Reaction force cone cutting device

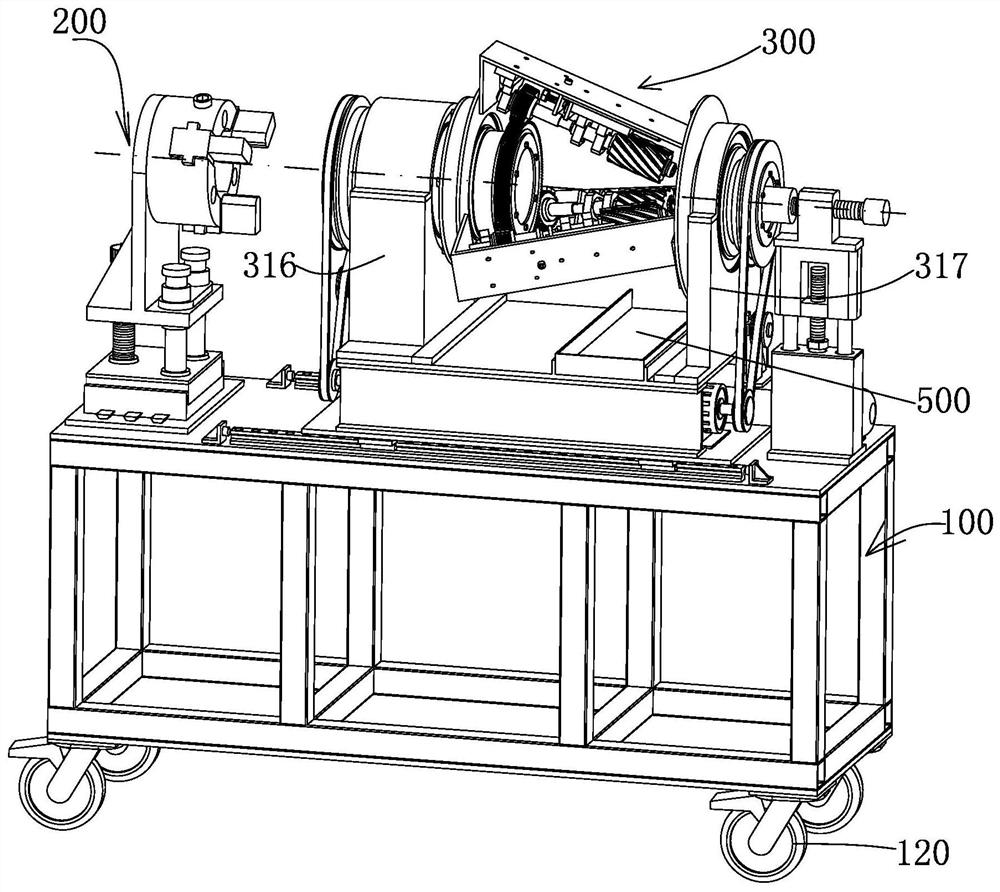

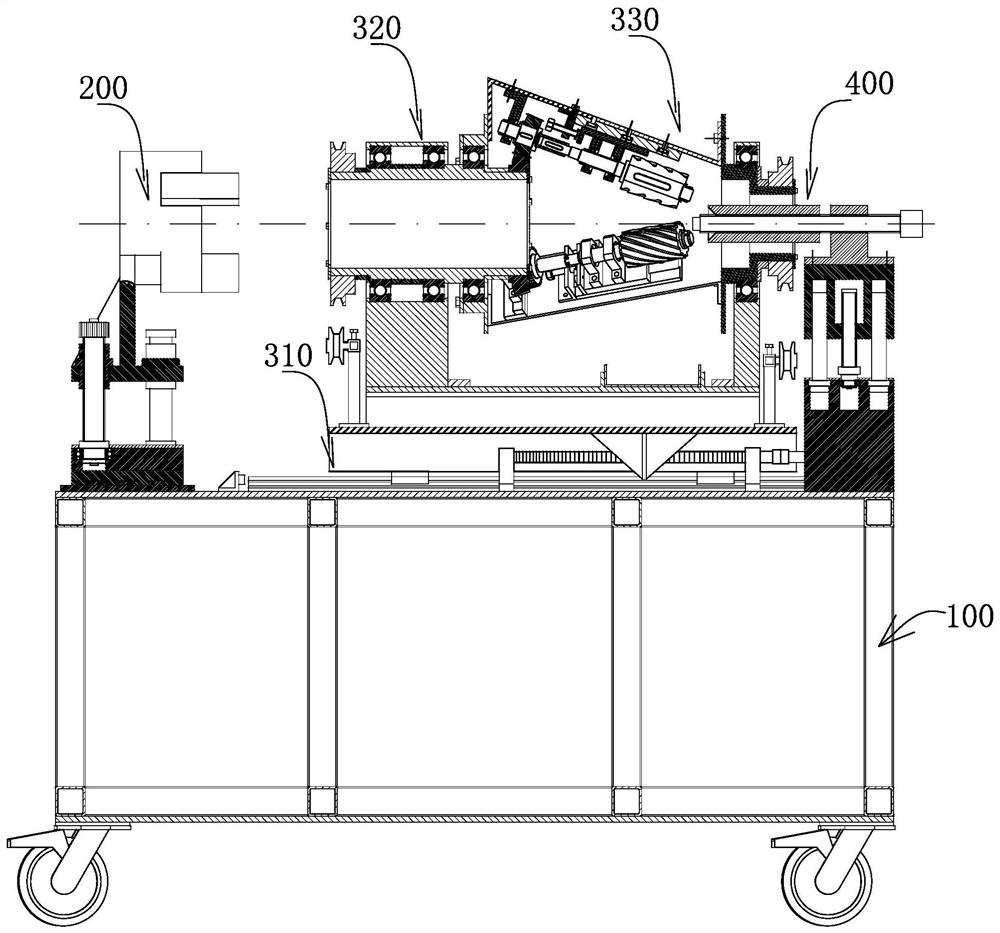

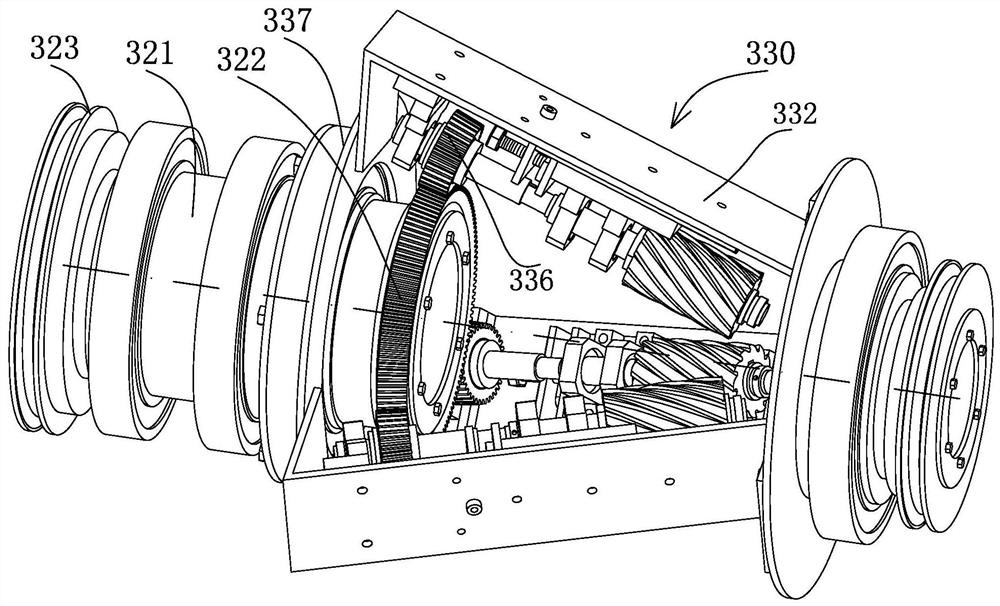

A technology of cutting device and reaction force cone, which is used in the manufacture of tools, chucks, metal processing machinery parts, etc., can solve problems such as low cutting efficiency, and achieve the effect of improving cutting efficiency, balancing cutting force, and avoiding uneven force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In the cable terminal production, since the metal sheath and insulation cutting, the original surface of the cable insulation is destroyed, the power line is concentrated on the shielding fracture of the outer semiconductor layer, and the electric field strength distribution is the least uniform. The highest field strength is the most likely to happen. Since the cross section is increased by the conductor continuous section, the thickness of the insulation, the dielectric constant and the cable body insulation is not more, the electric field distribution in the cable terminal and the electric field distribution in the intermediate connector A large change occurs, this change is mainly manifested in generating an axial electric field strength along the direction of the cable insulating surface, or is called axial stress.

[0060] In order to improve the electric field distribution of this part, it is necessary to cut the cable body insulated into a "pencil head" shape. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com