Device and method for manufacturing concrete three-point bending coped beam

A technology of three-point bending and concrete, which is applied to the device for making concrete three-point bending notched beams, and the device for making concrete three-point bending notched beams in the field of making concrete three-point bending notched beams, which can solve the complicated process of concrete three-point bending notched beams , low pass rate of test pieces and other problems, to achieve the effect of simple structure, convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

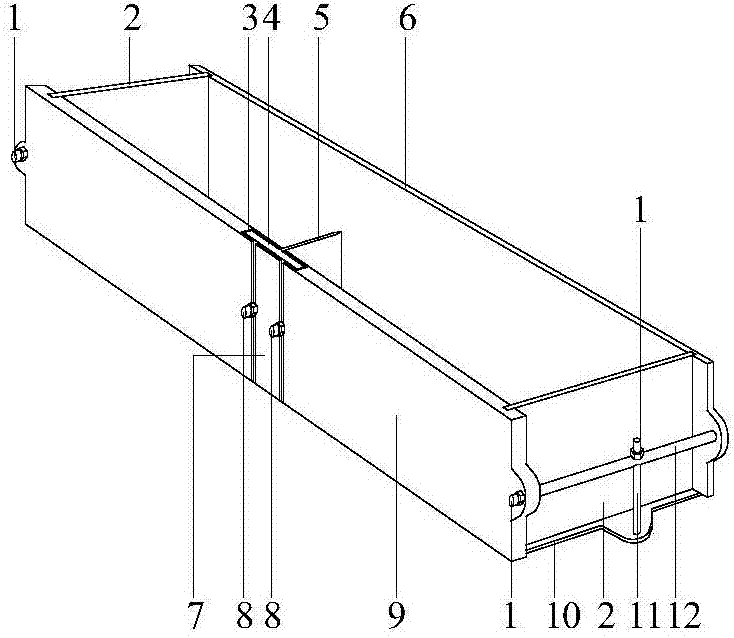

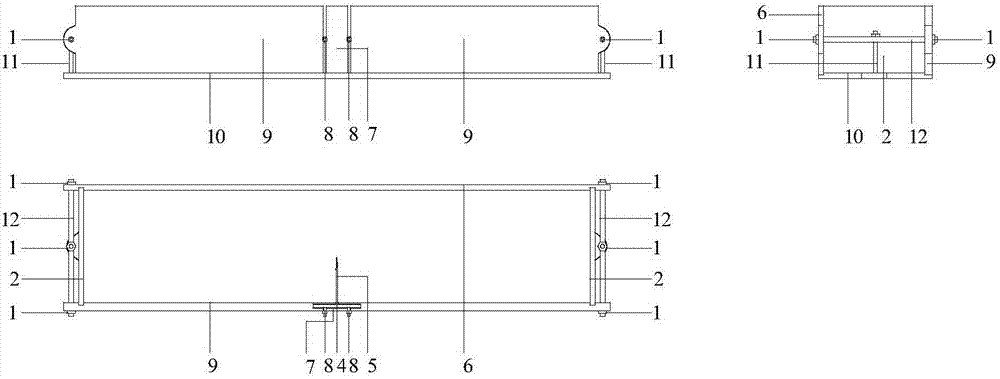

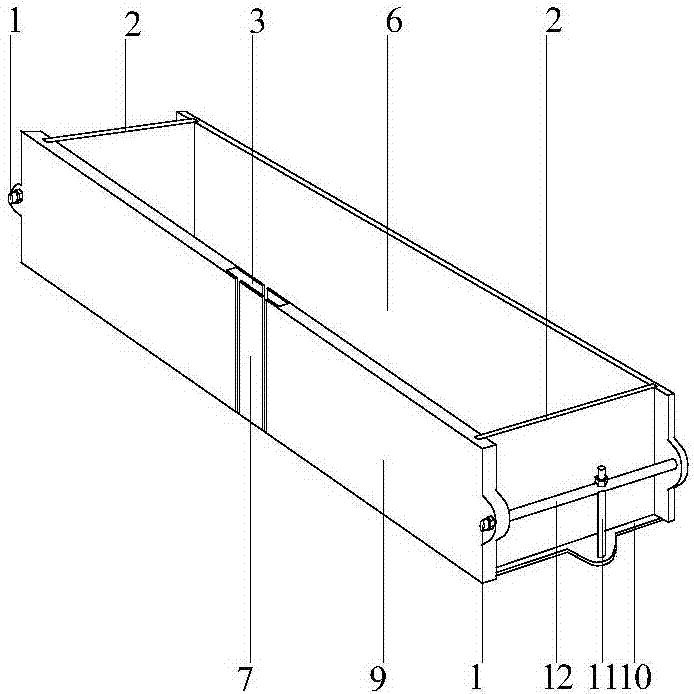

[0031] The present invention as Figure 1 to Figure 9 , including concrete three-point bending notched beam beam body and concrete three-point bending notched beam wedge-shaped body, specifically composed of nut 1, end plate 2, wedge-shaped body positioning groove 3, frame vertical plate 4, blade 5, rear side plate 6, The lateral positioning plate 7, the positioning bolt 8, the front side plate 9, the bottom plate 10, the longitudinal tie rod 11 and the horizontal tie rod 12 are formed.

[0032] Side plate grooves 61 are opened on two opposite short sides of the rear side plate 6 , and bottom plate grooves 101 are opened on three sides of the bottom plate.

[0033] Front side plate 9 is divided into two pieces, as Figure 8 As shown, cut off a small section at the midpoint of the long side direction, open the front side plate groove 91 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com