Indentation-free bending machine lower mold with adjustable opening

A bending machine and indentation technology, which is applied in the field of bending processing of sheet metal parts, can solve the problems of time-consuming and labor-consuming operation, indentation and scratches on the surface of workpieces, and low production efficiency, so as to avoid indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

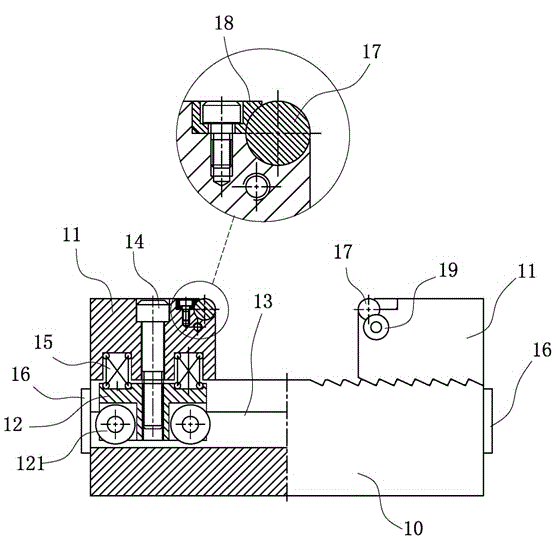

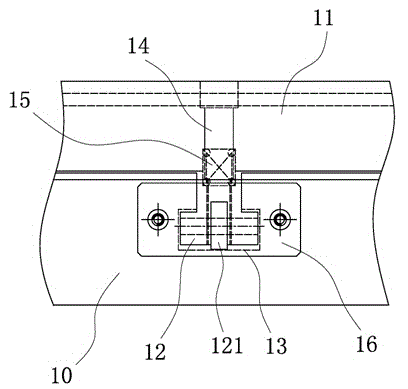

[0015] like figure 1 , 2 As shown, a lower mold of a bending machine includes a mold base 10, and the upper surface of the mold base 10 is provided with two modules 11 protruding upwards, and the two modules 11 are arranged symmetrically about the center line of the mold base 10. Between the two modules 11 and the mold base 10 is a split structure, and the two modules 11 are slidably arranged on the mold base 10 so that the two modules 11 form an open-close arrangement; Locking unit in stroke position.

[0016] Preferably, the upper surface of the mold base 10 is provided with a T-shaped slot 13, and the bottom of the module 11 is provided with a sliding seat 12, and the sliding seat 12 is stuck in the T-shaped slot 13 and slides along the length direction of the T-shaped slot 13, The two ends of the T-shaped groove 13 are provided with baffles 16, and the baffles 16 are fixed on the side of the mold base 10 by screws; A compression spring 15 is arranged between the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com