Intelligent optical fiber laser cutting machine with high safety

A laser cutting machine and intelligent optical fiber technology, applied in the field of optical fiber equipment, can solve the problems of poor safety performance of optical fiber laser cutting machines, affecting the respiratory health of operators, toxic and harmful gases or smoke, etc., to reduce burn accidents, increase practicability, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

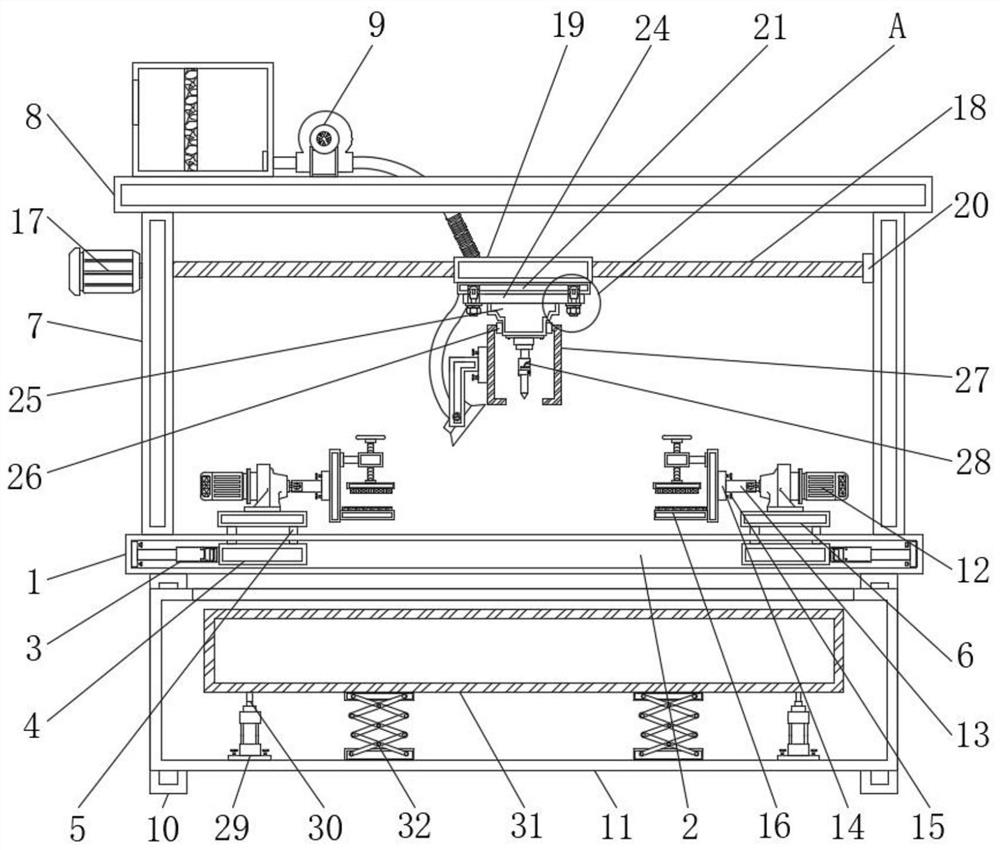

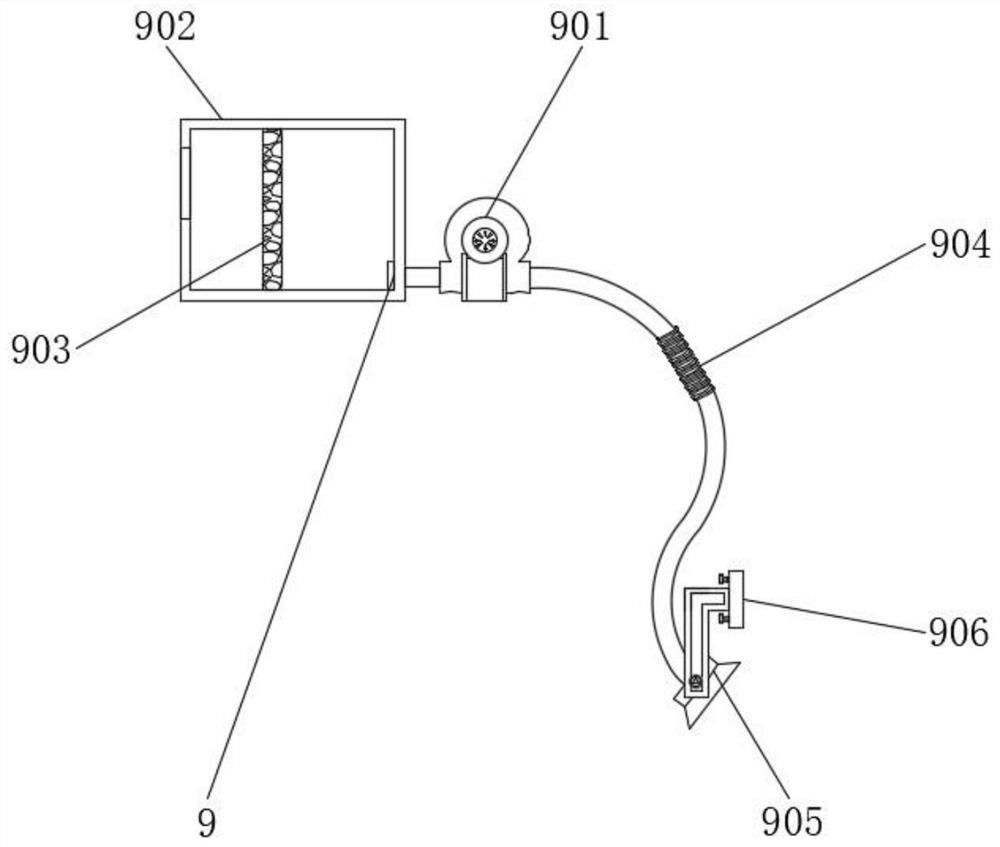

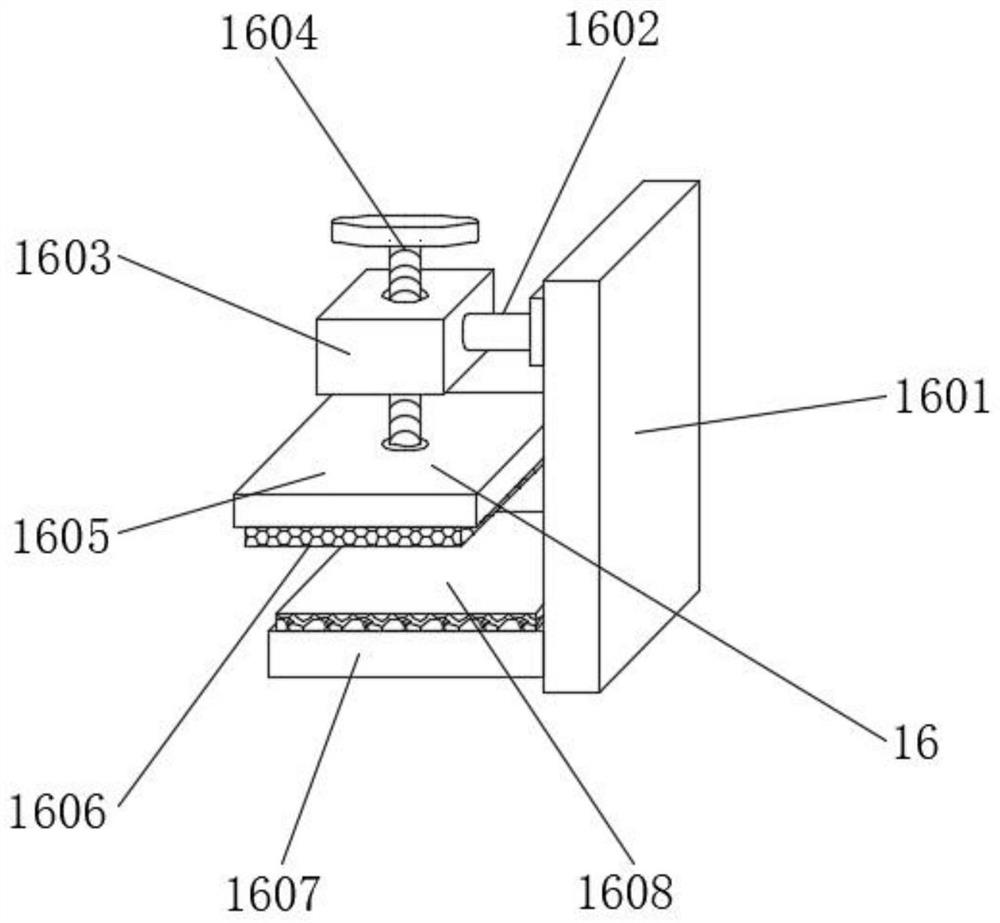

[0021] according to Figure 1-Figure 4 As shown, this embodiment provides an intelligent fiber laser cutting machine with high safety, including a base 1, and a cavity 2 is opened inside the base 1, and electric motors are fixedly installed on both sides of the inner wall of the cavity 2. Push rod 3, described one side is fixedly connected with slide block 4, and the upper end of described slide block 4 is welded with connecting rod 5, and described connecting rod 5 penetrates base 1 and is welded with moving seat 6, and described moving seat 6 passes through slide The block 4 is slidingly connected with the base 1, the upper end of the base 1 is welded with side plates 7 on both sides, the upper end of the side plates 7 is welded with a horizontal plate 8, and the upper end of the horizontal plate 8 is provided with a purification mechanism 9, so Both sides of the lower end of the base 1 are welded with support legs 10, and the front surface of the two support legs 10 is weld...

Embodiment 2

[0030] according to Figure 5 As shown, an intelligent fiber laser cutting machine with high safety is provided, and a motor box 33 is fixedly installed on the outside of the rotating motor 17, and a plurality of cooling holes 34 are provided on one side of the motor box 33, through which The rotating motor 17 can be protected under the effect of the motor box 33, avoiding the rotating motor 17 from being damaged, and prolonging the service life of the rotating motor 17. The normal heat dissipation of the rotating motor 17 avoids damage to the internal components of the rotating motor 17 caused by excessive temperature, further improves the service life of the rotating motor 17, and increases the practicability of the fiber laser cutting machine.

[0031] A shock-absorbing pad 35 is bonded to the bottom of the supporting leg 10, and a tool box 36 is fixedly installed on one side of the supporting leg 10, and the fiber laser cutting machine can be reduced in use under the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com