Patents

Literature

47results about How to "Flat bottom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

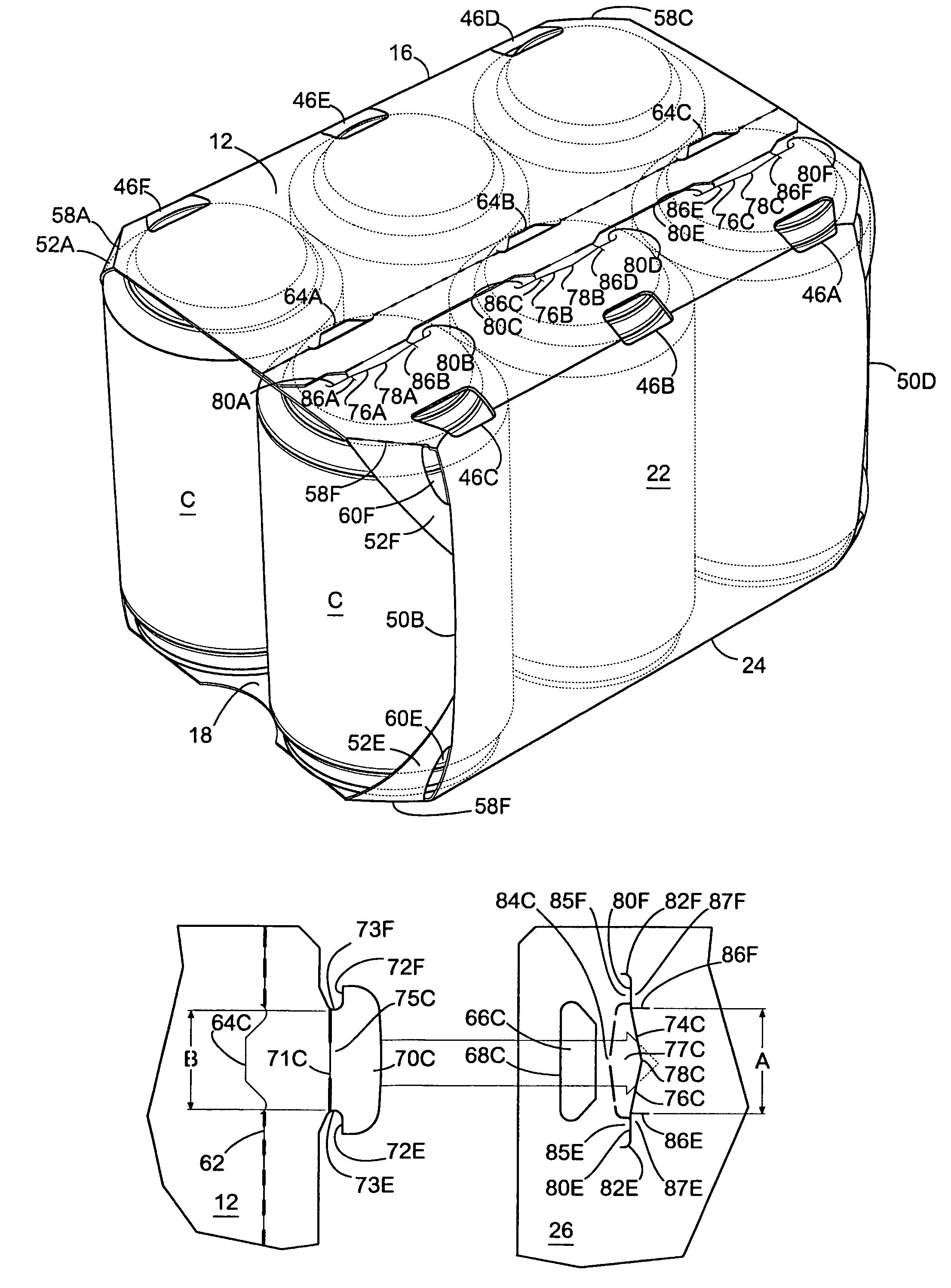

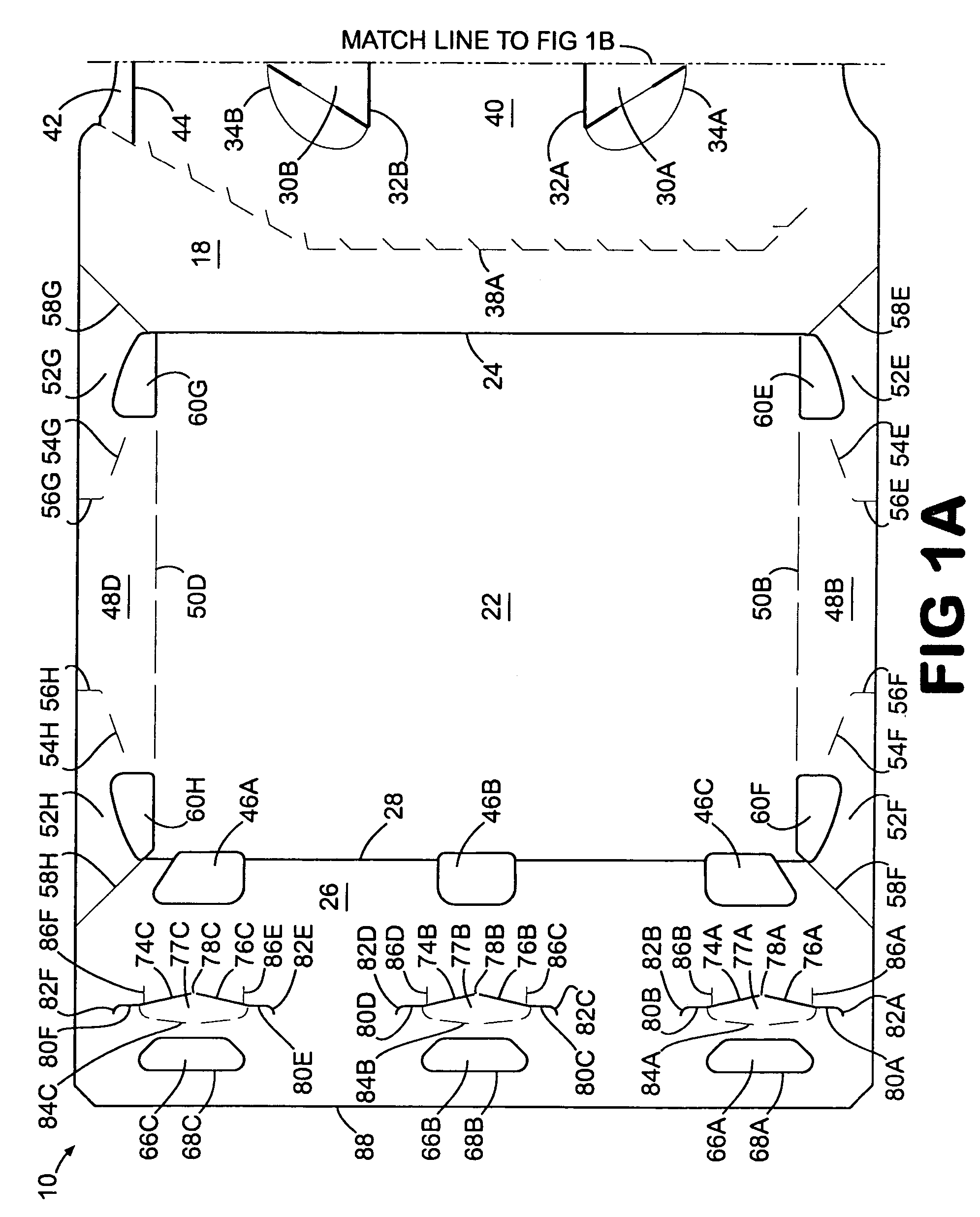

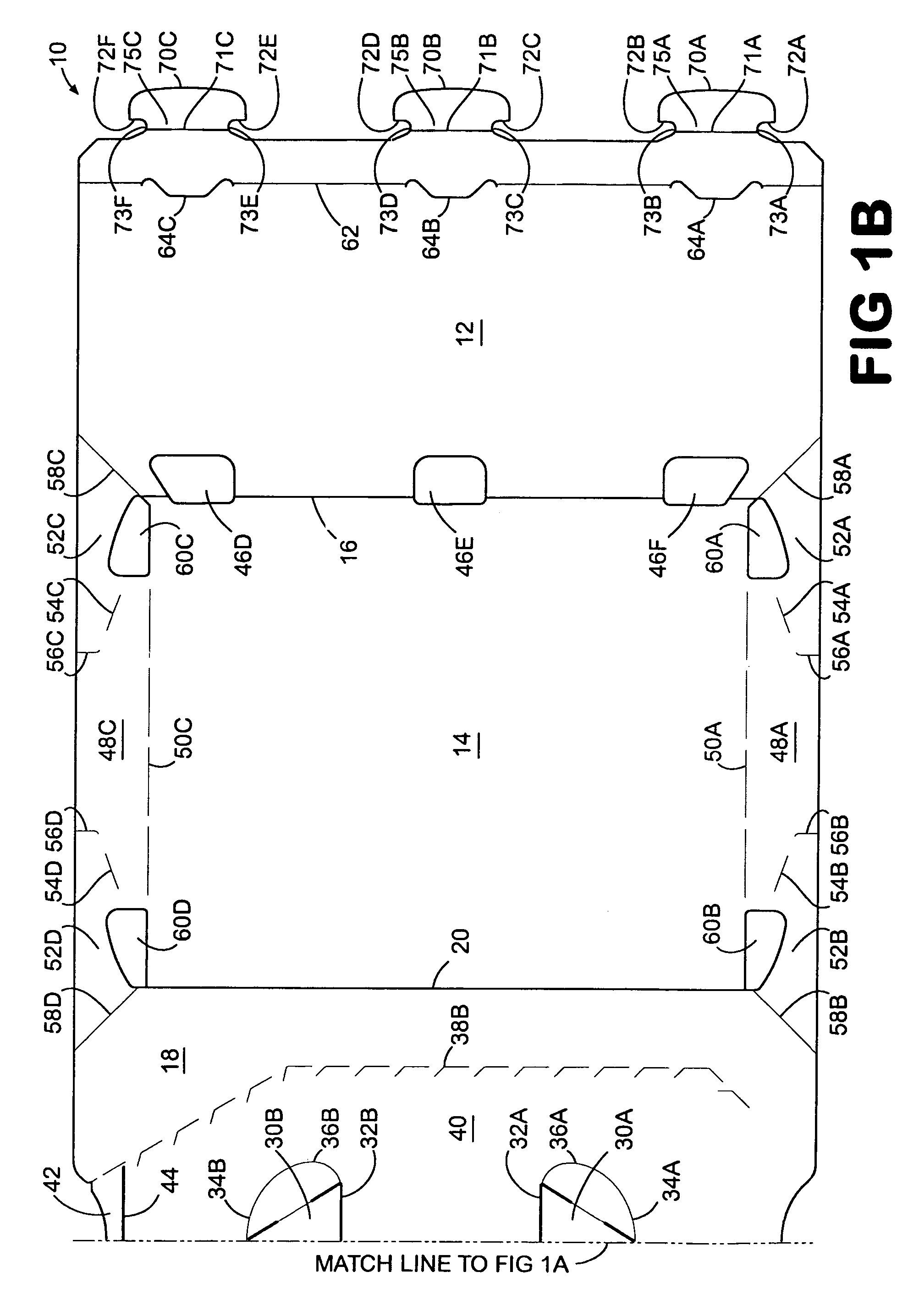

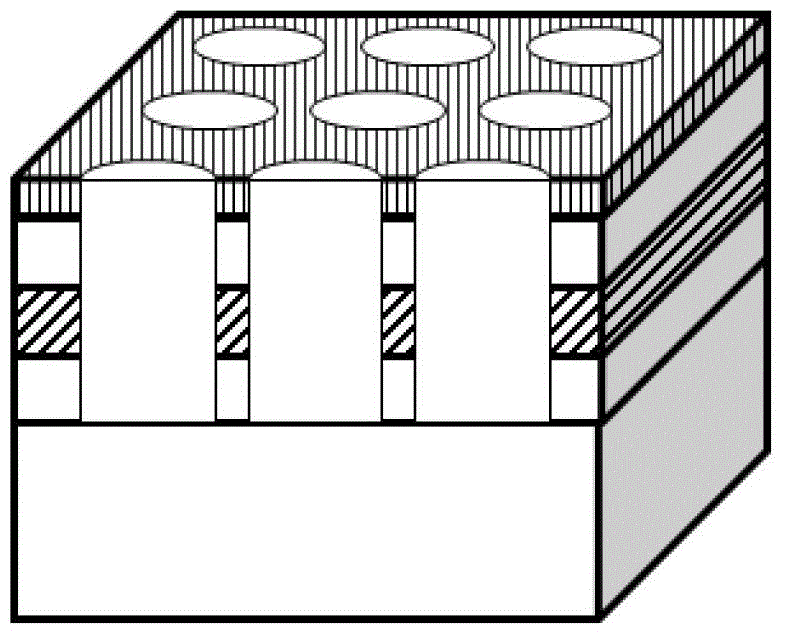

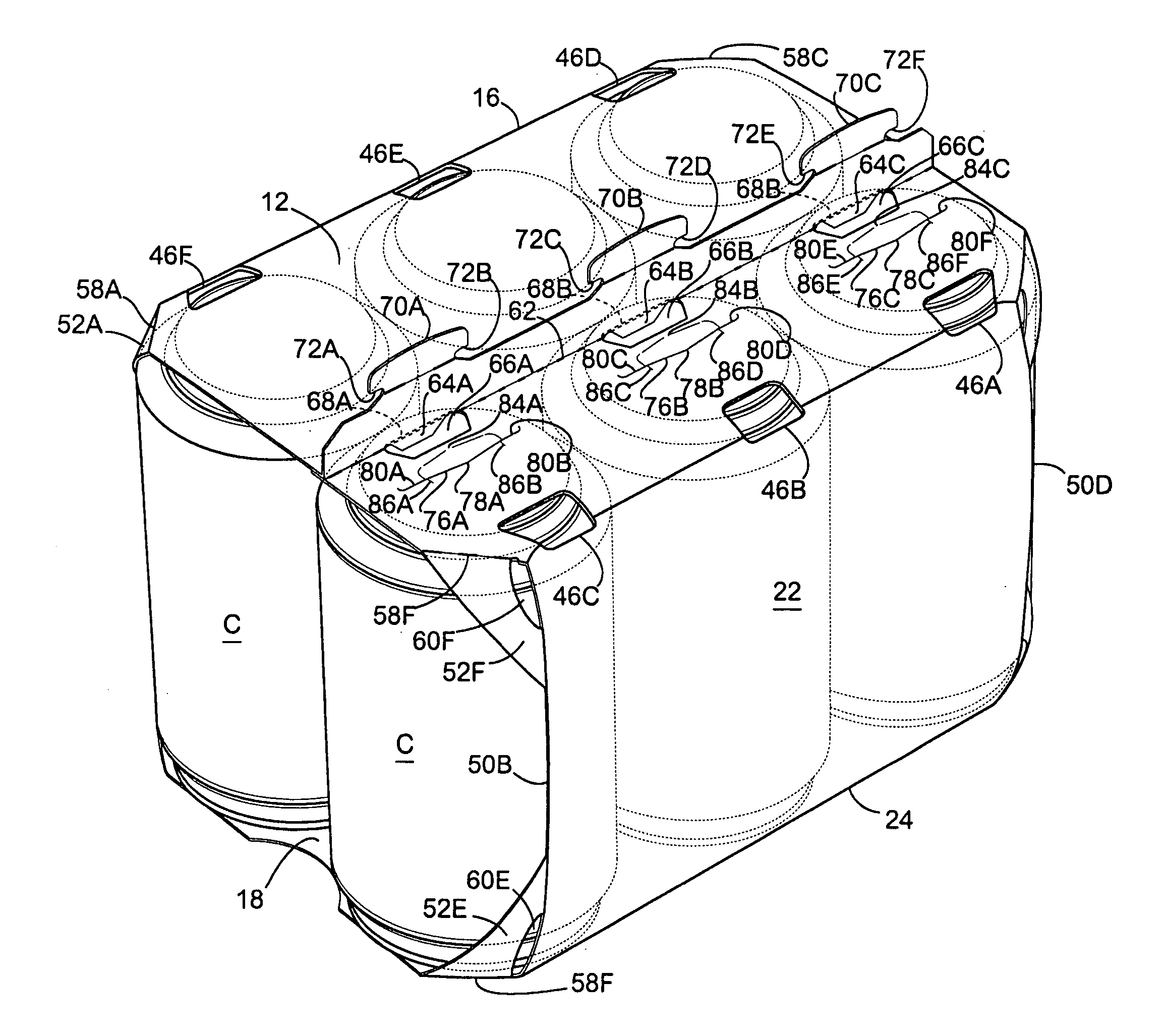

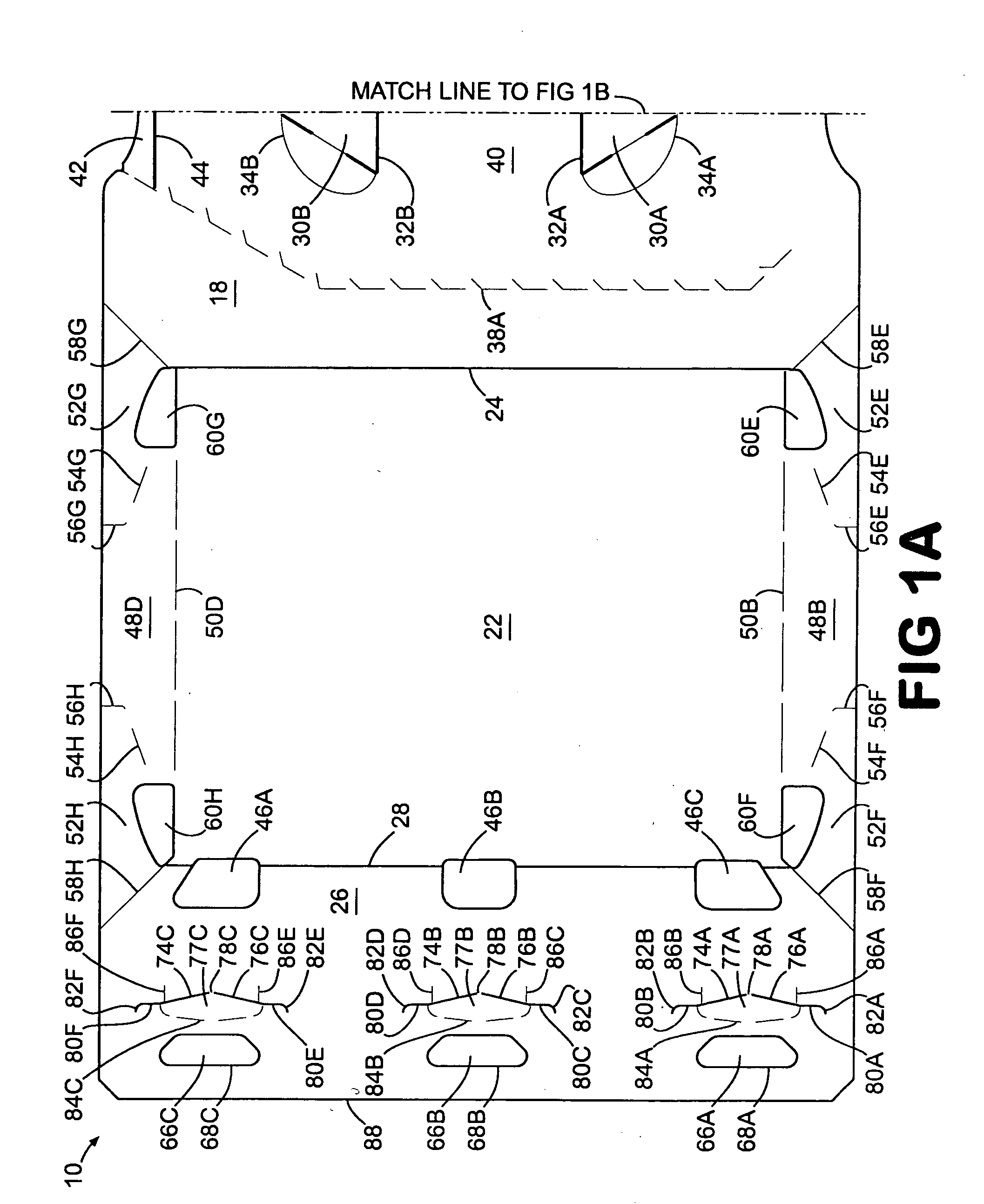

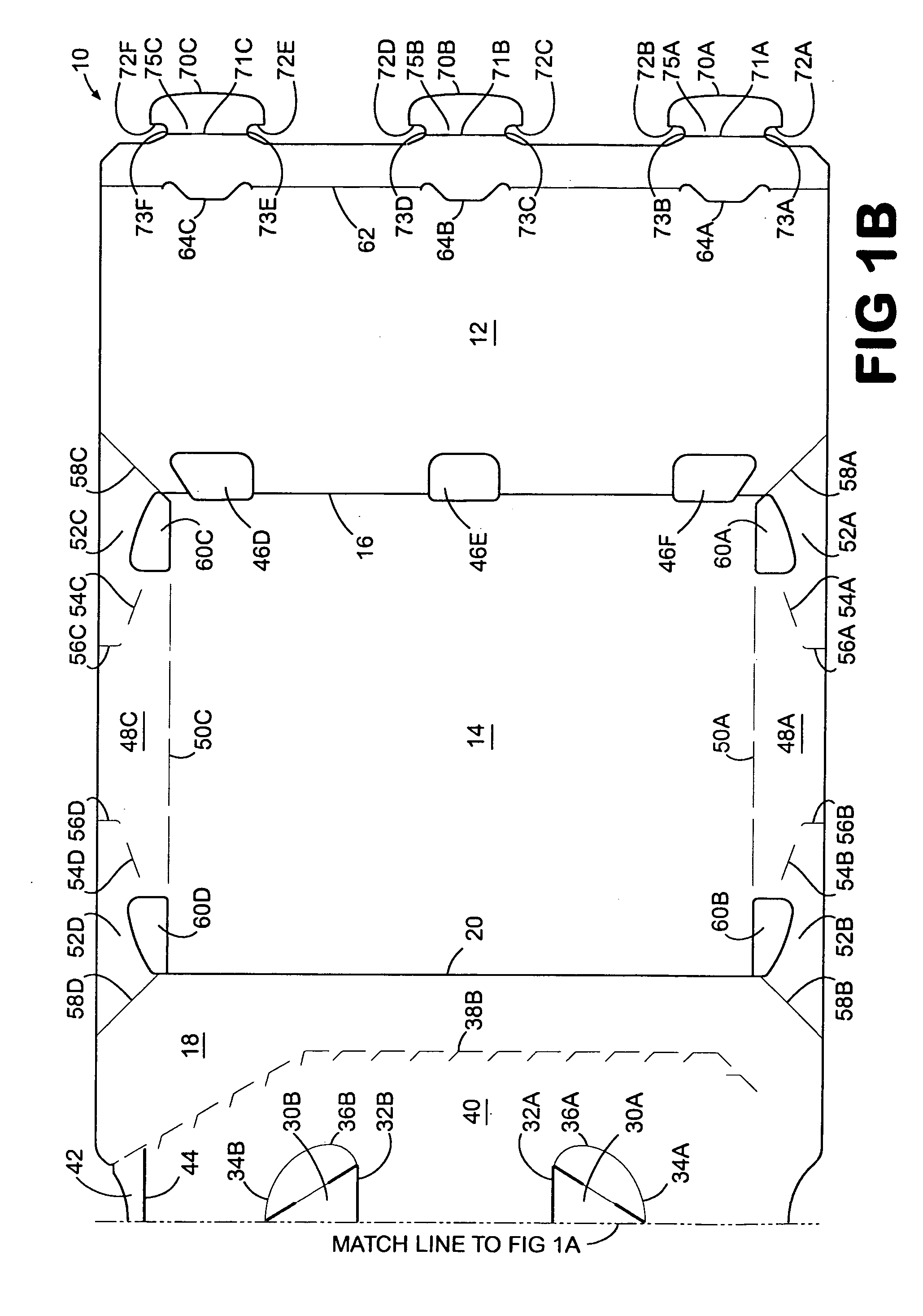

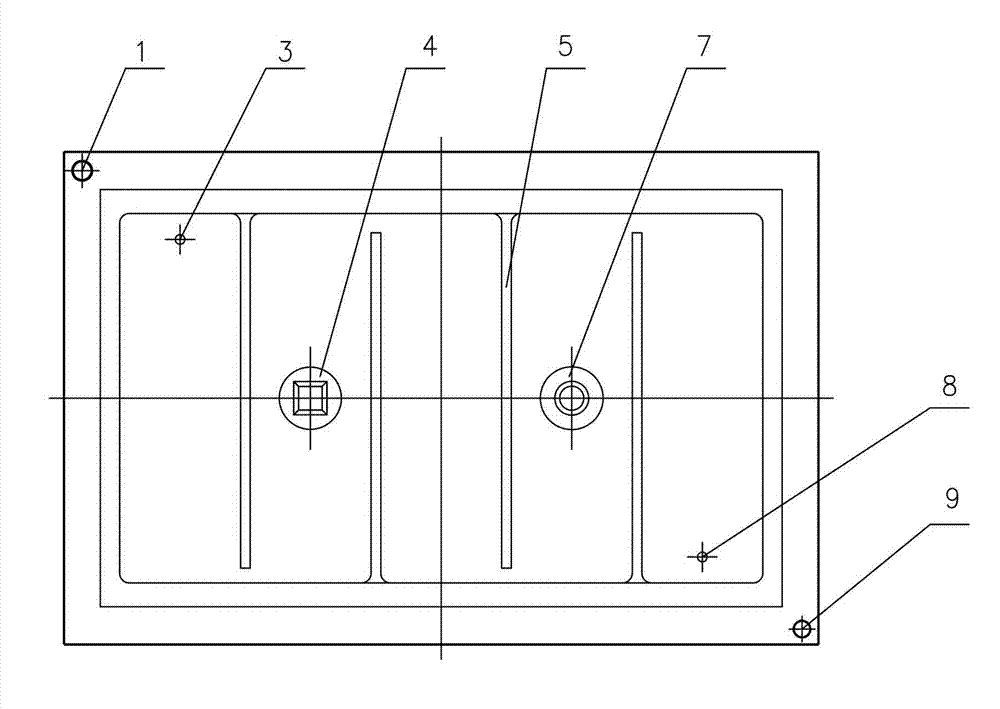

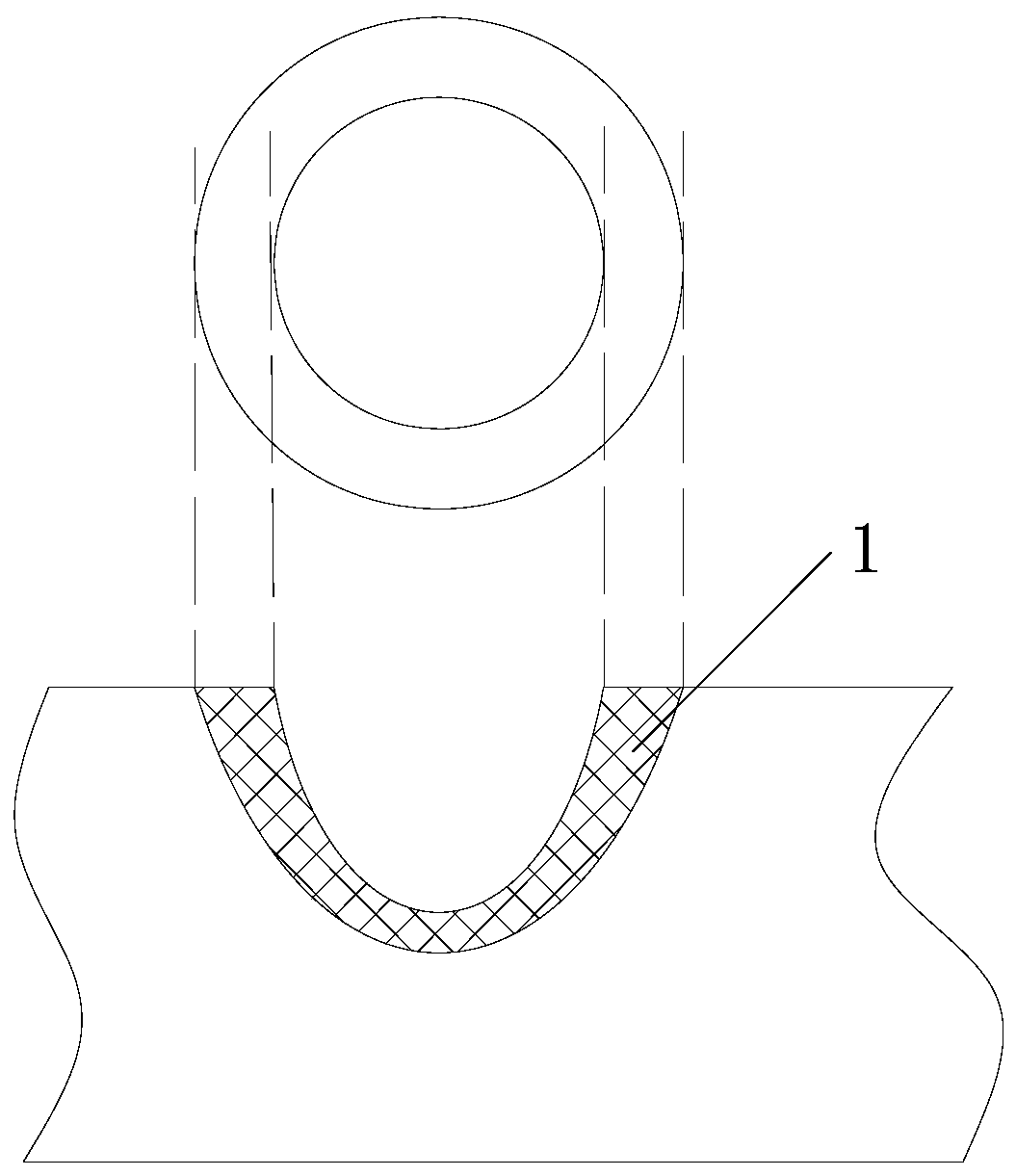

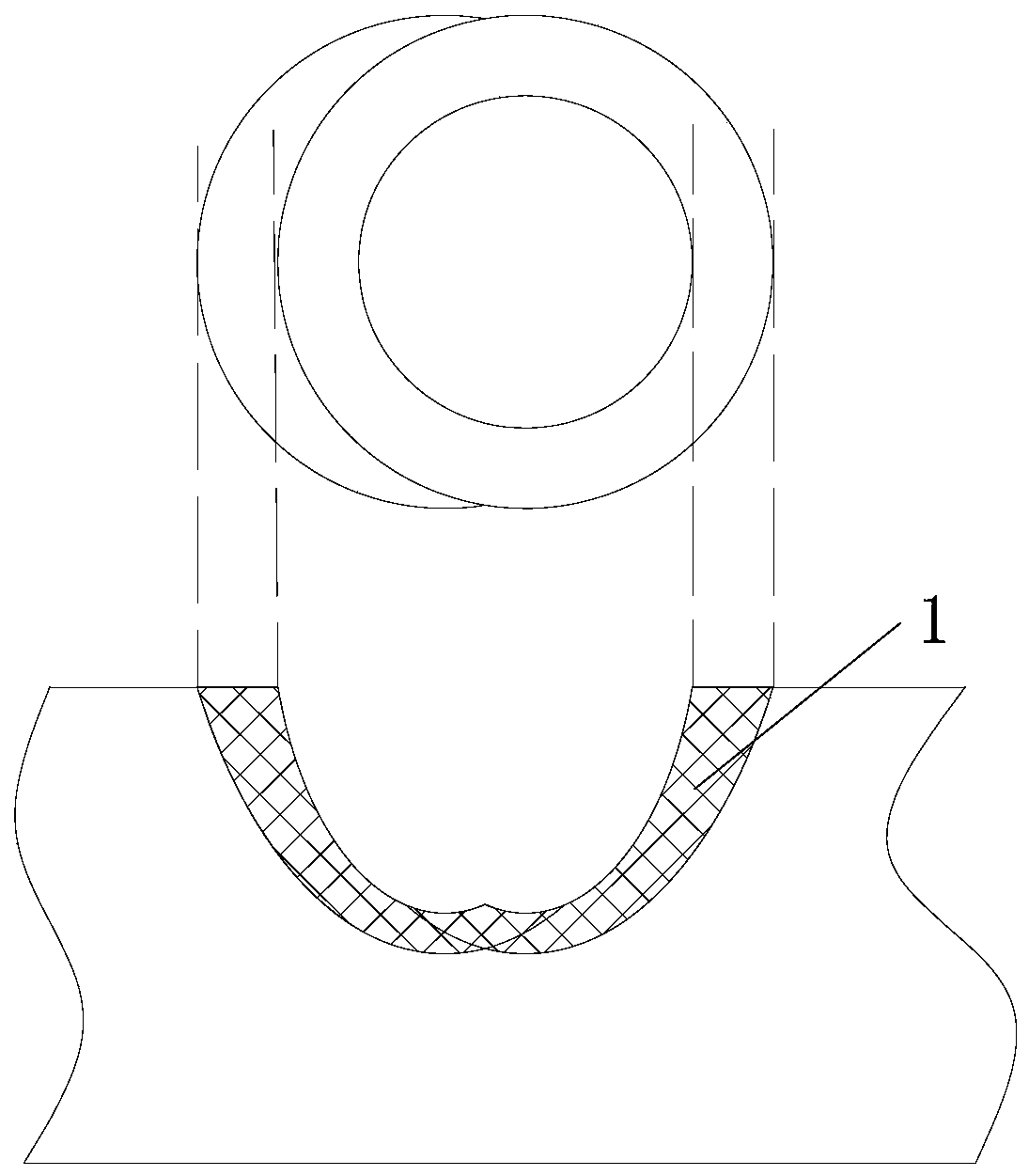

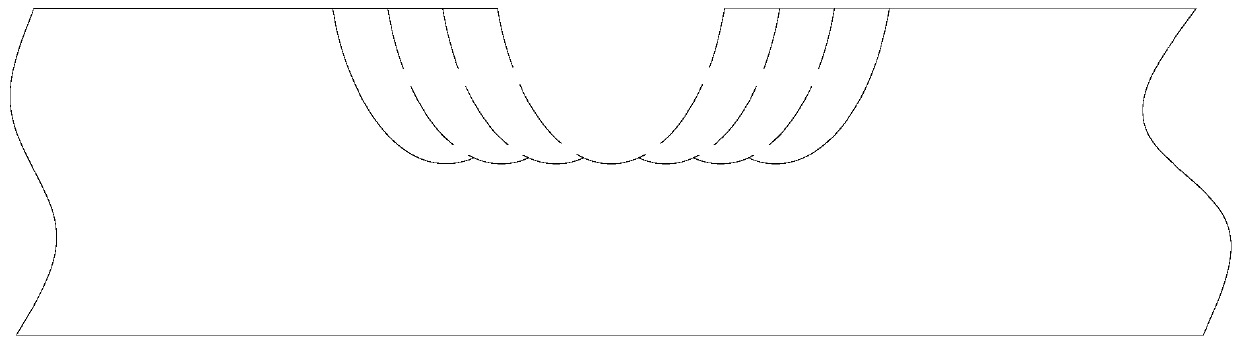

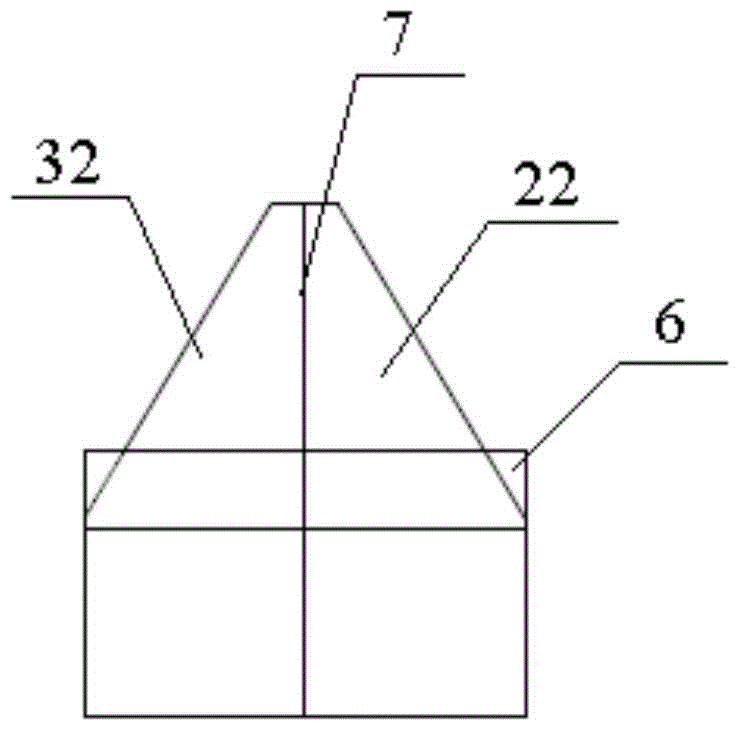

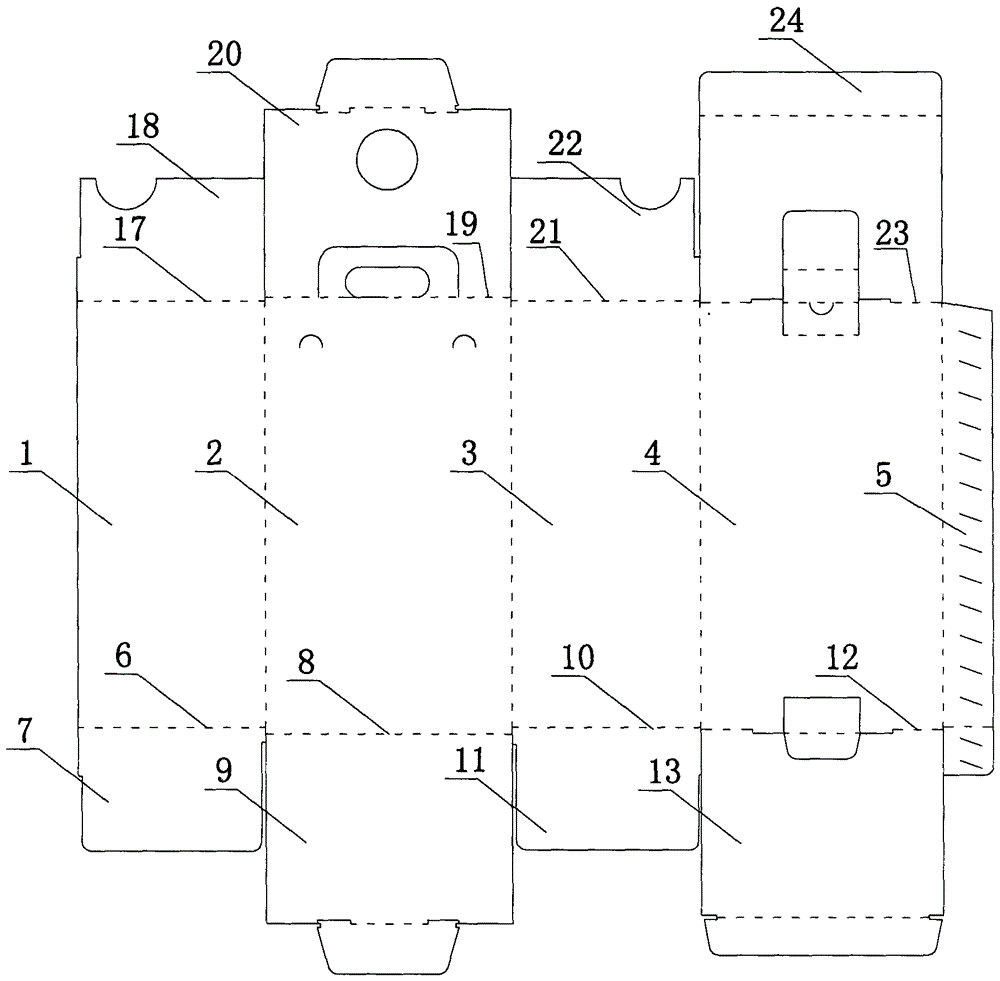

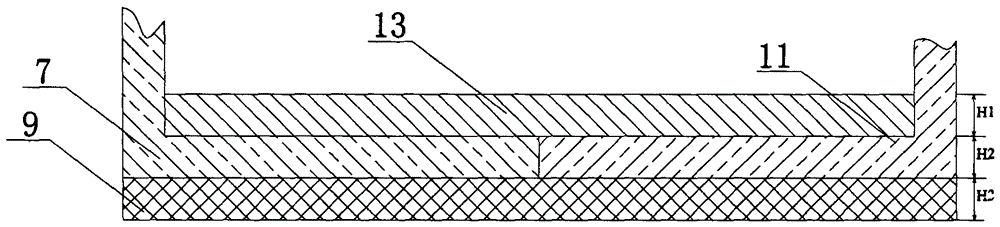

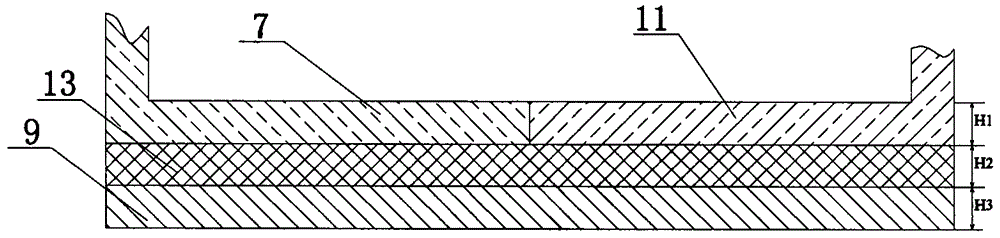

Flat primary and secondary locking system

InactiveUS7175020B2Flat bottomContainer/bottle contructionMetal working apparatusEngineeringMechanical engineering

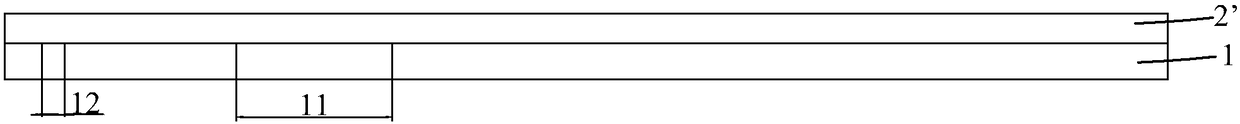

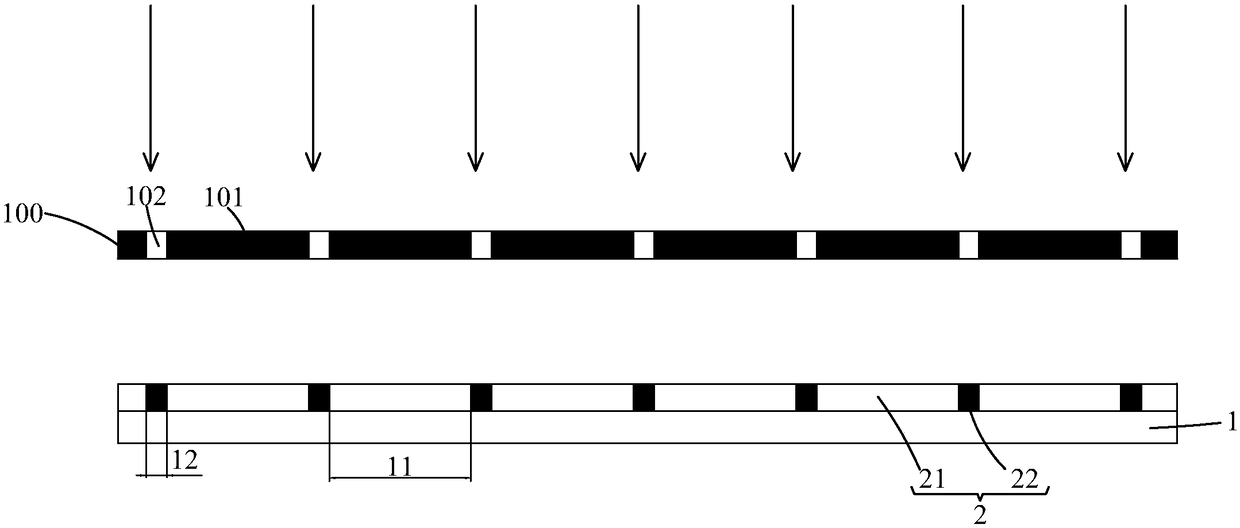

A new type of secondary locking system for article carriers consisting of at least one secondary male lock with two shoulders that is attached by a neck to the edge of a outer flap on the carrier for use with a primary locking system. An inner flap has a secondary female opening for each secondary male lock. The secondary female opening is formed by a secondary cut line and fold line with the center of the fold line projecting towards the edge of the flap while of the center of the secondary cut line projects away from the edge of the flap to guide the secondary male lock into a flat position against the inside of the inner flap. The shoulders on the secondary male lock are engaged against locking ledges along the extensions of the secondary cut line. A pair of slits may be formed at the end of the fold lines that project inwardly to allow the secondary male lock to slide into a flat position. This locking system is especially useful in wrapping containers that have a flat bottom that would interfere with conventional locking systems.

