A kind of wire saw beads with uniform distribution of abrasive particles and manufacturing method

A wire saw beaded and evenly distributed technology, which is applied in the tool manufacturing, manufacturing tools, sawing device and other directions of the sawing machine device, can solve the problem of uneven distribution of abrasive particles, and achieve the effects of ensuring uniform consumption, reducing usage and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

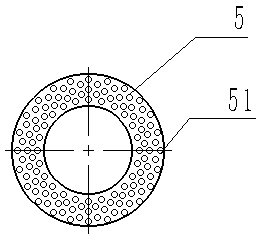

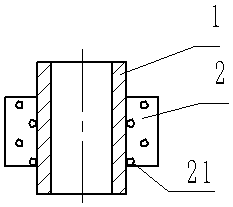

[0044] Specific embodiment 1: as Figure 3-9 As shown, extra small diameter (φ6.30mm-6.0mm) diamond evenly distributed wire saw bead manufacturing

[0045] Substrate 1 is a 45# circular cylinder with a length of 10mm and an inner and outer diameter of φ3.70 and φ4.50mm respectively, and a diamond particle size of 45 / 50 (particle size φ0.30-0.36mm). The main element is FeCuNiSn pre-alloyed powder, The theoretical density is about 8.11g / cm3, the outer diameter of the beaded working layer is φ6.50mm before cutting, and the height is 6.00mm. It is assembled and sintered by four cutting unit ring blanks. Bead production process: 1. Cr12 is selected for the cold press mold, and the size of the cold press mold is determined according to the size of the beads. The outer diameter of the upper pressing rod 3 is φ6.50mmH8, the inner diameter is φ4.50h7mm, and the inner diameter of the main mold 4 is φ6.50H8mm , the outer diameter of the inner ring top column of the lower ejector rod 5 i...

Embodiment 2

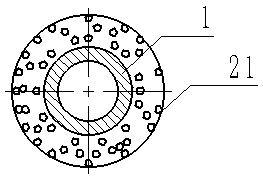

[0046] Embodiment 2: as Figure 10 As shown, regular size models (φ12.0mm-6.5mm) made of concrete cutting rope beads

[0047] Substrate 1 is a 45# circular cylinder with a length of 12mm and an inner and outer diameter of φ5.0 and φ7.0mm, respectively, and a diamond particle size of 40 / 45 (particle size φ0.35-0.43mm). The main element is FeCoCu pre-alloyed powder, The theoretical density is about 8.78g / cm 3 , The recommended sintering temperature is 900°C.

[0048] The outer diameter of the beaded working layer is φ12.0mm, the inner diameter is φ7.00mm, and the height is 6.50mm. It is assembled and sintered by four cutting unit ring blanks. Bead production process: 1. Select cold press mold material Cr12, determine the size of the cold press mold according to the design size of the beads, the outer diameter of the upper pressing rod 3 is φ12.00mmH8, the inner diameter is φ7.00h7mm, and the inner diameter of the main mold 4 is φ12.00H8mm, the outer diameter of the inner ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com