Medical drug intermediate rapid grinding and screening integrated machine equipment

An intermediate and all-in-one machine technology, applied in grain processing, etc., can solve the problems of reduced grinding efficiency and achieve the effects of improving grinding quality, ensuring size consistency, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

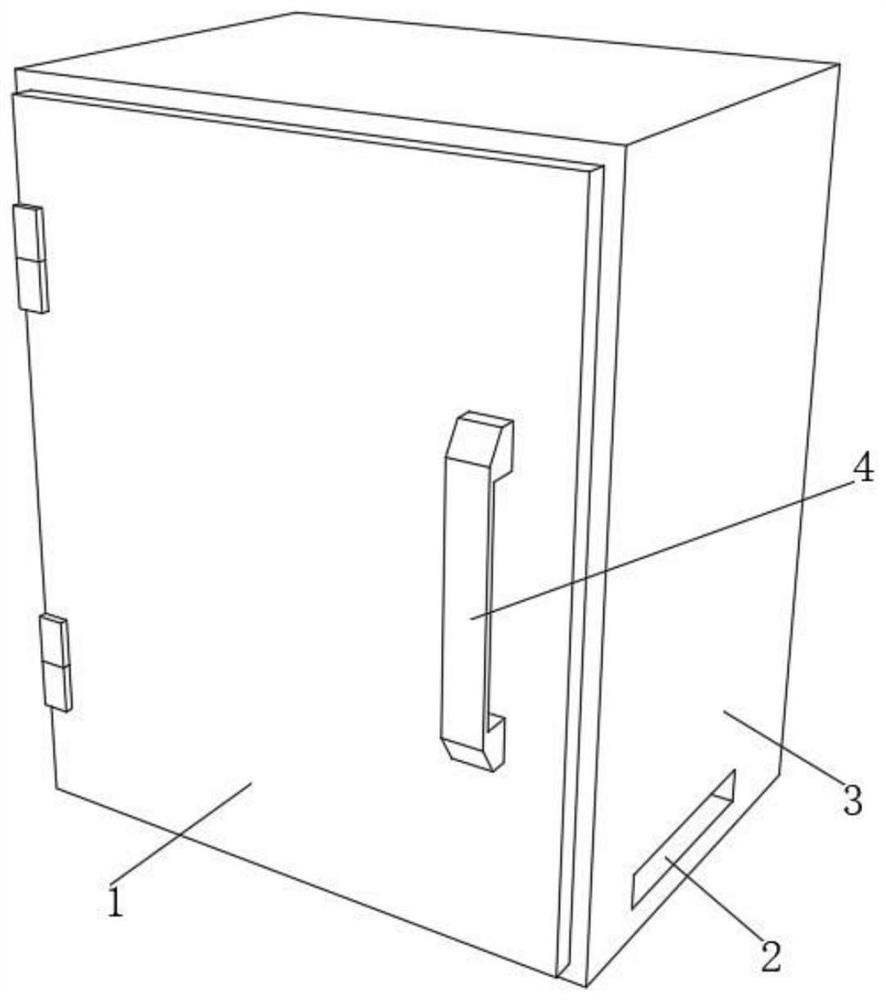

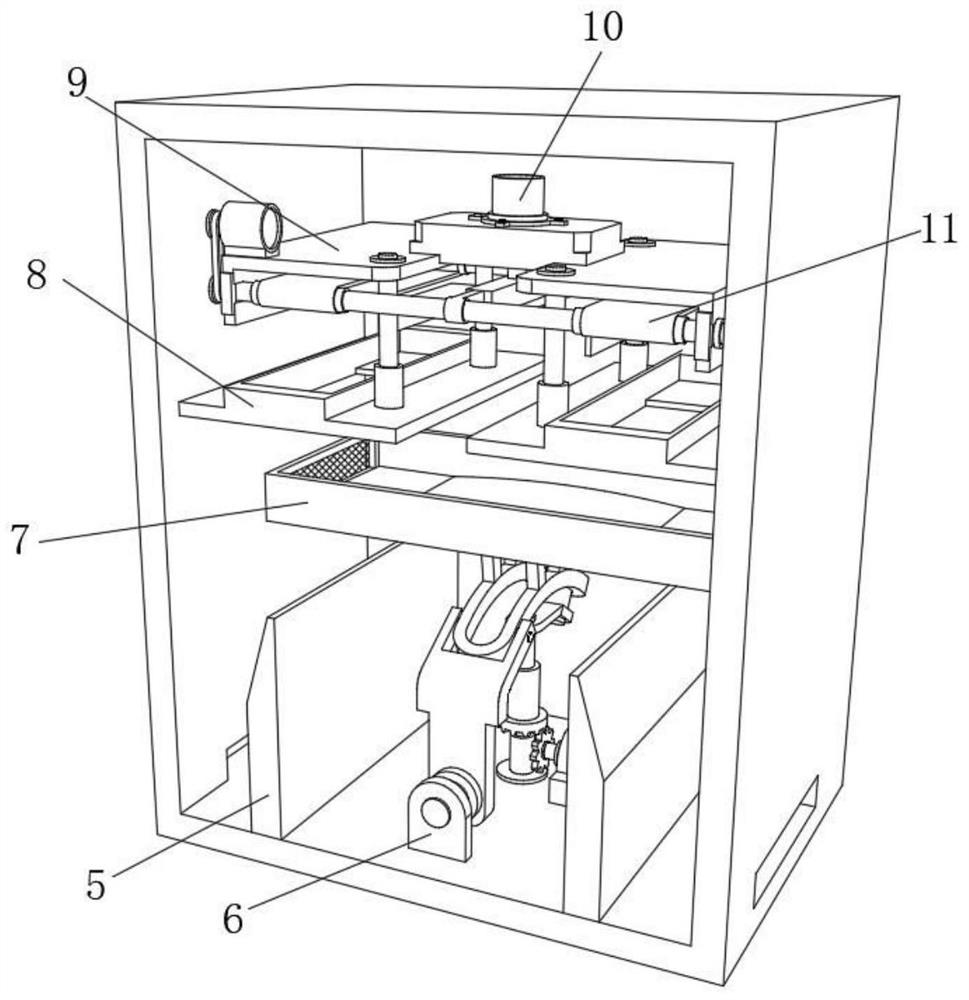

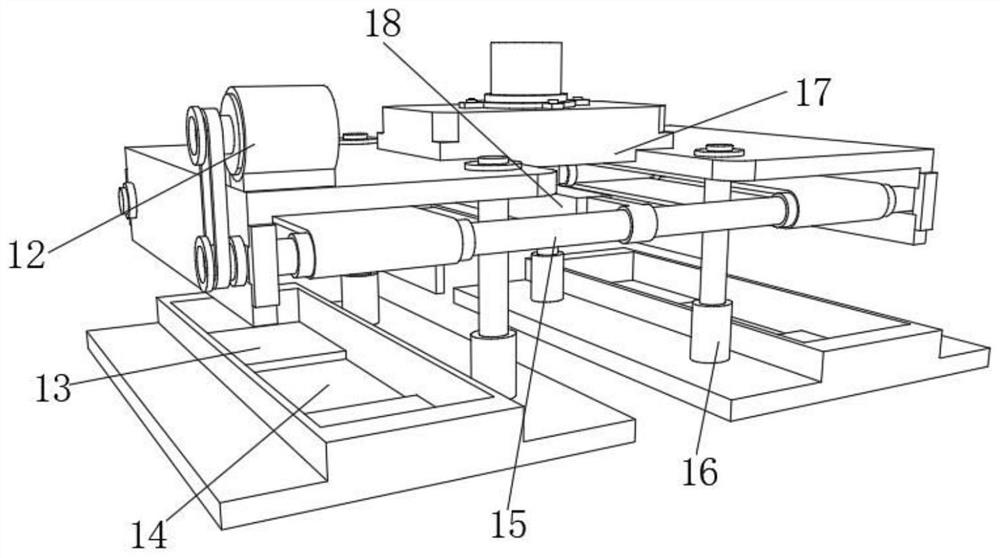

[0033] A rapid grinding and screening all-in-one machine equipment for medical pharmaceutical intermediates, such as Figure 1-4As shown, it includes a main body box 3, and the outer walls on both sides of the bottom of the main body box 3 are respectively provided with discharge ports 2, and the front outer wall of the main body box 3 is fixed with a box door 1 through a hinge, and the front side outer wall of the box door 1 passes through Bolts are fixed with handles 4, and the outer walls on both sides of the main body box 3 are respectively fixed with bottom plates 8 by bolts, and the top outer walls of the two top bottom plates 8 are provided with grinding mechanisms. The top outer wall of the hopper 13 is provided with a discharge hole 14, and the inner walls on both sides of the bottom of the main body box 3 are respectively fixed with partitions 5 by bolts, and the bottom inner wall of the main body box 3 is close to the bottom between the two partitions 5 by bolts. A ...

Embodiment 2

[0038] A rapid grinding and screening all-in-one machine equipment for medical pharmaceutical intermediates, such as Figure 5 As shown, in order to promote the quality of scrap screening; this embodiment makes the following improvements on the basis of Embodiment 1: the bottom inner wall of the receiving plate 7 is bonded with arc-shaped protrusions 27, and the inner walls on both sides of the bottom of the receiving plate 7 The sharp cones 28 distributed equidistantly are bonded respectively; through the setting of the arc-shaped protrusions 27 and the sharp cones 28, the problem of backlogging of the broken materials during screening is promoted. The function of slitting ensures the quality of crushed material screening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com