Owner:GRAPHIC PACKAGING INT

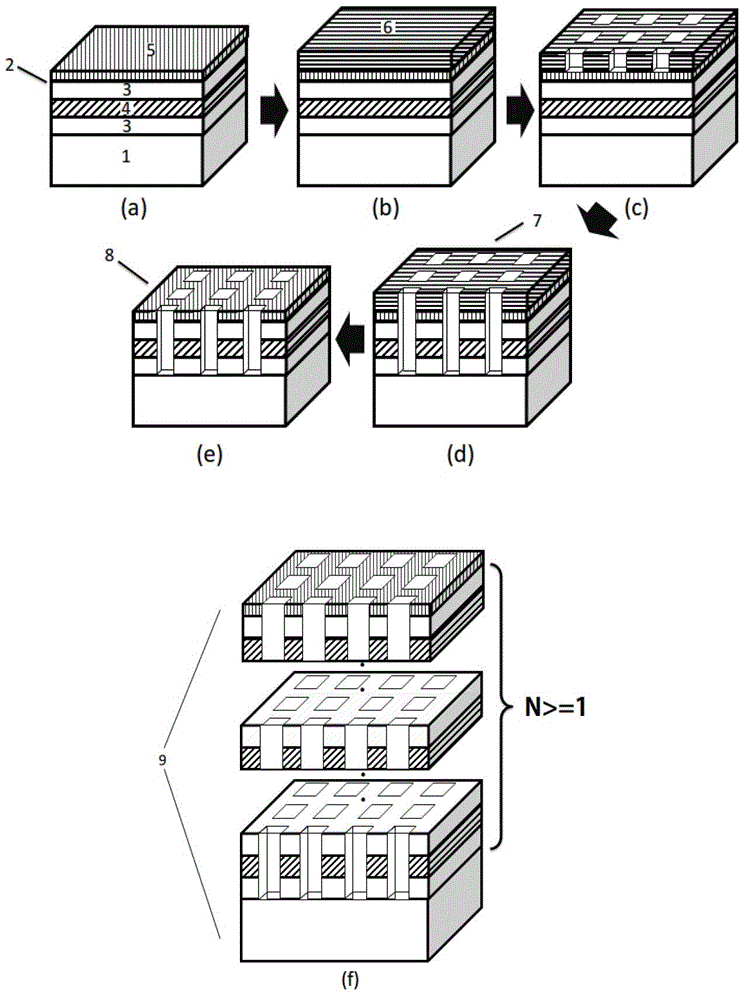

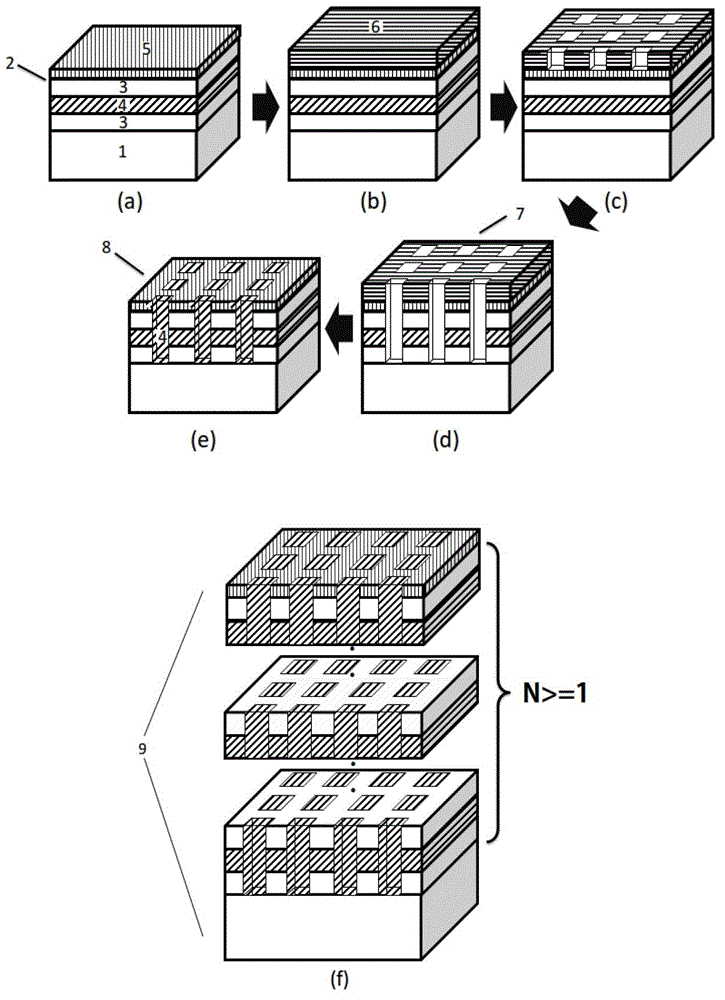

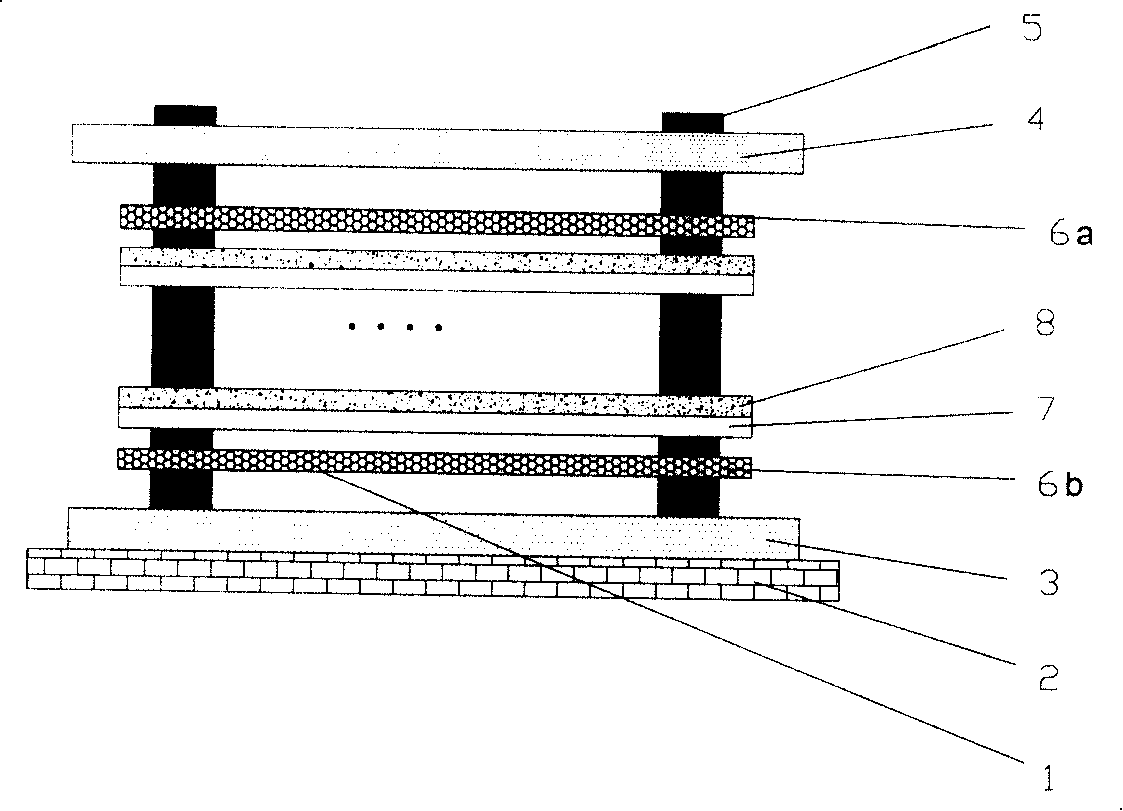

Tunable left-handed metamaterial based on phase-change material

The invention provides a tunable left-handed metamaterial based on a phase-change material. The phase-change material is introduced into the left-handed metamaterial based on a multi-layer structure, so that a working band with a negative refractive index of the left-handed metamaterial is enabled to have tunability, and the technical problem that the working frequency range of the left-handed metamaterial is narrow is solved. By the characteristic that the dielectric coefficient of the phase-change material is changed along with the change of an external electric field or temperature, the tunable function of the working frequency of the left-handed metamaterial is realized, and the maximum tuning amplitude can reach 43%.

Owner:DALIAN UNIV OF TECH

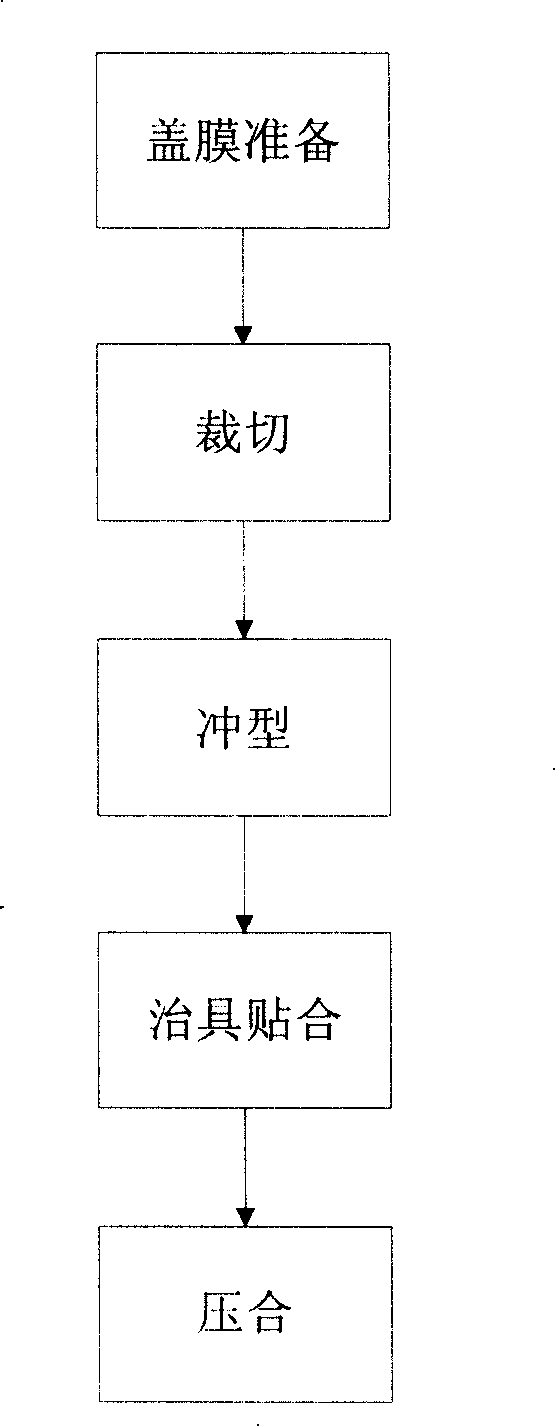

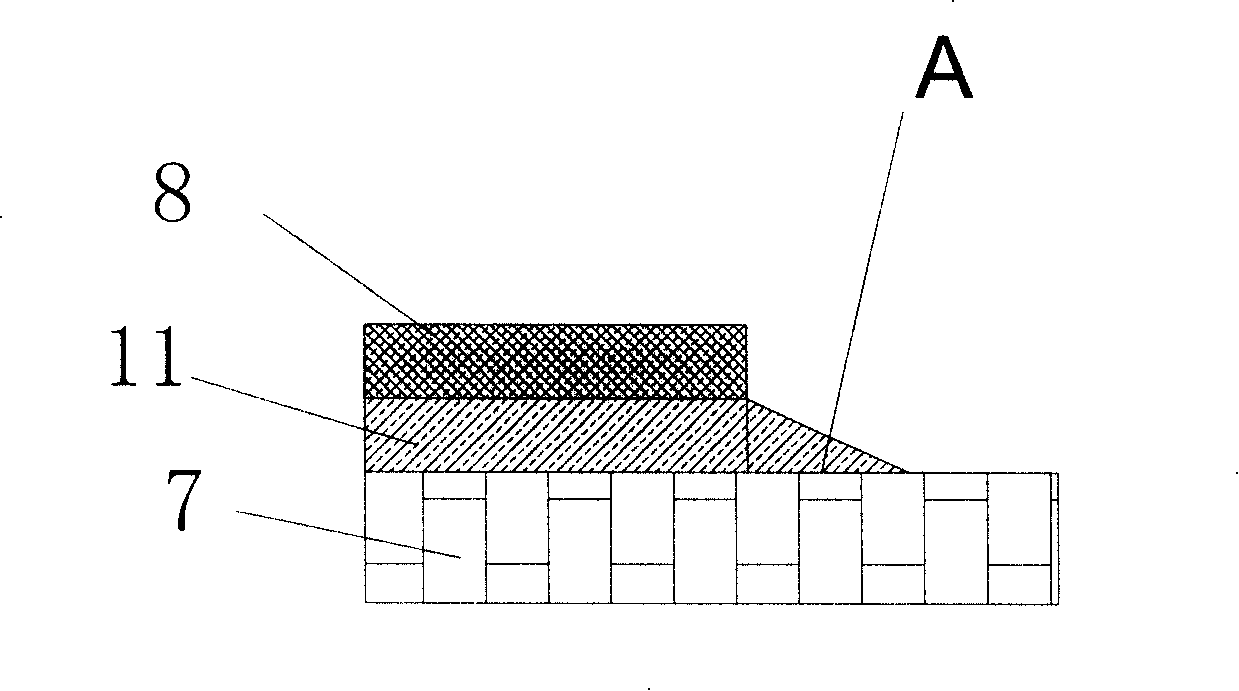

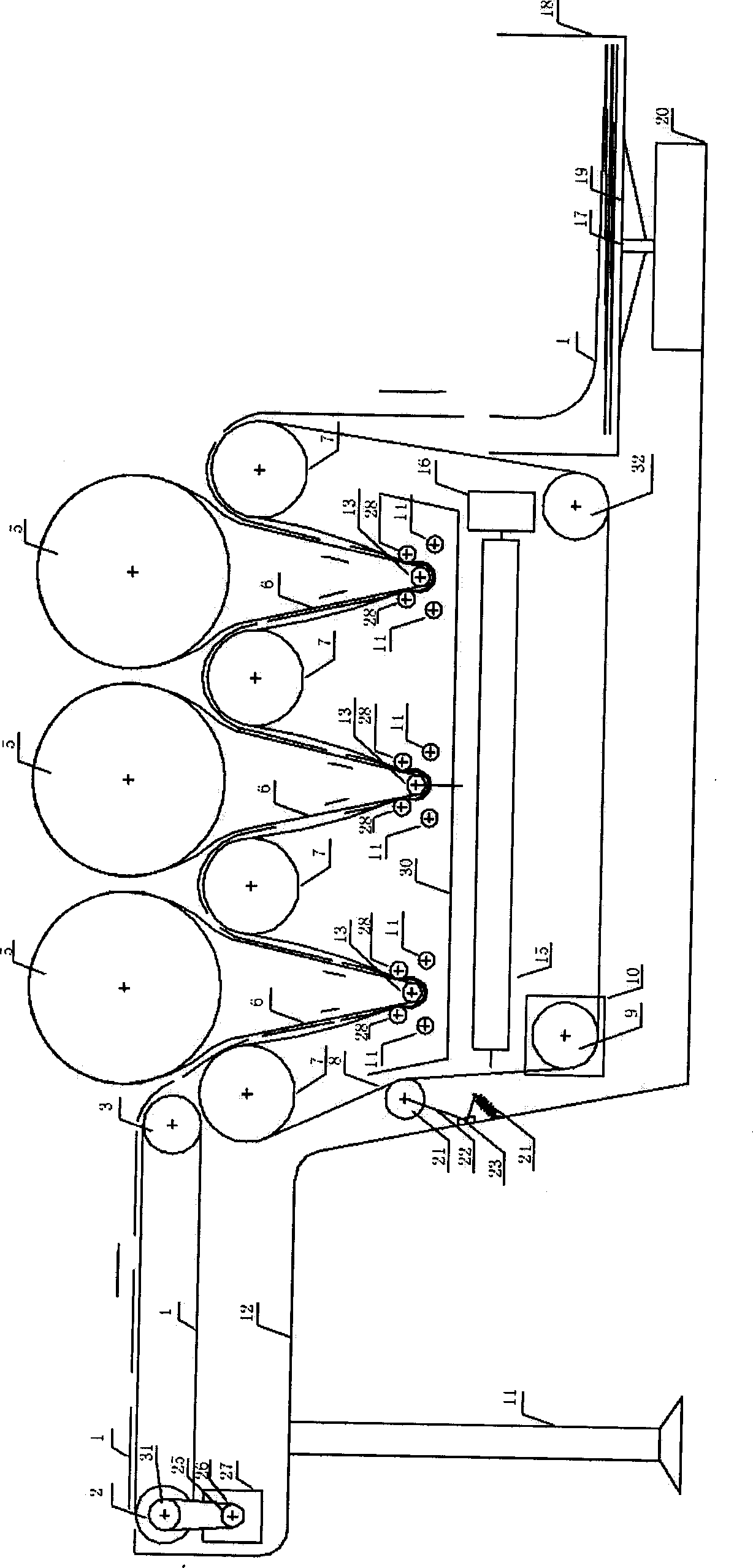

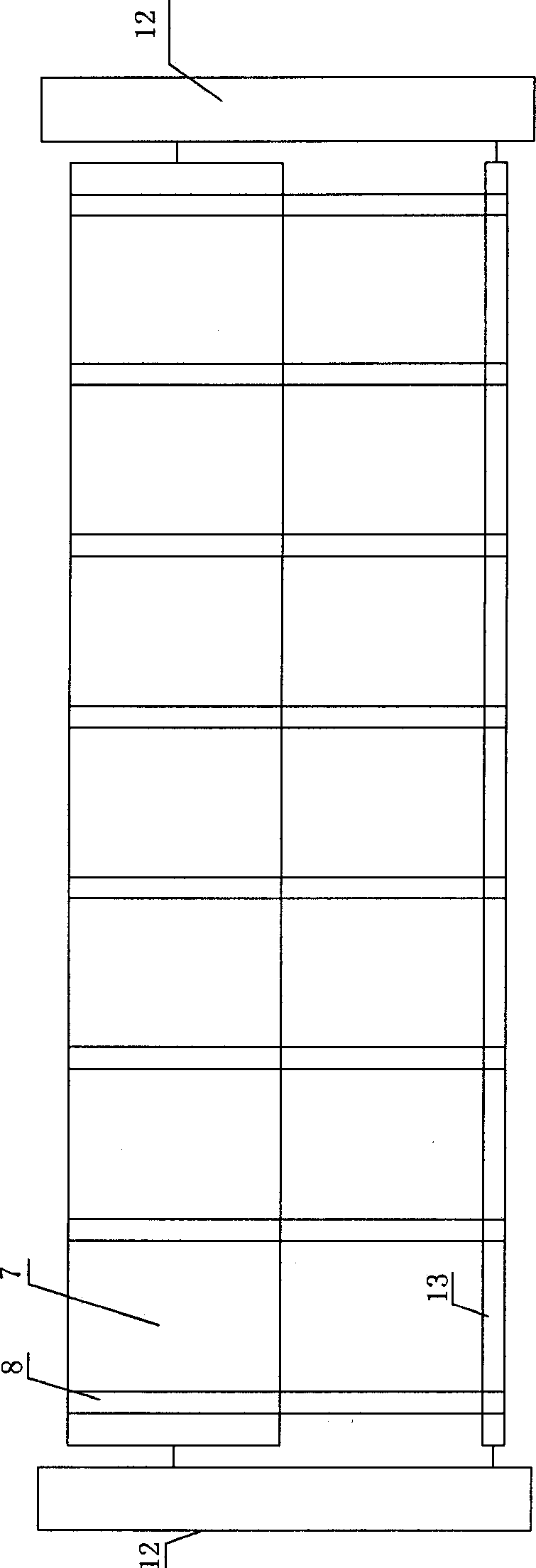

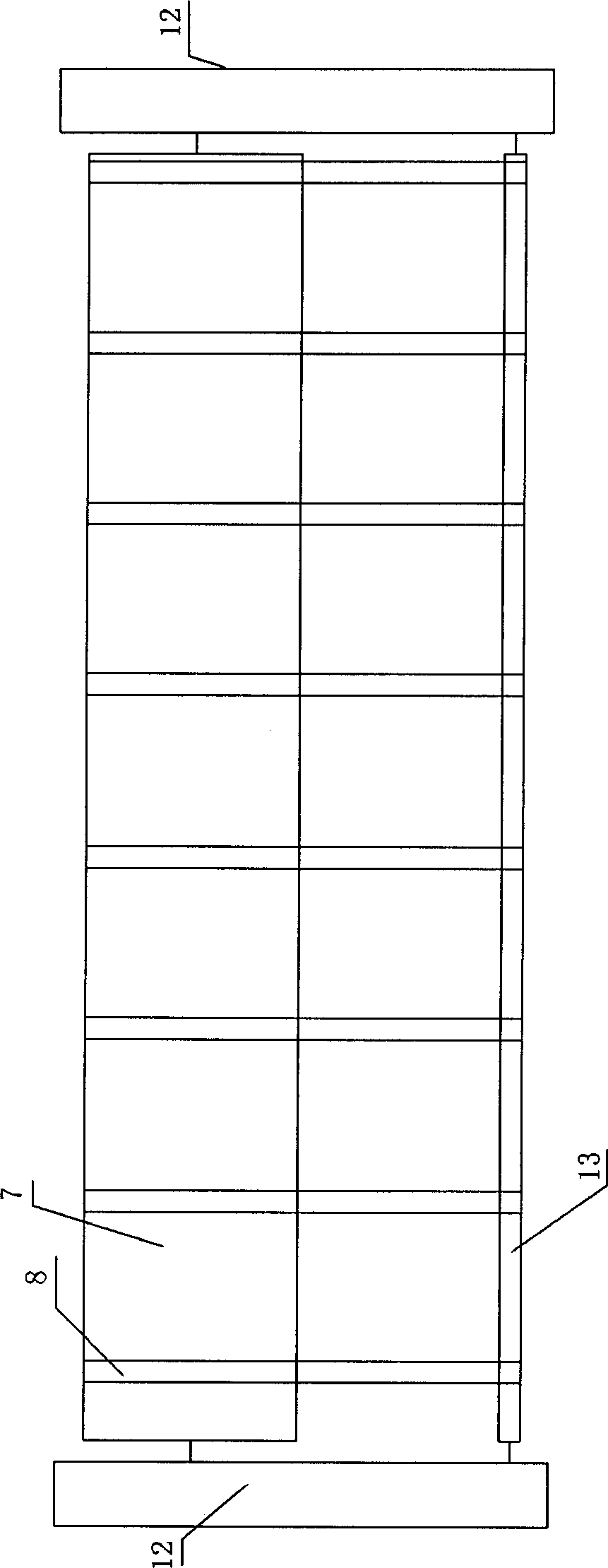

Joint tool and method for flexible printed circuit board

The method includes steps in sequence: in fixture jointing step, multilaminar copper foils with cover layers to be integrated closely and corresponding cover layers are lined up and piled together through pins of the fixture, and pins are pulled out after well piled; in baking step, putting the fixture, multilaminar copper foils and cover layers in the fixture into heater unit to be baked; in pressfitting step, placing baked copper foils and cover layers into hot-press to be pressed. The fixture includes pins, supporting board in use for supporting product, and top cover plate in use for cooperating with supporting board to clamp product. There are location holes, which are corresponding to the mating holes on product, on the supporting board and on the top cover plate. The pins can be inserted into the location holes, and pulled out from the location holes. Advantages are: raised jointing precision and efficiency, and controlling quantity of overflowed glue effectively.

