Ultra high torque double shoulder tool joint

An inner shoulder, higher technology, applied in the field of oilfield pipeline thread connection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

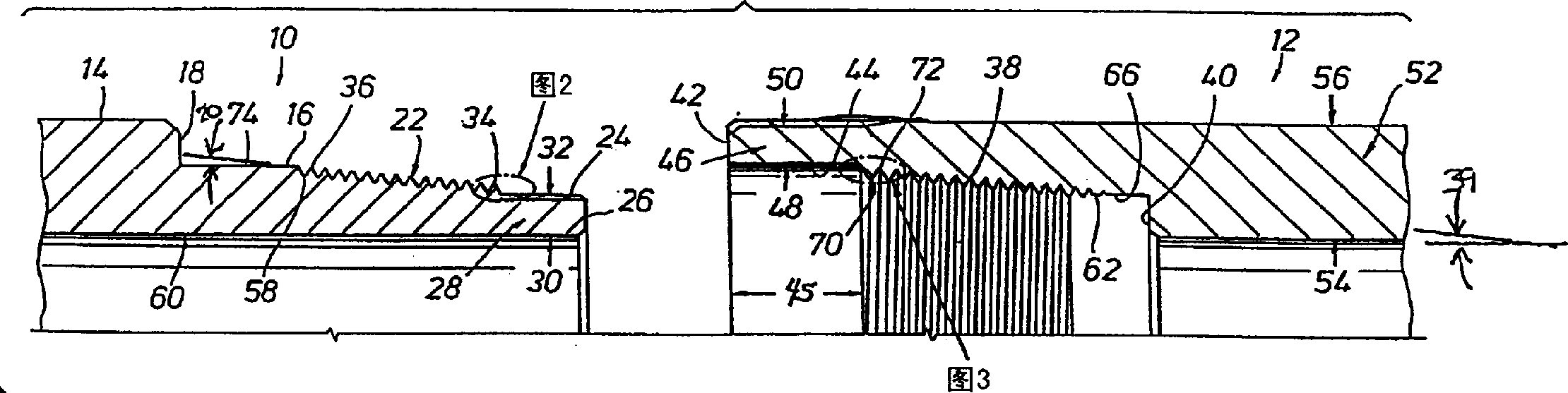

[0036] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

[0037] see now figure 1 , a tubular male threaded joint 10 is located at one end of a section of drill pipe, and is used to cooperate with a tubular type female threaded joint 12 of another section of drill pipe. The other end of the drill pipe with male nipple 10 has a female nipple similar to female nipple 12 . Likewise, the other end of the drill pipe with the female nipple 12 has a male nipple similar to the nipple 10 .

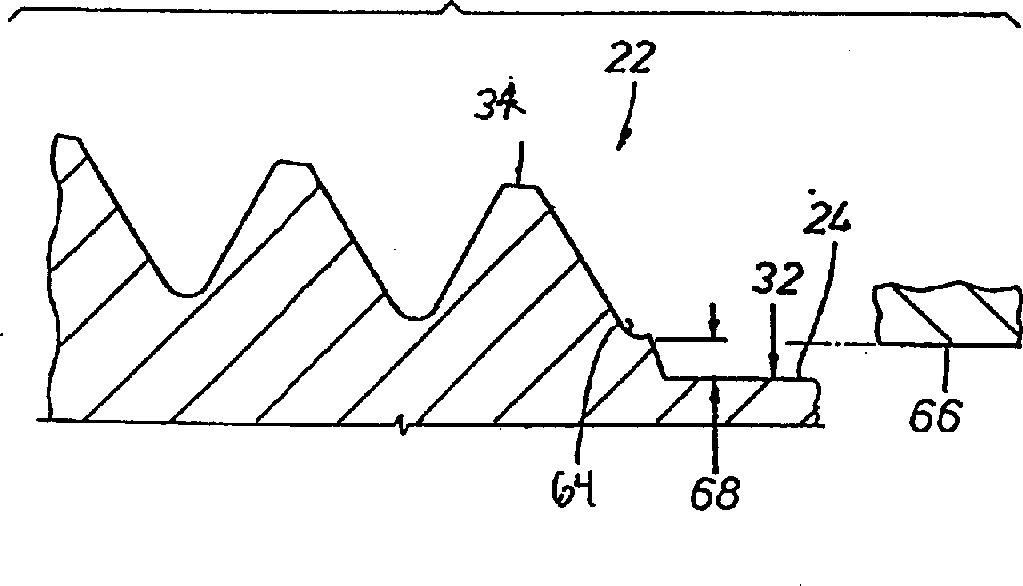

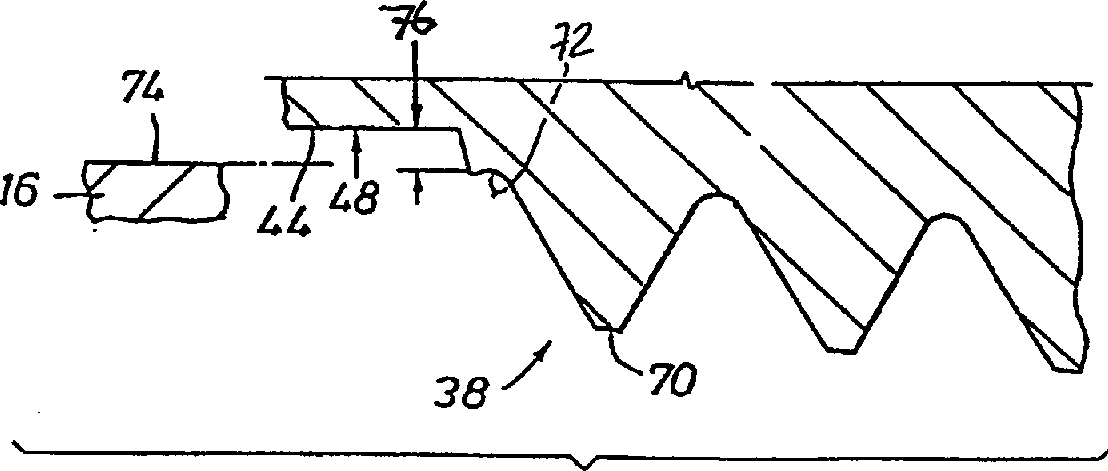

[0038] The male tubular nipple 10 includes external threads 22 extending axially between a radially outward outer shoulder 18 and a radially inward male nipple surface 26 . The male nipple 10 also includes a base portion 16 extending axially between the outer shoulder 18 and the external thread 22 and a forward portion extending axially between the male nipple surface 26 and the external thread 22 twenty four. The nose portion 24 defines a nose cross-sectional area 28 between its inner diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com