Medical nuclear magnetic resonance equipment head processing method

A nuclear magnetic resonance and processing method technology, which is applied in the field of head processing, can solve the problems of unguaranteed concentricity of the center hole, high service life requirements, and installation deviations, etc., to achieve high product concentricity, high production efficiency, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

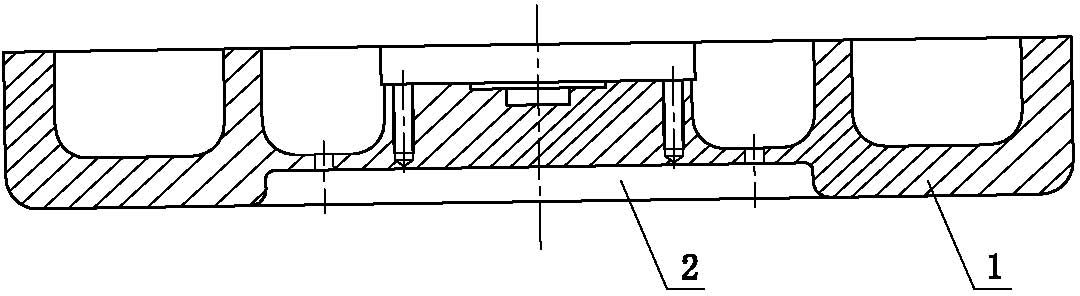

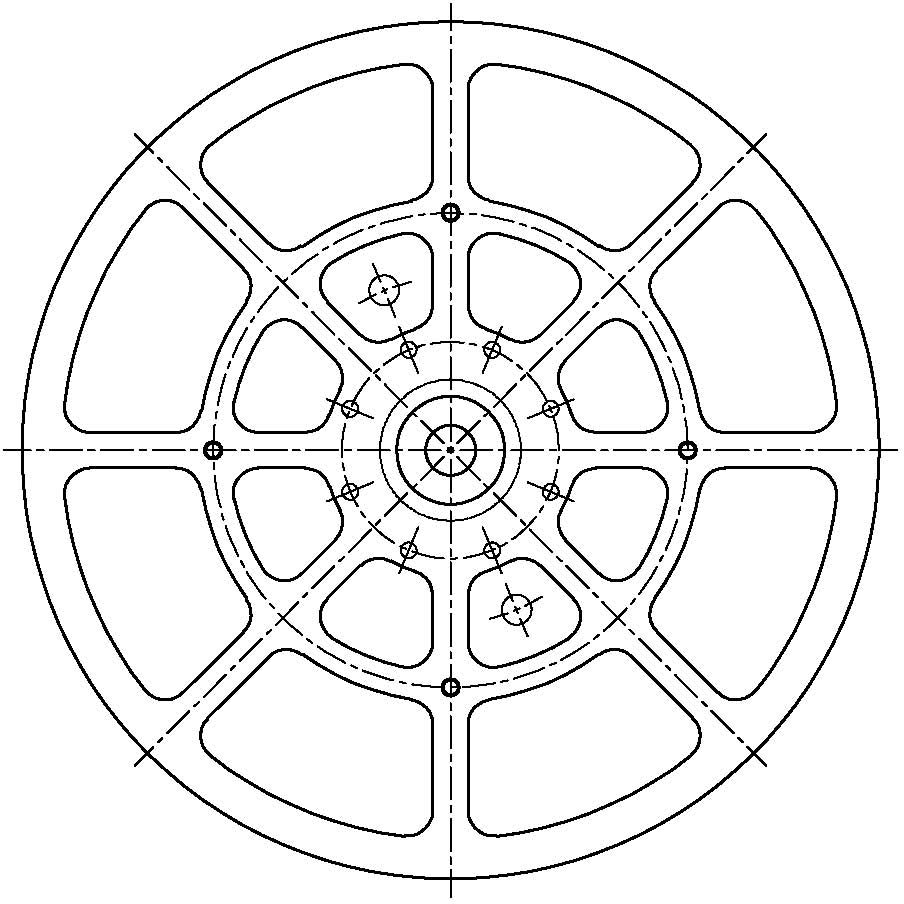

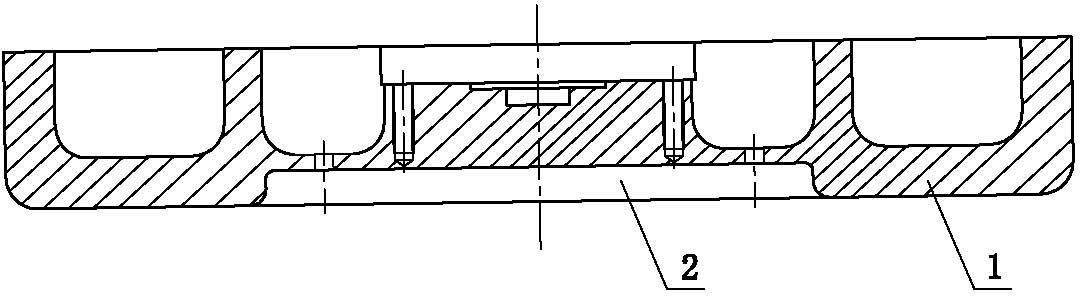

[0019] The present invention first uses the upper die 1 of the head (such as figure 1 , 2 As shown) positive punching is performed on the stainless steel material plate, so that the outer edge of the stainless steel material plate forms an R position to form a rough product of the head; then the center of the rough product of the head after positive punching is opened; after that, the upper mold of the head is disassembled and reversed placed in the opposite direction, and place the rough head product after the above hole is placed on the reversely placed upper mold of the head; through the center stamping head and the punching hole 2 in the center of the upper mold of the head, the rough product of the head is punched centrally, That is, recoil to form a central hole; then trim the outer edge of the rough head and the edge of the central hole to get the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com