Rotary tool and its cutting part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0035] the present invention is described with reference to the accompanying drawings. Although a case where a film applied to the outer surface of a work surface S is to be removed is illustrated in this embodiment, working according to the present invention is not limited thereto. The present invention is also widely applicable to removal of other “films” such as adhesives, resin sheets and resin tiles adhered to work surfaces or work surfaces made of other materials.

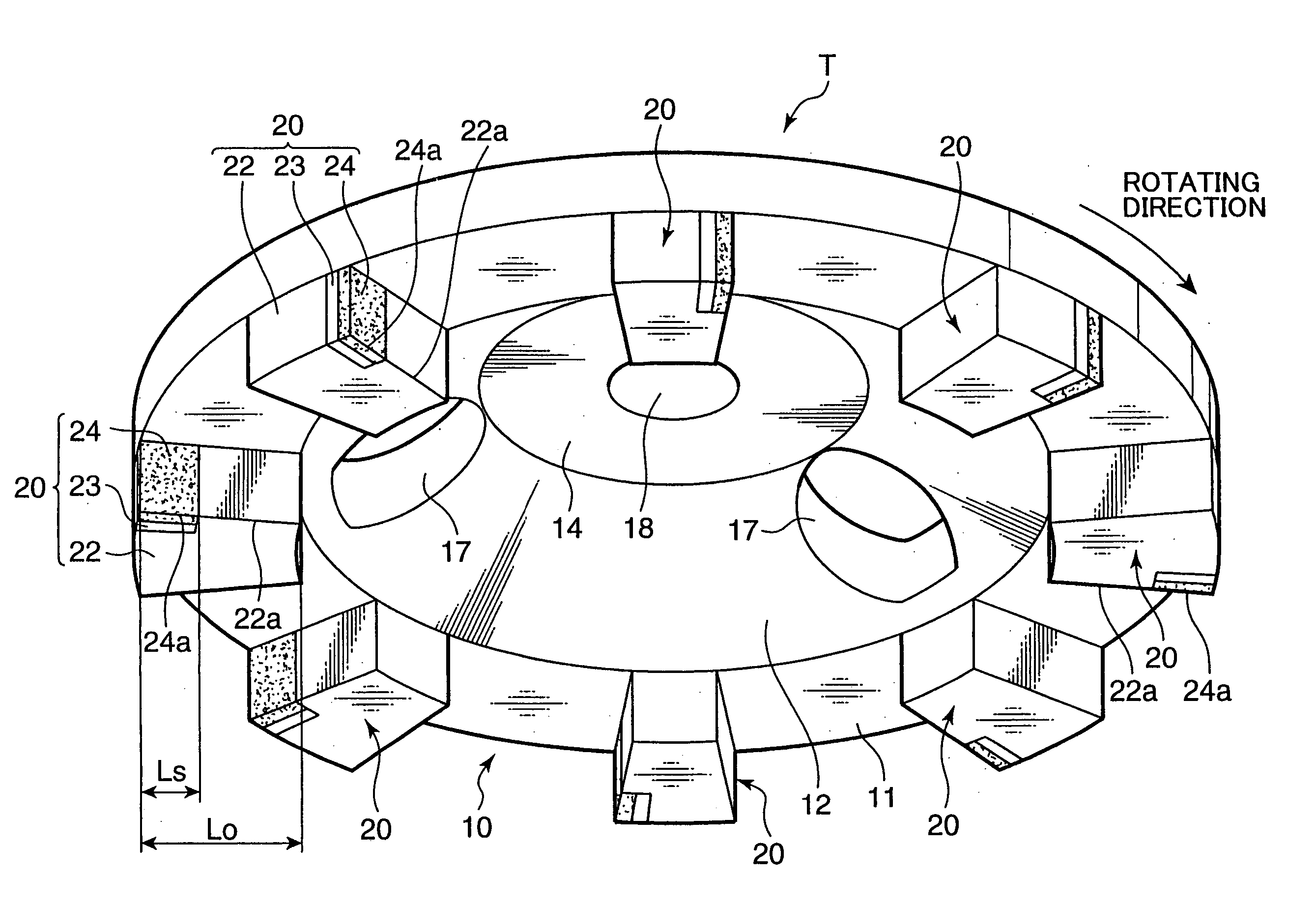

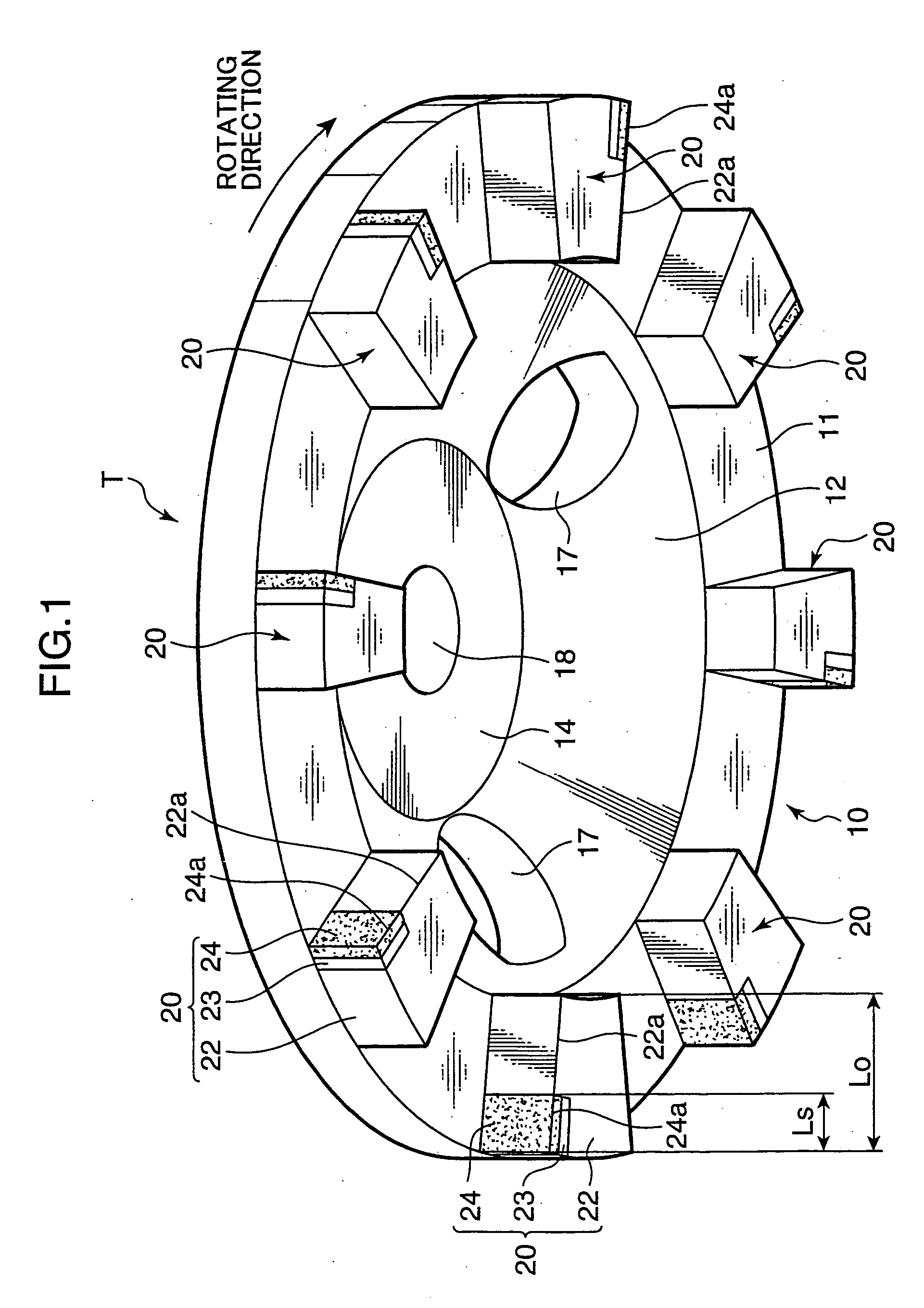

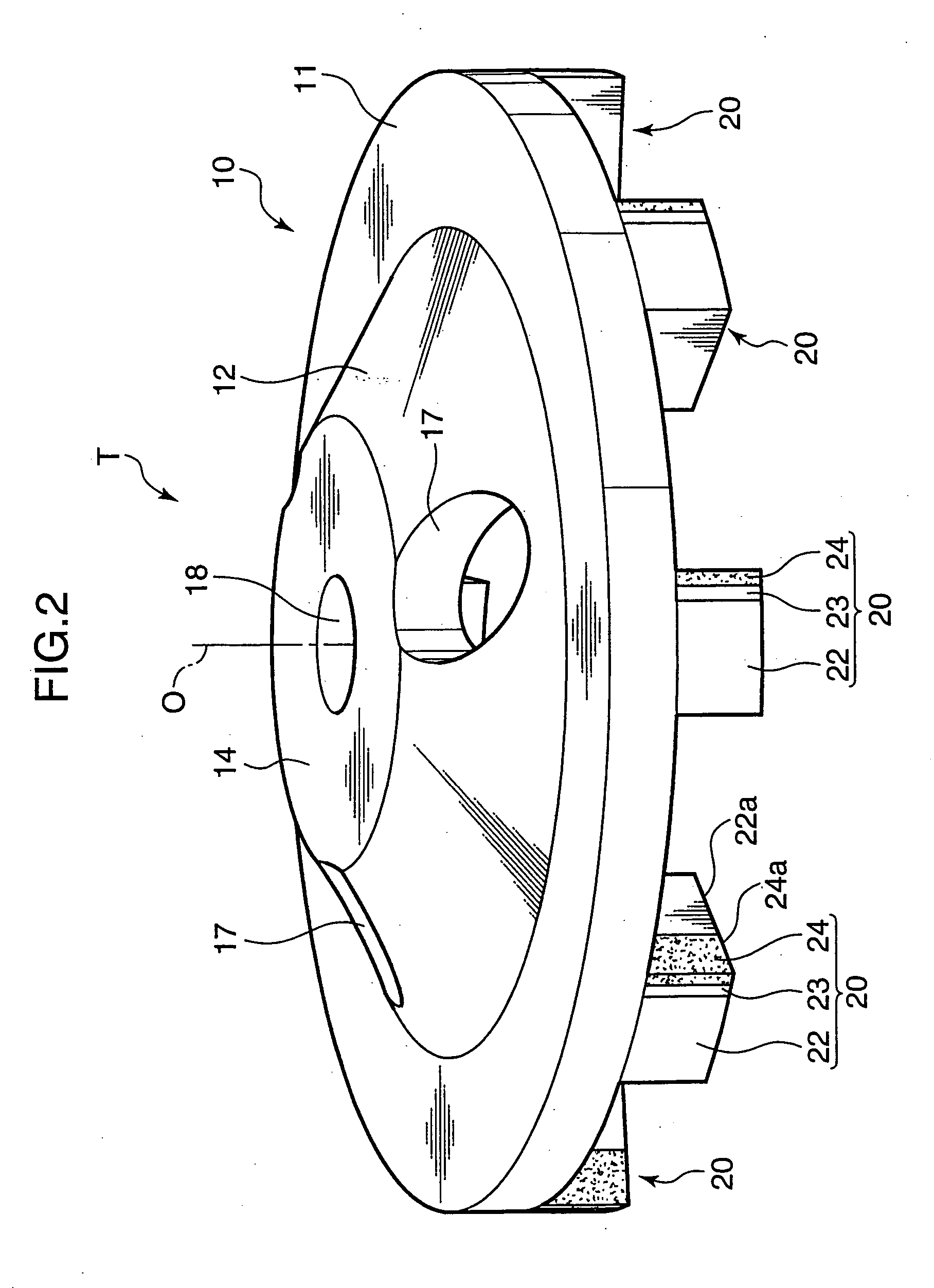

[0036] A rotary tool T shown in FIGS. 1 to 4 is comprised of a rotary segment 10 made of a metallic plate and a plurality of cutting parts 20 mounted on the rotary segment 10.

[0037] The rotary segment 10 integrally includes an outer peripheral portion 11 in the form of a flat plate 11 and an inner portion 12 formed inside the outer peripheral portion 11.

