Automobile sealing strip cutting device

A technology for automobile sealing strips and cutting equipment, applied in the field of machinery, can solve the problems of inclined section, poor safety, large dust, etc., and achieve the effect of smooth section, ensuring safety, and ensuring health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are preferred embodiments of the present invention, but they do not limit the protection scope of the present invention.

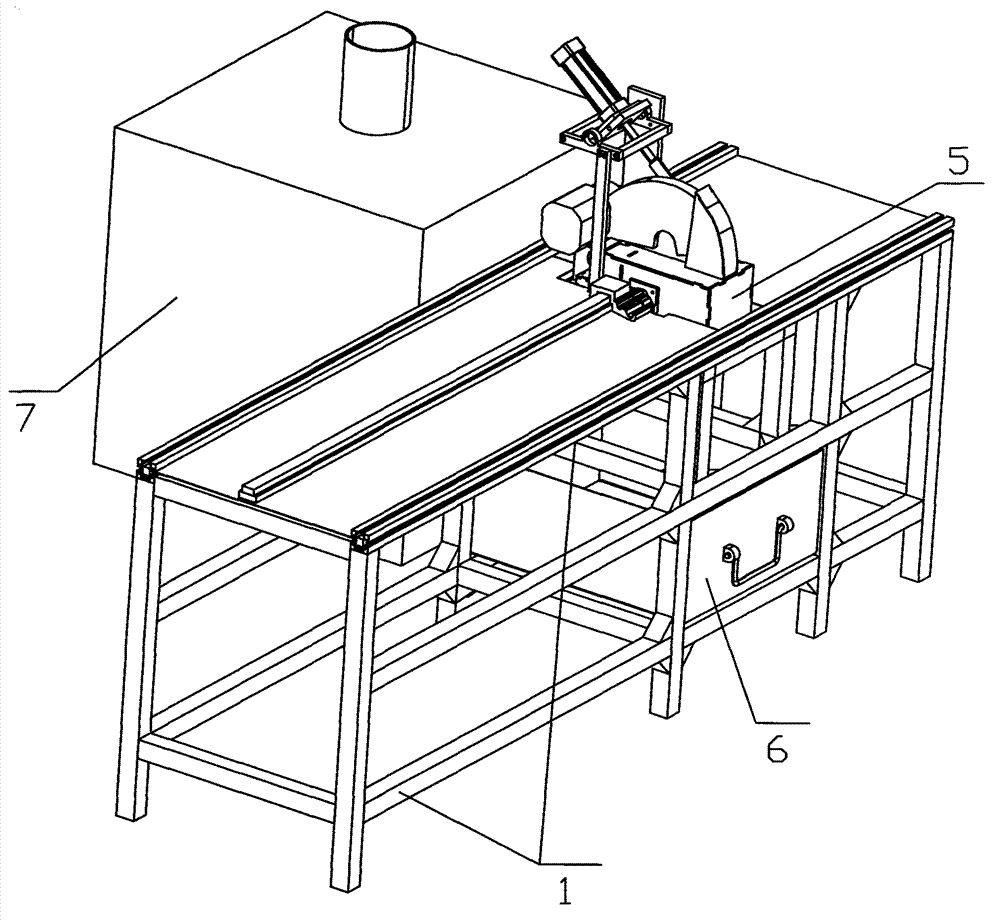

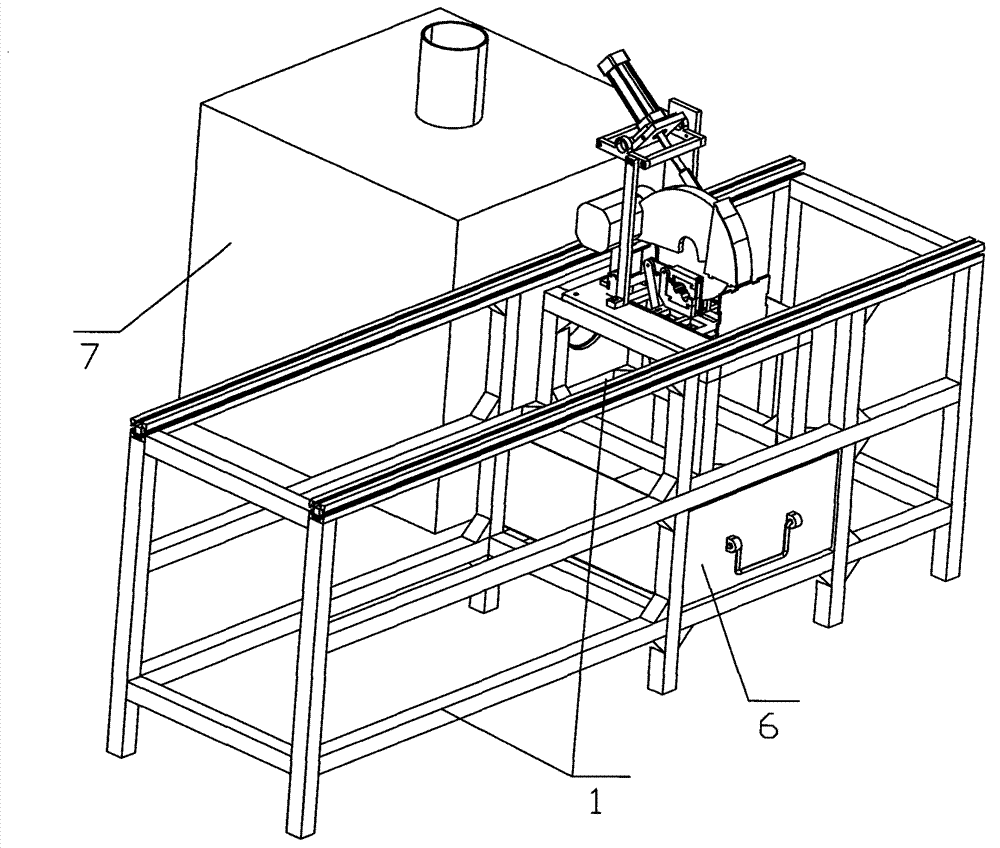

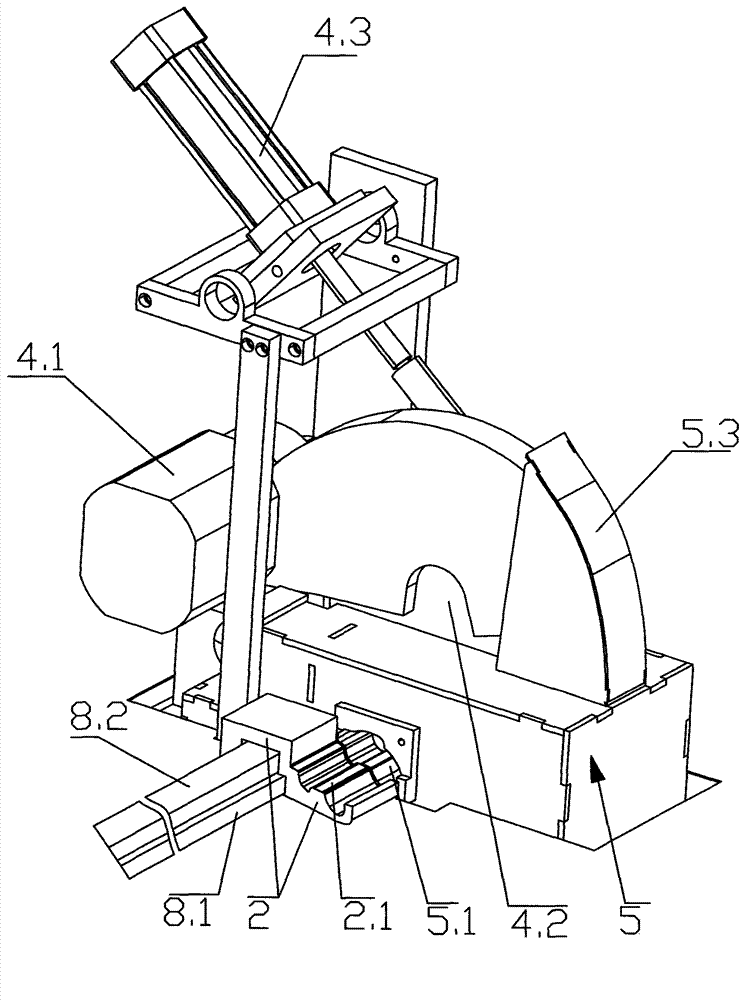

[0023] refer to Figure 1-Figure 6 As shown, an automobile weather strip cutting device of the present invention includes a frame 1, a guide assembly, a locking assembly, a cutting assembly and a protective cover 5, and the guide assembly and the locking assembly are located on the upper surface of the frame 1 and are Arranged in the same line, the cutting assembly is located above the locking assembly, and the protective cover 5 is covered outside the locking assembly.

[0024] The guide assembly includes a guide block 2, the upper surface of the guide block 2 is provided with a guide groove 2.1 matching the shape of the material strip, and the guide groove 2.1 is placed on the upper surface of the frame 1. The guide assembly can make the material strip be inserted into the protective cover 5 smoothly, and then locked by the locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com