Plastic extruding plate cutting machine

A board cutting machine and extruded board technology, applied in the direction of metal processing, etc., can solve the problems of extruded boards easy to move, complicated devices, and poor pressing effect of the pressing structure, so as to improve the cutting quality and save equipment costs , to avoid the effect of cutting quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

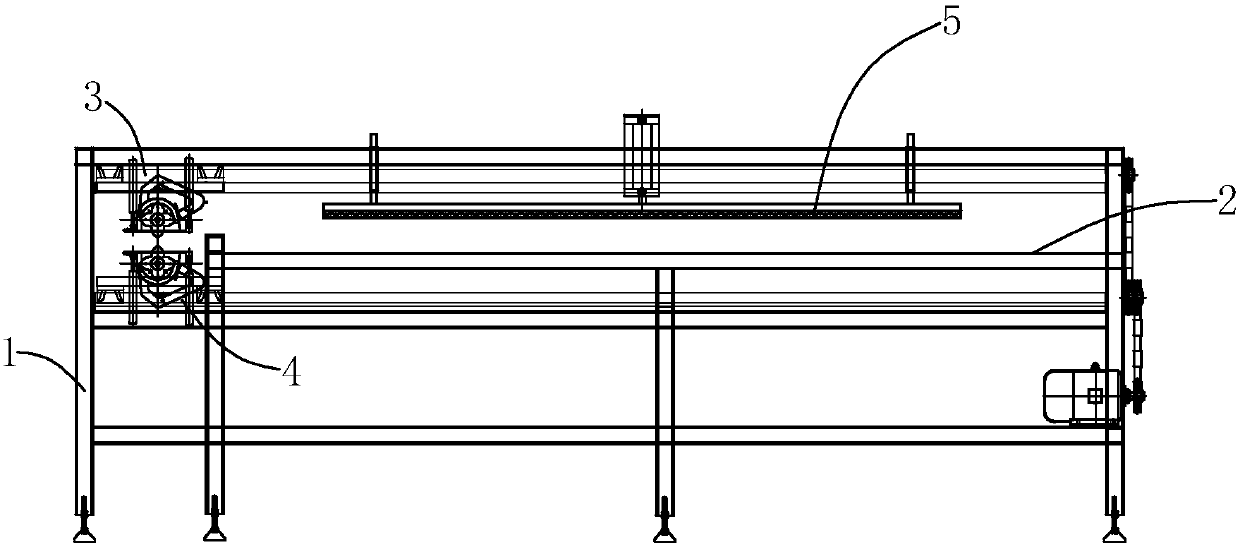

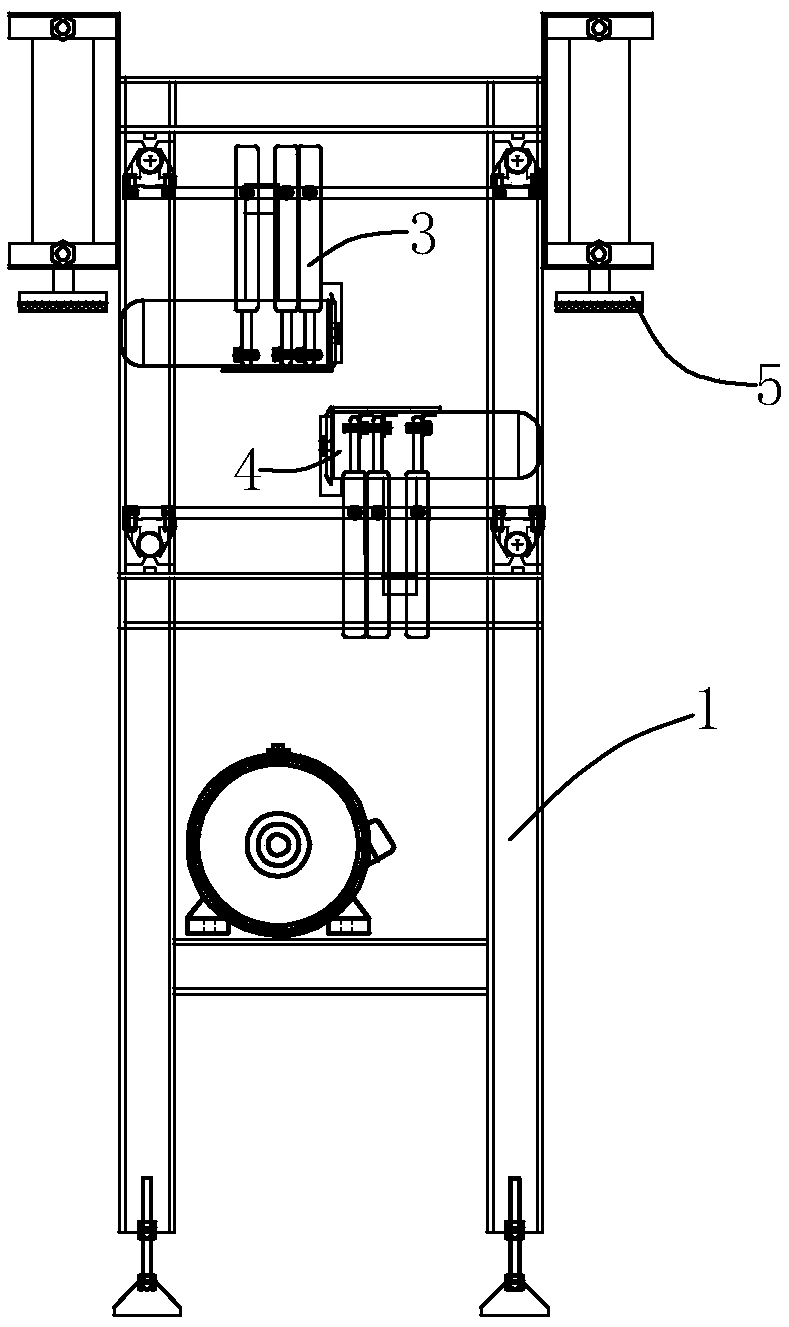

[0017] refer to Figure 1 to Figure 2 , an extruded board cutting machine of the present invention includes a frame 1, the frame 1 is provided with a workbench 2 for supporting the extruded board, and a bar-shaped gap is arranged transversely in the middle of the workbench 2, and the bar A first cutting device 3 and a second cutting device 4 are arranged directly above and directly below the notch, and the first cutting device 3 and the second cutting device 4 are all provided with annular blades, and the two annular blades are vertically distributed. And the vertical direction is tangent, which can ensure that the two annular blades cooperate to completely cut the extruded board. The annular blade is connected with a motor that drives its rotation. The first cutting device 3 and the second cutting device 4 can be horizontally Move synchronously, the first cutting device 3 and the second cutting device 4 are always placed directly above the strip-shaped gap, and the cutting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com