Owner:BYD CO LTD

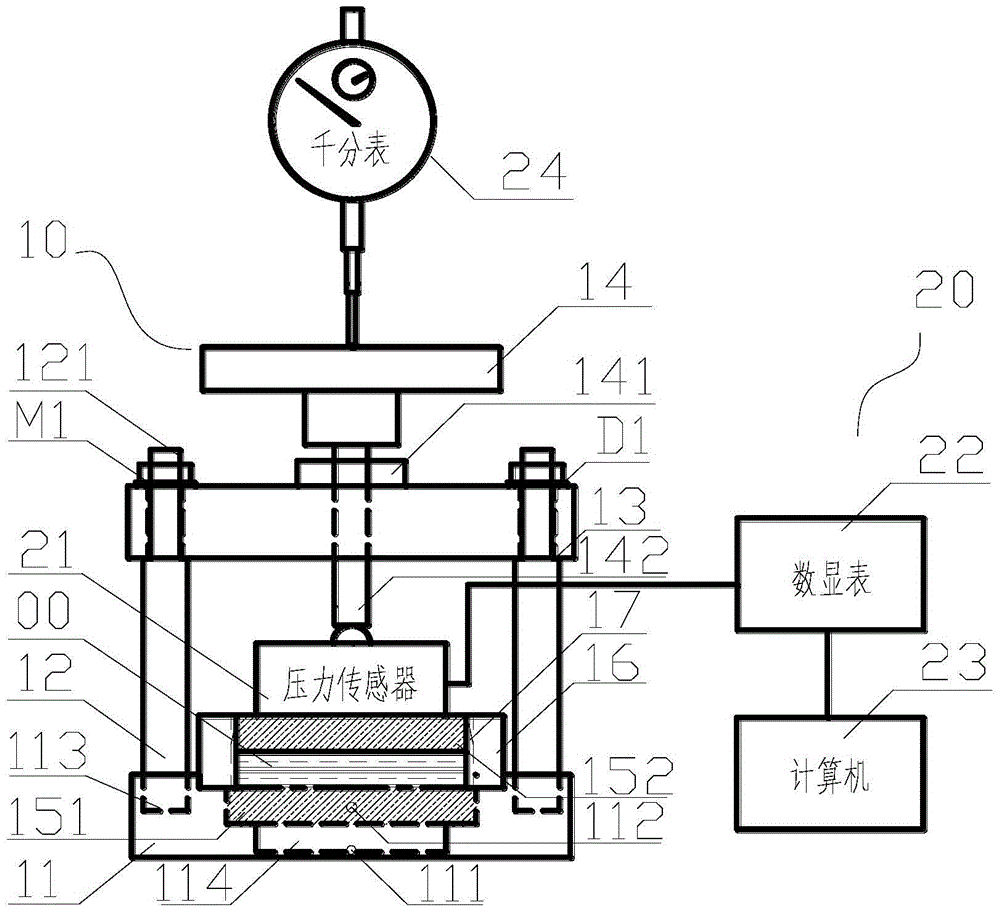

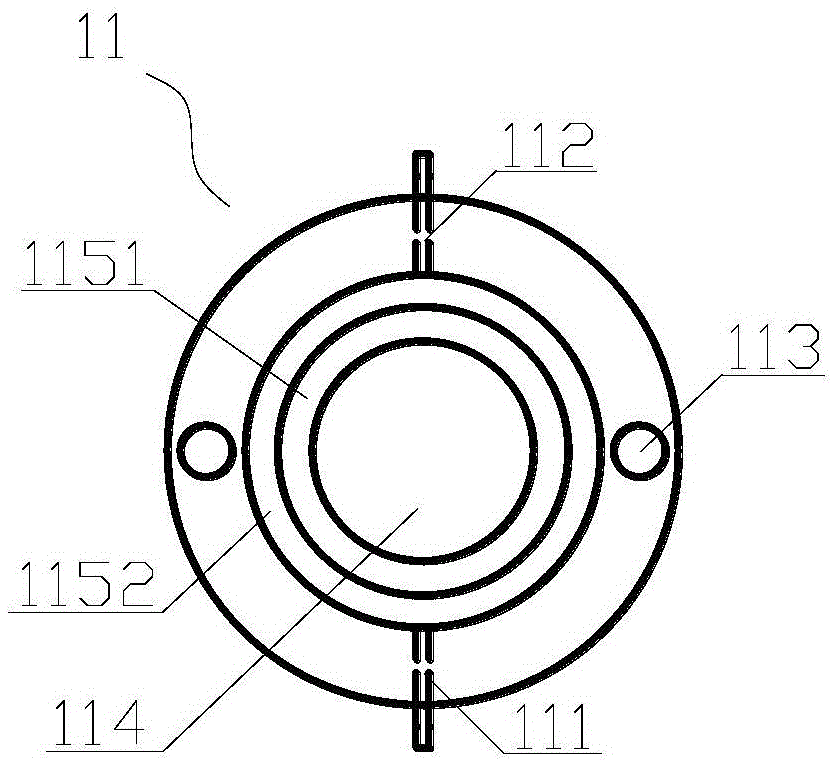

Dilatometer for measuring expansive force by constant volume method

ActiveCN105571758AHigh precisionLarge rangeMaterial thermal coefficient of expansionApparatus for force/torque/work measurementData displayTemperature control

The invention discloses a dilatometer for measuring the expansive force by a constant volume method, and relates to geotechnical test apparatuses. According to the structure of the dilatometer, a fixing system is connected with a measuring system, the fixing system comprises a fixing base, circular steel columns, a square crossbeam with a hole, a knob, a lower permeable stone, an upper permeable stone, a cutting ring fixing cylinder, a cutting ring, a nut, and a gasket, and the measuring system comprises a pressure sensor, a data display meter, a computer, and a dial gauge. The dilatometer is advantageous in that 1) constant volume: the volume of a soil sample in the whole test process is invariable; 2) high precision: the pressure sensor is advantaged by high precision and large measuring range, and the precision of test results is improved; 3) wide range: the dilatometer is applicable to measurement of the change of the expansive force in the soaking process of the soil sample and with the change of the environmental humidity condition and the test of the expansive force under the temperature control; and 4) the structure is good, the installation is convenient, the operation is simple, and the data display is visual.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Sugar-free cream egg roll and method for producing the same

InactiveCN101461398AEasy to eatExtended shelf lifeBakery productsFood preparationBiotechnologyGluten

The invention relates to a sugar-free butter roll, characterized by comprising the materials with the weight percent: egg 150-900 parts, sugar-free modifier 50-200 parts, low gluten powder 200-800 parts, baking powder 2-10 parts, milk sachet 2-10 parts, cake oil 10-100 parts, milk essence 2-10 parts, liquid edible oil 20-100 parts, butter 500-2000 parts. The inventive butter roll is fragrant and soft in mouth feel, particularly the sugar-free modifier is used as main materials, blood glucose value is not increased after being eaten, more suitable for the diabetics.

Owner:天津金世制药有限公司

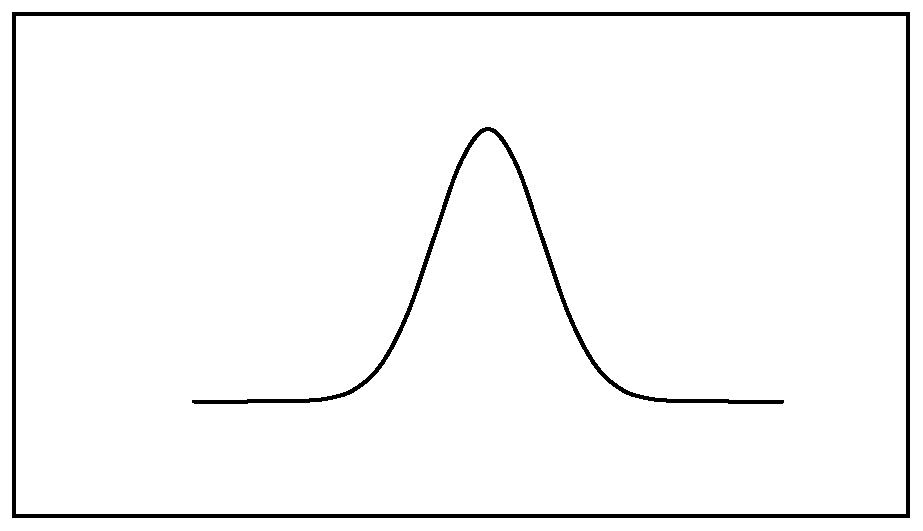

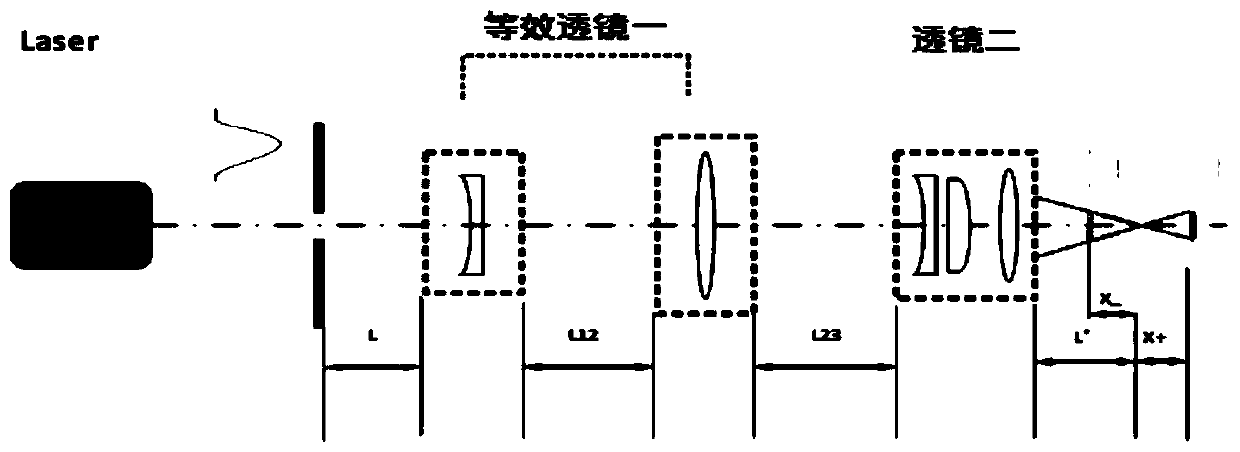

Laser processing device and method for film material removal

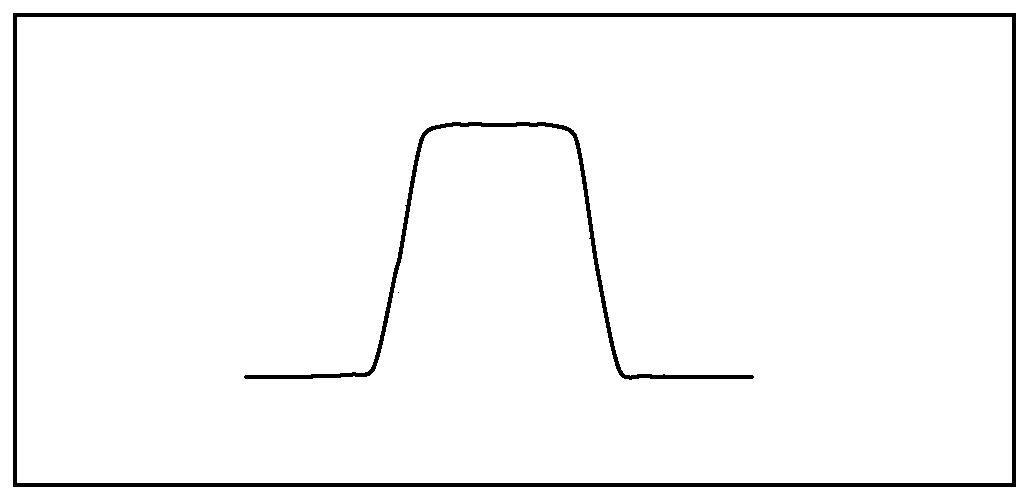

ActiveCN110125536ASolve the melting phenomenonEasy to adjustLaser beam welding apparatusLaser processingDiffraction order

The invention discloses a laser processing device for film material removal. A laser, a small aperture diaphragm and a lens system are arranged in sequence along a laser light propagation path. The lens system comprises a first equivalent lens and a second lens. Gaussian beam emitted by the laser passes through the small aperture diaphragm and the lens system and then forms an image with sharp edges, meanwhile, after the Gaussian beam passes through the small aperture diaphragm, diffraction orders with unobvious edges occur due to the diffraction phenomenon, and light spots of Gaussian beam are imaged into sharp-edged and flat-topped light after different diffraction orders are gathered and superimposed through the lens system. The invention further discloses a laser processing method forfilm material removal. Through the device and method disclosed by the invention, the problems that a flat-topped light spot shaping technology is complicated, and application to film materials is difficult are solved.

Owner:WUHAN HGLASER ENG CO LTD

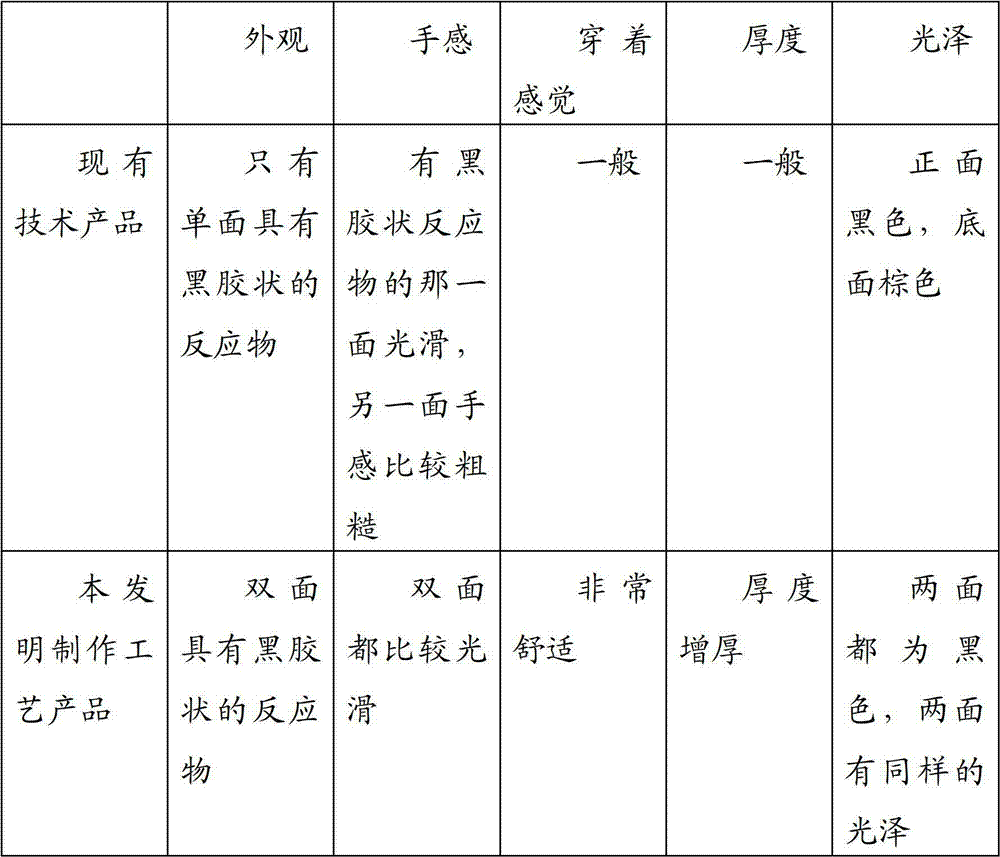

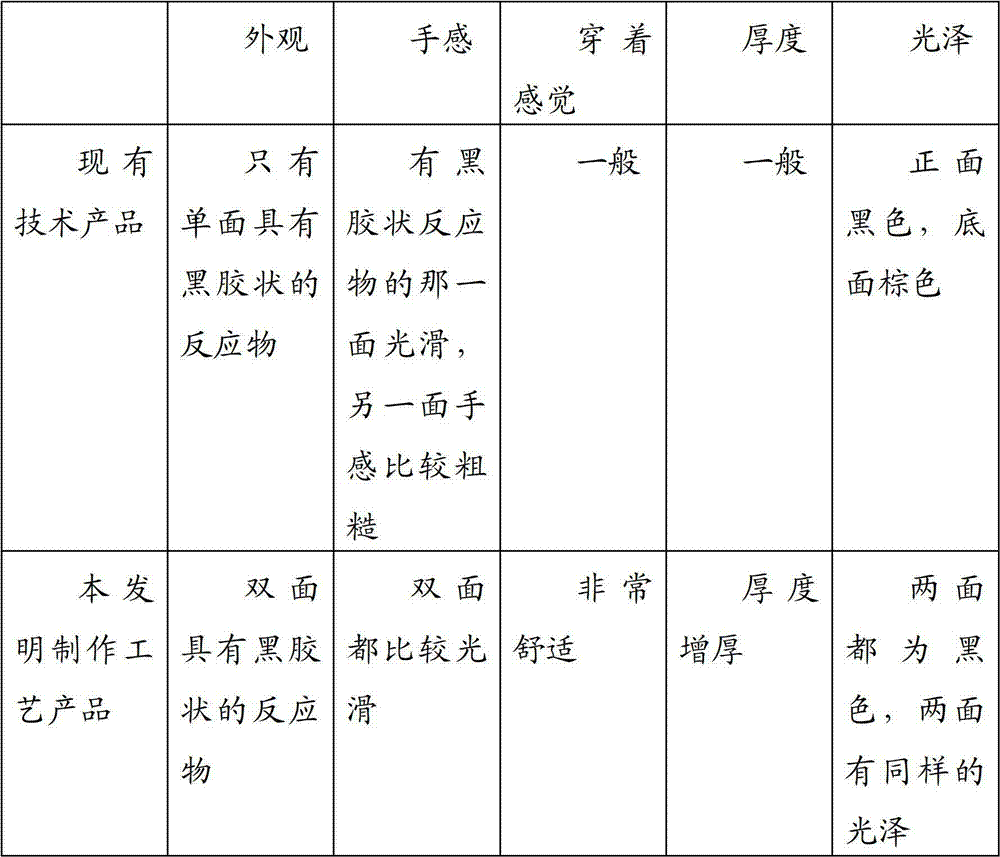

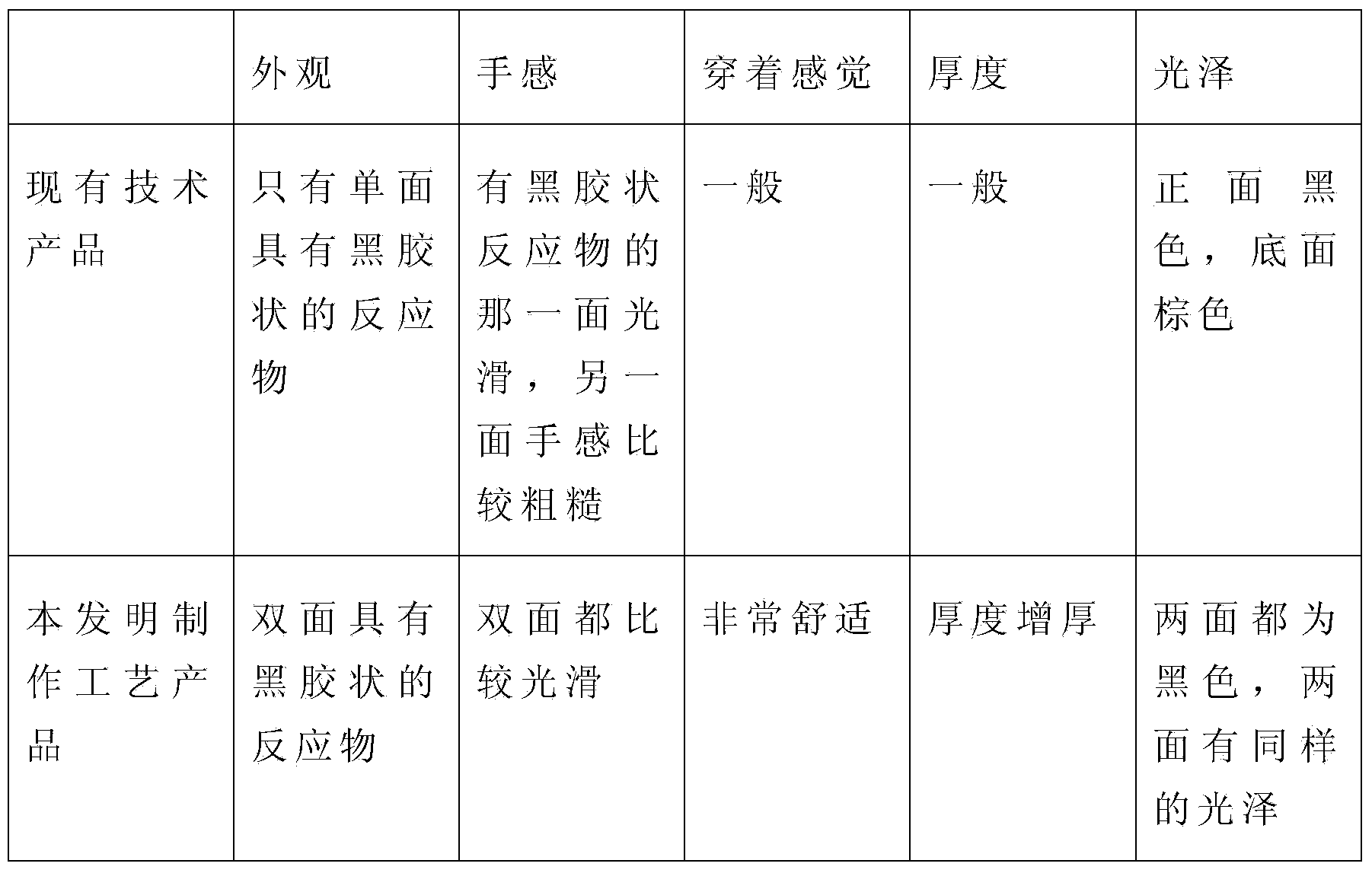

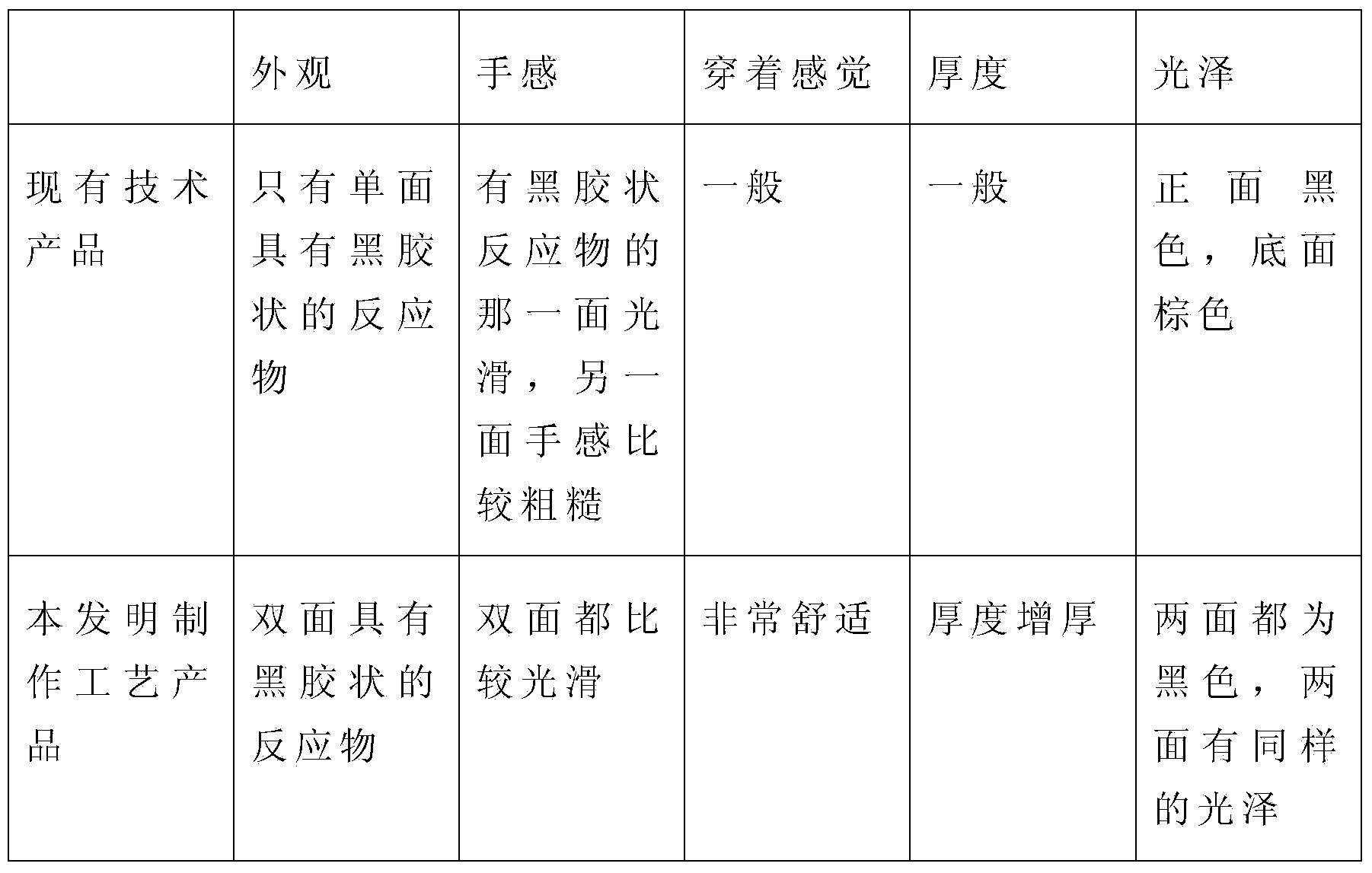

Process for producing double-sided gambiered Guangdong silk

ActiveCN102733182ASame inner and outer fabricConsistent appearanceDyeing processAnimal fibresState of artChemistry

The invention discloses a process for producing double-sided gambiered Guangdong silk, which comprises the following steps: (1) preparing greige; (2) preparing Chinese pennisetum water; (3) stamping the greige (soaking the greige in the Chinese pennisetum water for the first time); (4) sprinkling the Chinese pennisetum water on the greige; (5) soaking the greige in the Chinese pennisetum water; (6) soaking and drying the greige in the sun; (7) boiling the greige; (9) removing mud; (10) soaking the greige in the Chinese pennisetum water which obtained by filtering for the second time and drying the greige in the sun; (11) soaking and drying the back surface of the greige in the sun; (12) spreading mud on the back surface of the greige; and (13) soaking the back surface of the greige in the Chinese pennisetum water which obtained by filtering for the second time and drying the back surface of the greige in the sun. Two surfaces of the product produced by adopting the process are provided with black jellied ferrous tannate, the front surface and the back surface have the same qualities, internal and external cloth qualities are same, and appearances of two surfaces are consistent. Compared with the prior art, the product produced by adopting the process has a smooth back surface so that the product is conformable to wear. The product is thick and has good handfeel. In addition, two surfaces of the product have shiny gloss and the characteristics of the gambiered Guangdong silk.

