Energy-saving feed processing granulator

A feed processing and pellet mill technology, applied in feed, food science, application, etc., can solve the problems of mechanical failure, high cost, high energy consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

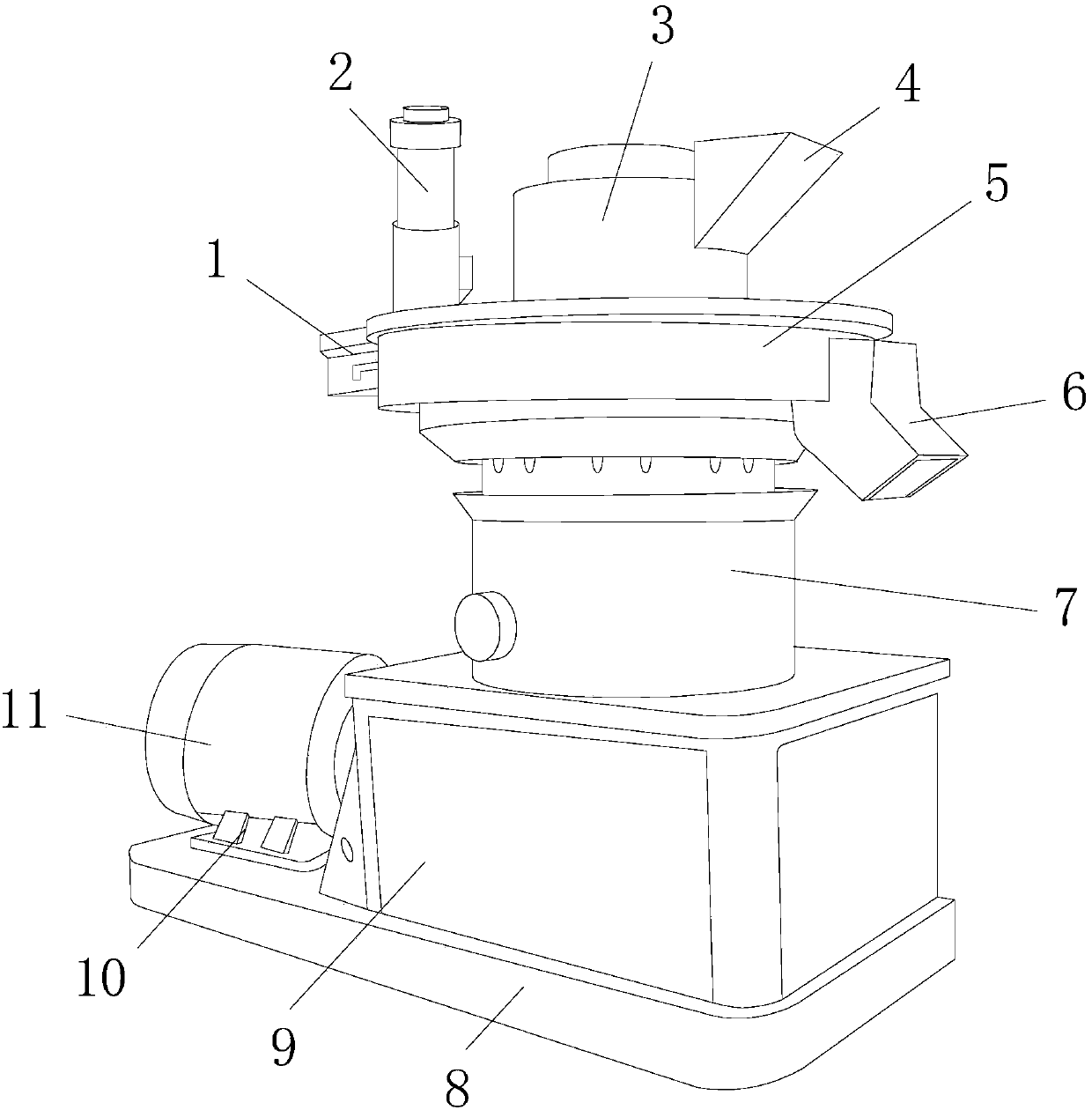

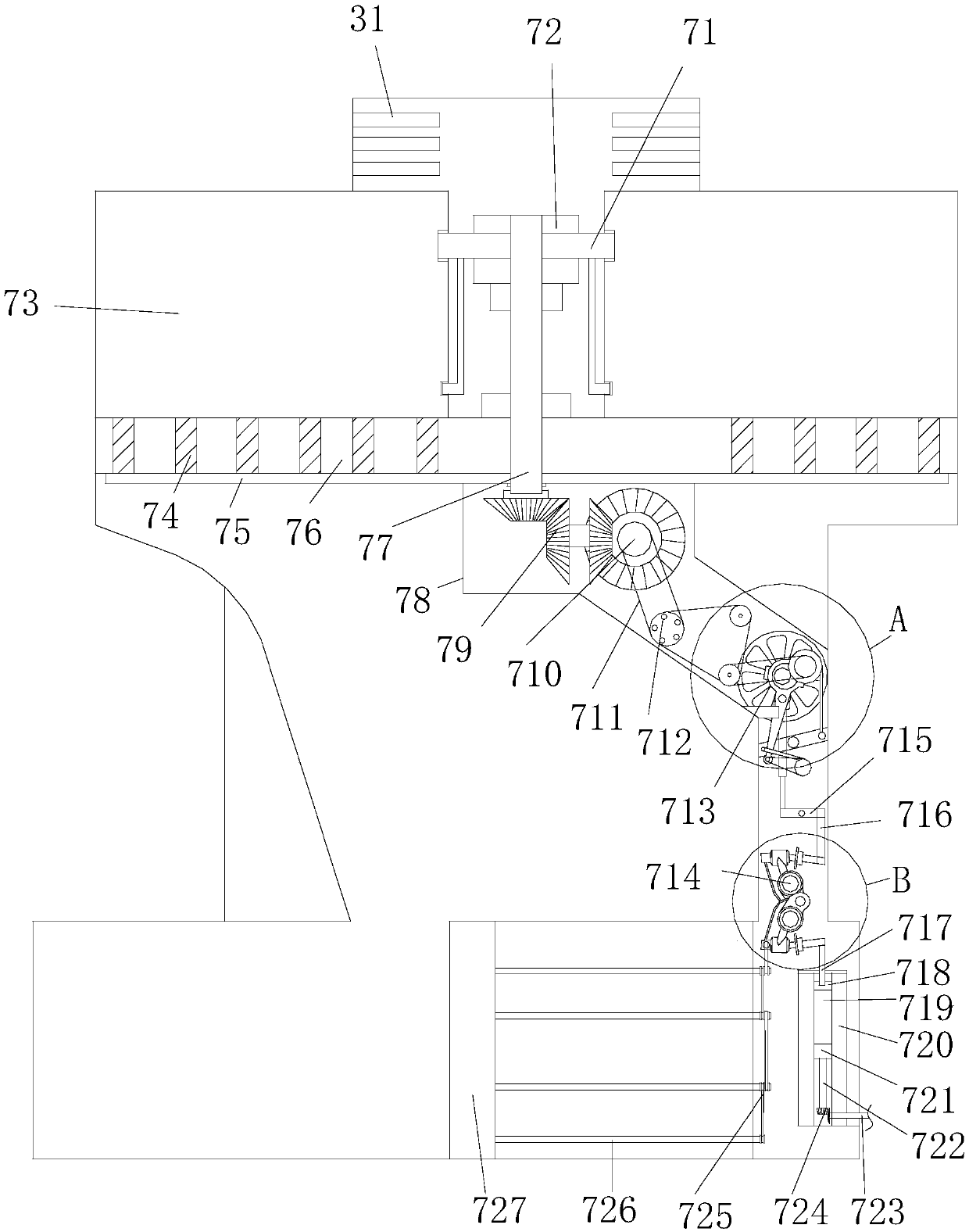

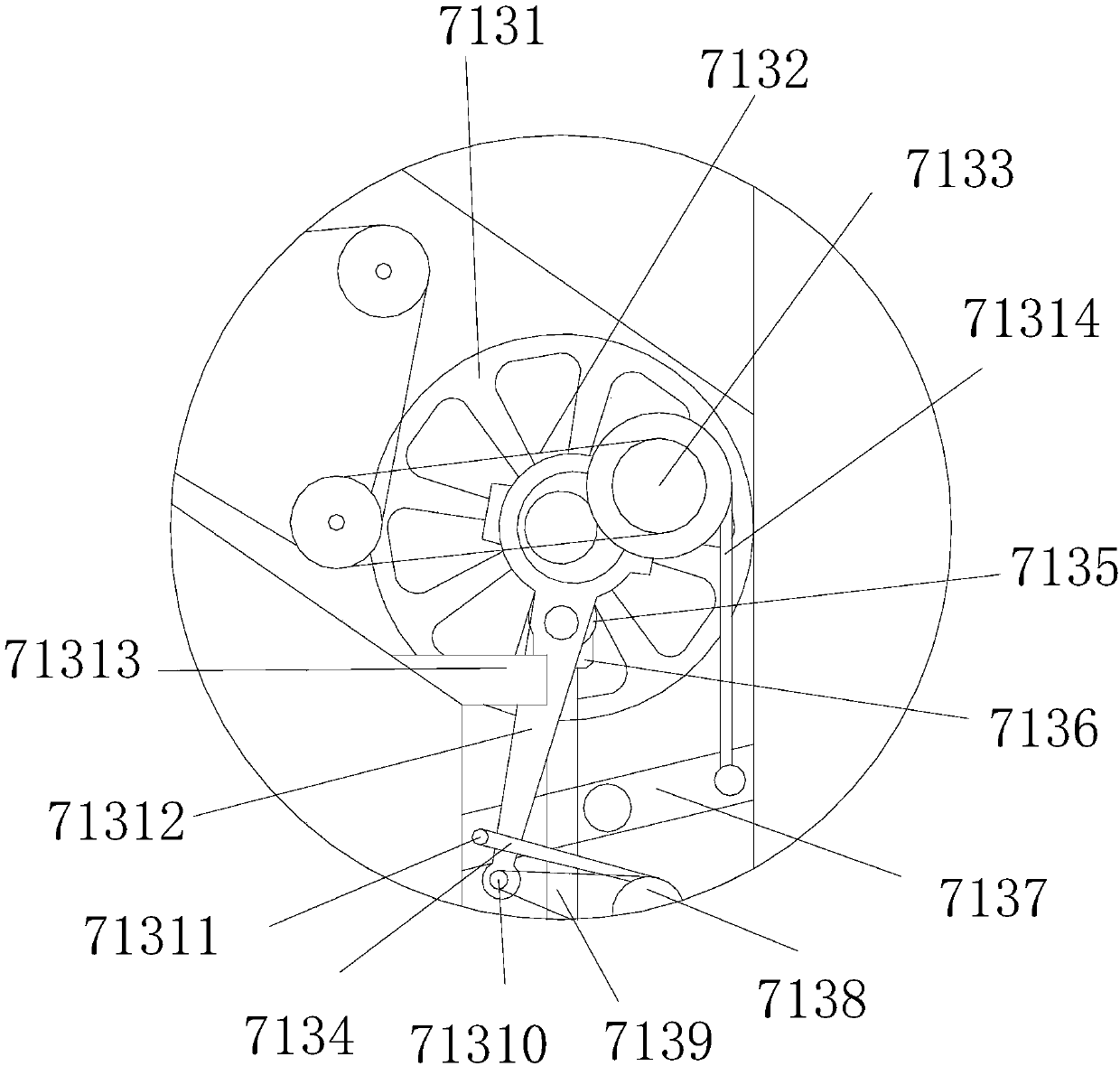

[0022] see Figure 1-Figure 4 , the present invention provides an energy-saving feed processing granulator, the structure of which includes a hinge 1, a ventilator 2, a crushing cylinder 3, a feed port 4, a granulating disc 5, a dross outlet 6, a granulating mechanism 7, and a base 8 , material storage box 9, motor base 10, motor 11, described base 8 is equipped with motor 11 and material storage box 9 side by side, described motor 11 bottom is also equipped with motor base 10, described material storage box 9 A granulation tray 5 is installed vertically above, and the granulation tray 5 communicates with the storage box 9. A waste outlet 6 is installed on one side of the granulation tray 5, and a through-hole outlet 6 is installed on the other side through the hinge 1. Gas cylinder 2, crushing material cylinder 3 is vertically installed in the middle of the top surface of the granulating disc 5, and a feeding port 4 is fixedly provided on one side of the crushing material cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com