Multimode fiber beam splitter and production method thereof

A technology of multimode optical fiber and manufacturing method, which is applied in light guides, optics, instruments, etc., can solve problems such as the difficulty in coupling optical fiber light energy, the difficulty in controlling the splitting ratio and additional loss, etc., and achieve the reduction of taper difficulty, small taper, and beam The effect of small waist diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

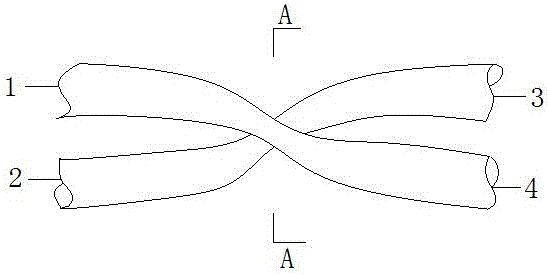

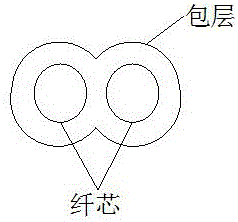

[0044] An embodiment of the present invention provides a multimode optical fiber beam splitter, including an input optical fiber and three output optical fibers fixedly connected, the input optical fiber is an OM3 multimode optical fiber with a core diameter of 50 microns, and the output optical fiber is Three G.652D single-mode fiber single-mode fiber.

[0045] The input fiber uses OM3 multimode fiber, which is convenient for high power intensity and M 2 A laser with a large factor and a large beam waist diameter is coupled into the input fiber to achieve a high input laser coupling efficiency; the output fiber uses a single-mode fiber to obtain a small divergence angle, small beam waist diameter, and uniform power distribution. output laser.

[0046] This embodiment also provides a method for manufacturing a multimode optical fiber beam splitter, which is used to manufacture the above-mentioned multimode optical fiber beam splitter, and the method is carried out according t...

Embodiment 2

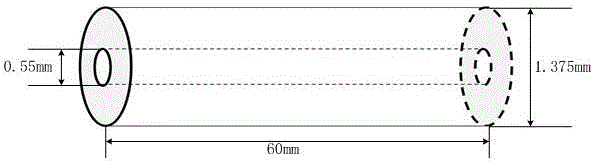

[0059] The difference between this embodiment and Embodiment 1 is that in the step S102, a hydrofluoric acid solution with a concentration of 20% is used to corrode the outer cladding of the single-mode optical fiber, so that the outer cladding radius of the optical fiber is changed from 0.0625 mm to 0.025 mm , even if the diameter of the outer cladding is 40% of the original diameter, the rest are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0061] The difference between this embodiment and Embodiment 1 is that in the step S102, the outer cladding radius of the single-mode optical fiber is changed from 0.0625 mm to 0.0375 mm by using a mechanical grinding method, even if the outer cladding diameter is 60% of the original diameter, the corresponding Yes, in the step S101, the inner diameter of the tapered quartz capillary glass tube after stretching is 0.17mm, and the outer diameter is 0.44mm, and the rest are the same as those in Example 1, and will not be repeated here.

[0062]In other embodiments of the present invention, the multimode fiber at the incident end can be replaced with other types of multimode fiber, such as 105 / 125, 200 / 220 and other types of multimode fiber; the single-mode fiber can be replaced with other types of multimode fiber Single-mode or multi-mode fiber, depending on the type of fiber at the input end; and the number of fibers at the output end can be larger: such as 7, 19, 37, etc., when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com