Rope core taking drill

A core drilling tool and rope technology, which is applied in the direction of extracting undisturbed cores, earthwork drilling, etc., can solve the problems of short drilling interval, scrapped drilling, slow drilling speed of drilling tools, etc. The effect of prolonging the service life and excellent working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

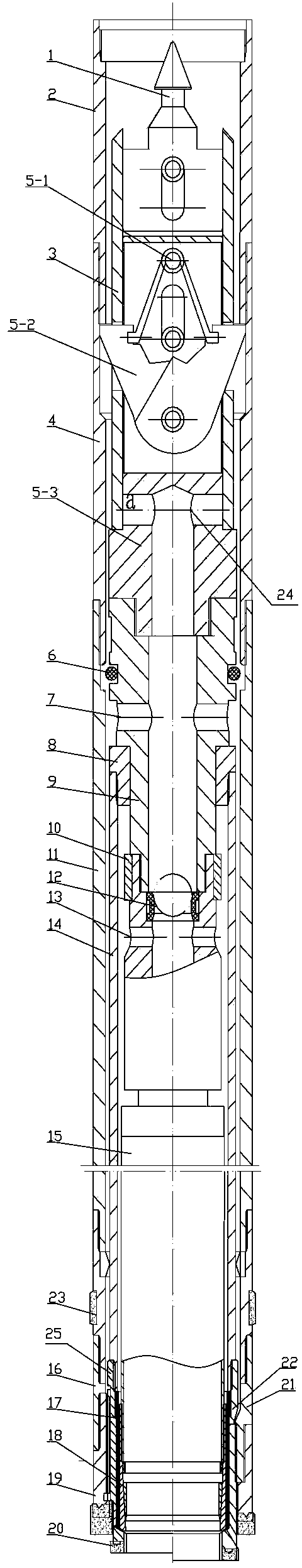

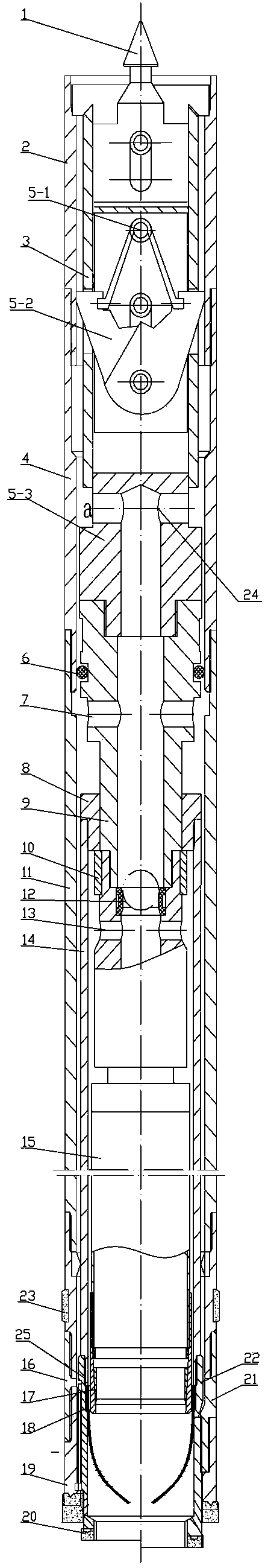

[0032] Please refer to figure 1 The left side structure of the drill is shown, which provides a core drill with inner drill bit without a drill-for-drilling-bit spring-retaining cord. The drilling tool is composed of an outer tube assembly and an inner tube assembly.

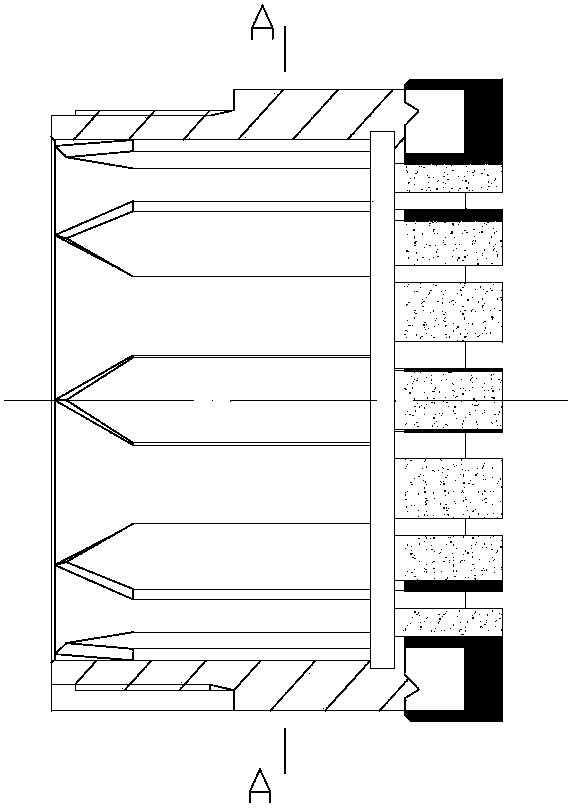

[0033] The outer tube assembly includes the cartridge stopper 2, the cartridge chamber 4, the outer tube 11, the reamer 23, the additional joint 16, the outer drill bit 19, and the outer drill bit is an inner spline drill bit with a chamfer (such as image 3 , Figure 4 ), the above-mentioned parts are connected with threads in order from top to bottom.

[0034] The inner tube assembly is sequentially arranged with the spearhead 1, the spring 5-1, the elastic caliper 5-2, the recovery tube 3, the elastic card holder 5-3, and the combination of the above components forms the elastic card in the inner tube assembly. Mechanism. When installing, first install the recovery tube 3 on the elastic card holder 5-3, then insta...

Embodiment 2

[0042] Please refer to figure 1 The structural form shown on the right side of the drilling tool provides a split-type step drill bit with a spring core-protecting rope core drilling tool. The drilling tool is divided into outer tube assembly and inner tube assembly. The upper part of the reamer 23 is the same as the rope core drill of the first embodiment, and the lower part of the reamer 23 is connected to the drill bit base 21 by a threaded button. The internal thread is connected with the internal drill bit 20 to form the outer tube assembly of this drill tool structure; the inner tube assembly is basically the same as the structure of the first embodiment, except that the lower end of the inner tube 14 is replaced by a spring seat 22 External spline internal drill bit 20 with chamfer, in drilling state (such as figure 1 Right) and salvage status (e.g. figure 2 Right) Same as Example 1. The structure of the split stepped drill bit is such as Figure 8 As shown, the split...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com