Irregular circular small-diameter iron core winding machine

A ring-shaped, small-diameter technology, applied in the direction of coil manufacturing, etc., can solve the problems of inability to wind the core with holes in the back of the winding, miniaturization and irregularization can not meet the requirements, etc., to achieve convenient control methods, improve operating efficiency, and install The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

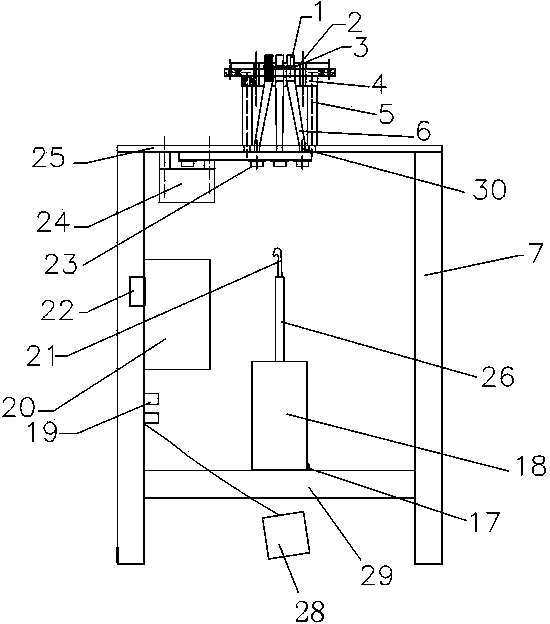

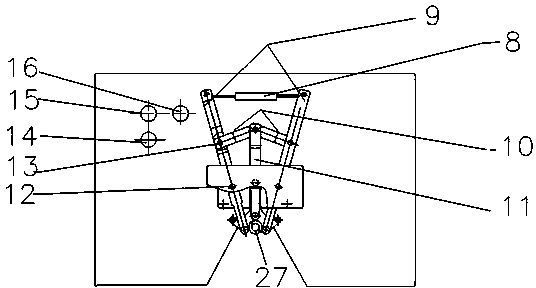

[0015] like figure 1 As shown, a non-regular ring type small-diameter iron core winding machine includes a workbench, an overall active clamping and clamping frame, a multi-coupling power drive device, a copper wire hook pulling device, and a PLC control system. It is characterized in that: the workbench 25 is welded by steel plates on square steel, the overall active clamping clamping frame includes left and right clamping arms 9, cross arms 10, and middle clamping arms 11, and the left and right clamping arms 9 and the resin wheel 1 at the front end of the middle clamping arm 11 are set on the same circle, and the other end is provided with a miniature cylinder 8; the multi-group coupling power drive device includes a speed regulating motor 24, a coupling 30 and a transmission rod 6 , the transmission rod 6 in the multi-coupling power drive device is composed of tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com