Foaming agent with high universality for construction and preparation method thereof

A foaming agent, a general-purpose technology, used in the field of foaming agent production, can solve the problems of low powder or particle mesh number, accelerated equipment damage, increased processing cost, etc., and achieves high grinding efficiency, improved efficiency, and thorough cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A foaming agent with high versatility for construction, the foaming agent is composed of the following materials in parts by weight:

[0052] Base material 60-70 copies;

[0053] Ingredients 50-60 servings;

[0054] The base material is composed of the following parts by weight of materials:

[0055] Zeolite 30-70 copies;

[0056] 15-20 parts of high-viscosity attapulgite clay;

[0057] The ingredients are composed of the following parts by weight of materials:

[0058]

[0059]

[0060] The foaming agent also includes the following material composition in parts by weight:

[0061] Waterproof acrylic paint 10-15 copies;

[0062] Vinyl bis-stearamide dispersant 5-12 parts.

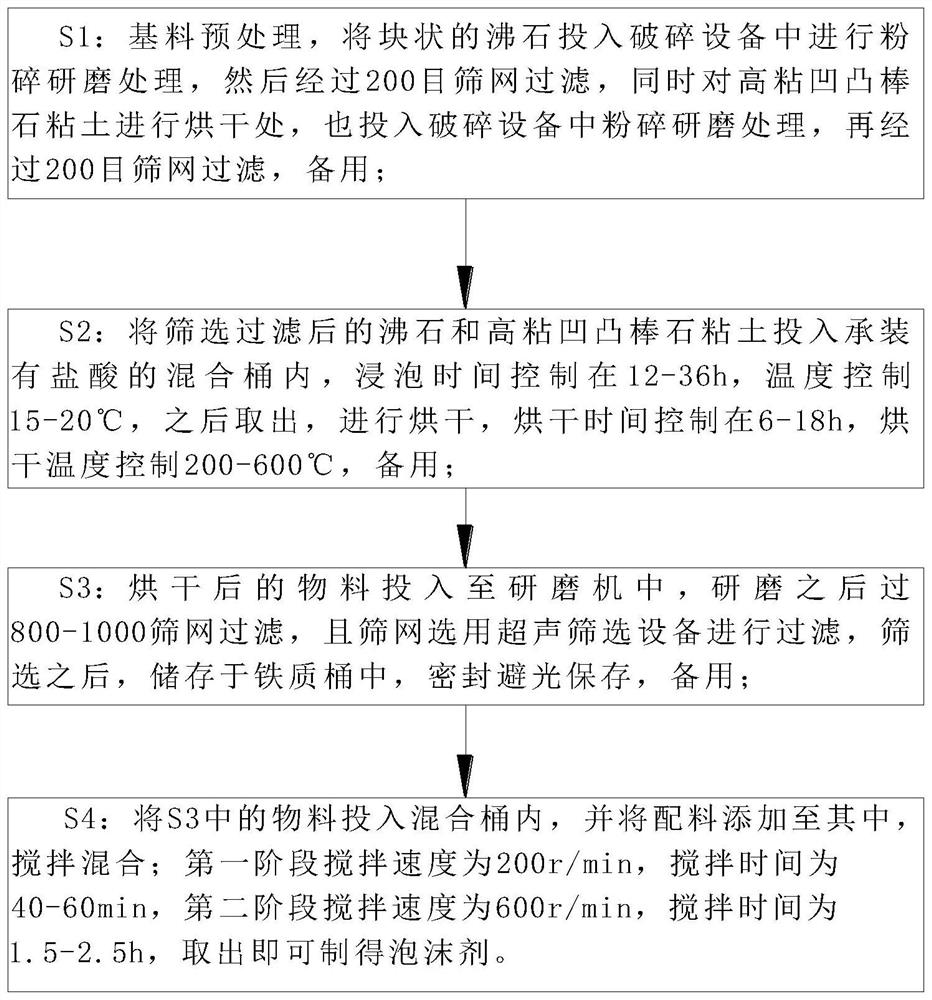

[0063] refer to figure 1 , a preparation method of a foaming agent with high versatility for construction, the preparation method is used to prepare any of the above-mentioned foaming agents with high versatility for construction,

[0064] S1: Base material pretreatment, put the massive...

