Board edge cutting device with automatic alignment function

An automatic alignment and edge trimming technology, which is applied in the field of wood cutting devices and automatic alignment wood edge trimming equipment, can solve the problems of low work efficiency and high labor intensity, and achieve the effects of reducing labor intensity, improving alignment effect, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

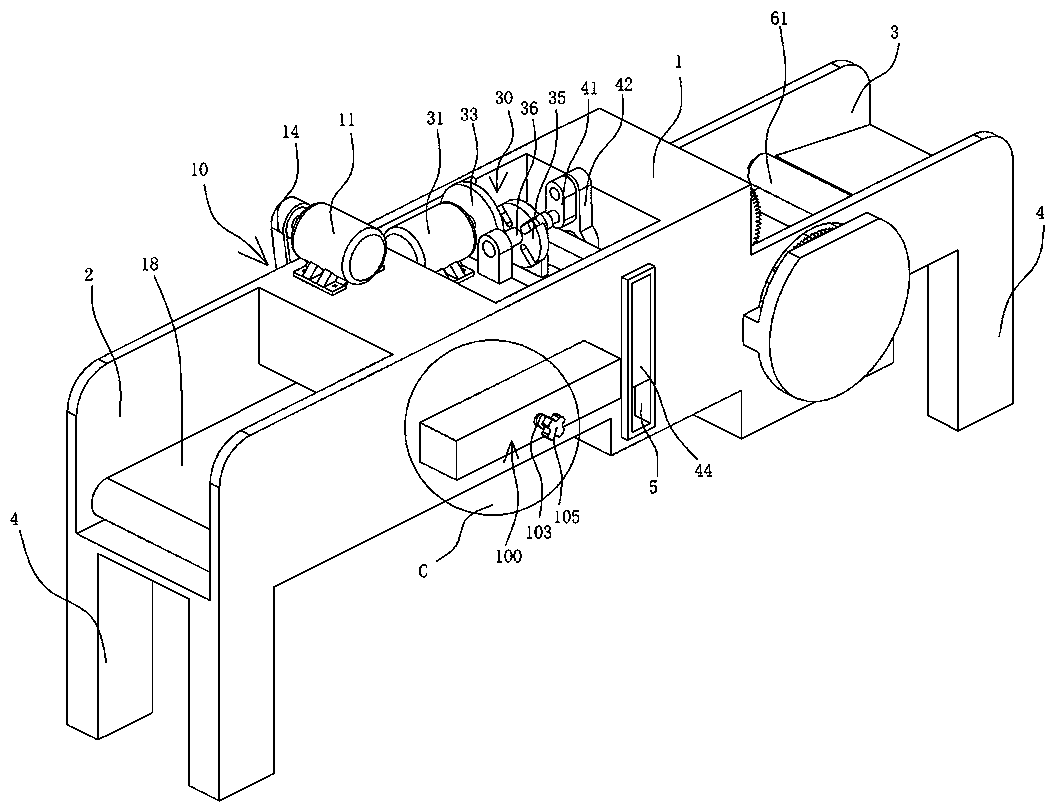

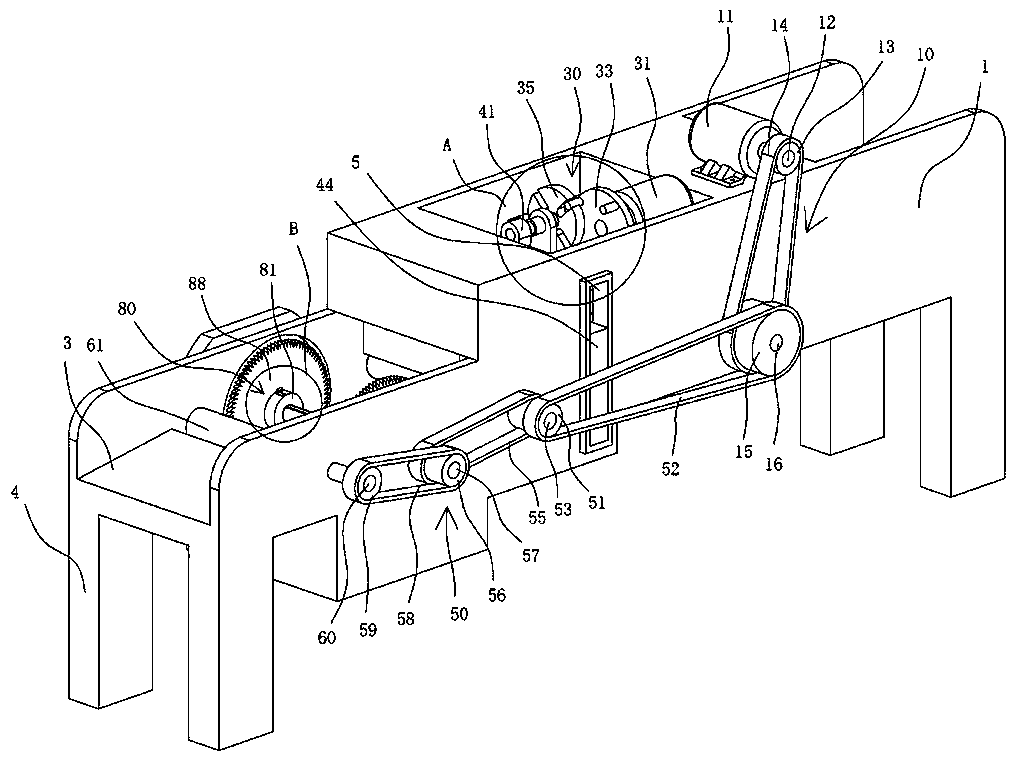

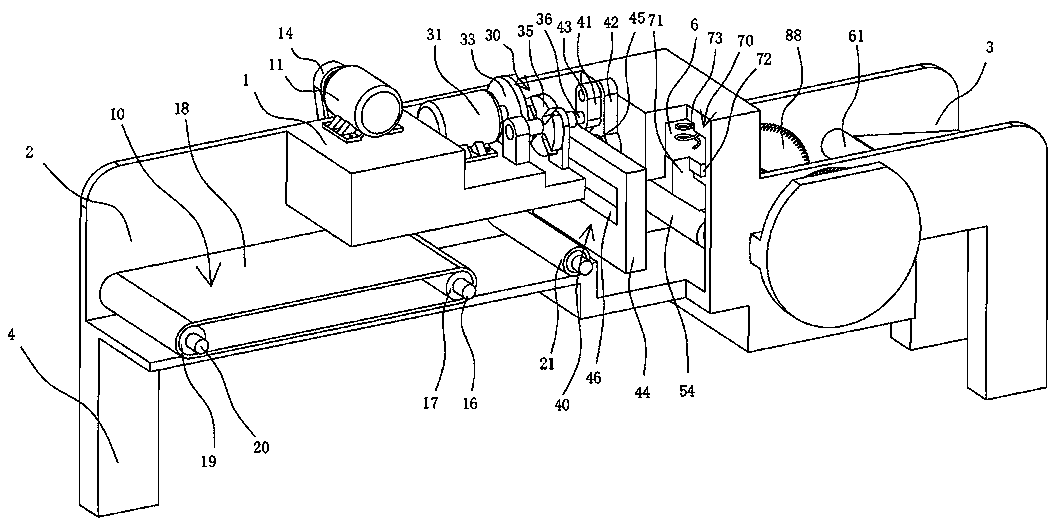

[0029] Such as figure 1 and figure 2 As shown, the wood edge trimming equipment capable of automatic alignment of the present invention includes a body 1, the left end of the body 1 is provided with a material inlet 2, the right end of the body 1 is provided with a discharge port 3, and the bottom end of the body 1 is provided with four evenly distributed legs 4. The left end of the body 1 is provided with a first transportation mechanism 10, the upper end of the body 1 is provided with a power mechanism 30 that provides intermittent rotational power, and the right end of the power mechanism 30 is provided with a liftable stopper mechanism 40, which is located on the first transport mechanism 40. On the right side of mechanism 10, the right end of first transportation mechanism 10 is provided with second transportation mechanism 50, and the upper side of second transportation mechanism 50 is provided with the stabilizing mechanism 70 that prevents planks from bouncing. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com