Owner:佛山市顺德区顺熙贸易有限公司

Salt cake and method for producing the same

InactiveCN101461400AEasy to eatExtended shelf lifeBakery productsFood preparationBiotechnologyMonosodium glutamate

The invention relates to salted cake, characterized by comprising the materials with the weight percent: 150-900 parts of eggs, 50-200 parts of sugar-free modifier, 200-800 parts of low gluten powder, 2-10 parts of baking powder, 2-10 parts of monosodium glutamate, 2-10 parts of lean ground meat, 2-10 parts of sauce, 10-100 parts of cake oil, 2-10 parts of shallot, 2-10 parts of salt. The inventive salted cake is fragrant and soft in mouth feel, particularly the sugar-free modifier is used as main materials, blood glucose value is not increased after being eaten, more suitable for the diabetics.

Owner:天津金世制药有限公司

Novel special equipment for demolding resin diamonds

The invention relates to the processing field of resin diamonds, in particular to novel special equipment for demolding resin diamonds. A feeding conveying mechanism is used for conveying a silicone mold with a resin diamond, a silicone mold deformation mechanism is used for demolding so that the resin diamond can be taken out of a mold hole of the silicone mold rapidly, demolding is operated repeatedly layer by layer, no missing is caused and the efficiency is high; and then, a resin diamond discharging mechanism is used for automatically collecting the demolded resin diamonds, the mold hole can be effectively prevented from being damaged and deformed, the bottoms of the produced flat-base resin diamond are flat and can be coated conveniently, industrial automatic operation can be carried out, the manual operation cost is greatly reduced, the molds and the products can be prevented from being damaged by humans, and the interference of outside adverse factors is reduced; besides, a silicone mold recovery mechanism is used for automatically collecting the silicone molds, therefore, the silicone mold can be utilized repeatedly and circularly; when the silicone molds are used again, residues and attached resin diamonds in the mold holes do not need to be cleaned again, the period is shortened, the production efficiency is improved and the labor cost is lowered.

Owner:HENAN INST OF SCI & TECH

Sugar-free apricot round cake and method for producing the same

InactiveCN101461397AEasy to eatExtended shelf lifeBakery productsFood preparationBiotechnologyGluten

The invention relates to a sugar-free almond cake, characterized by comprising the materials with the weight percent: egg 150-900 parts, sugar-free modifier 50-200 parts, low gluten powder 200-800 parts, baking powder 2-10 parts, milk sachet 2-10 parts, cake oil 10-100 parts, milk essence 2-10 parts, liquid edible oil 20-100 parts. The inventive sugar-free almond cake is fragrant and soft in mouth feel, particularly the sugar-free modifier is used as main meterials, blood glucose value is not increased after being eaten, more suitable for the diabetics.

Owner:天津金世制药有限公司

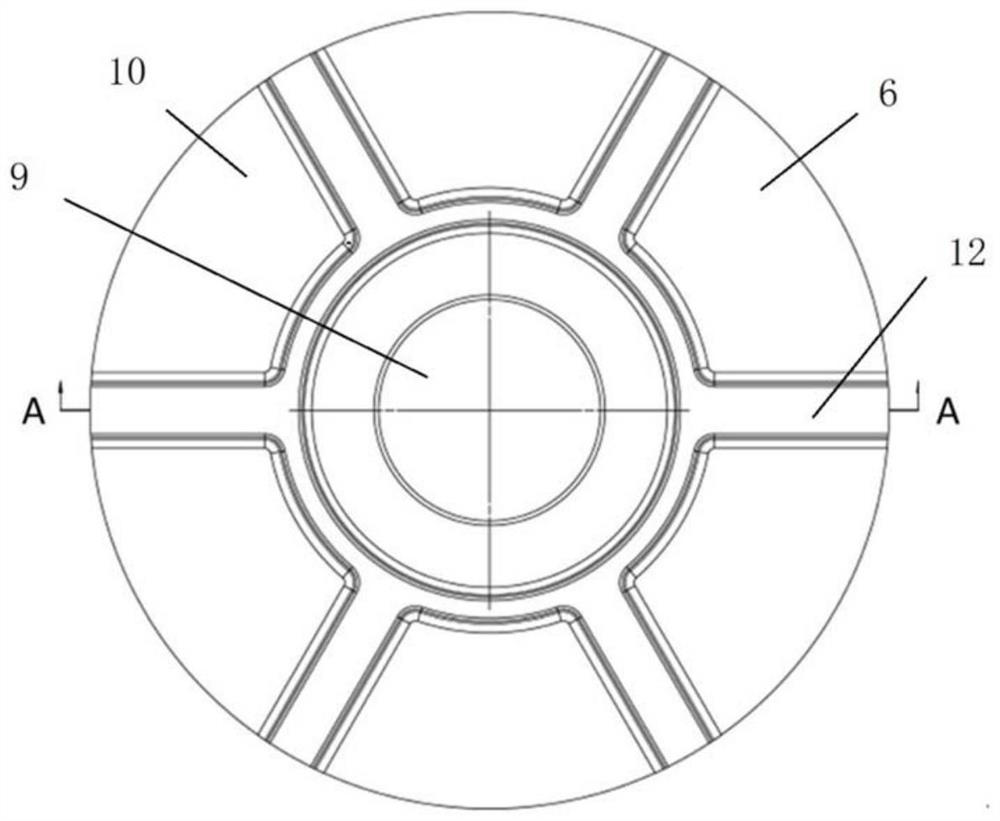

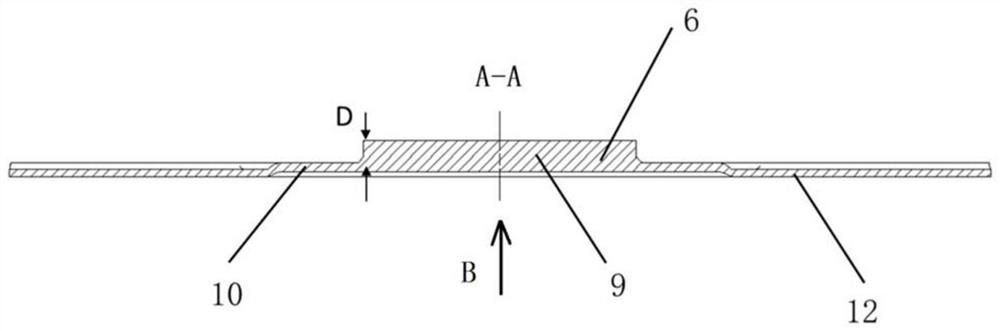

Flat primary and secondary locking system

A new type of secondary locking system for article carriers consisting of at least one secondary male lock with two shoulders that is attached by a neck to the edge of a outer flap on the carrier for use with a primary locking system. An inner flap has a secondary female opening for each secondary male lock. The secondary female opening is formed by a secondary cut line and fold line with the center of the fold line projecting towards the edge of the flap while of the center of the secondary cut line projects away from the edge of the flap to guide the secondary male lock into a flat position against the inside of the inner flap. The shoulders on the secondary male lock are engaged against locking ledges along the extensions of the secondary cut line. A pair of slits may be formed at the end of the fold lines that project inwardly to allow the secondary male lock to slide into a flat position. This locking system is especially useful in wrapping containers that have a flat bottom that would interfere with conventional locking systems.

Owner:GRAPHIC PACKAGING INT

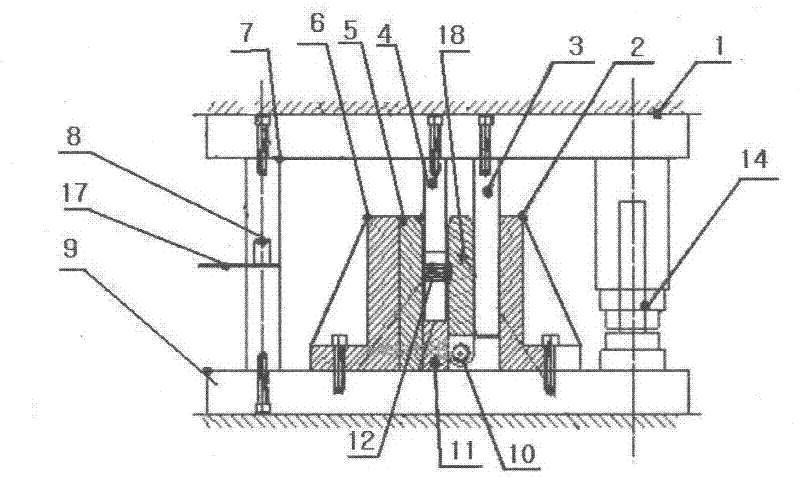

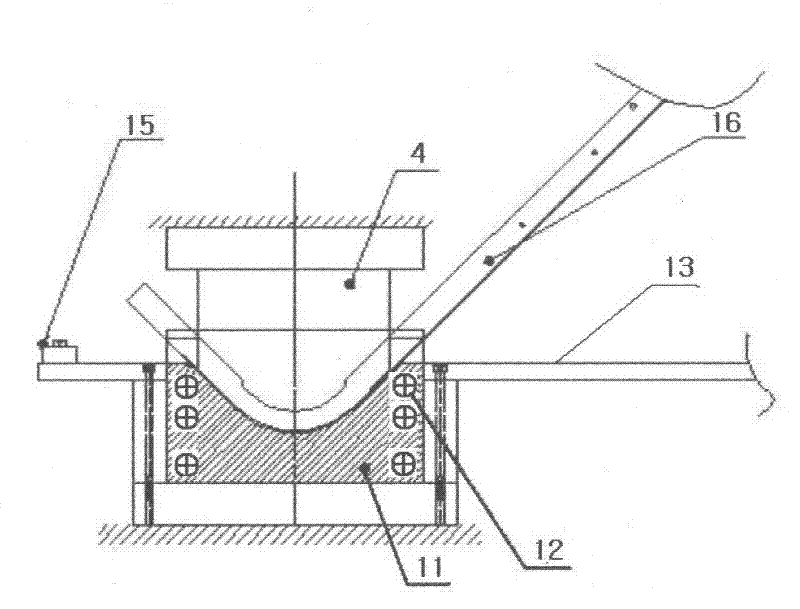

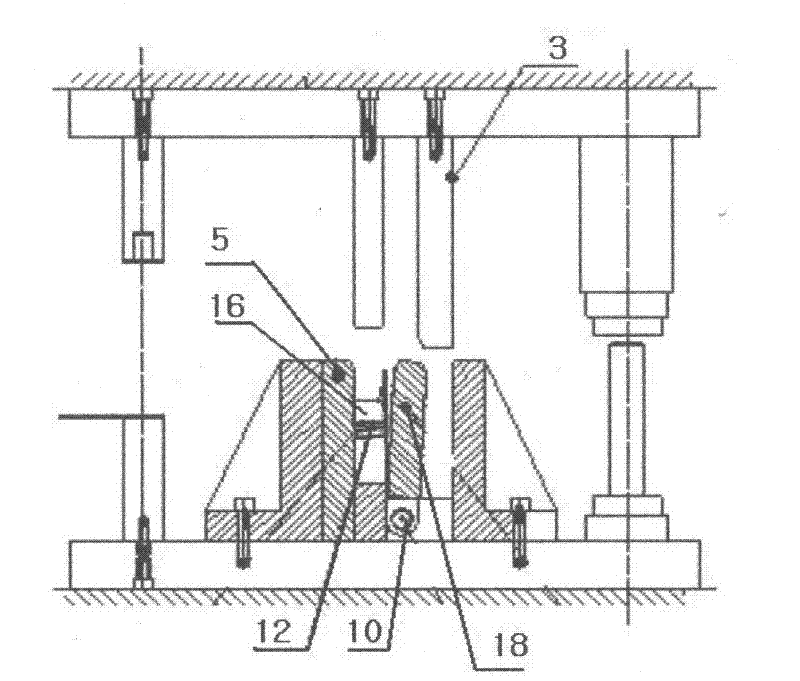

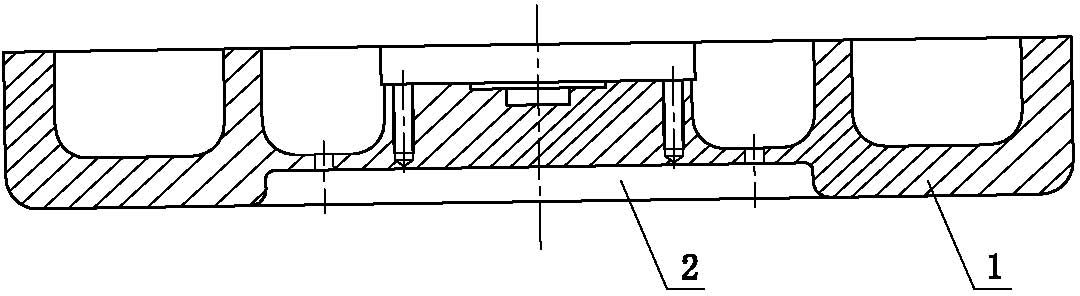

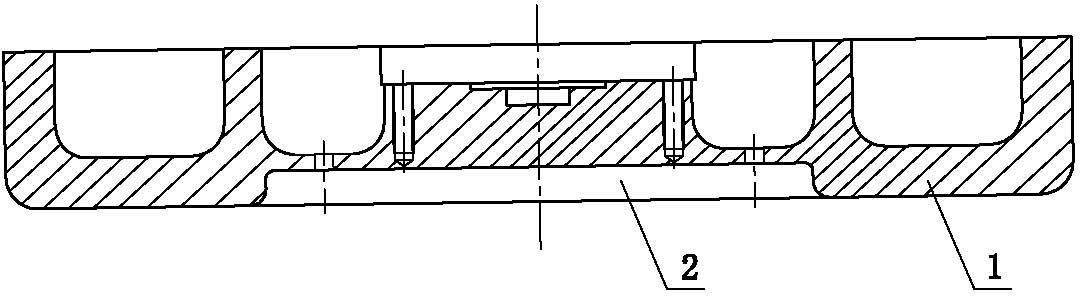

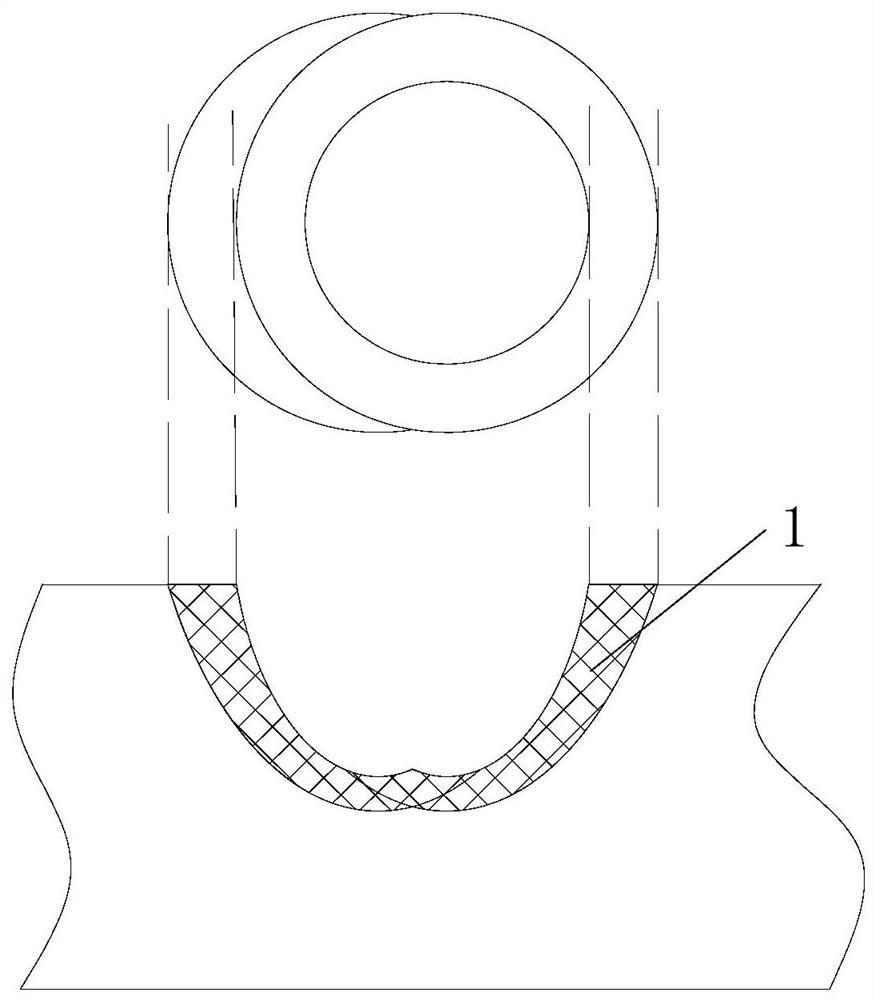

High-straight-edge splint-type bending correction mould

ActiveCN102189178AImprove work efficiencyHigh product precisionShaping toolsEngineeringCorrection method

The invention relates to a high-straight-edge splint-type bending correction mould which comprises an upper template and a lower template; a male mould, a tapered wedge and a limit block are fixed on the upper template; a pin shaft and a female mould are arranged on the lower template; an open and close splint is arranged on the pin shaft; and one side of the female mould is provided with a fixedsplint which is fixed on the lower template. According to the bending correction mould disclosed by the invention, the working efficiency and precision can be improved; the investment cost of equipment is reduced; the utilization rate of the equipment is improved; and the mould is tightly locked with the splint through the tapered wedge so that the plastic deformation of materials can be restrained, and a workpiece is fetched and placed conveniently; a bottom touching correction method is adopted so that the workpiece has stable angle and flat bottom.

Owner:QINGDAO HOSEN HEAVY IND

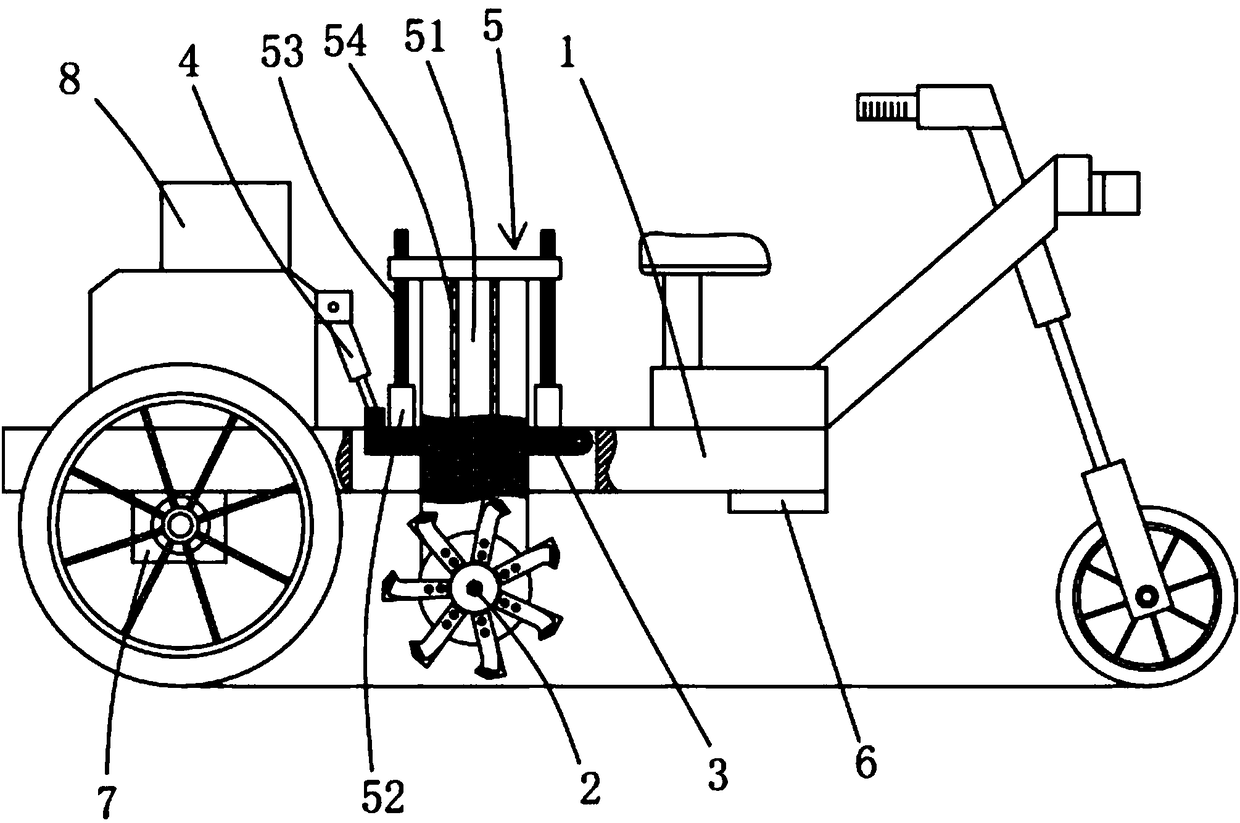

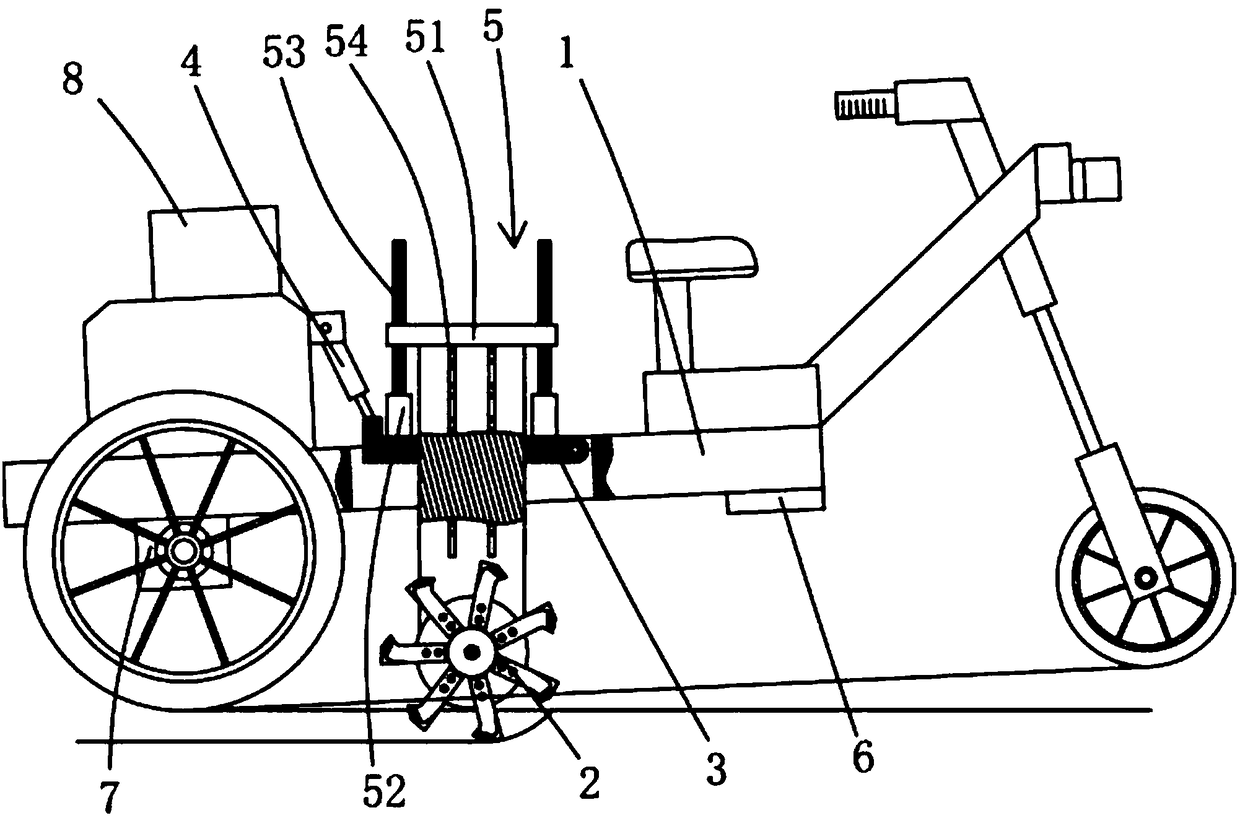

Rotary grooving machine with balance device

ActiveCN108222104AFlat bottomEasy to irrigateSoil-shifting machines/dredgersEngineeringData transmission

