Patents

Literature

52results about How to "Not prone to adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

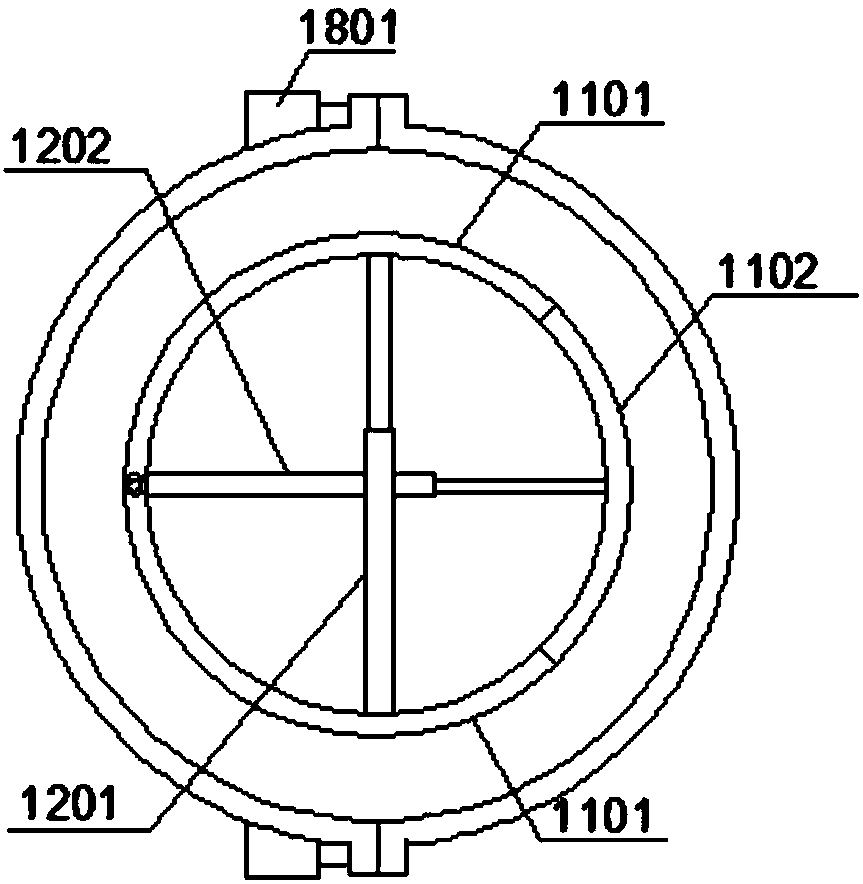

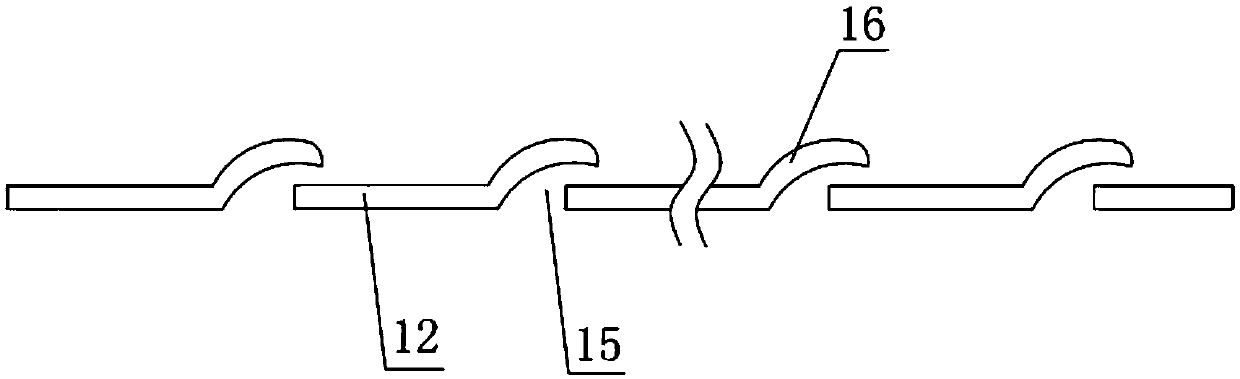

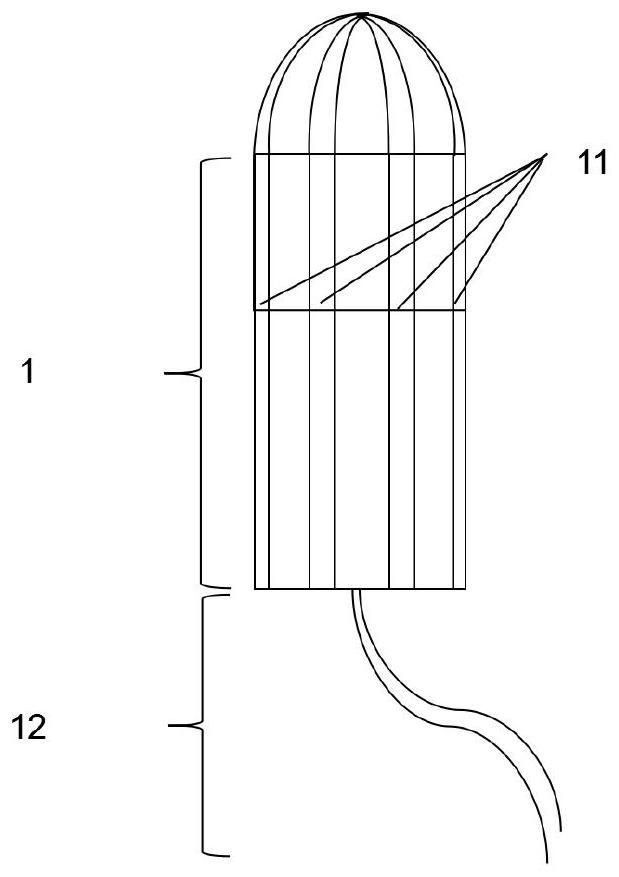

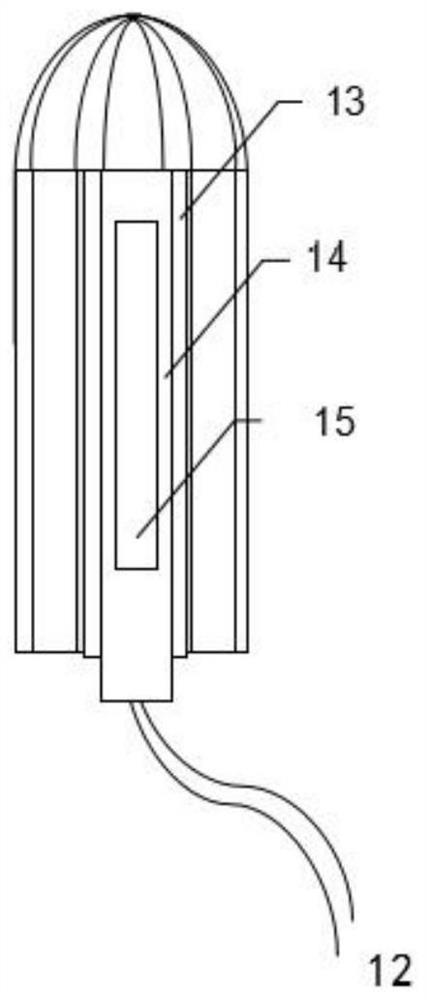

Suppressing vibration method for marine riser vortex-induced vibration and suppressing vibration apparatus thereof

