Battery cell and battery module

A cell and module technology, used in battery pack components, small-sized batteries/battery packs, secondary batteries, etc., can solve the problem of virtual welding, poor air tightness, and easy welding between the collector plate and the conductive shell. Wear and other problems, to achieve the effect of high welding strength, fast welding speed, convenient layout and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

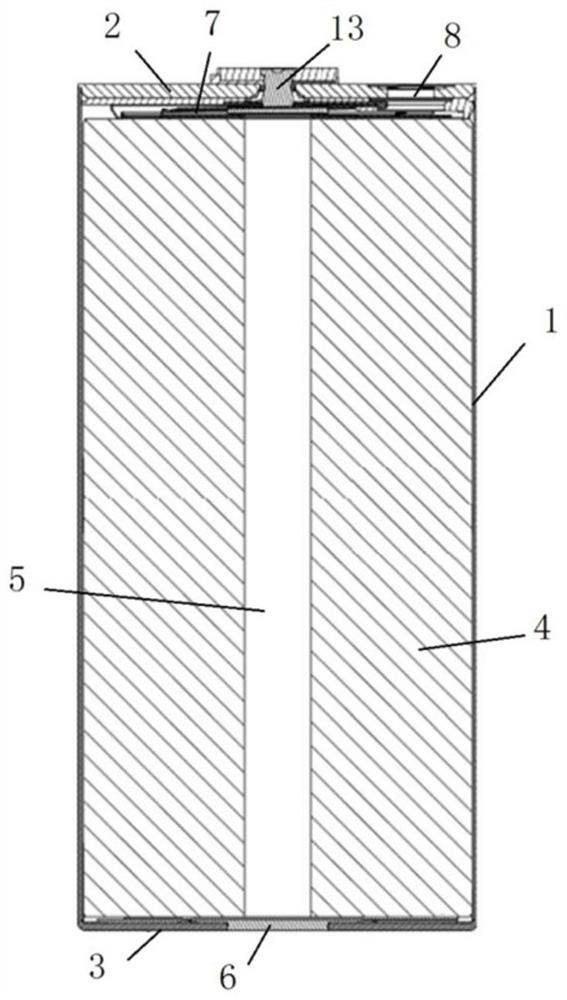

[0057] like Figure 1 to Figure 7 As shown, the cell is a cylindrical cell, and the cell includes a conductive shell 1 , a core body and a cover plate 2 . The conductive shell 1 is an aluminum shell and has a cylindrical shape. The interior of the conductive shell 1 has a cavity. The top of the conductive shell 1 is provided with a top opening, and the bottom of the conductive shell 1 has a shell bottom wall 3. The cover plate 2 covers The top opening of the conductive housing 1 is used to seal the top opening of the conductive housing 1 . The core body is located in the inner cavity of the conductive shell 1 and the core body is a winding core 4 which is rolled into a cylindrical shape. There is a central hole 5 running through up and down in the center of the winding core 4, and the top of the winding core 4 has a negative pole lug. The bottom end has positive tabs.

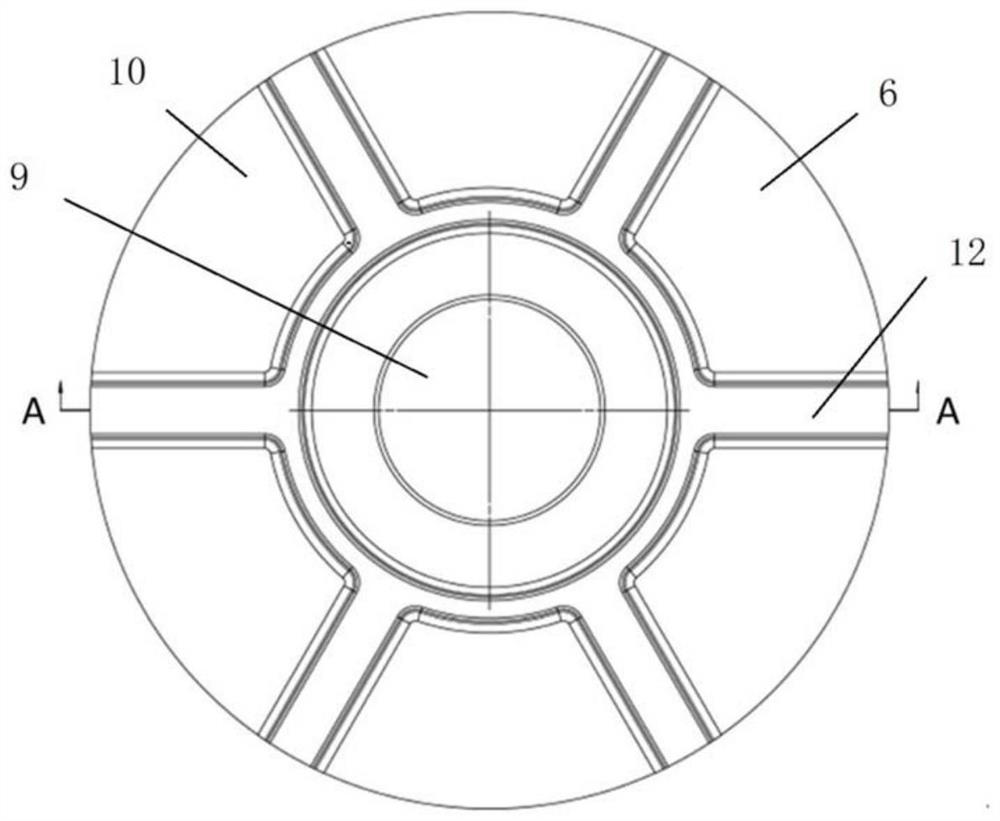

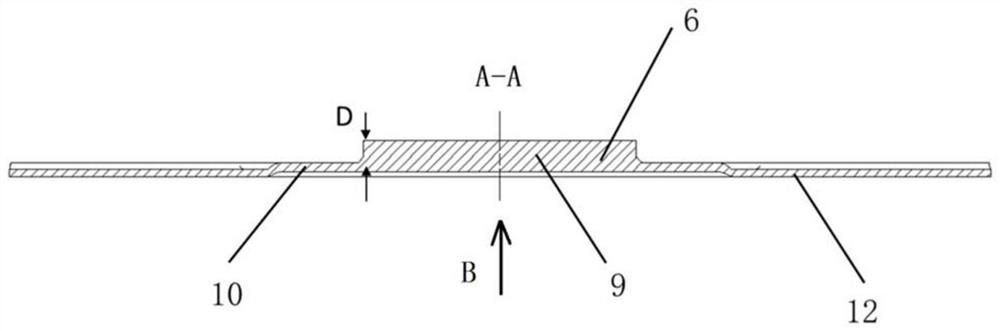

[0058] The battery cell also includes a positive electrode current collecting disk 6 and a negative electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com