Stone graving knife capable of achieving ordered arrangement for diamond brazing, and preparation method

A diamond and engraving knife technology, applied in stone processing equipment, stone processing tools, manufacturing tools, etc., can solve the problems of hindering the removal of cuttings, easy segregation and aggregation, and small grinding force of a single diamond.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

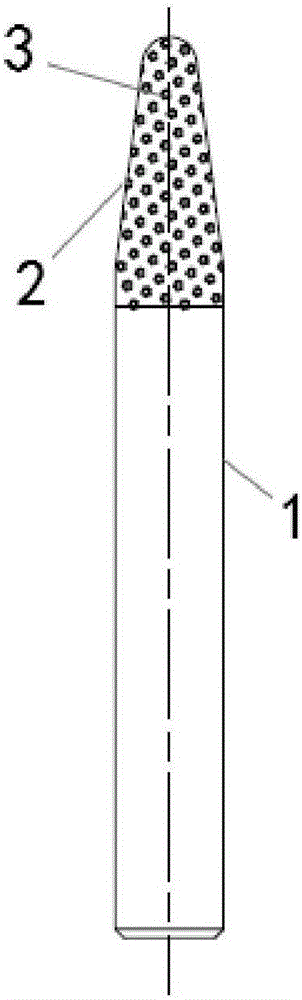

[0026] Embodiment 1: as figure 1 As shown, a diamond brazing stone carving knife arranged in an orderly manner, the handle 1 is connected to the head 2, and the diamonds 3 are arranged in an orderly manner on the head 2; the meaning of the orderly arrangement is: the diamond 3 and the adjacent The distance between the other diamond 3 or several other diamonds 3 is equal, the diamonds 3 are uniform, equidistant, and arranged symmetrically, the outer circumference of the cutter head 2 is conical, and the end is hemispherical. The blank space of the cutter head 2 in the figure It is a nickel-based brazing filler metal, and the diamond 3 is welded on the cutter head 2. Since the holes where the diamond 3 is welded on the cutter head 2 are very small and dense, the solder is coated on the entire cutter head 2.

[0027] According to the above solution, due to the orderly arrangement of diamonds on the engraving knife, the knife is evenly stressed and has higher sharpness on the basi...

Embodiment 2

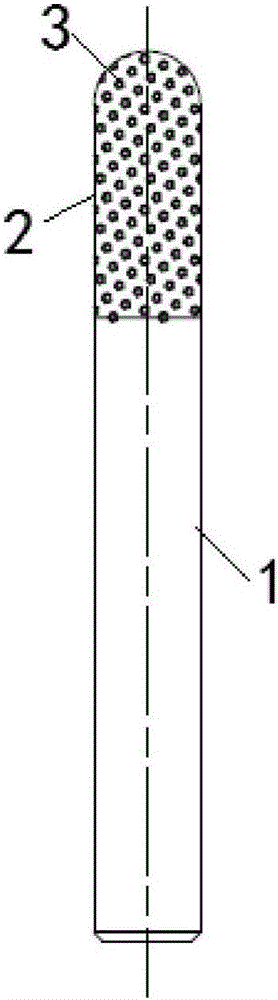

[0028] Embodiment 2: as figure 2 As shown, a diamond brazing stone carving knife arranged in an orderly manner, the handle 1 is connected to the head 2, and the diamonds 3 are arranged in an orderly manner on the head 2; the meaning of the orderly arrangement is: the diamond 3 and the adjacent The distance between the other diamond 3 or several other diamonds 3 is equal, the diamonds 3 are uniform, equidistant, and arranged symmetrically, the outer circumference of the cutter head 2 is cylindrical, and the end is hemispherical. In the figure, the cutter head 2 is blank Place is nickel-based brazing filler metal, and diamond 3 is welded on the cutter head 2, because the hole of the position of welding diamond 3 on the cutter head 2 is very small and dense, is to be coated on the whole cutter head 2 by solder.

[0029] It mainly solves the problems of uneven stress on diamonds, excessive wear, low grinding and cutting efficiency, and frequent burning of the diamonds during the ...

Embodiment 3

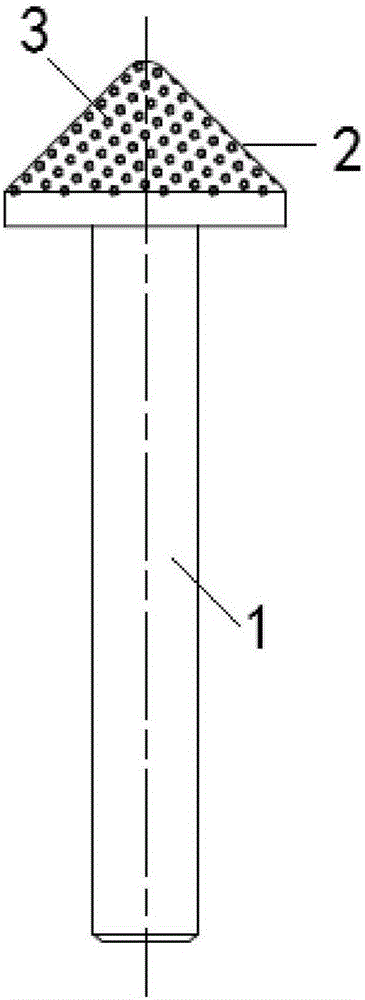

[0032] Embodiment 3: as image 3 , Figure 4 As shown, a diamond brazing stone carving knife arranged in an orderly manner, the handle 1 is connected to the head 2, and the diamonds 3 are arranged in an orderly manner on the head 2; the meaning of the orderly arrangement is: the diamond 3 and the adjacent The distance between another diamond 3 or several other diamonds 3 is equal, and the diamonds 3 are uniform, equidistant, and arranged symmetrically, such as image 3 As shown, the cutter head 2 is an umbrella-shaped outer circumference, and the end is hemispherical, and the diameter of the cutter head 2 is greater than the diameter of the steel body 1, such as Figure 4 As shown, the outer circumference of the cutter head is cylindrical, and the end face of the cutter head is flat and rounded. In the figure, the blank space of the cutter head 2 is nickel-based brazing material. The holes at the position of 3 are very small and dense, and the solder is applied to the entire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com