The invention discloses a rotary grooving machine with a balance device. The machine comprises a machine body, a rotating plate, a milling and planing machine, a lifting mechanism, an electronic level, an angle speed sensor, a data processing device and a control unit; an angle between the machine body and the horizontal plane is measured through the electronic level; a moving speed of the machinebody can be obtained through the angle speed sensor; the data processing device analyzes an adjusting height of the milling and planing machine and an adjusting angle of the rotating plate; the dataprocessing device transmits processed data to the control unit; and the control unit controls rotation of a motor to drive the lifting mechanism to move to achieve the purpose of adjusting the heightof the milling and planing machine, and controls movement of the driving device to drive rotation of the rotating plate on the machine body to achieve the purpose of always keeping the rotating platehorizontal, so that the grooving machine can cultivate grooves with a certain depths and inclinations in uneven lands as needed, and the bottom surfaces of the grooves are flat to facilitate irrigation.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

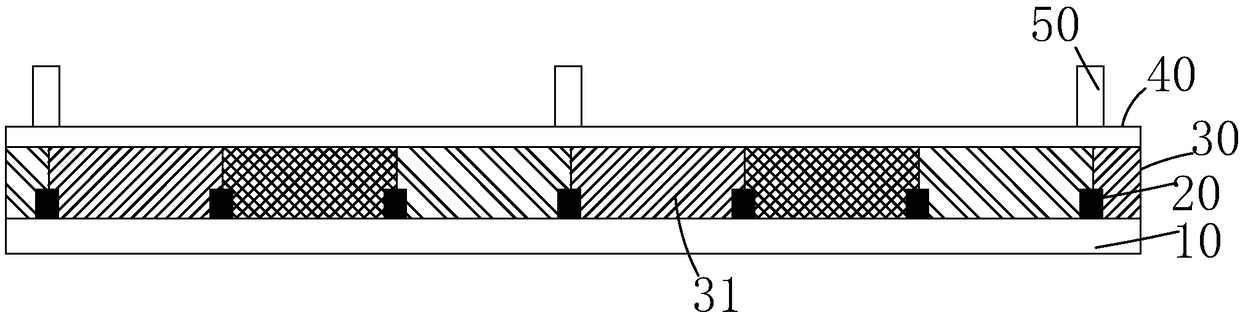

Manufacturing method for color filter substrate and color filter substrate

The invention provides a manufacturing method for a color filter substrate and the color filter substrate. The manufacturing method for the color filter substrate comprises the following steps that the substrate is provided, wherein the substrate comprises multiple pixel areas which are distributed in an array and non-pixel areas located among the adjacent pixel areas; transparent light resistancethin film is formed on the substrate; the light resistance thin film in the non-pixel areas is subjected to carbonization treatment to obtain a light resistance layer, wherein the light resistance layer comprises transparent parts in all the pixel areas and light shielding parts in all the non-pixel areas; a color filter layer is formed on the light resistance layer. Light shielding is conductedthrough the light shielding parts in the light resistance layer, the function of a black matrix is achieved, the color filter layer is subjected to bottom flatting through the transparent parts in thelight resistance layer, cattle horns or corner segment differences on the color filter layer are avoided, and the product quality is guaranteed.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

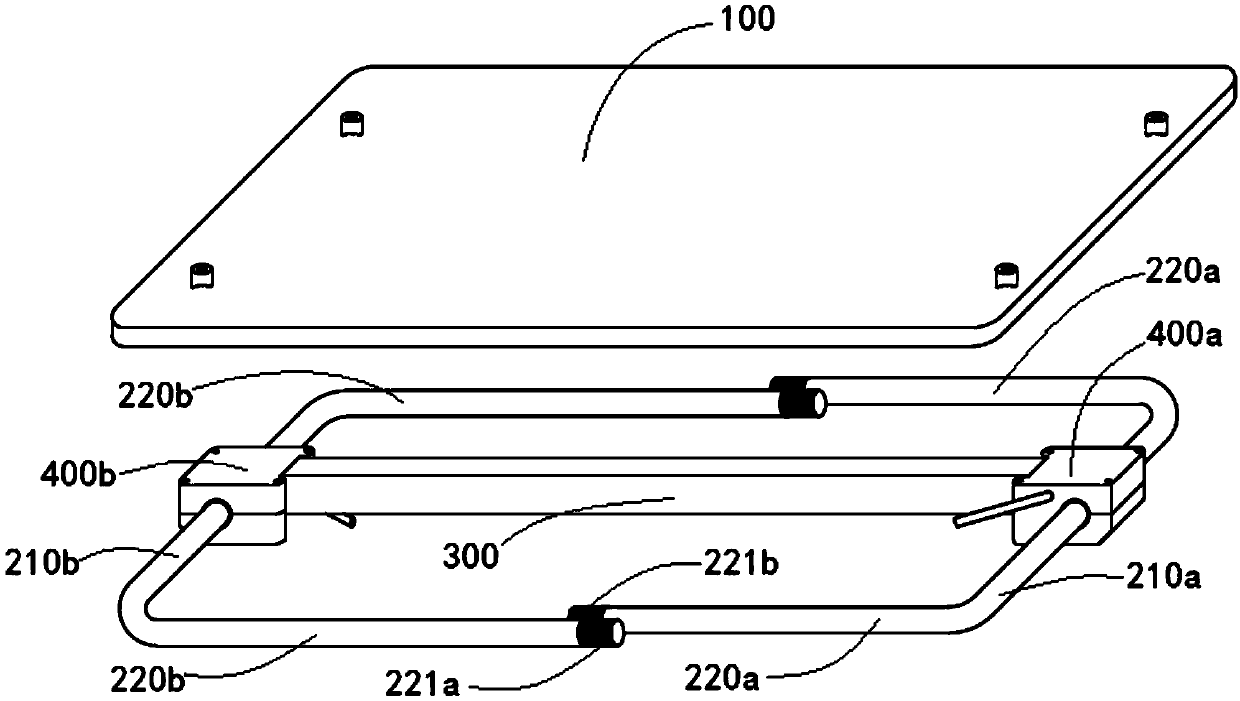

Circular pipe leg folding table

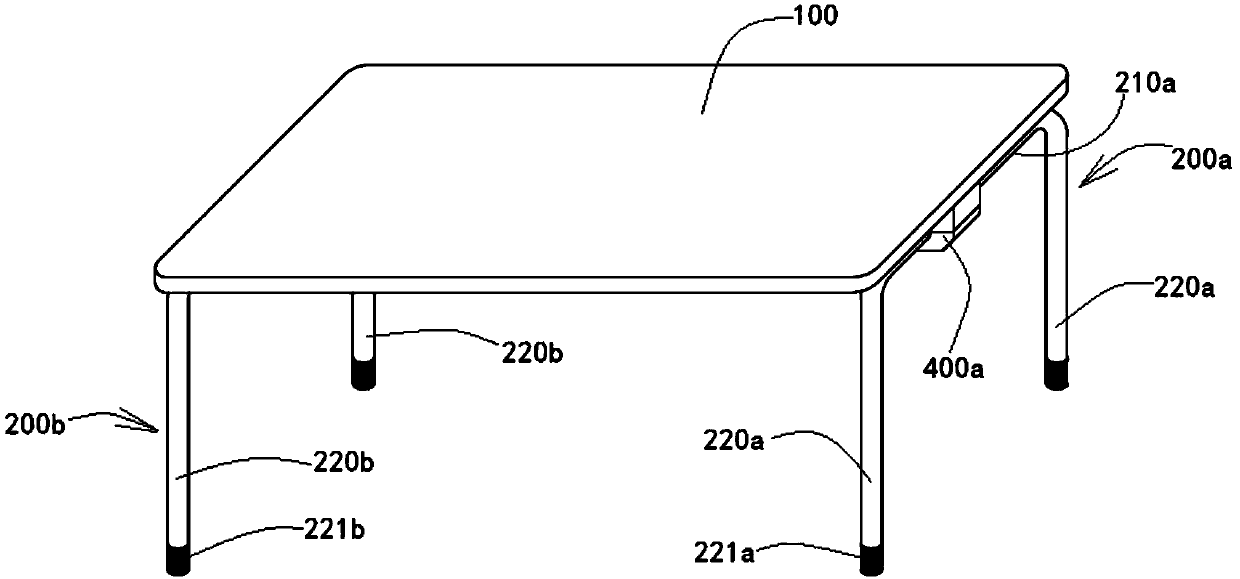

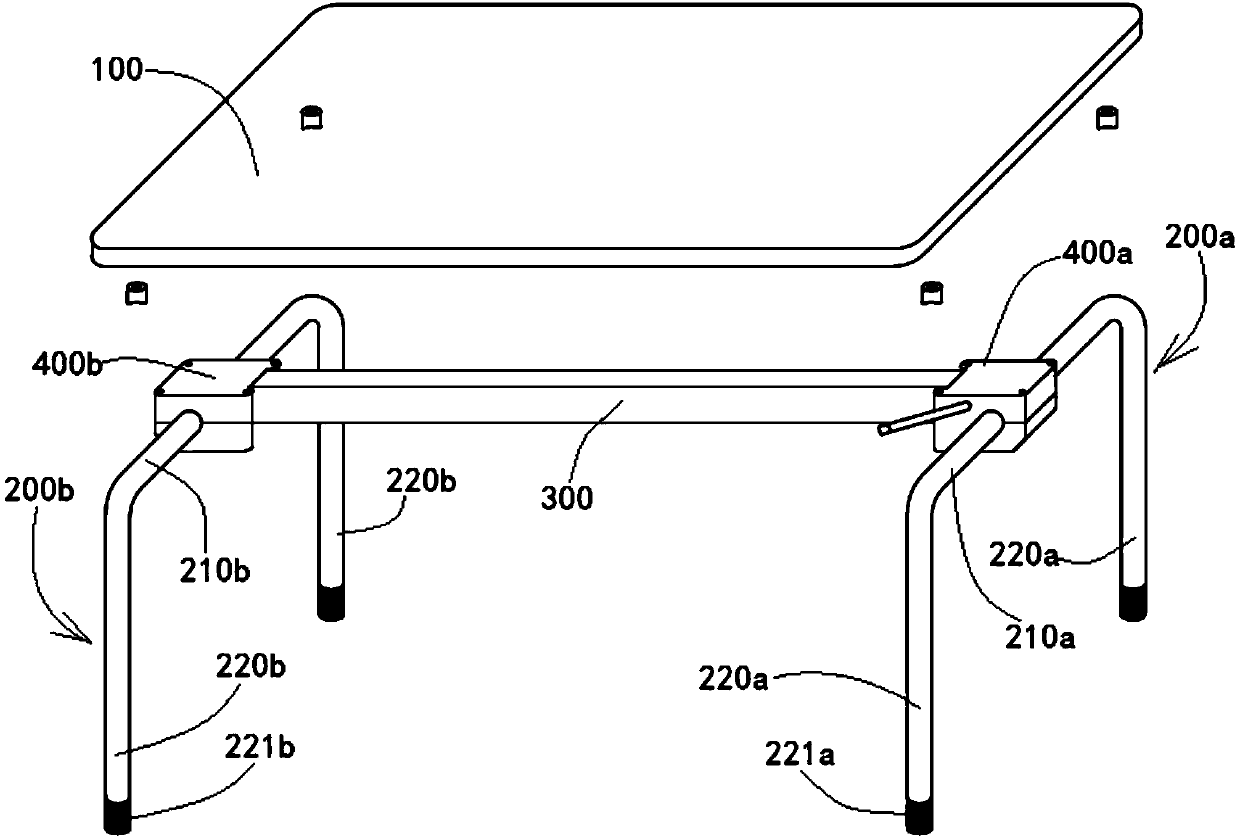

PendingCN107647590AFlat bottomEasy to stackFoldable tablesStowable tablesEngineeringLocking mechanism

The invention discloses a circular pipe leg folding table. The table includes a table board, a first support leg and a second support leg and further includes a table board cross beam and a first turnover deviation locking mechanism and a second turnover deviation locking mechanism, wherein the first support leg and the second support leg are symmetrically arranged at the two ends of the lower board face of the table board, the table board cross beam is arranged on the lower board face of the table board in the lengthwise direction of the table board and located between the first support leg and the second support leg, and the first turnover deviation locking mechanism and the second turnover deviation locking mechanism are arranged on the lower board face of the table board and fixedly connected with the two ends of the table board cross beam respectively. The first turnover deviation locking mechanism and the second turnover deviation locking mechanism cover and are connected with the middles of the circular pipe support leg cross beam of the first support leg and the second support leg. After the circular pipe leg folding table is folded and stored, the two support legs do not cross and overlap on the lower board face of the table board, therefore, the bottom face of the folded circular pipe leg folding table is relatively flat, multiple folding tables are convenient to place in a stack-up mode, the space is saved, and the appearance is attractive.

Owner:NOVAH SHANGHAI OFFICE SYST

Sugar-free spicy curry bread and method for producing the same

InactiveCN101461399AEasy to eatExtended shelf lifeBakery productsFood preparationBiotechnologyOnion bulb

The invention relates to a sugar-free spicy curry bread, characterized by comprising the materials with the weight percent: (1) outer skin: eggs 150-900 parts, sugar-free modifier 10-50 parts, middle wheat gluten 200-800 parts, baking powder 2-10 parts, barm 2-10 parts, mashed potatoes 2-10 parts, bread powder 10-100 parts; (2) filling: chicken 100-300 parts, onion bulb 1-2, garlic meat 2-5 parts, mixed bean 10-200 parts, milk sachet 5-10 parts, preserved chicken sauce 5-10 parts, pepper 0.1-1 parts, millet power 1-10 parts, spicy cooking materials 1-10 parts, liquid edible oil 20-100 parts. The inventive sugar-free spicy curry bread is mellow in taste, delicious in flavor, fragrant and soft in mouth feel, particularly for the breakfast of the diabetics.

Owner:天津金世制药有限公司

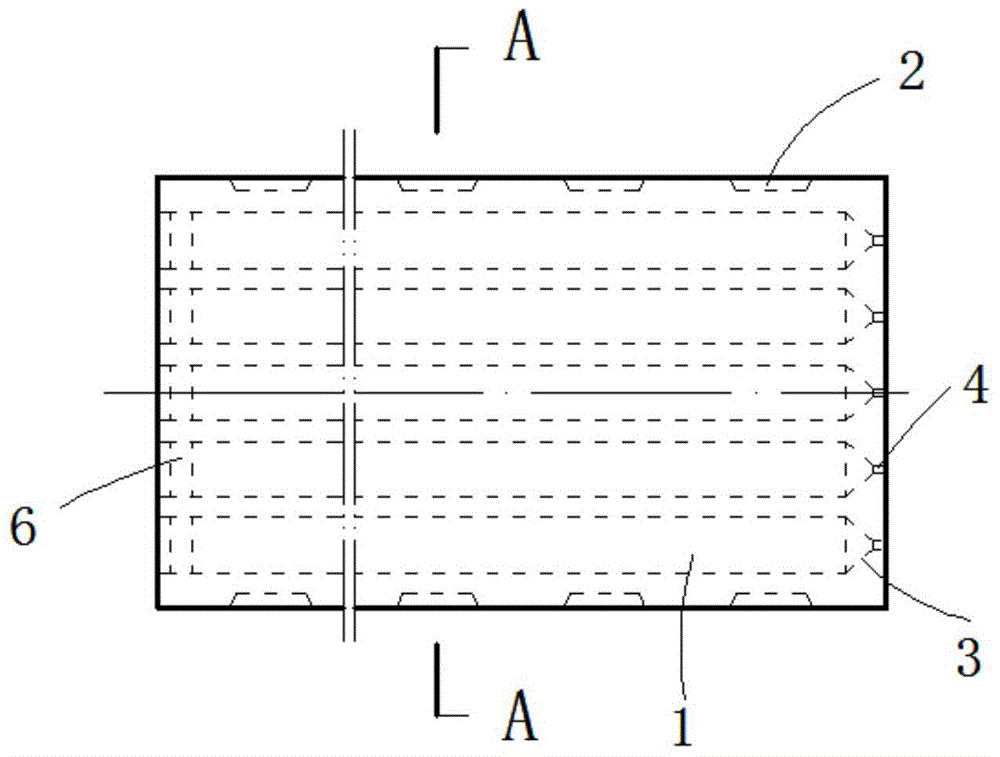

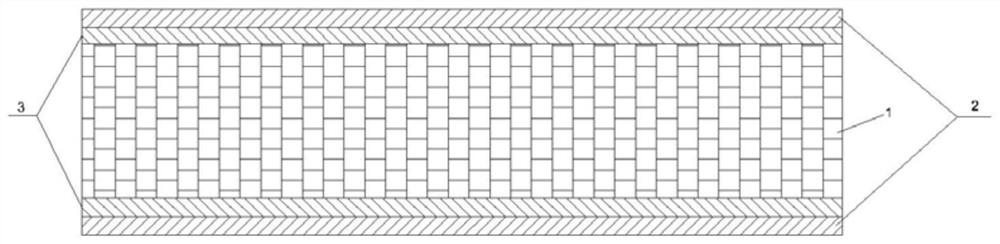

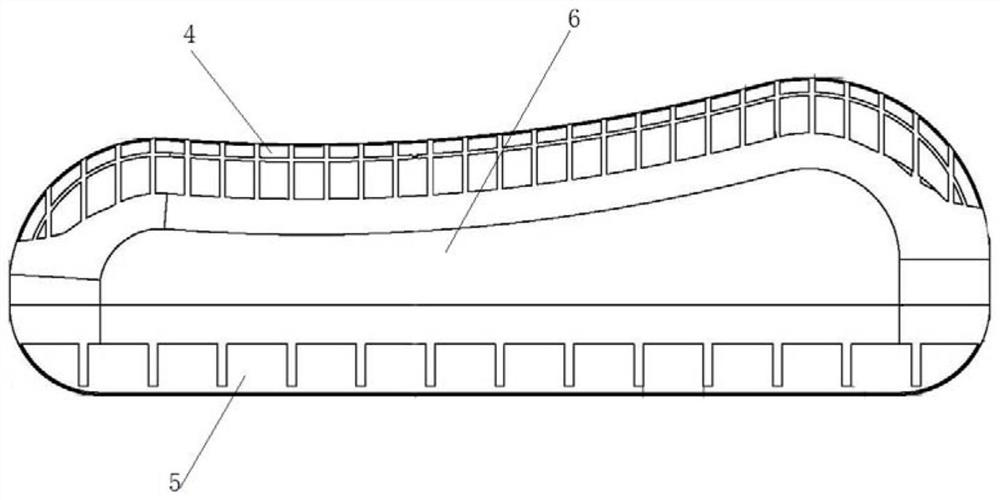

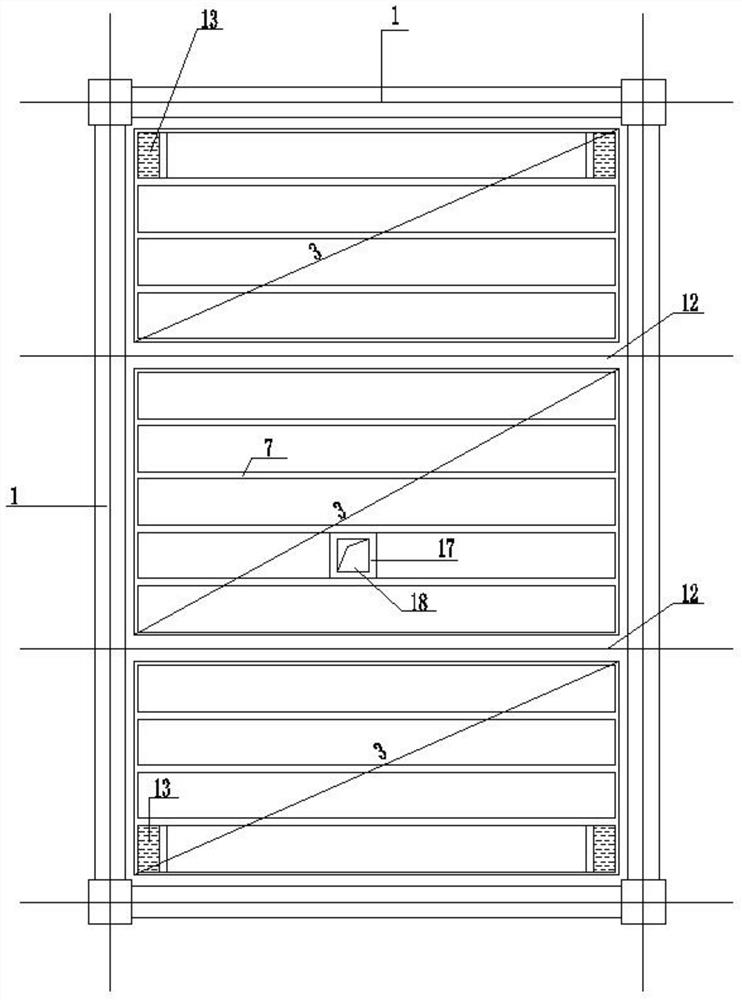

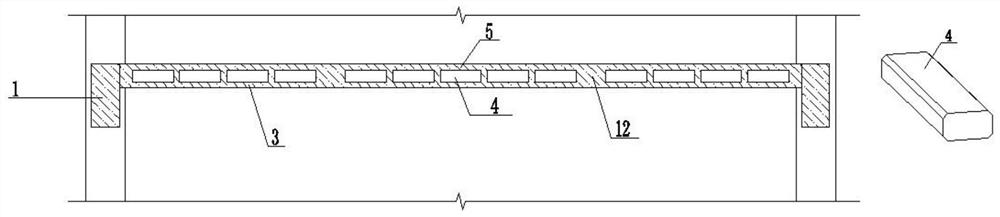

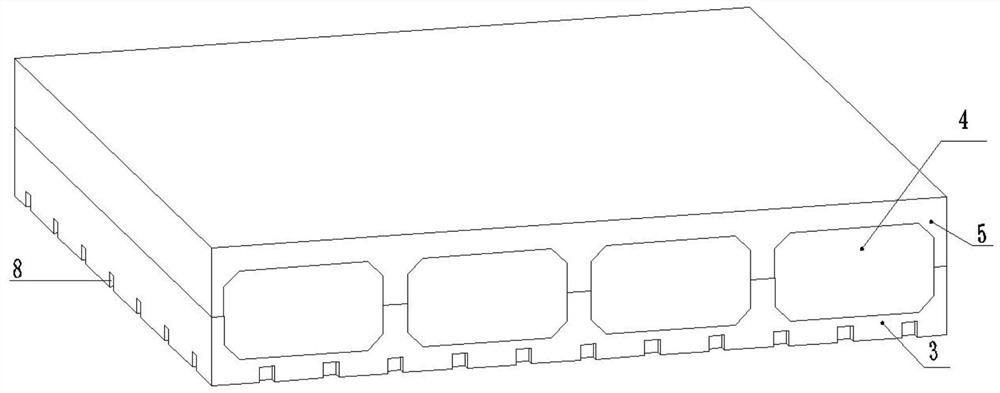

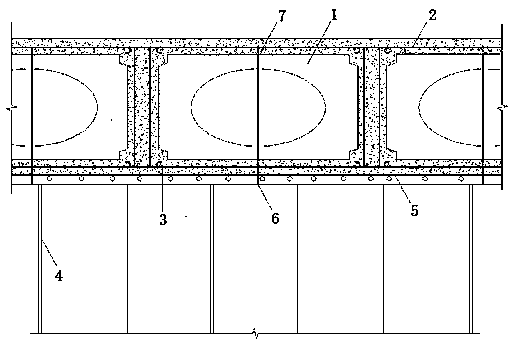

Hollow ribbon board, ribbed slab with hollow ribbon boards and construction formwork system with hollow ribbon boards

The invention discloses a hollow ribbon board provided with multiple through-long core pulling holes. The axial direction of the core pulling holes is the horizontal length direction, plugs are arranged in the core pulling holes, or one end of each core pulling hole is shrunk to form a small hole a; reinforcing ribs are arranged on the hollow ribbon board, and built-in or pin-key connection or overlapping structures are arranged on the side edges of the hollow ribbon board. The hollow ribbon board is soundproof, light, fireproof and capable of preserving heat. The invention discloses a ribbed slab with the hollow ribbon boards. The ribbed slab comprises ribbed hidden beams, surface boards and the hollow ribbon boards, the multiple hollow ribbon boards are arranged at intervals, and concrete is poured to the intervals and the tops of the hollow ribbon boards to form the ribbed hidden beams and the surface boards. The ribbed slab is convenient to construct, low in manufacturing cost and good in performance. The invention discloses a construction formwork system with the hollow ribbon boards. The construction formwork system comprises joists and permanent formworks, and the two sides of each permanent formwork are supported by the edges of the adjacent joists. The permanent formworks are the hollow ribbon boards, and the multiple hollow ribbon boards are arranged at intervals. The construction formwork system can be mounted rapidly, and is free of vertical supports, or supports are few.

