Pour the suspension N into the ultrasonic generator equipped with the suspension M, then add polyethylene glycol stearat...

Embodiment approach

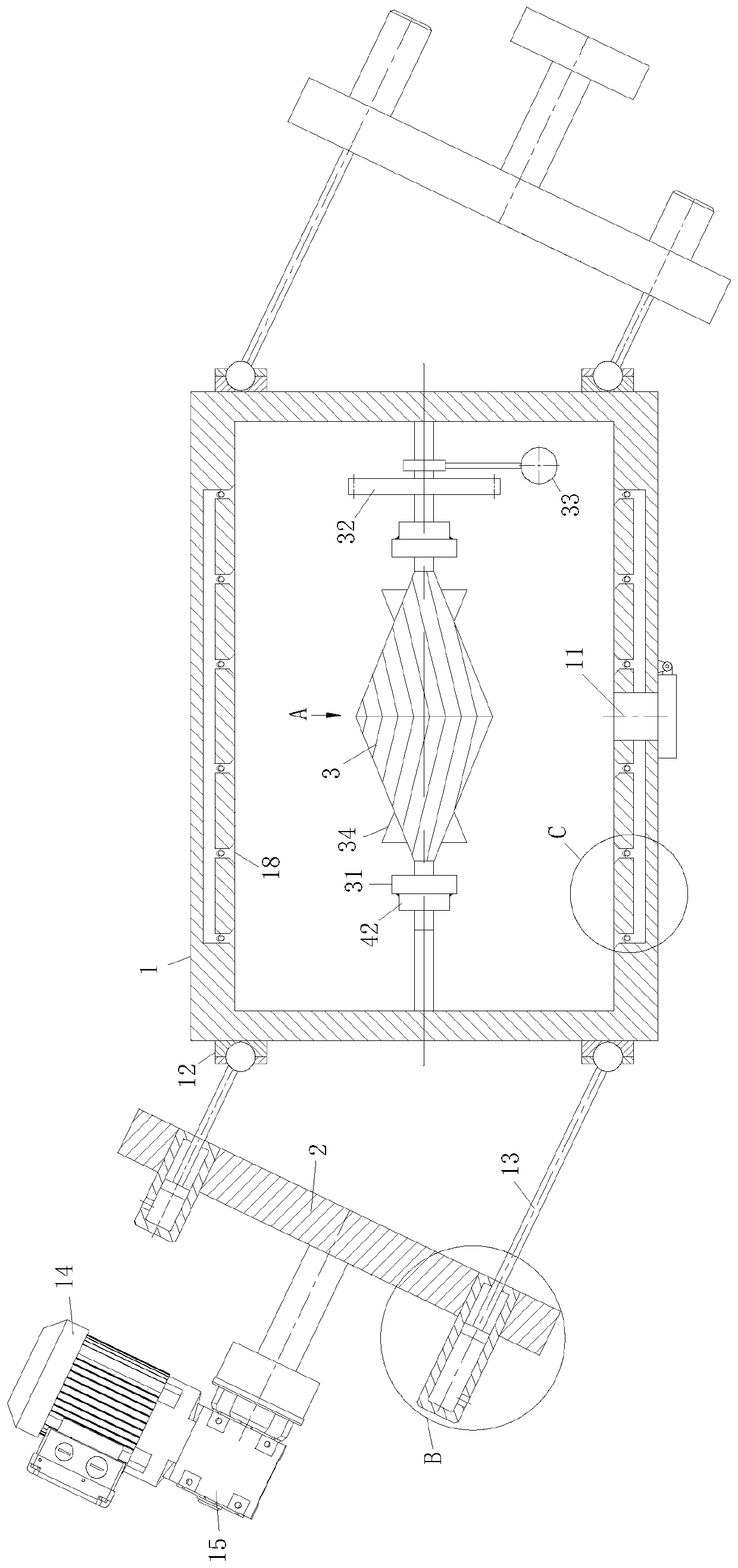

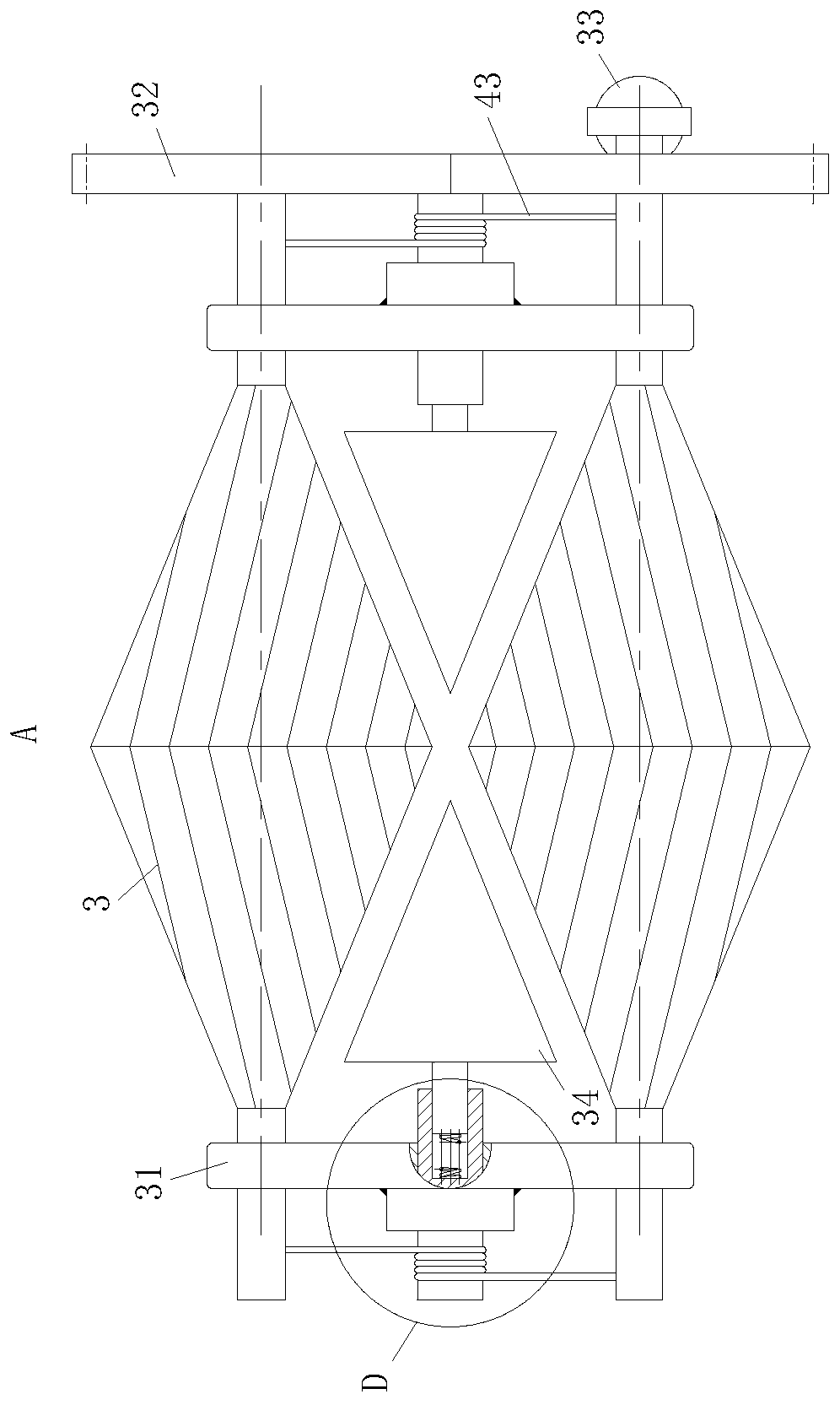

[0038] As an embodiment of the present invention, a group of rollers 3 arranged in parallel are arranged inside the cylinder 1, and the rollers 3 are rotatably connected to the fixed frame 31 in the cylinder 1; the rotating shaft on one side of the rollers 3 There are intermeshed gears 32 fixed on the top; one of the rollers 3 rotating shafts is fixedly connected with a gravity ball 33 through a rigid rod; when the cylinder 1 rotates, the gravity ball 33 drives the rollers 3 to rotate under the action of gravity, and the two rollers 3. Speed up the crushing speed of the raw material in the cylinder 1 after rotating, further increase the grinding and crushing efficiency of the ball mill; when the raw material is rotated and ground in the cylinder 1, when the cylinder 1 rotates, due to the gravity ball 33 always maintains a drooping state under the action of gravity , the gravity ball 33 drives the roller 3 to rotate through the rigid rod, and the two rollers 3 rotate together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com