Laser processing device and method for film material removal

A laser processing and thin-film material technology, applied in the laser field, can solve the problems of complex flat-top spot shaping technology and difficult application of thin-film materials, and achieve the effects of smooth edges, improved product yield and quality, and strong practicability

Active Publication Date: 2019-08-16

WUHAN HGLASER ENG CO LTD

View PDF7 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to address the problems existing in the prior art, provide a laser processing device and method for thin film material removal, and solve the problems of complex flat top spot shaping technology and difficult application of thin film materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0052] In one embodiment of the device and method disclosed herein, a picosecond laser with a power of 50W and a wavelength of 1064nm is used to process a 0.3mm thick cop plastic surface paint layer at a processing speed of 300mm / s. After processing, the cop plastic The surface paint layer is removed cleanly, there is no taper, no heat effect, and the roughness of the processed bottom is 0.2um.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

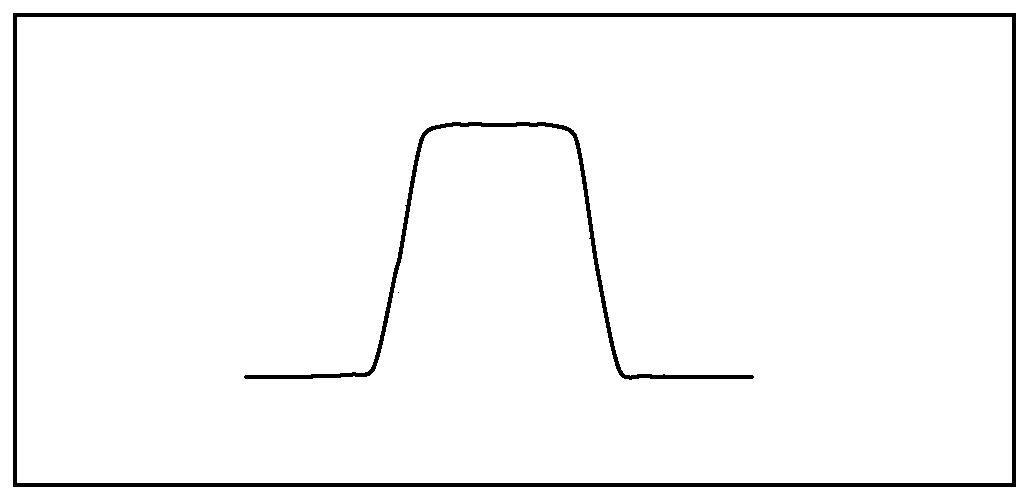

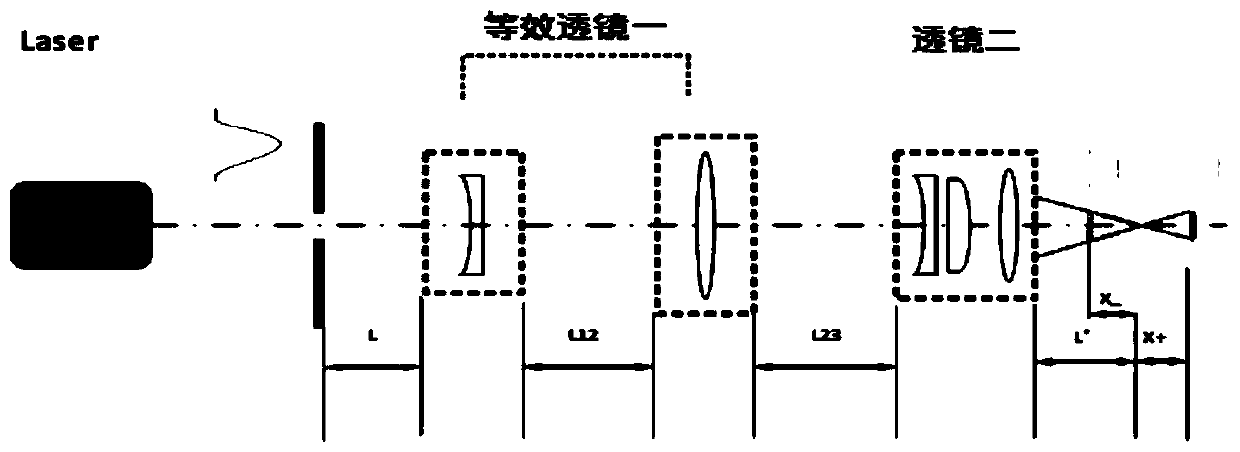

The invention discloses a laser processing device for film material removal. A laser, a small aperture diaphragm and a lens system are arranged in sequence along a laser light propagation path. The lens system comprises a first equivalent lens and a second lens. Gaussian beam emitted by the laser passes through the small aperture diaphragm and the lens system and then forms an image with sharp edges, meanwhile, after the Gaussian beam passes through the small aperture diaphragm, diffraction