InactiveCN101387188AReduce the amplitudeReduce weightDrilling rodsDerricks/mastsVertical tubeEngineering

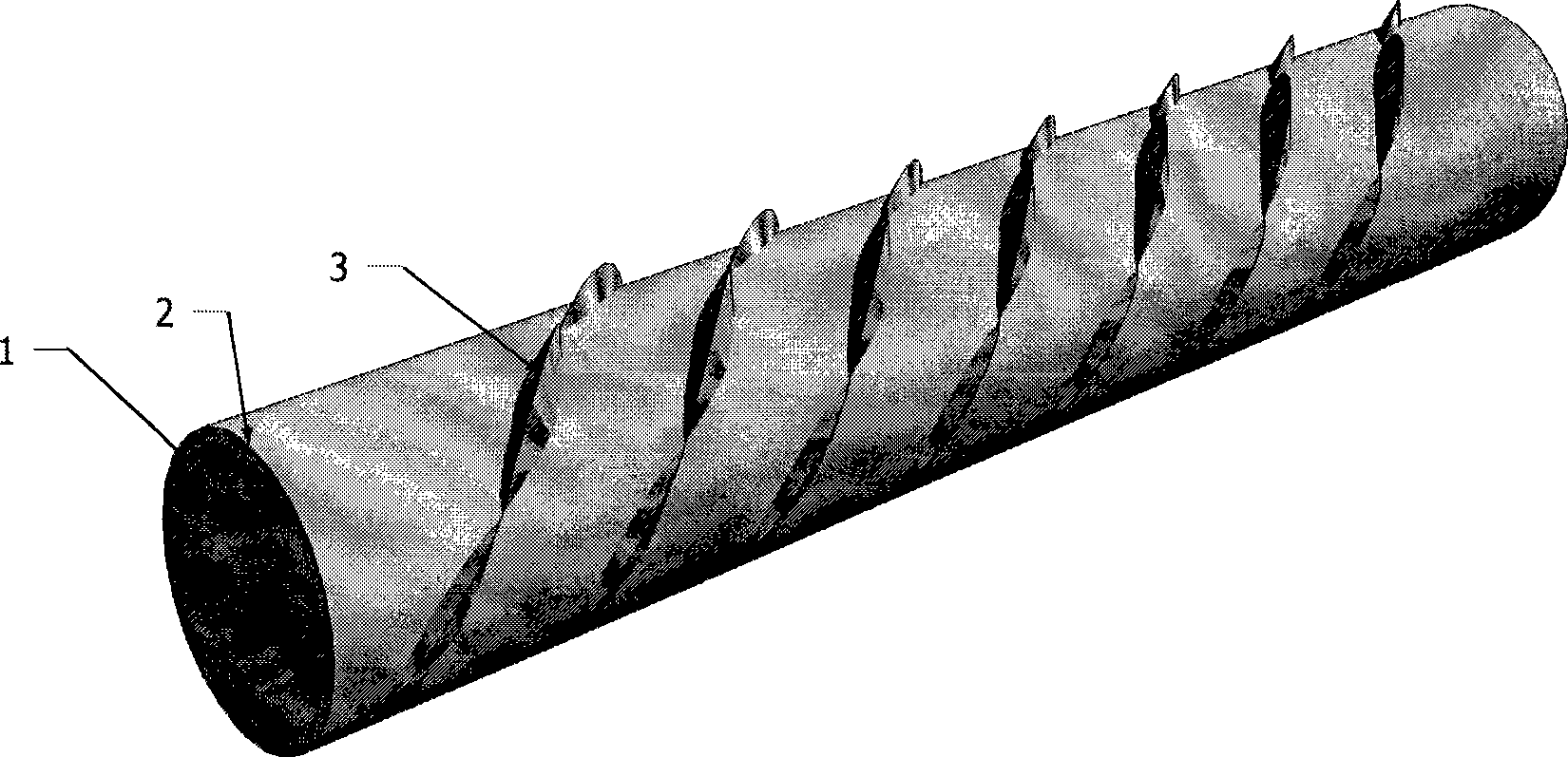

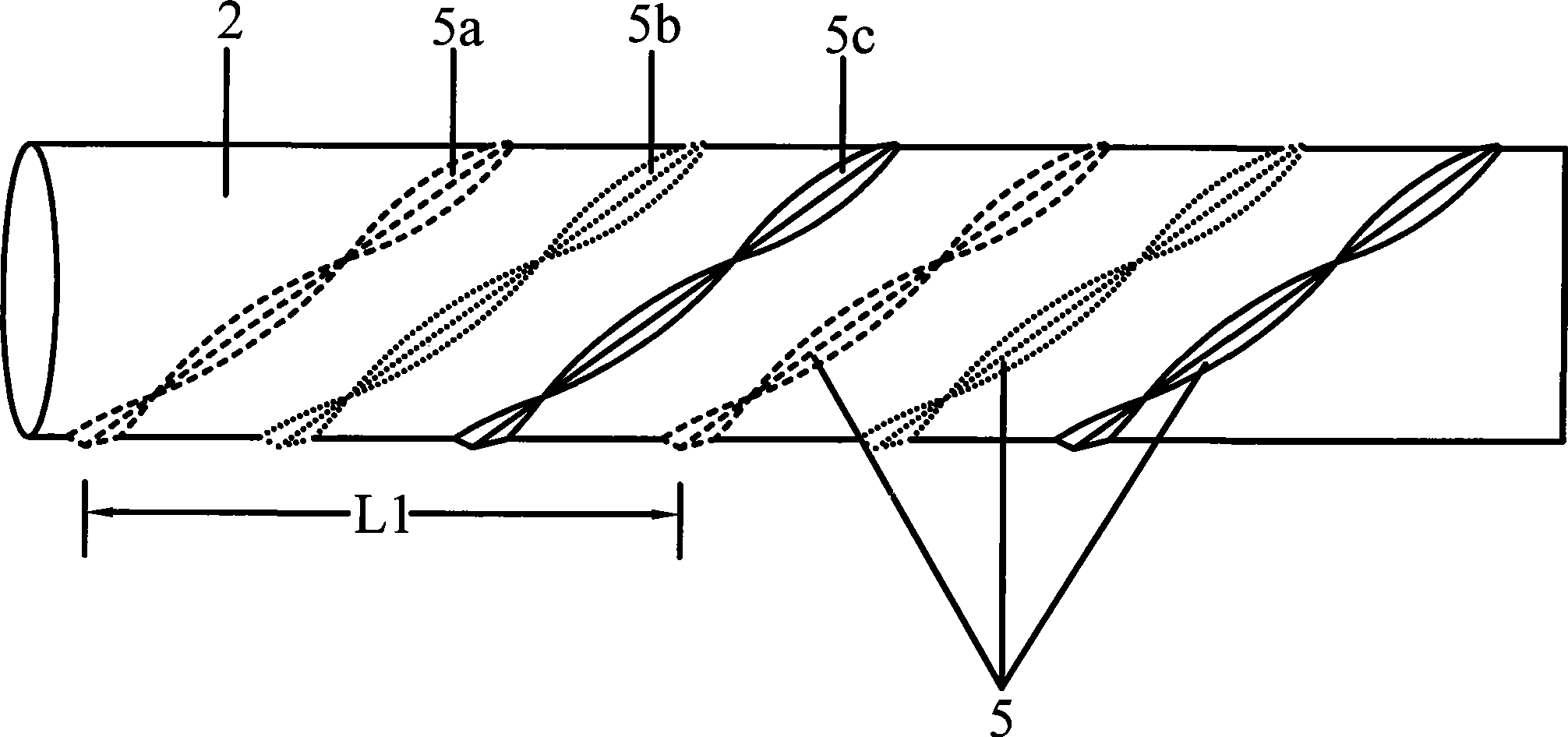

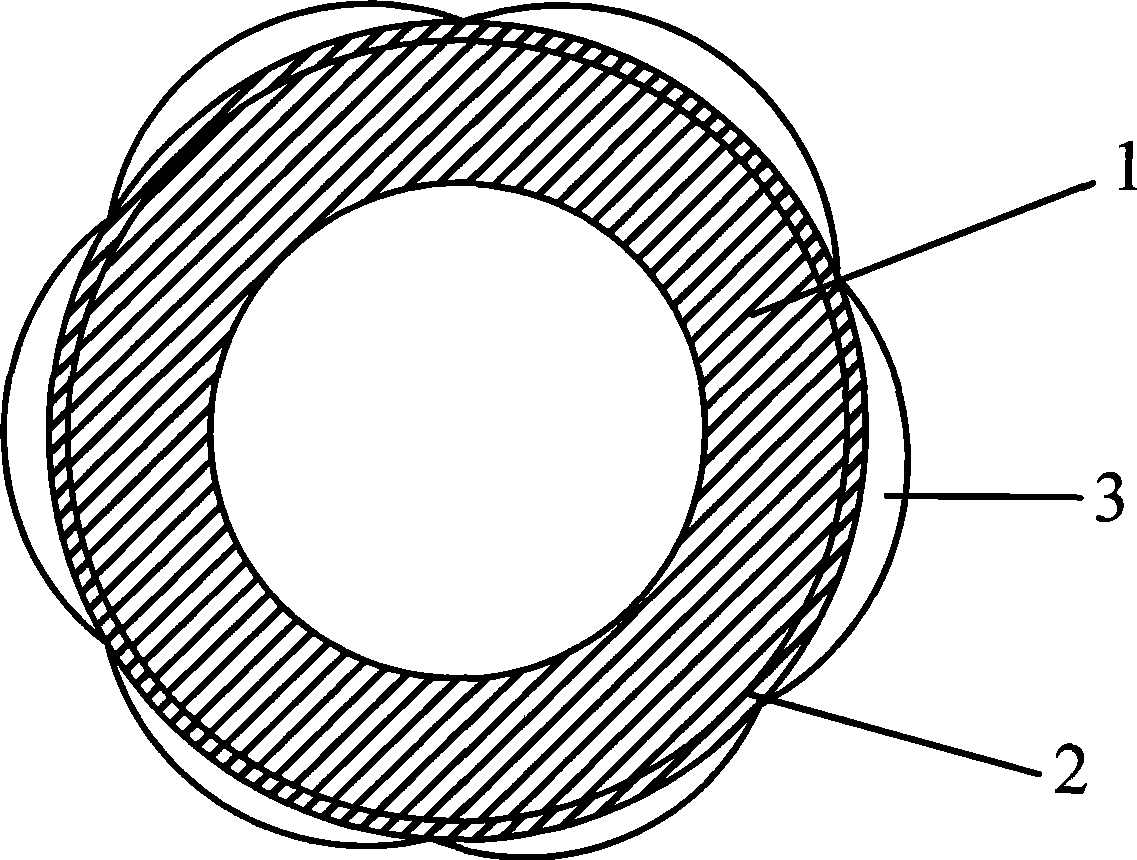

The invention relates to a vibration inhibiting method and a vibration inhibiting device capable of effectively inhibiting vortex-induced vibration of a marine riser. The vibration inhibiting device is provided with the riser, an air guide sleeve on the riser, and a flow disturbing device which is fixed on the air guide sleeve, and is characterized in that the flow disturbing device is a flow disturbing rib which is formed by a plurality of end-to-end crescent-shaped flow disturbing ribs; and the flow disturbing rib is arranged on the outer surface of the air guide sleeve in the form of being winded by a spiral line, and the screw pitch of the flow distributing rib is 5 to 15 times of the outside diameter of the riser. The vibration inhibiting method comprises the following steps: firstly, the air guide sleeve which is enwrapped and fixed on the outer surface of the riser is prepared according to the outside diameter of the riser required to be protected; secondly, one flow disturbing rib or a plurality of flow disturbing ribs which are manufactured are fixed on the outer surface of the air guide sleeve in advance according to the screw pitch or the position of the spiral line which is predefined and marked on the outer surface of the air guide sleeve; and thirdly, the air guide sleeve provided with the flow disturbing rib is arranged on the outer surface of the riser. Therefore, the vibration inhibiting method and the vibration inhibiting device can effectively inhibit the vortex-induced vibration of the riser; the weight of the device can be reduced from 30 percent to 60 percent; and the construction cost can be greatly reduced.

