Lead delay element rotary cutter

A technology of rotary cutting machine and extension body, which is applied in the direction of shearing device, accessory device of shearing machine, cutter used in shearing machine, etc., can solve the problems of irregular section shape and inaccurate length of extension body, etc., and achieve crushing The effect of less chips, fast cutting speed and fast revolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

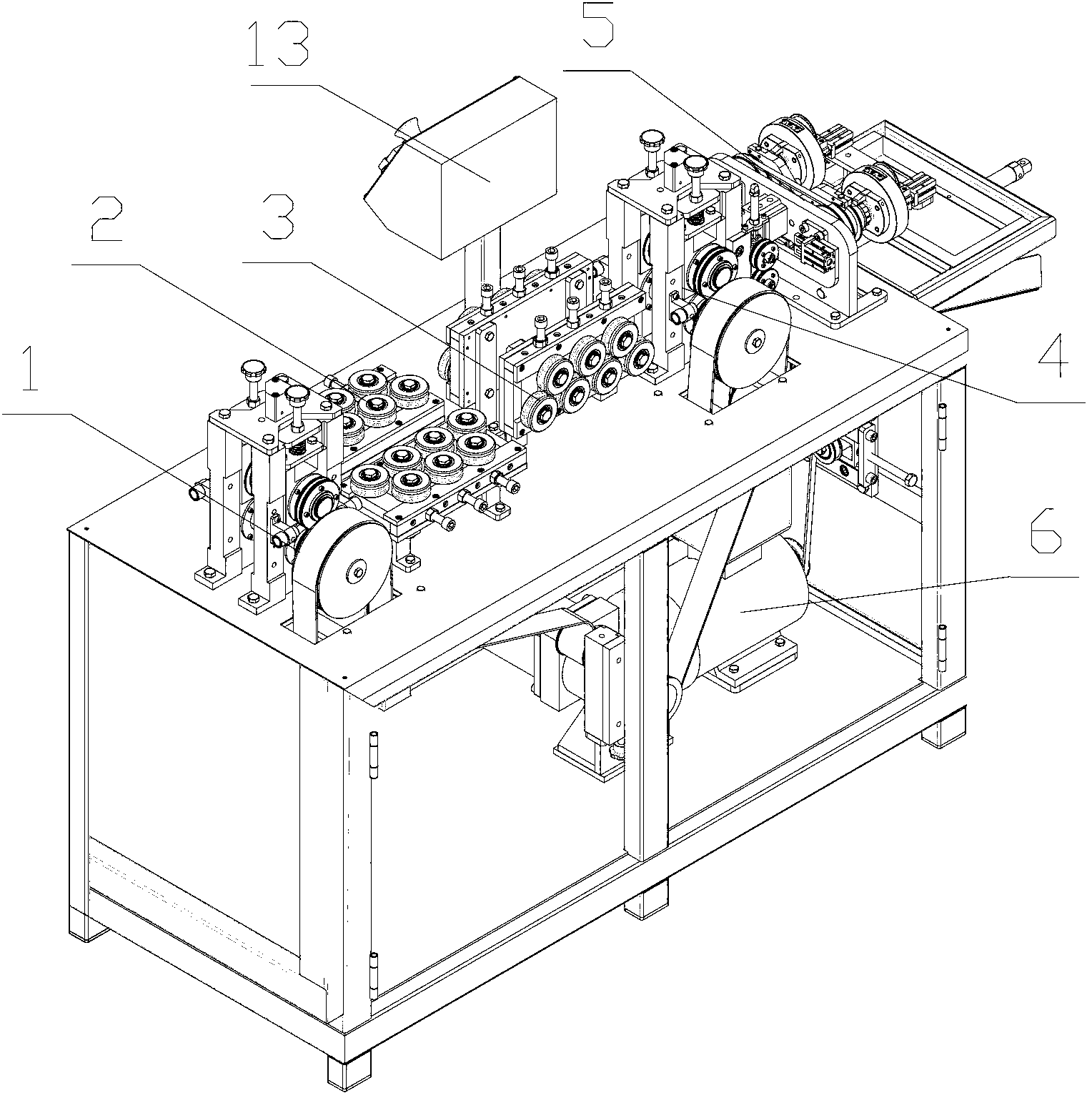

[0039] The present application discloses a rotary cutting machine for lead extension body, which includes a rotary cutting assembly 5 installed on a workbench 1 and an industrial computer, and the industrial computer is installed in an operation table 13 .