Owner:张玉华

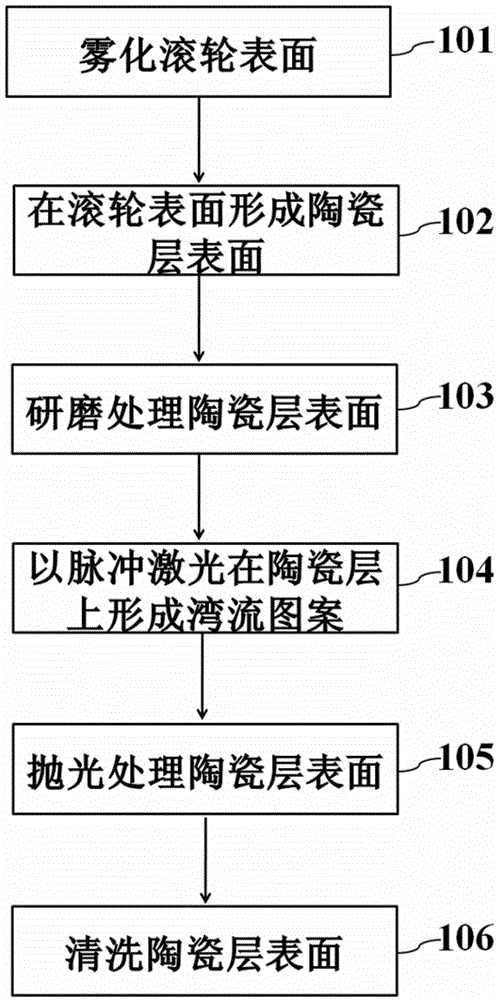

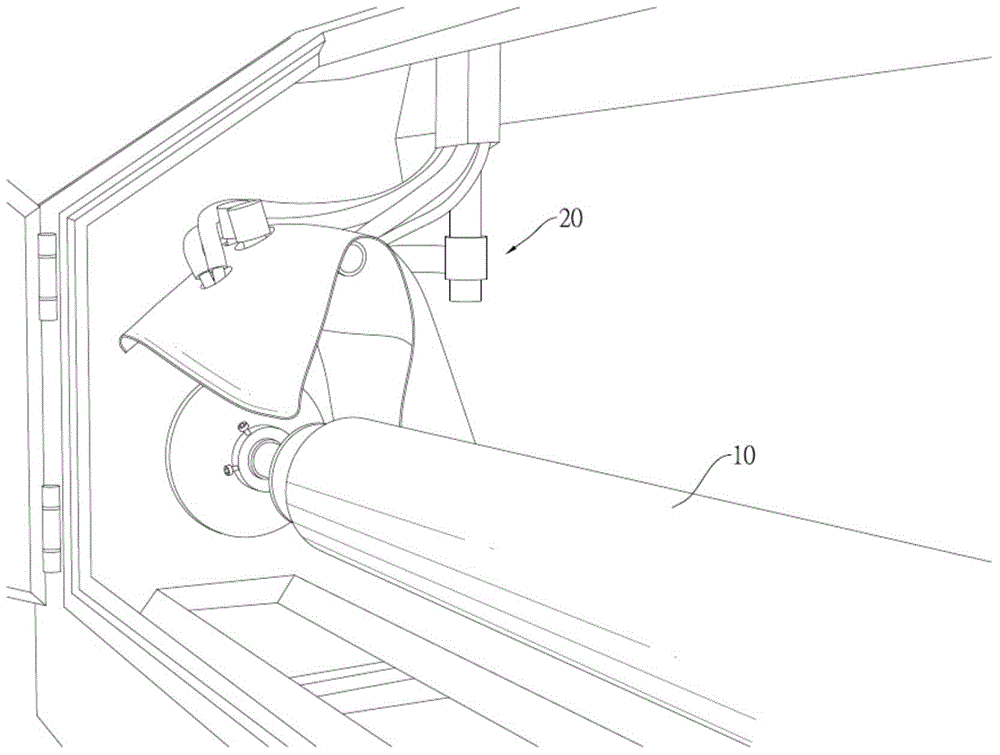

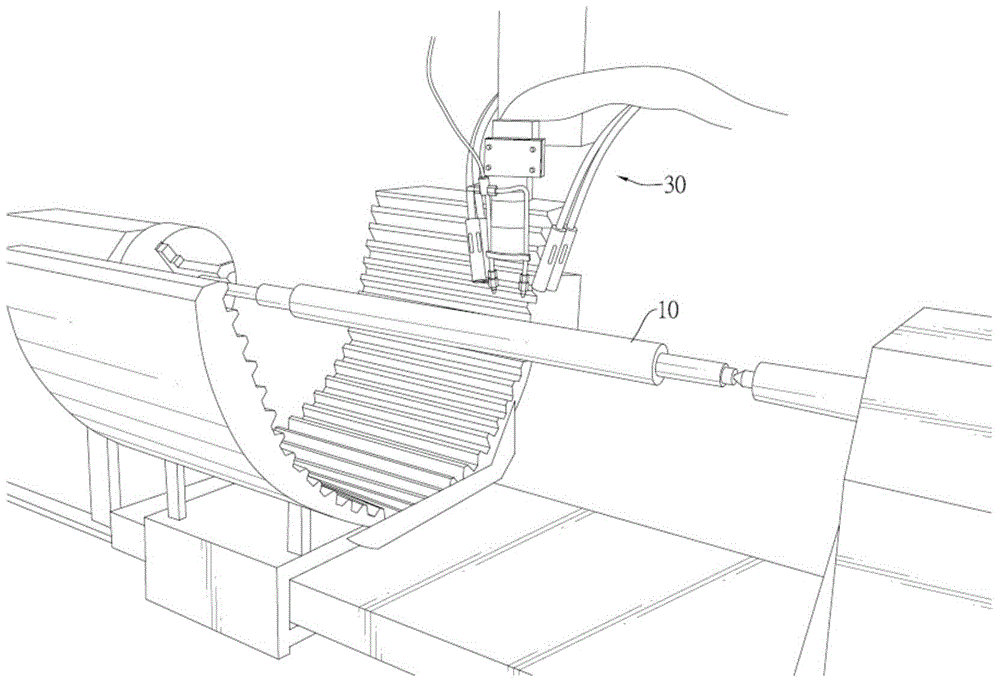

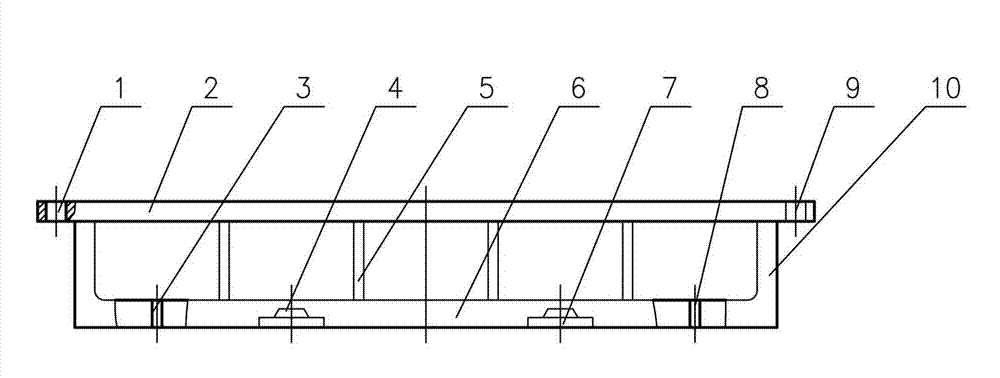

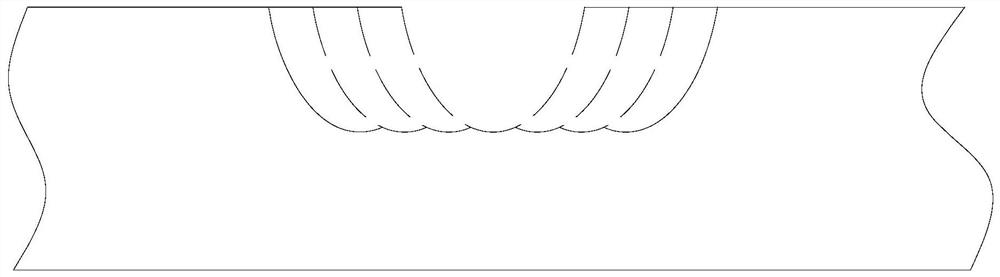

Method for manufacturing transfer printing roller tool with gulf stream pattern

The invention provides a method for manufacturing a transfer printing roller tool with a gulf stream pattern. The method comprises the following steps of forming a ceramic layer on the surface of a roller; grinding the surface of the ceramic layer; forming the gulf stream pattern on the ceramic layer through pulse laser; and cleaning the surface of the ceramic layer. The design that a gulf-stream-shaped channel and a gulf-stream-shaped trench wall are formed on the ceramic layer in an engraved manner through the pulse laser is utilized, and therefore the problem that the bent part of the gulf-stream-shaped channel is deep, and the non-bent part of the gulf-stream-shaped channel is shallow can be solved, so that the bottom of the gulf-stream-shaped channel is flat.

Owner:李大章

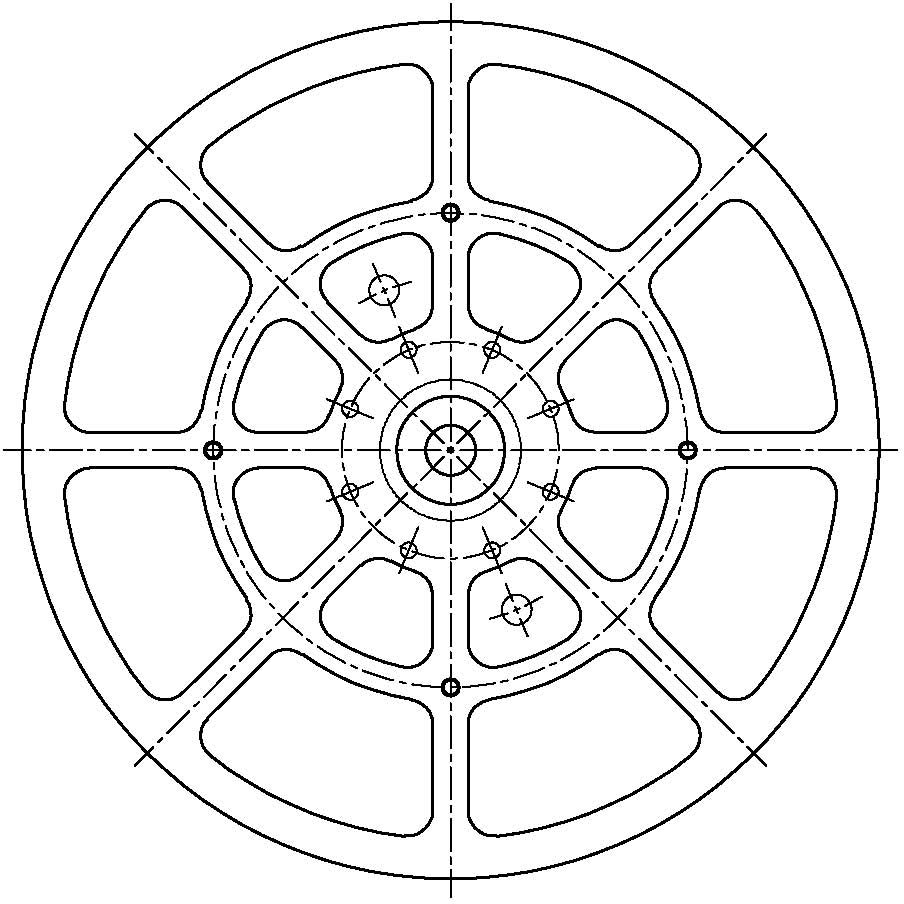

Mold base device

InactiveCN102814856AHigh density and uniformFlat bottomCeramic shaping apparatusEngineeringVolumetric Mass Density

The invention relates to a mold base device. The mold base device is structurally characterized in that a hollow cavity consists of an upper cover plate, side walls and a bottom plate, the inside of the hollow cavity is divided into a plurality of heating cavities by partition plates, the adjacent partition plates are staggered with one another, tops of the partition plates are connected with the inner side of the upper cover plate, bottoms of the partition plates are connected with the inner side of the bottom plate, two ends of the bottom plate are connected with the side walls, a heat source inlet and a heat source outlet are respectively arranged on two sides of the bottom plate, a second positioning hole and a third positioning hole are further arranged on the lower portion of the bottom plate and are not communicated with the hollow cavity, and a first positioning hole and a fourth positioning hole are arranged on the upper cover plate. The mold base device has the advantages that a mold sleeve, a mold base and a vibrating platform can be positioned on the same center line, and excitation force generated by the vibrating platform can effectively act on paste materials, so that produced anode or cathode carbon blocks are high and uniform in density; and bottom surfaces of the carbon blocks are smooth, and qualified rate of the products is increased.

Laser preparation method for microchannels of microfluidic chip

The invention discloses a laser etching preparation method for microchannels of a microfluidic chip. The method comprises the following steps: cleaning the surface of a substrate made from a high-polymer material, so as to remove surface attachments from the substrate; placing the substrate on a mobile platform, etching the substrate by using laser emitted from a gas laser to form microchannels, and meanwhile, measuring out width values of heat-affected zones at two sides of the microchannels; repeatedly carrying out laser etching on the two sides of the microchannels to form microchannels with trapezoidal cross sections, wherein an etched position of last time serves as an origin before each etching, and the mobile platform drives the substrate to transversely translate distances of the width values of the heat-affected zones; and subjecting the laser-etched substrate to annealing treatment, and then, subjecting a cover plate and the substrate to hot-pressing, thereby obtaining the microfluidic chip. According to the method, the trapezoidal microchannels with good morphologies can be obtained by only measuring width values of heat-affected zones of sides after primary etching without complicated calculating and then carrying out etching repeatedly by transversely translating the width values; and the microchannels are flat in bottom face and low in surface roughness.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

Process for producing double-sided gambiered Guangdong silk

ActiveCN102733182BSame inner and outer fabricConsistent appearanceDyeing processAnimal fibresChemistryPennisetum

Owner:佛山市顺德区顺熙贸易有限公司

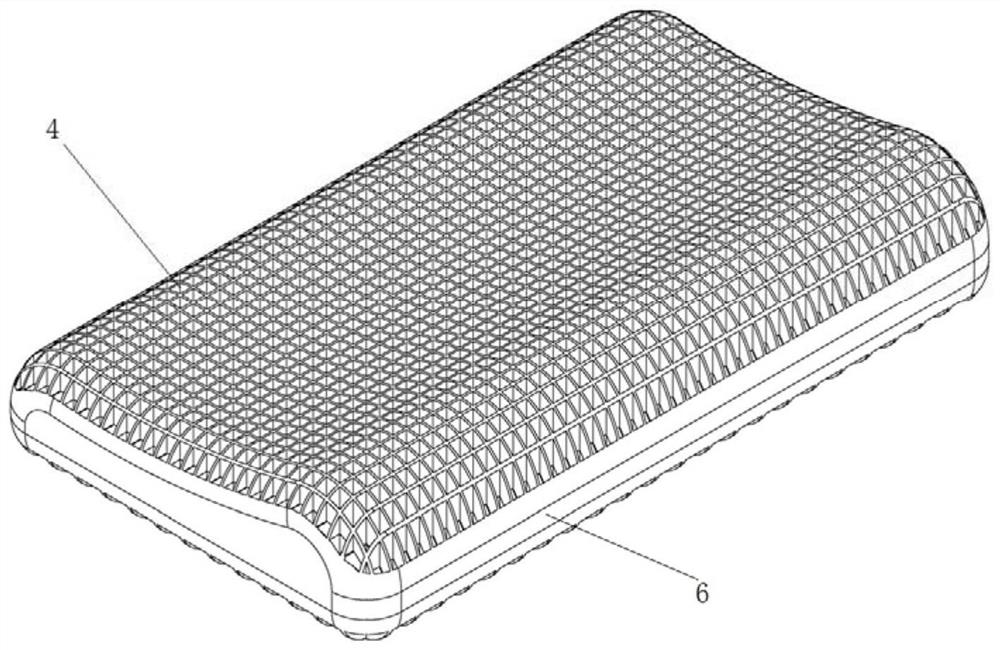

TPE honeycomb breathable pressure relief pillow

The invention belongs to the field of bedding articles, and particularly relates to a TPE honeycomb breathable pressure-relief pillow, which comprises a pillow inner and a pillow case, wherein the pillow inner is made of TPE elastomer, the upper half portion of the TPE elastomer is provided with an upper honeycomb pressure-releasing grid, the lower half portion of the TPE elastomer is provided with a lower honeycomb pressure-releasing grid, and the upper honeycomb pressure-releasing grid is communicated with the lower honeycomb pressure-releasing grid. A lining is arranged between the pillow inner and the pillowcase and is made of thickened moisture absorption quick-drying fabric, the pillowcase is made of double-faced double-feeling fabric, one face of the pillowcase is nylon cool, and the other face of the pillowcase is modal skin-friendly. The pillow inner is made of the TPE elastomer, the honeycomb pressure relief grids which are through up and down are arranged on the TPE elastomer, so that the pillow has the functions of pressure relief, ventilation and vibration isolation, and the performance is durable and stable and the pillow is not prone to aging; meanwhile, the pillow case is made of the double-faced double-feeling fabric, and the pillow case can feel cool, warm and universal in four seasons; by means of the lining, moisture absorption, sweat releasing and air permeability are improved.

Owner:CHENGDU QUSHUI TECH CO LTD

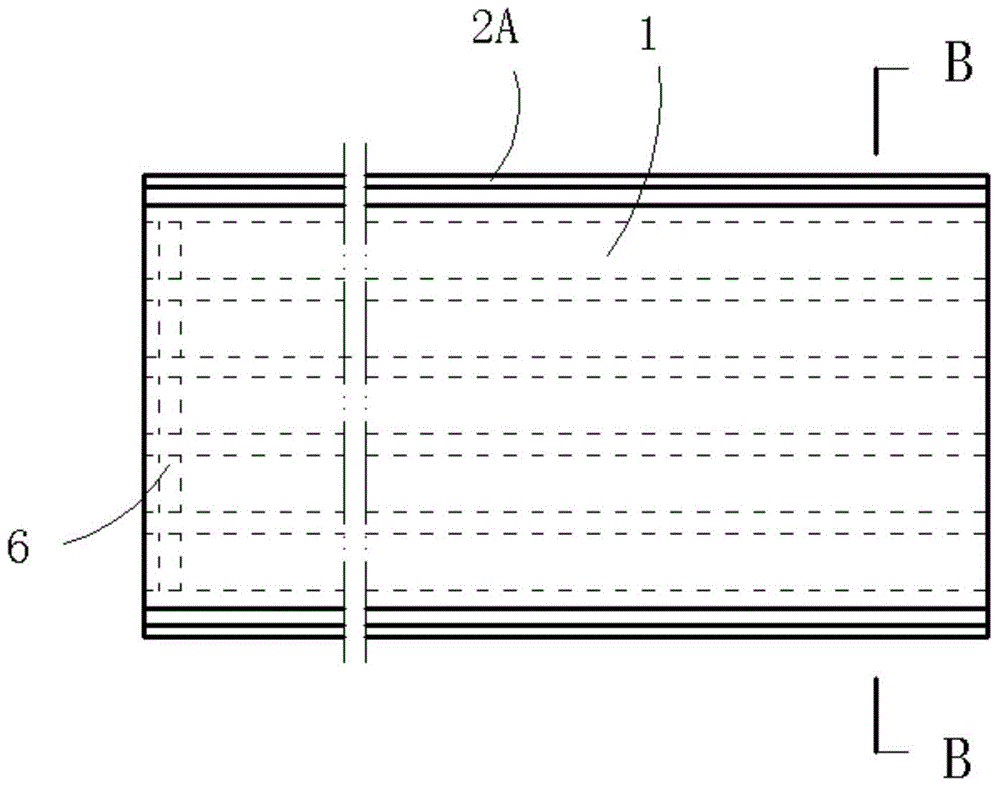

Fabricated integral type hollow floor and prefabricated high-rib laminated bottom plate thereof

The invention discloses a fabricated integral type hollow floor and a prefabricated high-rib laminated bottom plate thereof. The fabricated integral type hollow floor comprises a fabricated integral type hollow plate and laminated frame beams. The fabricated integral type hollow plate comprises the prefabricated high-rib laminated bottom plate, hollow plate built-in filling bodies, cast-in-place laminated layers and cast-in-place laminated ribs. The prefabricated high-rib laminated bottom plate is provided with upturning ribs, shear keys are arranged on the side face of the prefabricated high-rib laminated bottom plate and the upper surfaces of the upturning ribs, truss steel bars or shear short bars are arranged on the upper surfaces of the upturning ribs and connected with the cast-in-place laminated layers or the cast-in-place laminated ribs, and the upper surfaces of the upturning ribs are rough surfaces. The hollow plate built-in filling bodies are light filling blocks or thin-wall components or fast-easy net disassembly-free formworks. The laminated frame beams are arranged on the periphery of the fabricated integral hollow plate. The hollow floor structure is light in self-weight, large in plate span, large in plate rigidity and high in bearing capacity, the use number of steel bars is reduced, the structure height is remarkably reduced, the use clearance is improved, alarge number of formworks are saved, and the construction period is effectively shortened.

