Novel nuclear pore membrane

A technology of nuclear pore membrane and nuclear track membrane, which is applied in the field of filter membrane, can solve the problems of easy clogging of filter membrane, stuck particles, low etching sensitivity, etc., and achieve the effect of not easy to clog and improve etching sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

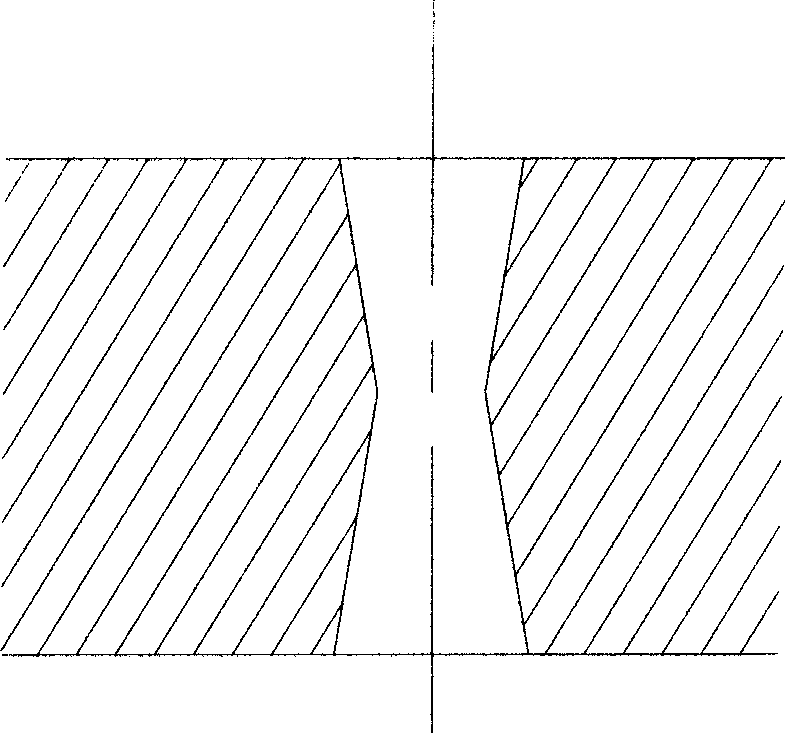

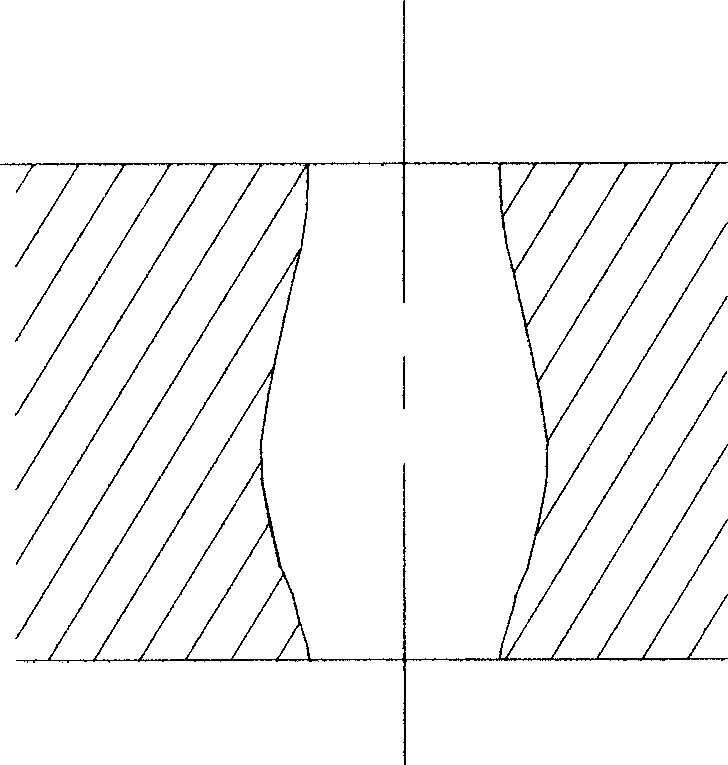

Image

Examples

Embodiment 1

[0023] Embodiment one: be that the oxygen ion irradiation of energy is 24MeV 15 microns thick polyester film, through ultraviolet light irradiation two hours, be that concentration is 6Mol, the temperature is that the sodium hydroxide solution solution of 60 degrees Celsius is etched in the last, film A voltage of 3V is applied on both sides. After 5 hours of etching, it was observed under a microscope that the surface pore diameter of the membrane was about 6 microns, and the pore diameter in the middle of the micropore was about 8 microns.

Embodiment 2

[0024] Embodiment two: be that the polycarbonate film of 10 micron thickness is irradiated with the chlorine ion energy of 35MeV, irradiated by ultraviolet light for two hours, at last be etched in the sodium hydroxide solution that concentration is 3Mol, temperature is 40 degrees centigrade, A voltage of 1.5 V was applied across the membrane. After 1 hour of etching, it was observed under a microscope that the surface pore diameter of the membrane was about 0.4 micron, and the micropores were in the shape of a cylindrical capillary.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com