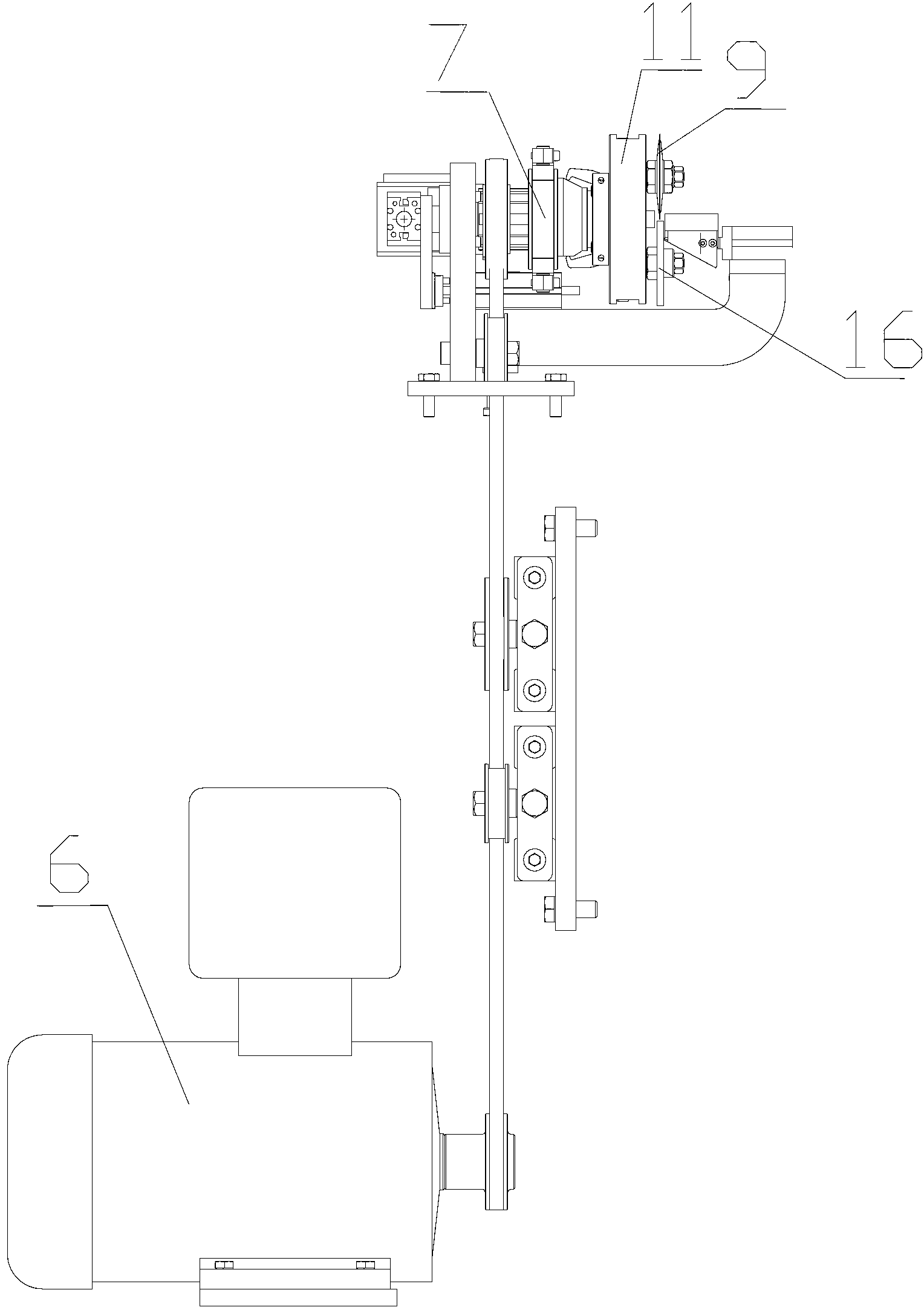

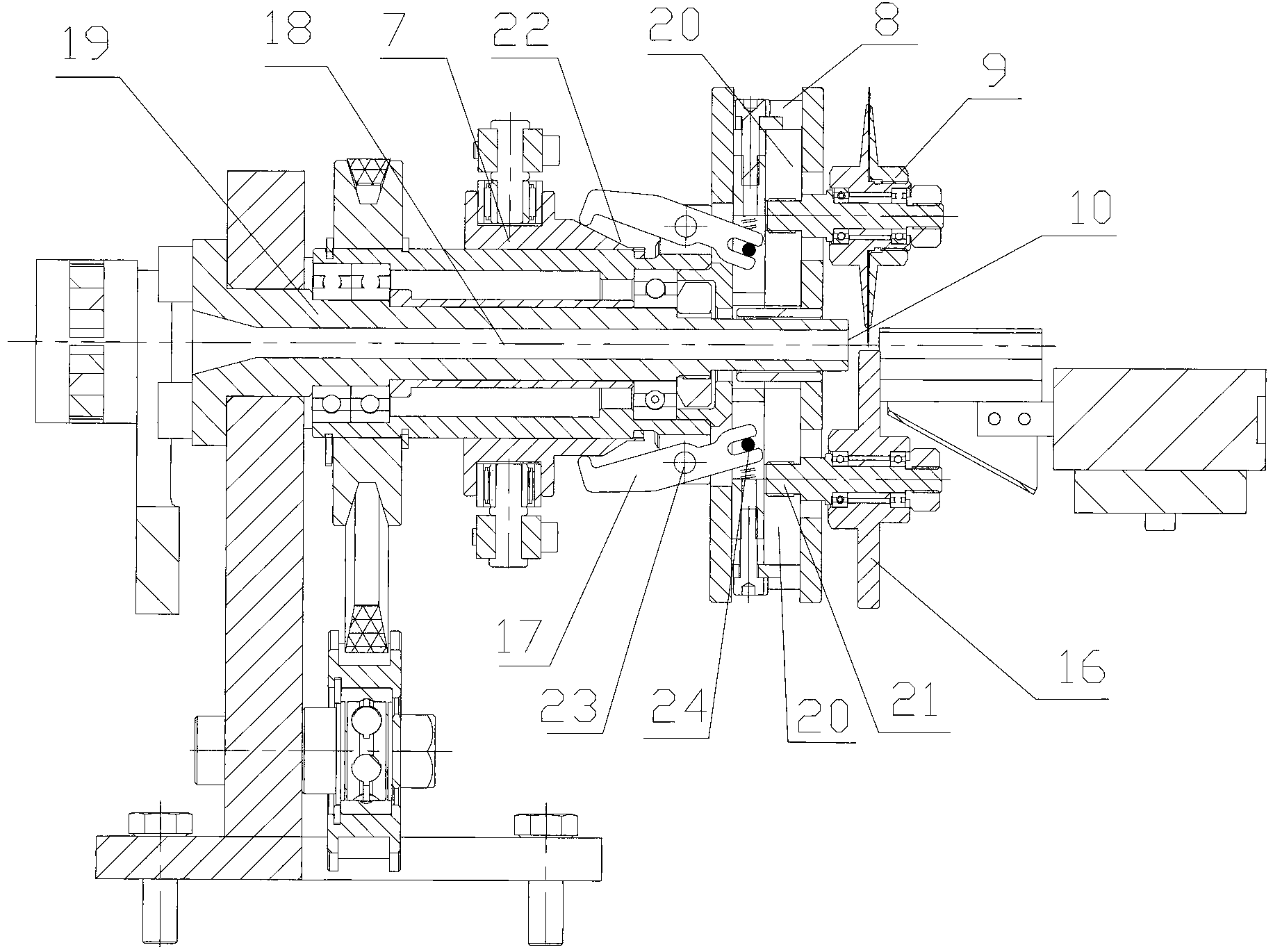

[0040] The rotary cutting assembly 5 is the core device for cutting the lead extension cable with a length of several meters to tens of meters into a specified length of extension body. Wheel 7, rotary cutting connecting rod 17, at least one adjustable rotary cutter head 8, rotary cutting supporting roller 16 and rotary cutting blade 9 installed on the adjustable rotating cutter head 8; rotary cutting supporting wheel 16 corresponds to rotary cutting blade 9 Radial installation, located on both sides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com