Owner:OCEAN UNIV OF CHINA

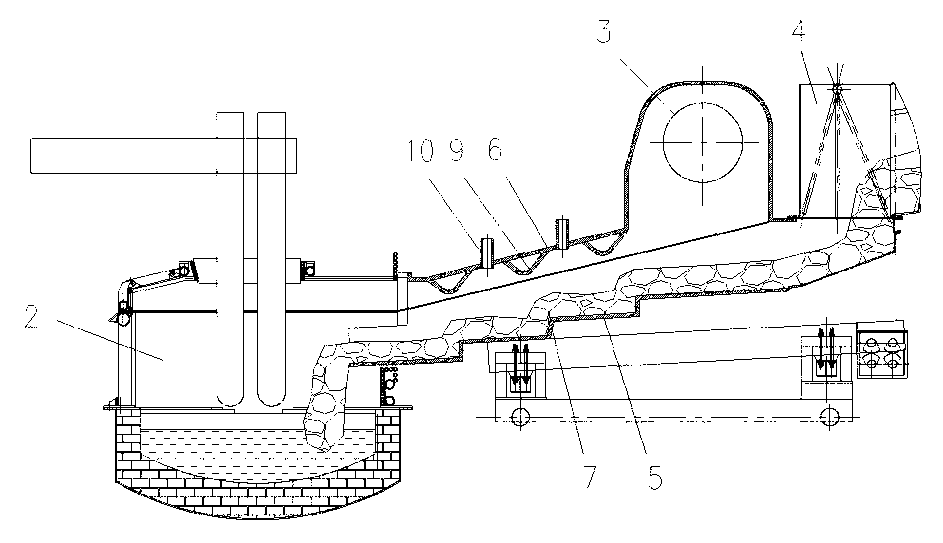

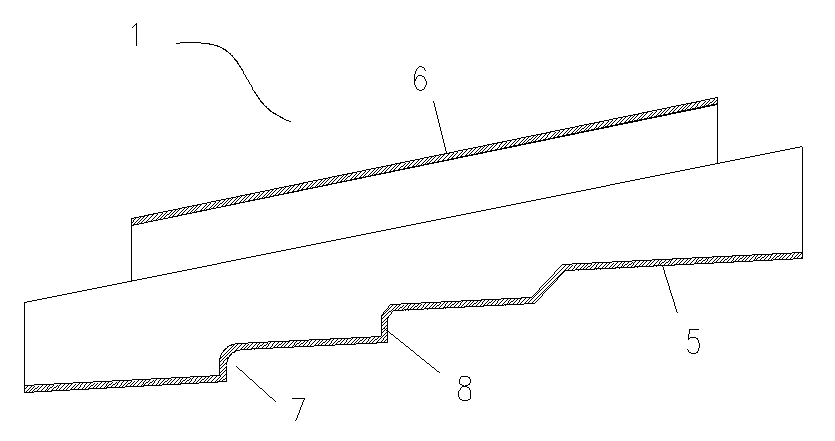

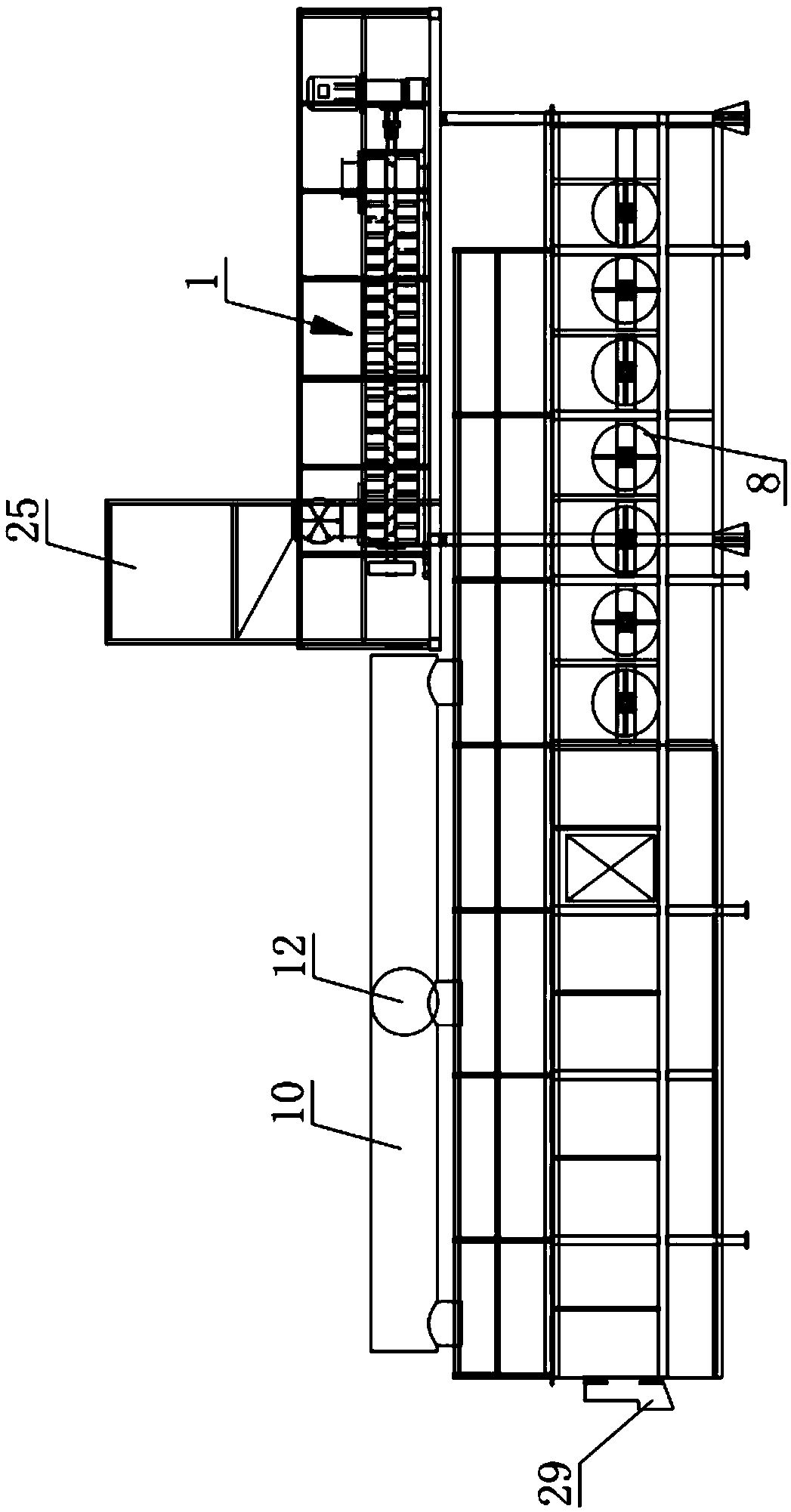

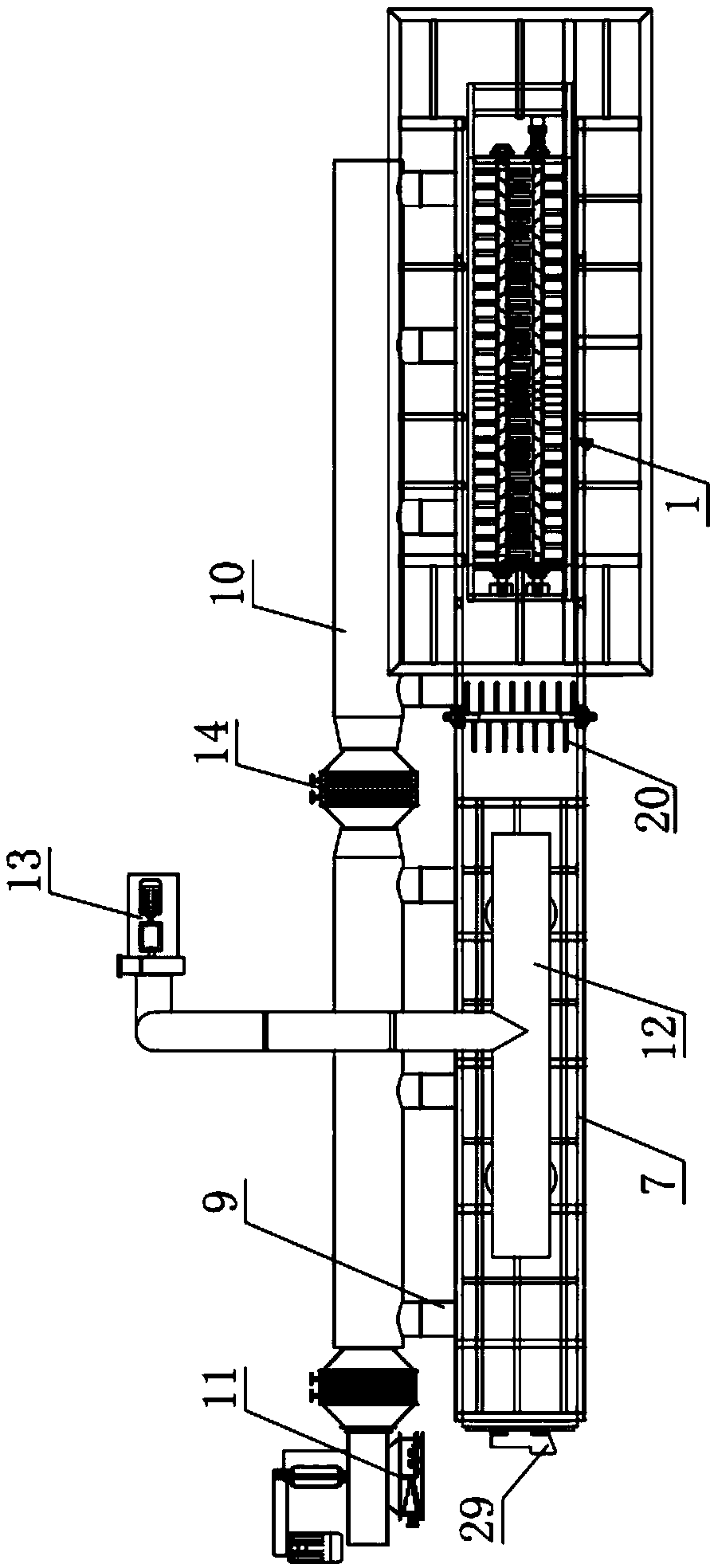

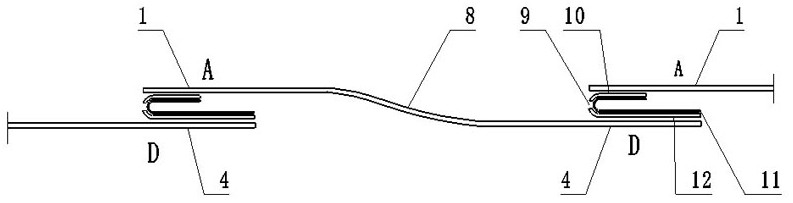

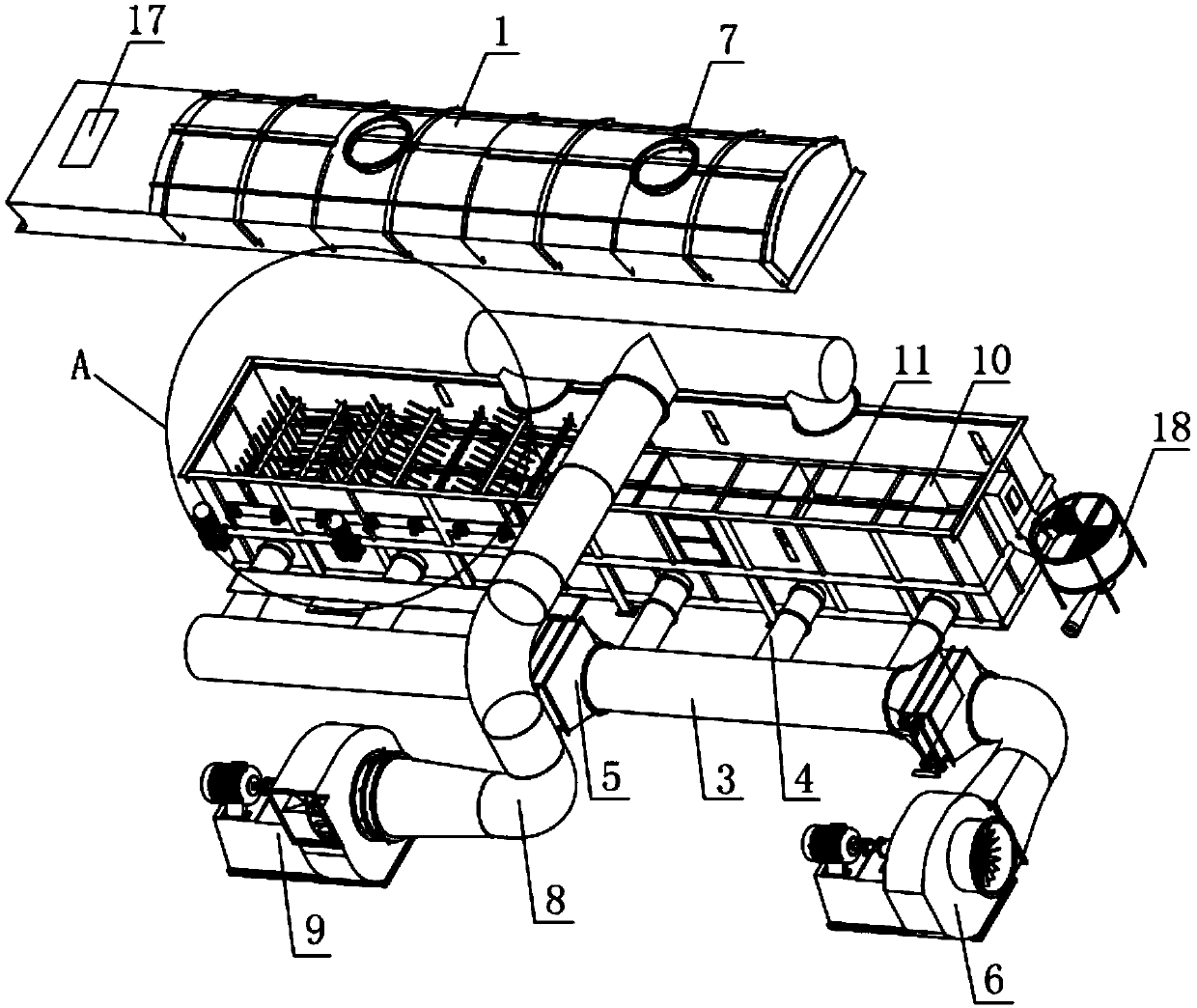

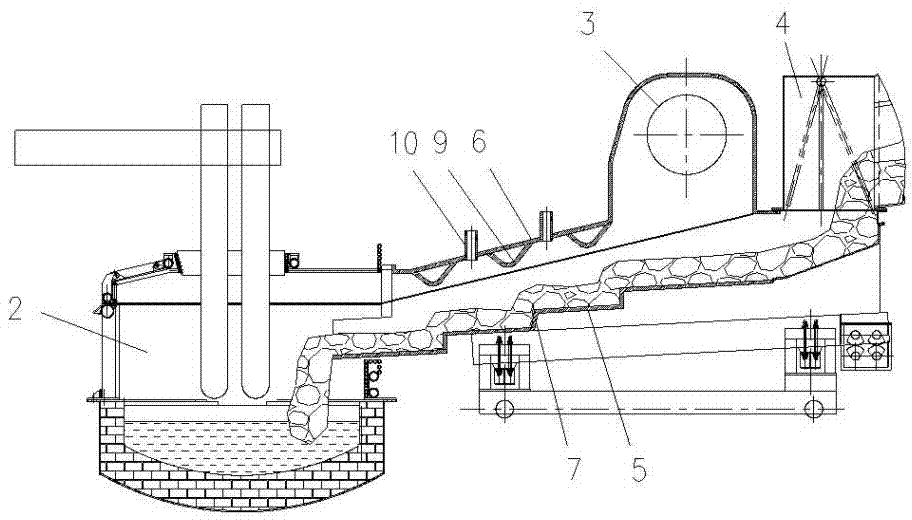

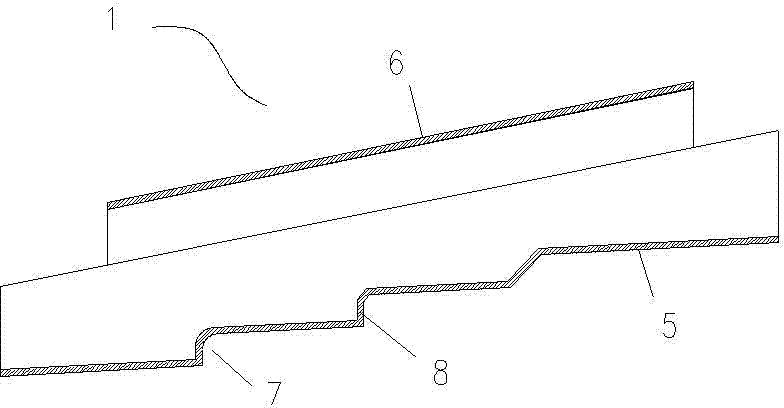

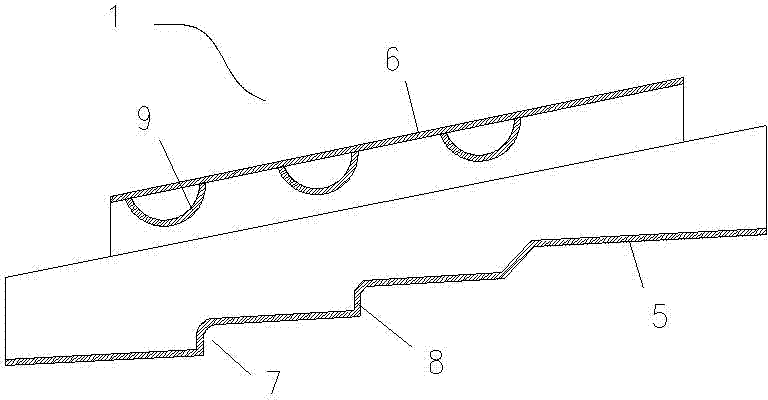

Steel scrap preheater and preheating method of electric-arc furnace step disturbance culvert

The invention discloses a scrap preheater of an electric-arc furnace step disturbance culvert. The scrap preheater comprises a heat-exchanging culvert, the low side of the heat-exchanging culvert is connected with a furnace, the high side of the heat-exchanging culvert is respectively connected with a smoke-collecting and dust-removing pipe and a feed sealing device, the heat-exchanging culvert comprises a material- conveying groove and a smoke guide cover, the material-conveying groove is used for conveying steel scrap materials to the electric-arc furnace, the smoke guide cover is covered on the material- conveying groove and is used for guiding smoke, the heat-exchanging culvert is provided with at least one cross-section abrupt change structure in the height-extending direction, and the cross-section abrupt change structure is used for disturbing the steel scrap material flow state and the smoke flow state. The invention further discloses a preheating method of the electric-arc furnace step disturbance culvert, and the steel scrap materials can be added to the material-conveying groove by the feed sealing device; the steel scrap material flow state is disturbed under the combined action of the cross-section abrupt change structure on the heat-exchanging culvert and horizontal vibration, so that the steel scrap materials have air permeability in a certain area; and the smoke flow state can be disturbed in the smoke guide cover, so that the smoke and the steel scrap materials can be subjected to heat exchanging fully.

