BZS cavity composite floor structure and construction method thereof

A construction method and technology for floor slabs, which are applied to floors, building components, building structures, etc., can solve the problems of difficult construction of gypsum mould boxes, unsatisfactory forming conditions, floating displacement of mould boxes, etc., so as to save building materials and reduce the total construction period. The effect of shortening and reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

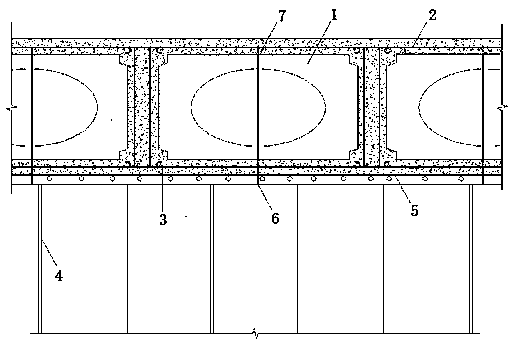

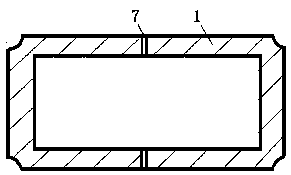

[0031] (1) According to the structural design of the BZS cavity composite floor, the size of the BZS cavity composite mold box provided is 580mm×580mm×200mm; the size of the cubic concrete standard block provided is 60mm×60mm×60mm, and the block is placed on the BZS cavity The four corners under the cavity compound mold box support the mold box to facilitate the flow of concrete into the bottom of the mold box, ensure that the concrete can be vibrated and compacted, and avoid holes, honeycombs, and exposed tendon defects in the concrete at the bottom of the mold box.

[0032] (2) Since the BZS cavity composite mold box is light in weight and has good water absorption, the mason is required to water it one day in advance before pouring, and then water the mold box before pouring concrete to increase the quality and prevent floating.

[0033] (3) After the BZS cavity composite mold box is installed, the anti-floating steel bars are tied according to the design requirements, and t...

Embodiment 2

[0037] (1) According to the construction method of the BZS cavity composite floor, prepare the BZS cavity composite mold box, carry out construction preparations, and carry out construction according to the steps of Example 1;

[0038] (2) Concretely analyze and control the new and difficult points in the construction process:

[0039] 1) When pouring and tamping, the construction worker controls the size of the fine concrete aggregate and the slump. The size of the aggregate should not be greater than 30mm, and the slump must be controlled between 180mm and 210mm;

[0040] 2) Unloading workers must put concrete between the ribs of the mold box and prevent excessive accumulation at one time;

[0041] 3) Pouring and compacting must be carried out in layers. The method of skipping ribs is adopted, combined with high-efficiency vibration, and the vibration time is sufficient. Only when there is concrete overflow on the other side of the mold box can the next place be vibrated.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com