Sliding track stretching and positioning apparatus

A technology for positioning devices and slide rails, which is applied to furniture parts, household appliances, drawers, etc., and can solve problems such as easy to prevent failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

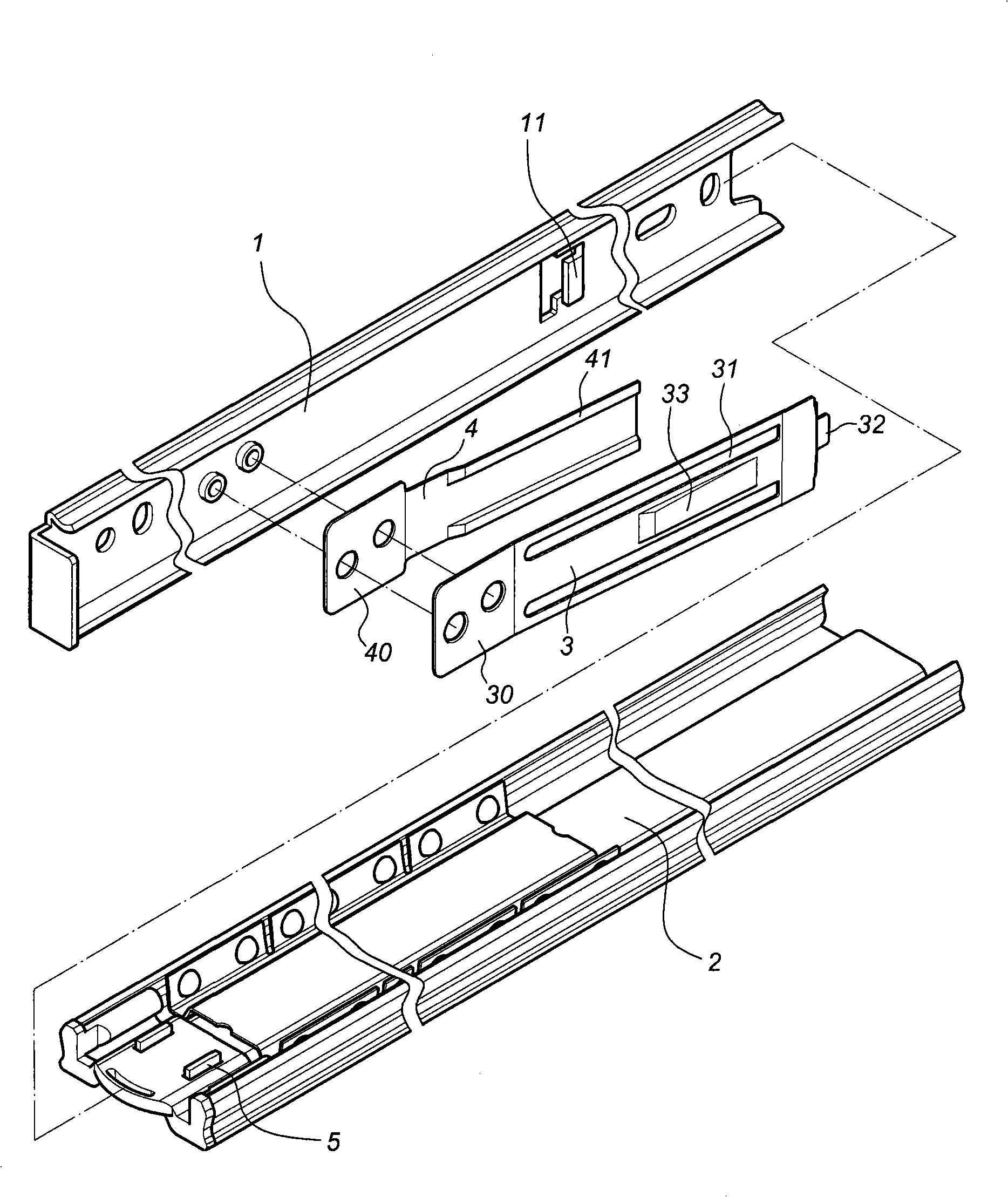

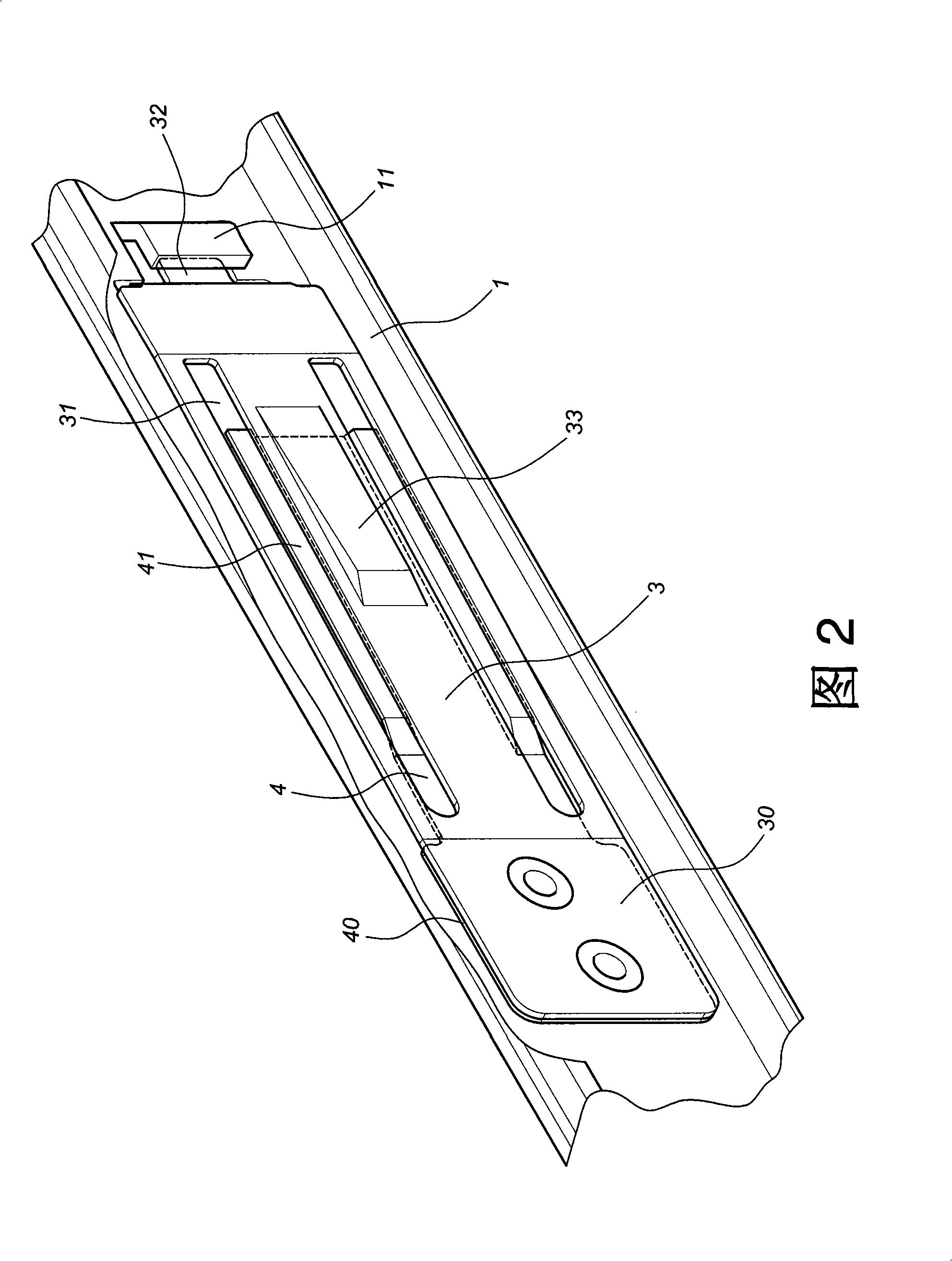

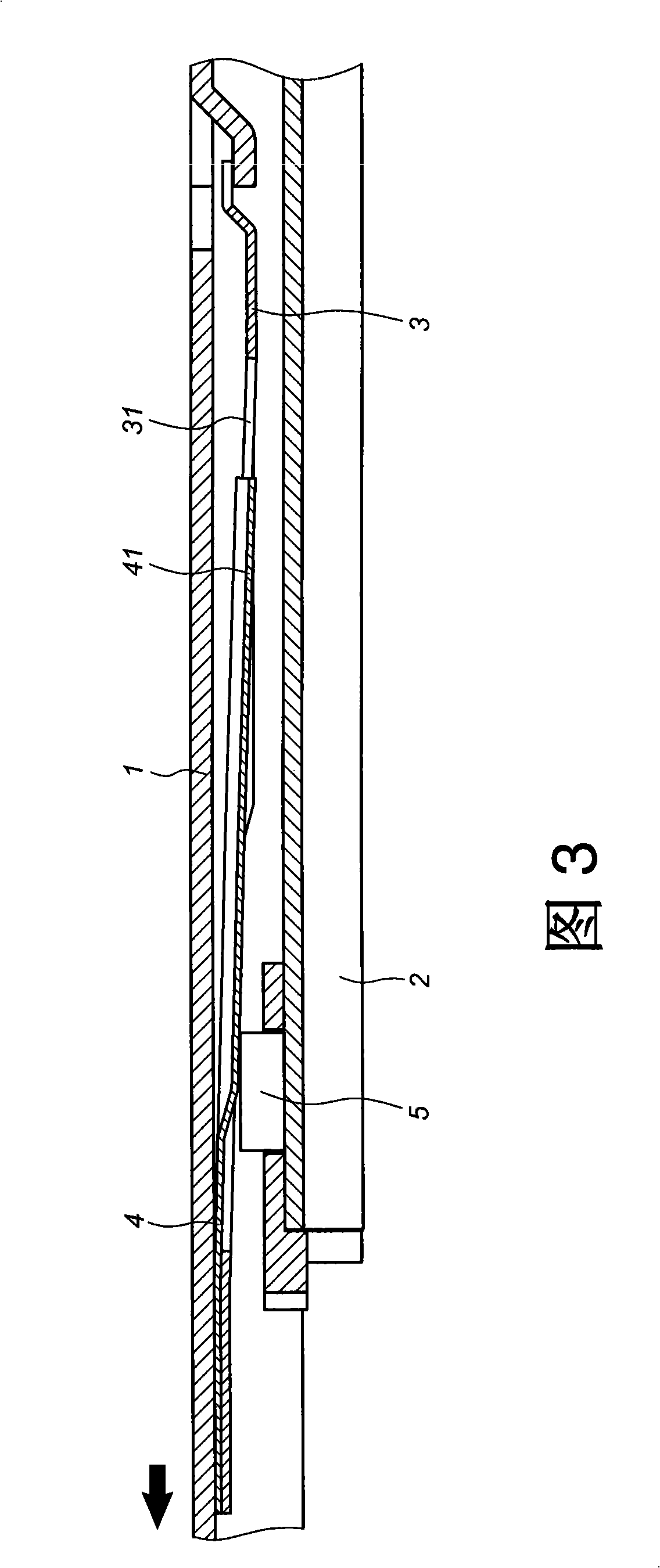

[0020] Such as figure 1 As shown in Fig. 2, the specific embodiment of the present invention includes a first rail 1, a second rail 2, an anti-loosening shrapnel 3, a stopper 4 and a fixing plate 5, wherein:

[0021] The first rail 1 is provided with a limiting piece 11;

[0022] The second rail 2 corresponds to the first rail 1 of the sleeve slide;

[0023] The anti-stripping piece 3 has a fixed end 30, a slot hole 31, a protruding piece 32 and a pressing area 33. The fixed end 30 is fixed on the first rail 1, and the protruding piece 32 is pressed against the limiting piece 11 of the first rail 1. The pressing area 33 is embossed to be pressed by the user;

[0024] The stop piece 4 is located between the anti-loosening elastic piece 3 and the first rail 1, and has a fixed end 40 and a stop portion 41, and the fixed end 40 is fixed on the first rail 1 corresponding to the fixed end 30 of the anti-loosening elastic piece 3 , and the resisting portion 41 is a convex rib and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com