[0038] The inner portion 12 bulges out upward substantially in the form of a cone from the inner edge of the outer peripheral portion 11, and a flat portion 14 paral...

fourth embodiment

[0063] Specifically, as shown in FIG. 10 as a fourth embodiment, even in such a construction that cutting parts each including only the hard sintered material tip 24a are provided at positions radially more outward than the cutting parts 26 (cutting parts made by the hard sintered materials 24 are secured in recesses 16 formed in the opposed surface of the rotary segment 10 in the shown example), i.e. even in such a construction that the grinding tool segment tips 22a shown in FIG. 1 and other figures are deleted, the tips 26a of the cutting parts 26a made of the grinding tool segment can suppress excessive cutting-in, assist cutting by the tips 24a and grind off or finish scratches caused by the cutting by the tips 24a.

fifth embodiment

[0064] Further, as shown in FIG. 11 as a fifth embodiment, the rotary tool may be such that a grinding tool segment 28 having a shape continuous along a peripheral direction of the rotary segment 10 (ring shape in the shown example) is provided, and cutting parts each including the hard sintered material tip 24a are provided at positions more outward than this grinding tool segment 28 with respect to the radial directions of the rotary segment 10. In this way, even if the grinding tool segment 28 has no tip, it can assist the cutting by the hard sintered material tips 24a by its abrading action, and the abrasion thereby can grind off or finish scratches formed by cutting by the hard sintered material tips 24a. Of course, an effect of preventing excessive cutting-in can also be given.

[0065] However, if all the cutting parts are those according to the present invention and peripherally arranged at even intervals as in the first embodiment, cutting ability can be made uniform along per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com