Embodiment 2

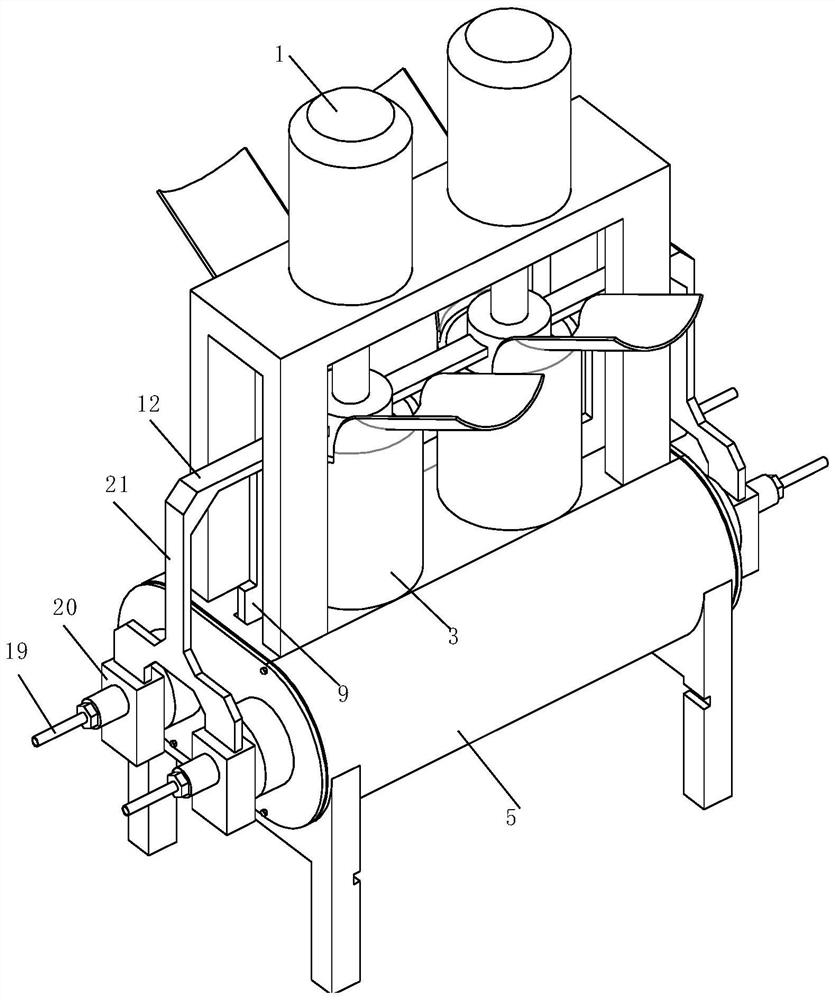

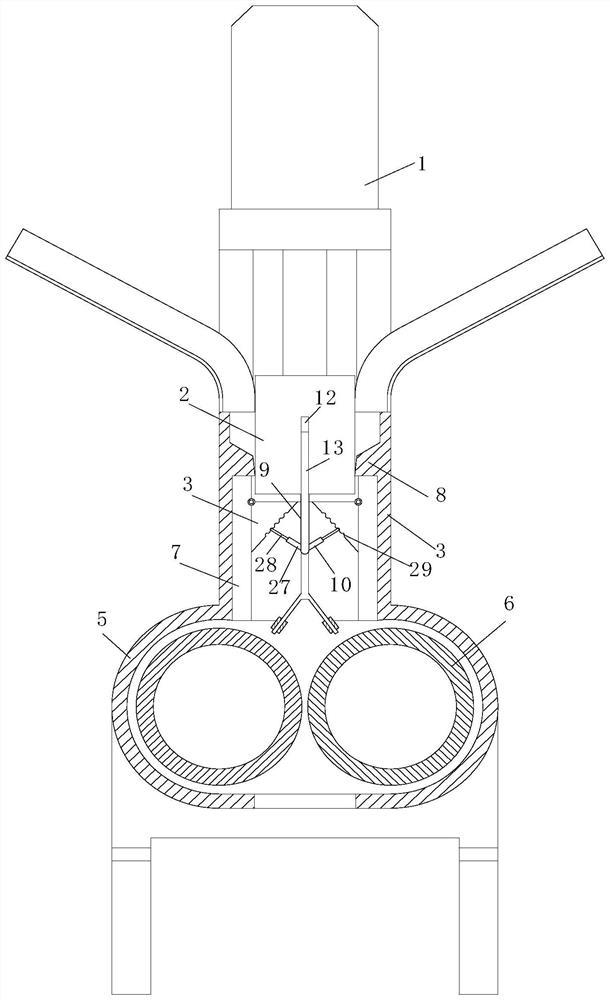

[0078] refer to Figure 9 , Comparative Example 1, as another embodiment of the present invention, wherein the horizontal surface of the extrusion table 4 is provided with a sharp cone 30, the lower end surface of the extrusion column 2 is also provided with a sharp cone 30, and the sharp The cones 30 are interdigitated and meshed with each other; the block-shaped zeolite falls on the extrusion table 4 along the guide groove, and first collides with the sharp cone 30 to break part of the zeolite. When the extrusion column 2 is close to the extrusion table 4 , the sharp cones 30 squeeze each other and crush the zeolite, increase the extrusion pressure of the extrusion column 2 to the block zeolite, and effectively crush the zeolite into particles.

[0079] Working principle: put the block-shaped zeolite on the reverse flow plate, and roll it into the guide groove according to the reverse flow plate. Drop onto the extrusion table 4, the extrusion column 2 falls, and the zeolite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com