Owner:CISDI ENG CO LTD

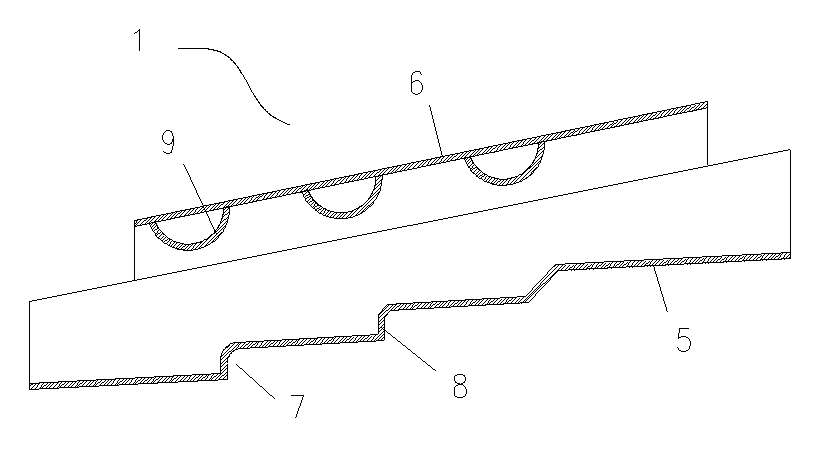

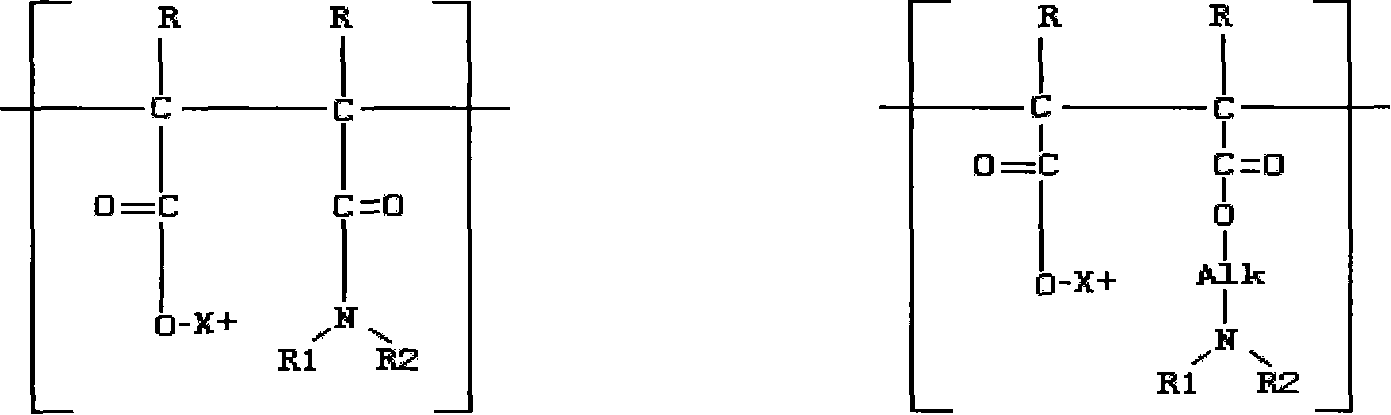

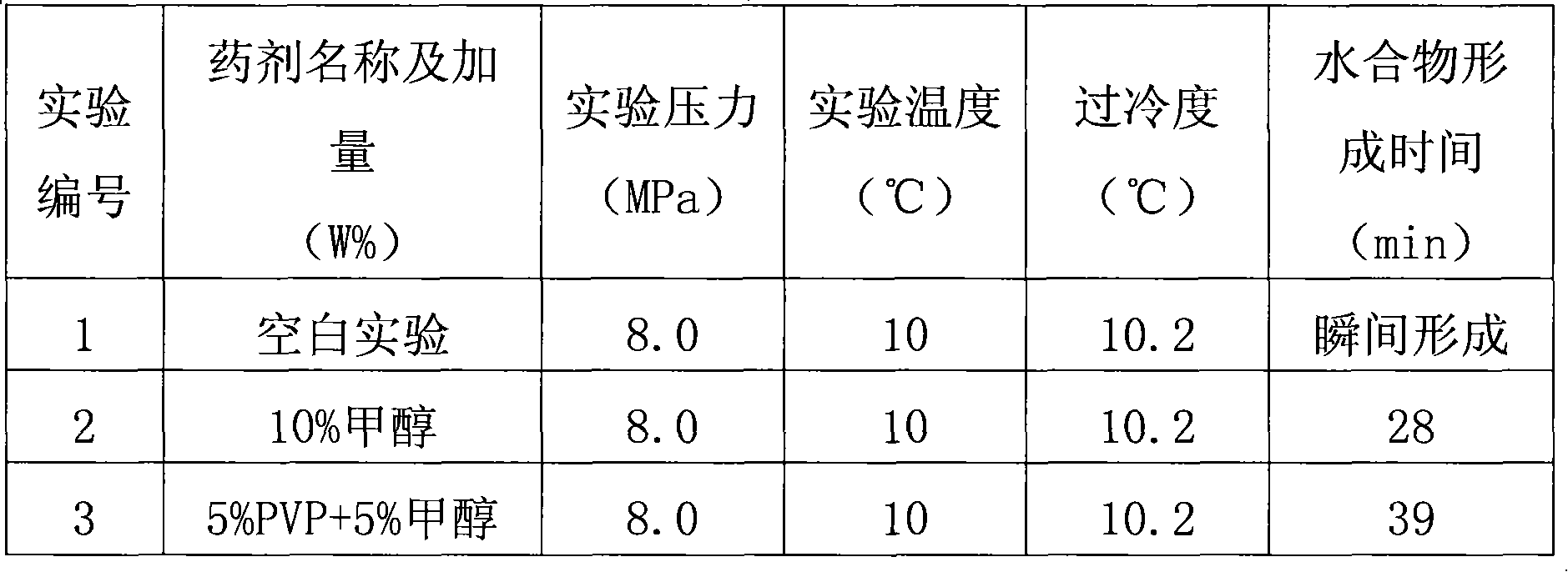

Inhibitor for preventing the formation of natural gas hydrates of high-sulfur acid gas fields

ActiveCN101608118APrevent anti-corrosion effectNot easy to aggregateGaseous fuelsFluid removalBiopolymerCO2 content

The invention relates to an inhibitor for preventing the formation of natural gas hydrate of high-sulfur acid gas fields, which comprises the following components in percentage by weight: 5 to 30 percent of biopolymer, which has the weight average molecular weight of between 3,000 and 10,000, of vinyl pyrrolidone and vinyl caprolactam or terpolymer, which has the weight average molecular weight of between 65,000 and 100,000,of the vinyl pyrrolidone, the vinyl caprolactam and N, N-(dimethylamino)ethyl methacrylate, 5 to 30 percent of amido group-containing and lipid group-containing polyesteramide or amidation product which is formed by polymerizing maleic anhydride, a derivative thereof and alkyl alcohol amine and has the number average molecular weight of between 1,000 and 15,000, 10 to 15 percent of surfactant and defoaming agent, and 50 to 70 percent of mixture of methanol or ethanol and glycol. The inhibitor has better inhibition effect on acid natural gas hydrate which has the H2S content between 0 and 8 percent, the CO2 content between 0 and 5 percent, and no hydrocarbon components above C2.