Owner:吴永兴

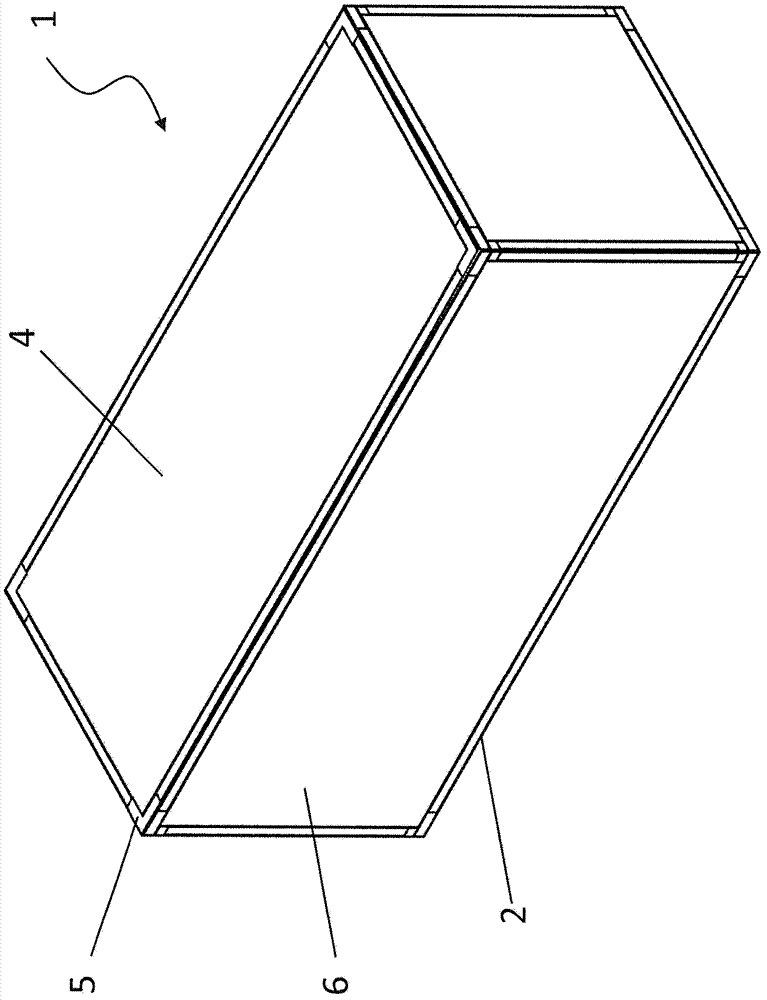

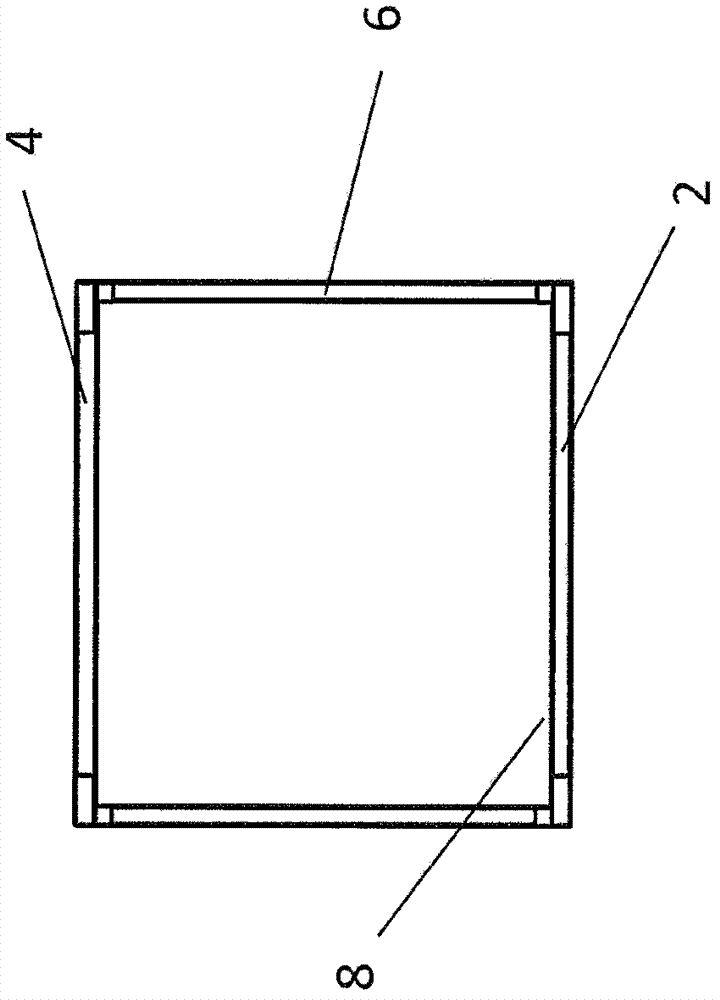

Transport container and floor thereof

InactiveCN103171835AIncrease stiffnessGood impact resistanceFloorsLarge containersStructural engineeringMartensite

The present invention relates to a floor structure (2) for a transport container (1) and to the transport container. The floor structure (2) comprises a first surface layer (8) forming a floor surface and support arrangements (10, 11, 24) for supporting the first surface layer (8). According to the present invention, the first surface layer (8) is formed from hardened martensitic steel sheet.

Owner:RAUTARUUKKI

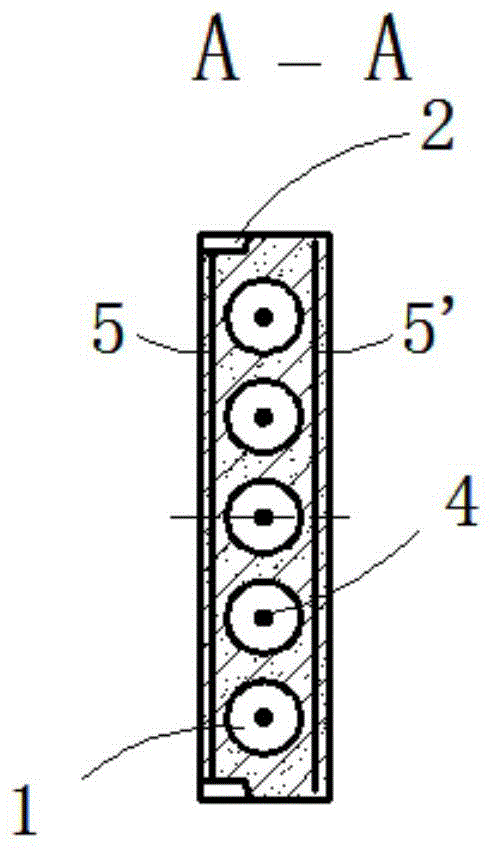

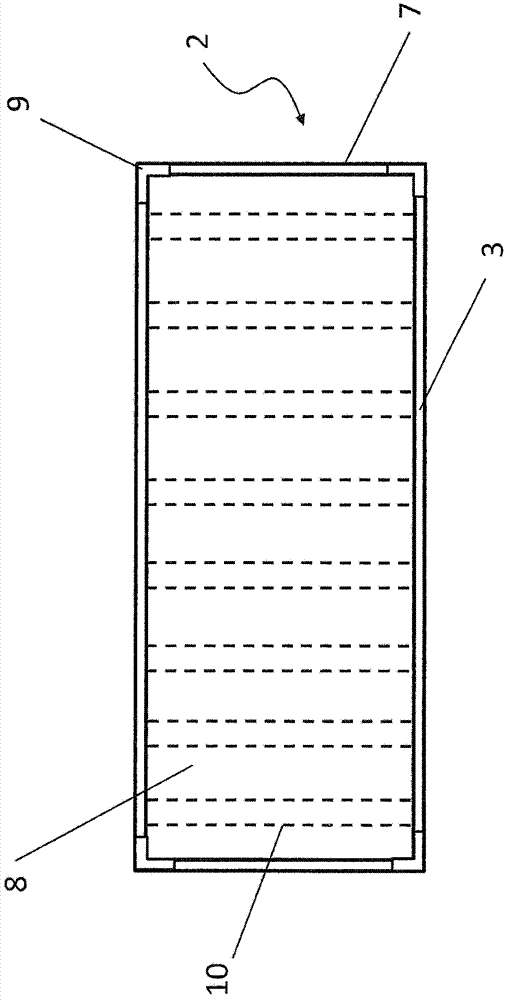

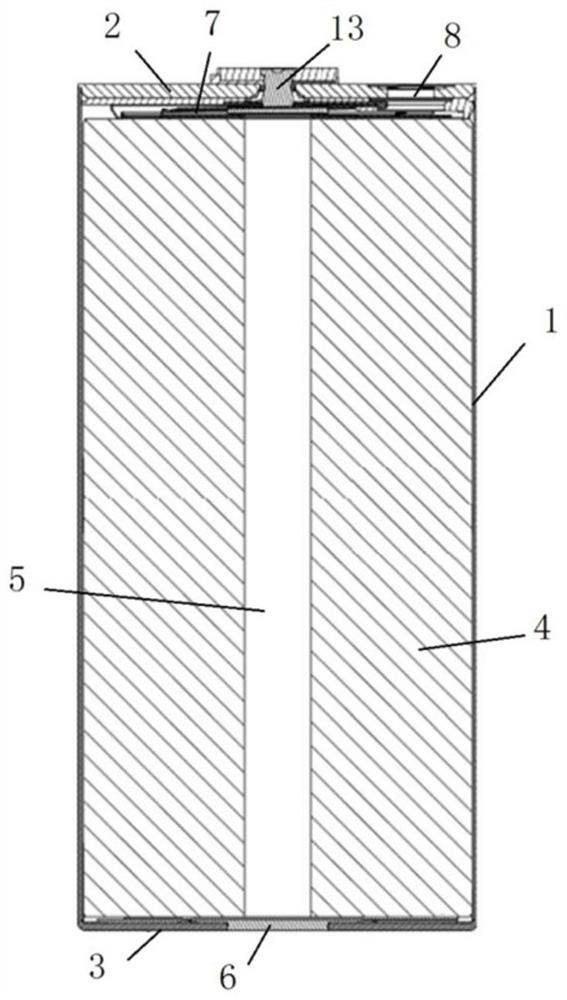

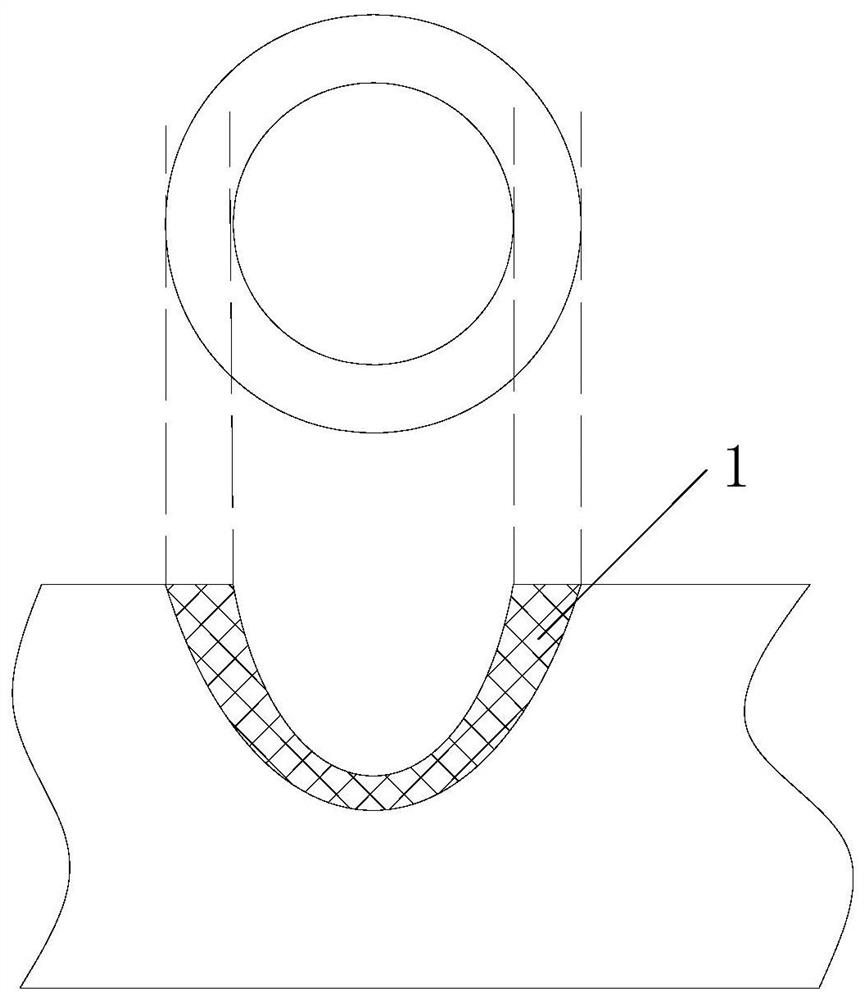

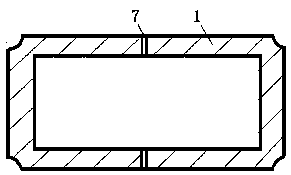

Battery cell and battery module

PendingCN114784464AFlat bottomOptimize layoutSmall-sized cells cases/jacketsSecondary cellsSolderingMechanical engineering

The invention relates to the technical field of batteries, in particular to a battery cell and a battery module. The electric core comprises a conductive shell, a core body and a cover plate, the top of the conductive shell is provided with a top opening, the bottom of the conductive shell is provided with a shell bottom wall, the cover plate covers the top opening of the conductive shell in a sealing mode, the core body is arranged in the conductive shell, the electric core further comprises a positive electrode collector plate and a negative electrode collector plate, and the top end of the core body is provided with a negative electrode lug; a collector plate tailor-welding hole is formed in the bottom wall of the shell, the positive collector plate comprises a welding column and an annular plate body, the annular plate body is conductively connected with the positive tab, and the welding column extends into the collector plate tailor-welding hole and is fixed with the conductive shell in a tailor-welding manner; the bottom end face of the welding column is located in the flow collecting disc tailor-welding hole or is flush with the outer side face of the bottom wall of the shell. According to the battery cell, the problems of weld penetration, pseudo soldering and poor air tightness which are easy to occur when the conductive shell and the positive collector plate are welded by adopting a laser penetration welding process in the prior art are effectively avoided, and the welding yield is improved.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

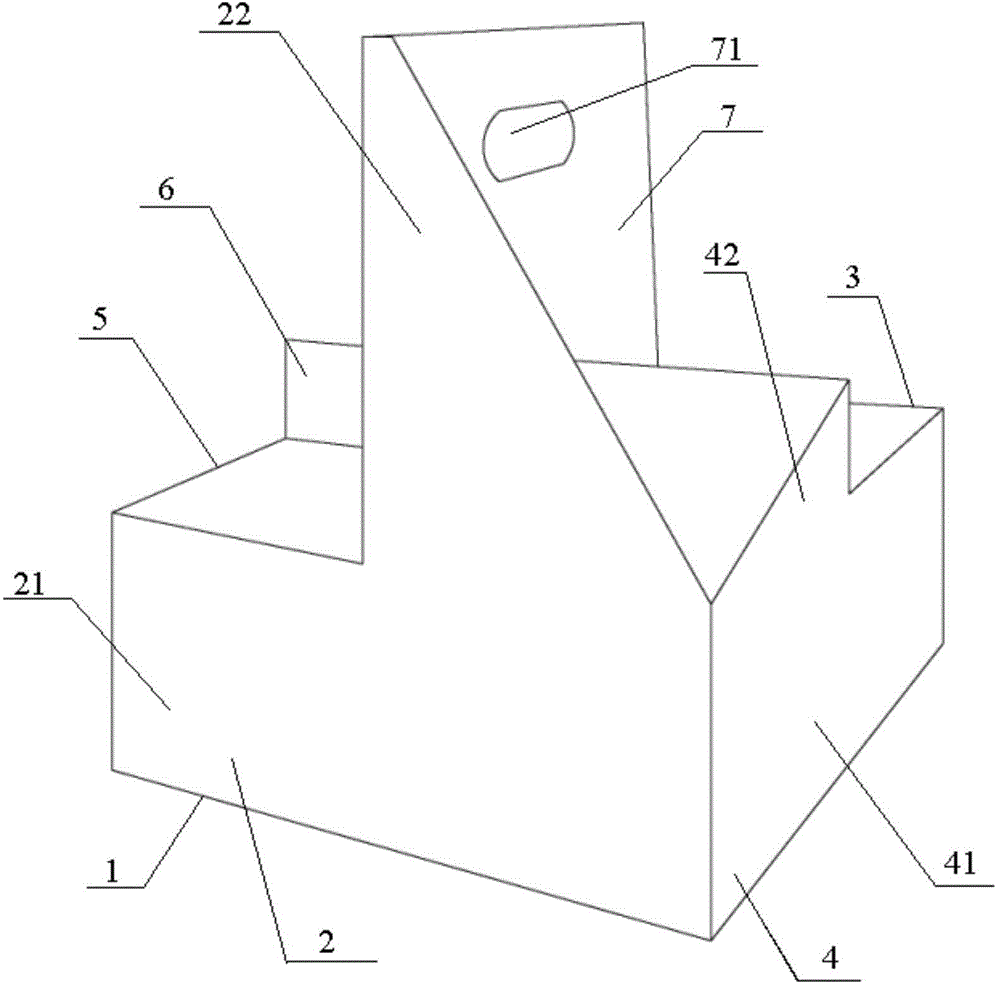

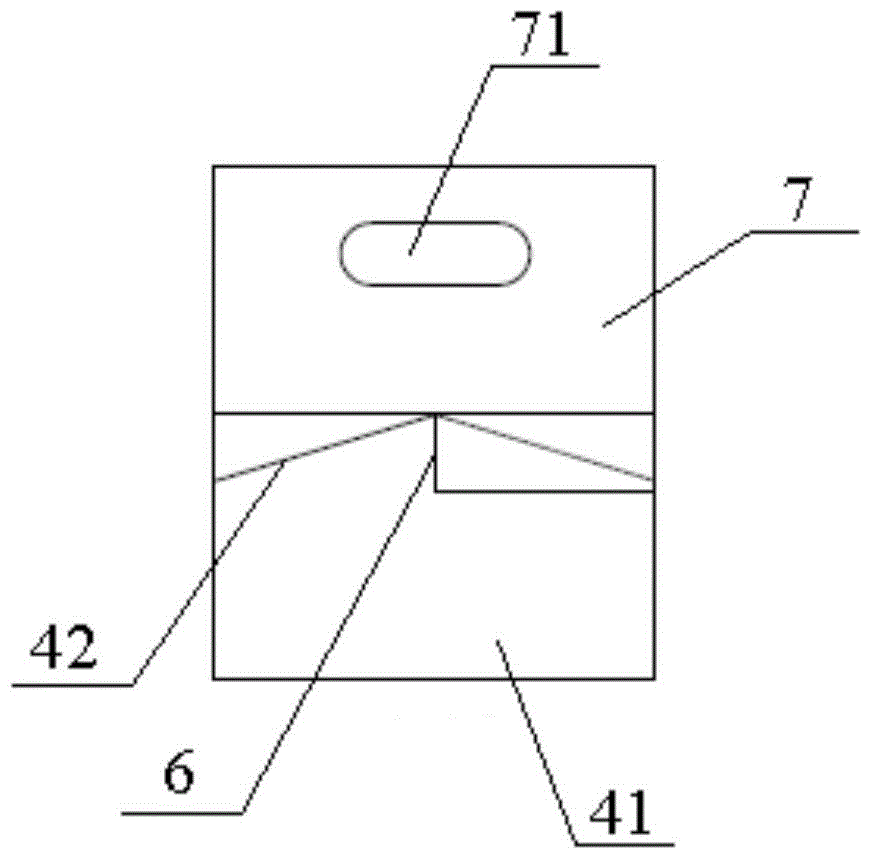

Drink lifting basket

The invention discloses a drink lifting basket. The drink lifting basket comprises a baseplate, and four side walls connected with the baseplate; the baseplate is square; the four side walls consist of a left side wall, a right side wall, a front side wall and a back side wall; the front side wall consists of a rectangular part vertically arranged, and a right triangle part vertically arranged; the back side wall and the front side wall are central symmetry figures, and the symmetry centers are the center of the baseplate; the left side wall consists of a rectangular part longitudinally arranged, and a right trapezoidal part longitudinally arranged; the right side wall and the left side wall are central symmetry figures, and the symmetry centers are the center of the baseplate; a separation plate is longitudinally arranged between the front side wall and the back side wall; and a handle plate is vertically arranged between the left side wall and the right side wall. The drink lifting basket is formed by folding a paperboard, can hold four drinks once, is provided with the handle to bring convenience for carrying, has a smooth bottom to enable the drinks to be not easy to spill out, is green and environment-friendly, and can be recycled.

Owner:上海中华商务联合印刷有限公司

A recycling carton for medical waste needles

ActiveCN103211657BFlat bottomNo conflictSurgical furnitureNursing accommodationCardboardMedical waste

The invention provides a medical waste needling instrument recycling carton. The carton body of the recycling carton is formed by gluing two pieces of 440g / m<2> high-grade brown paper; and after being folded, an upper cover and a lower bottom are of a triplex board structure. The recycling carton is high temperature resistant, is capable of resisting water immersion, and is excellent in dropping resistance and puncturation resistance; and the recycling carton can be stably placed, and the bottom of the recycling carton does not plump, so that the recycling carton can not tilt on a 15-degree inclined plane.

Owner:DACHENG PACKAGING PROD SUZHOU

Medical nuclear magnetic resonance equipment head processing method

The invention discloses a medical nuclear magnetic resonance equipment head processing method, characterized by comprising the processing steps of: firstly, performing positive punching on a stainless steel slab by a head upper mold to form an R part on the outer edge of the stainless steel slab to form a head crude product; punching a hole in the center of the head crude product after positive punching; then disassembling and reversely placing the head upper mold, and putting the head crude product after punching the hole on the reversely placed head upper mold; performing center punching on the head crude product by matching the center punch head with the punched hole in the center of the head upper mold; and trimming the outer edge and the center hole edge of the head crude product to obtain the head product. The processing method disclosed by the invention has high production efficiency, is suitable for mass production, improves the efficiency by 50% compared with the prior art, and causes the head to have stable position, high precision, high concentricity of products and flat bottom surface in production, and the produced head has long service life.

Owner:宜兴华威封头有限公司

A laser fabrication method for microchannels in microfluidic chips

The invention discloses a method for preparing a microchannel of a microfluidic chip by laser etching, which comprises the following steps: cleaning the surface of a substrate made of a high polymer material, and removing attachments on the substrate surface; The laser emitted by the laser etches the substrate to form a microchannel. At the same time, the width of the heat-affected zone on both sides of the microchannel is measured; multiple laser etching is performed on both sides of the microchannel to form a microchannel with a trapezoidal cross section. Before each etching, the last etching position is taken as the origin, and the moving platform drives the substrate to translate the distance of the width of the heat-affected zone laterally; the substrate after laser etching is annealed, and then the cover sheet is thermally bonded to the substrate , to obtain a microfluidic chip. This method does not require complex calculations, and only measures the width of the side heat-affected zone after one etching, and then translates the width value laterally for multiple etchings to obtain a trapezoidal microchannel with a flat bottom surface and a flat surface. Small roughness.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

BZS cavity composite floor structure and construction method thereof

A BZS cavity composite floor structure and a construction method thereof are provided. The BZS cavity composite floor structure comprises filling mold boxes, a template, cushion blocks, stressed steelbars and distributed steel bars. At least one steel wire hole is reserved in each filling mold box for steel wires to penetrate and be fixed. The stressed steel bars are respectively arranged in theupper and lower parts of the filling mold boxes. The distributed steel bars are arranged between the filling mold boxes. After concrete is poured, the stressed steel bars and the distributed steel bars form the template. The filling mold boxes are permanently buried in a concrete floor as internal molds. The filling mold boxes are glass fiber reinforced gypsum cavity molds, namely, BZS mold boxes.Steel wire holes are reserved in the BZS mold boxes for steel wires to penetrate and be fixed. The cushion blocks of the same height are placed under the four corners of each BZS mold box. By using the BZS cavity composite floor structure, the amount of concrete used in the floor can be reduced by 10-30%, the amount of steel used in the floor can be reduced by 20-30%, and the total construction period can be shortened by 10-15%. The comprehensive cost is significantly reduced, and the comprehensive engineering cost is 5-15% lower than that of buildings adopting an ordinary floor structure.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com