Subcritical variable-speed ball mill

A variable speed ball and ball mill technology, applied in grain processing, etc., can solve the problems of lack of variable speed ball mills, achieve the effects of shortening ball milling time, improving efficiency, and eliminating short grinding distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

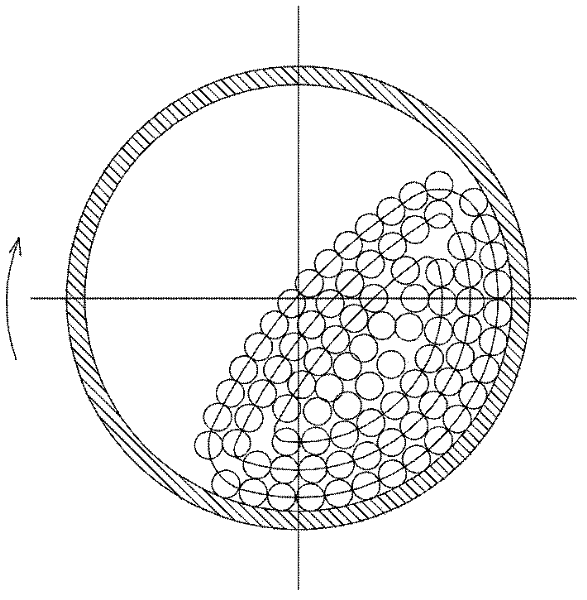

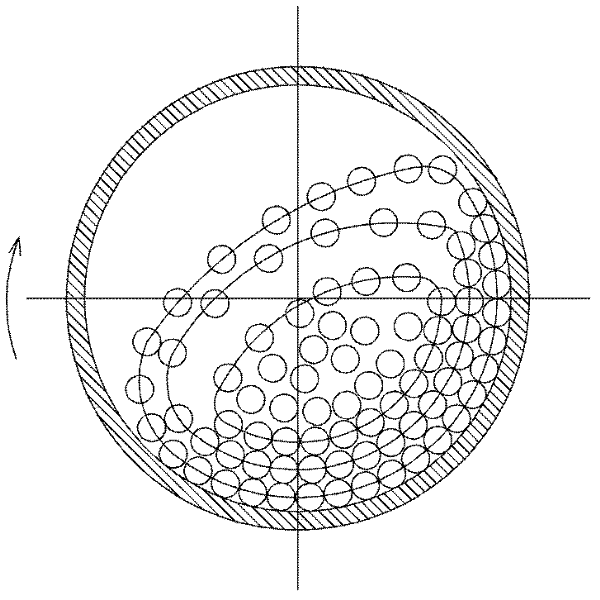

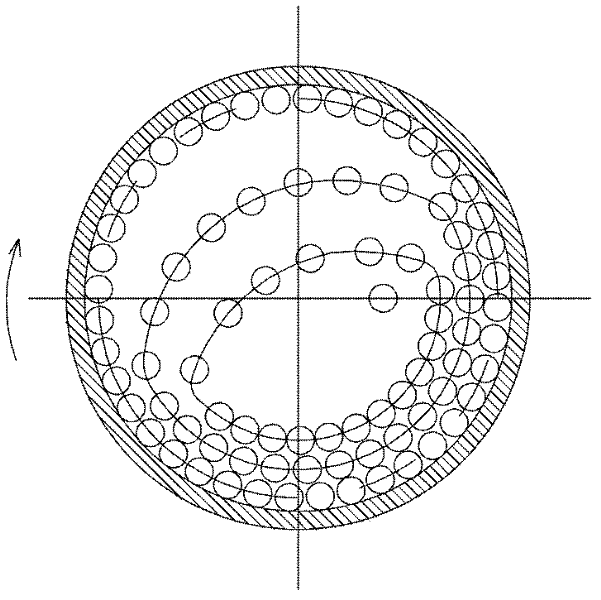

[0031] Now elaborate the present invention in conjunction with accompanying drawing:

[0032] The following takes the DC variable speed ball mill as an example for further explanation, including a base 1, a ball mill cylinder 2, a motor and a hydraulic coupler 3, the motor is a DC motor 4 controlled by a control circuit, and the control circuit has input data in advance to control the DC motor 4 rotation, the main shaft of the DC motor 4 is connected with a pneumatic clutch 5-hydraulic coupler 3-reduction box 6 in sequence, the hydraulic coupler 3 is to reduce the impact generated when the DC motor 4 starts and changes speed, The output shaft and the ball mill cylinder 2 are connected by a transmission belt 7, so that the power is transmitted from the reduction box 6 to the ball mill cylinder 2. On the base 1, one end of the ball mill cylinder 2 is provided with a mechanical brake that drives the ball mill cylinder 2 to decelerate. 8. The other end is provided with an electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com