orders with unobvious edges occur due to the diffraction phenomenon, and light spots of Gaussian beam are imaged into sharp-edged and flat-topped light after different diffraction orders are gathered and superimposed through the lens system. The invention further discloses a laser processing method forfilm material removal. Through the device and method disclosed by the invention, the problems that a flat-topped light spot shaping technology is complicated, and application to film materials is difficult are solved.

Description

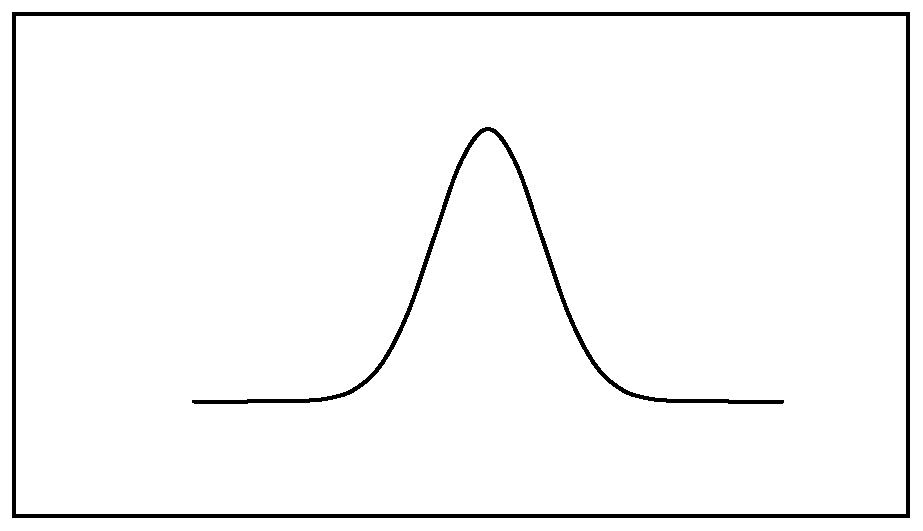

technical field [0001] The invention relates to the field of laser technology, in particular to a laser processing device and method for removing thin film materials. Background technique [0002] With the development of laser technology and the deepening of laser research, the application fields and application methods of laser processing have also expanded, and the requirements are also extremely high. The general laser output is the fundamental mode, and the cross-sectional light intensity in the beam propagation direction is Gaussian distribution, such as figure 1 As shown, it shows a distribution that is strong in the middle and gradually weakens around the periphery. Therefore, when the laser with Gaussian irradiance distribution is used to selectively remove thin film materials on the surface of heat-sensitive substrates, due to the difference in light intensity between the middle region and the edge region, or the middle region reaches a suitable energy density in a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K26/06B23K26/064B23K26/36B23K26/402

CPCB23K26/0648B23K26/36B23K26/402B23K26/064

Inventor 王雪辉王建刚温彬王玉莹白娟娟

Owner WUHAN HGLASER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com