Joint bearing low-temperature wear test system and assembly method thereof

A joint bearing and low-temperature wear technology, which is applied in the direction of mechanical bearing testing, measuring devices, testing wear resistance, etc., can solve the problems of bulky test fixtures, poor design versatility, waste of funds, time and resources, and avoid deformation of the mandrel or fracture, reasonable structural stress, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

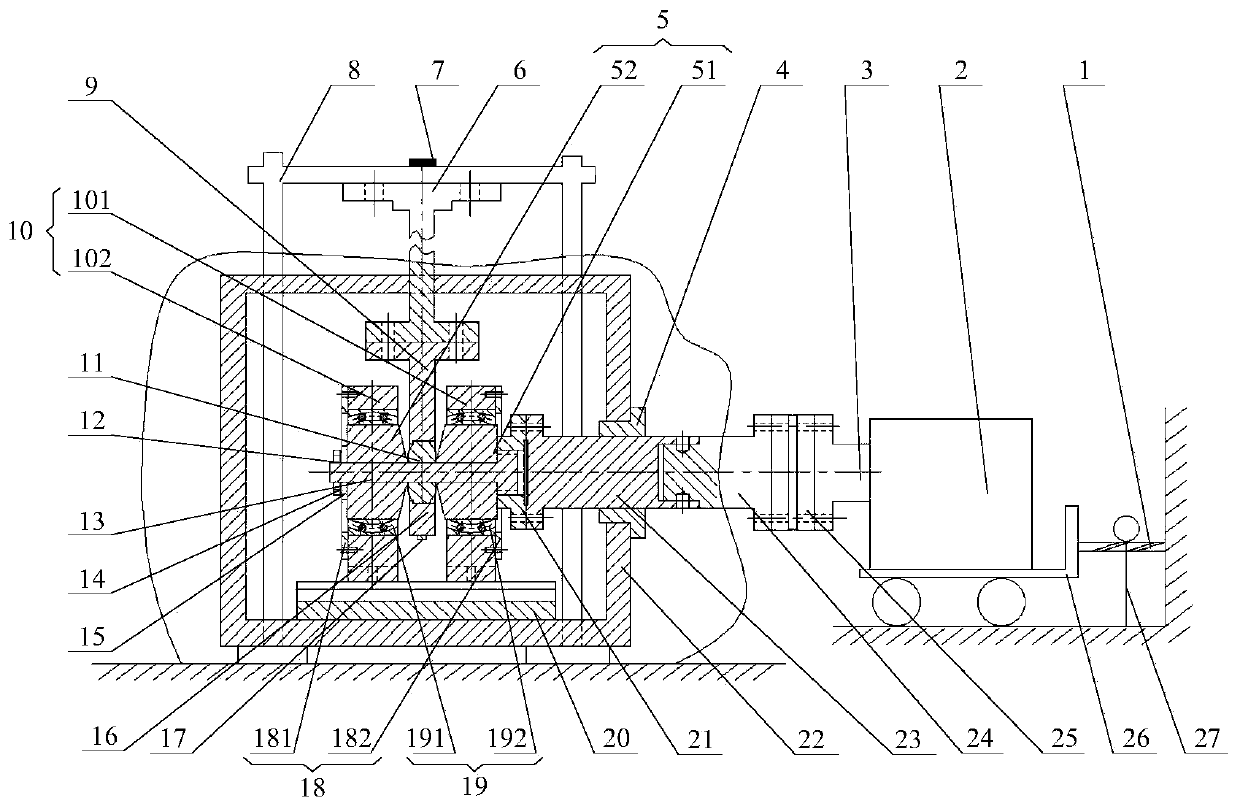

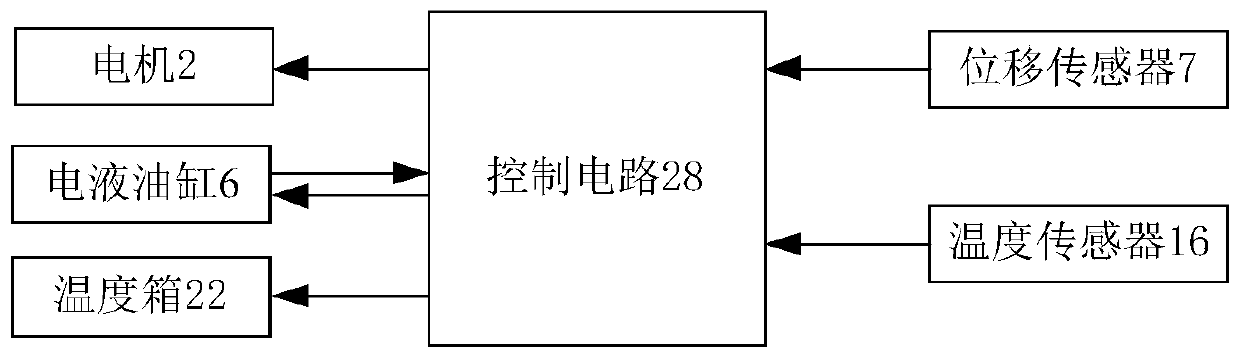

[0036] The embodiment of the invention discloses such as figure 1 A low-temperature wear test device for joint bearings is shown, which includes: screw 1, motor 2, motor shaft 3, rubber sleeve 4, jacking block 51, jacking block 52, electro-hydraulic cylinder 6, displacement sensor 7, bench 8. Loading plate 9, bearing seat 101, bearing seat 102, joint bearing under test 11, nut 12, mandrel 13, elastic gasket 14, bushing 15, temperature sensor 16, reflective strip 17, end cover 181, end cover 182, accompanying test bearing 191, accompanying test bearing 192, base 20, adapter 21, temperature box 22, box-through shaft 23, flange shaft 24, shaft coupling 25, motor base 26, hand wheel 27 and control circuit 28.

[0037] In this embodiment, the mandrel and the inner ring of the tested spherical plain bearing have a clearance fit of 0.013 to 0.038 mm; the material of the mandrel is 9Cr18 bearing steel; the material of the loading plate is Q275 carbon steel; other test fixture material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com