Owner:PETROCHINA CO LTD

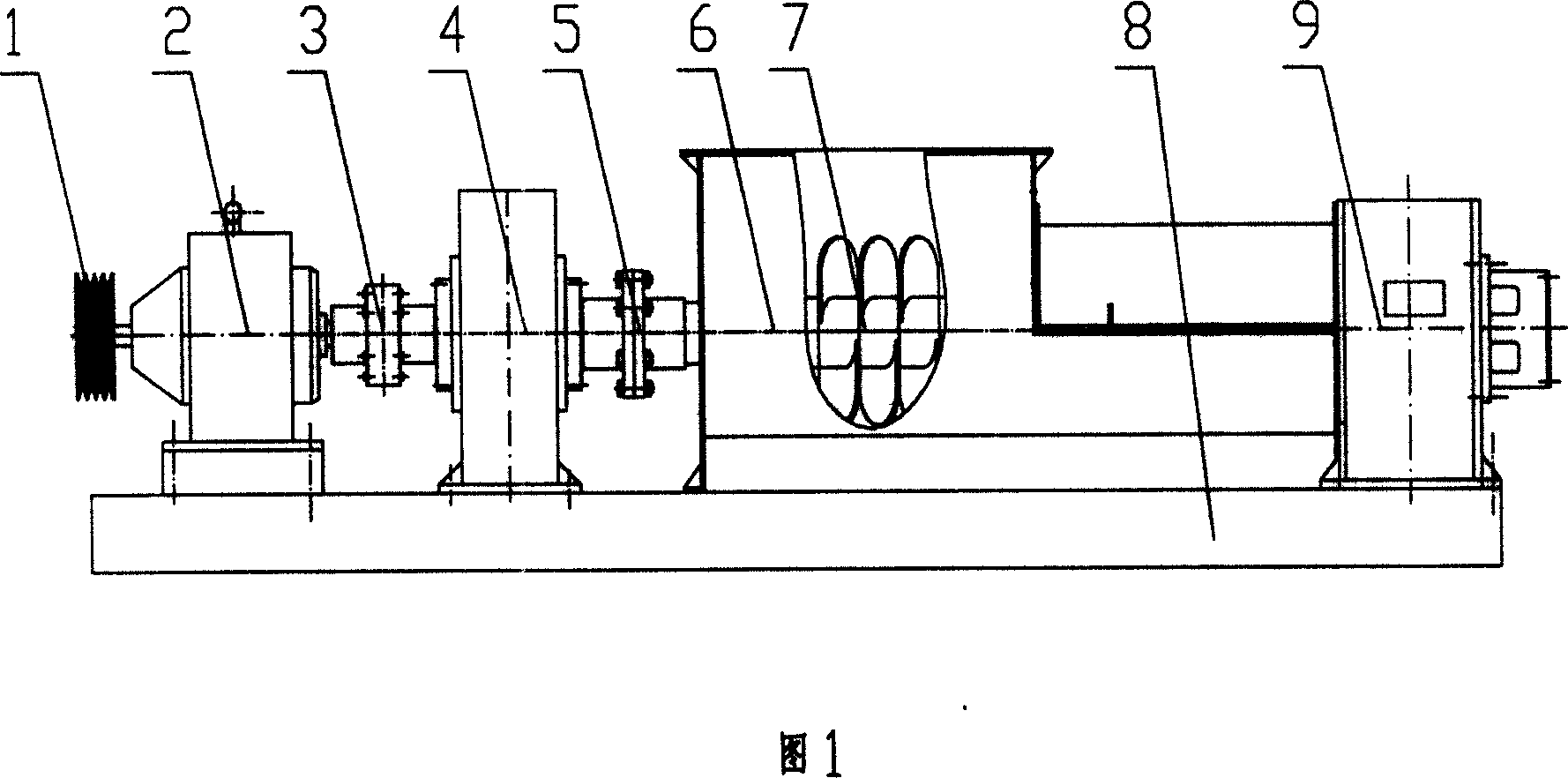

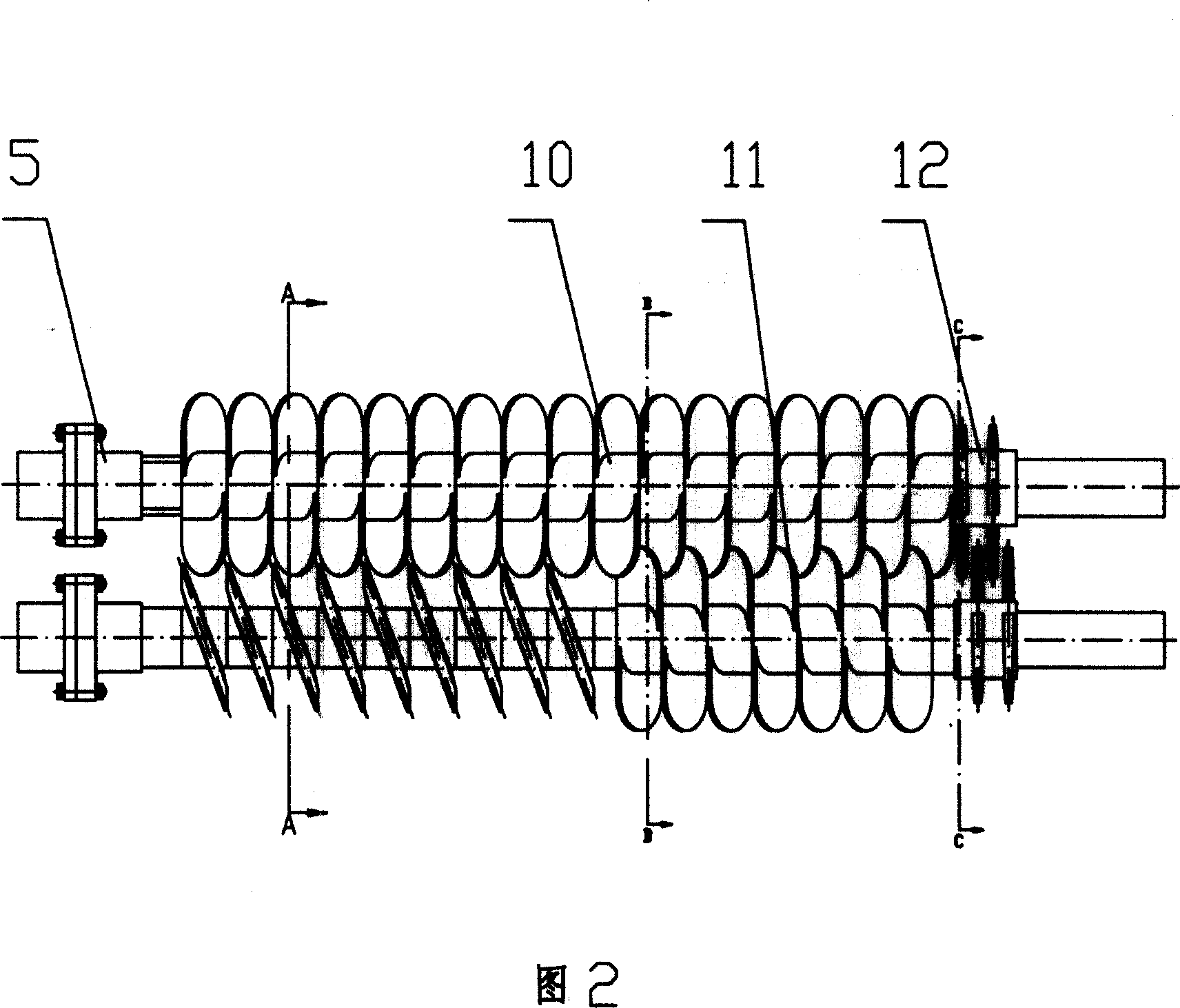

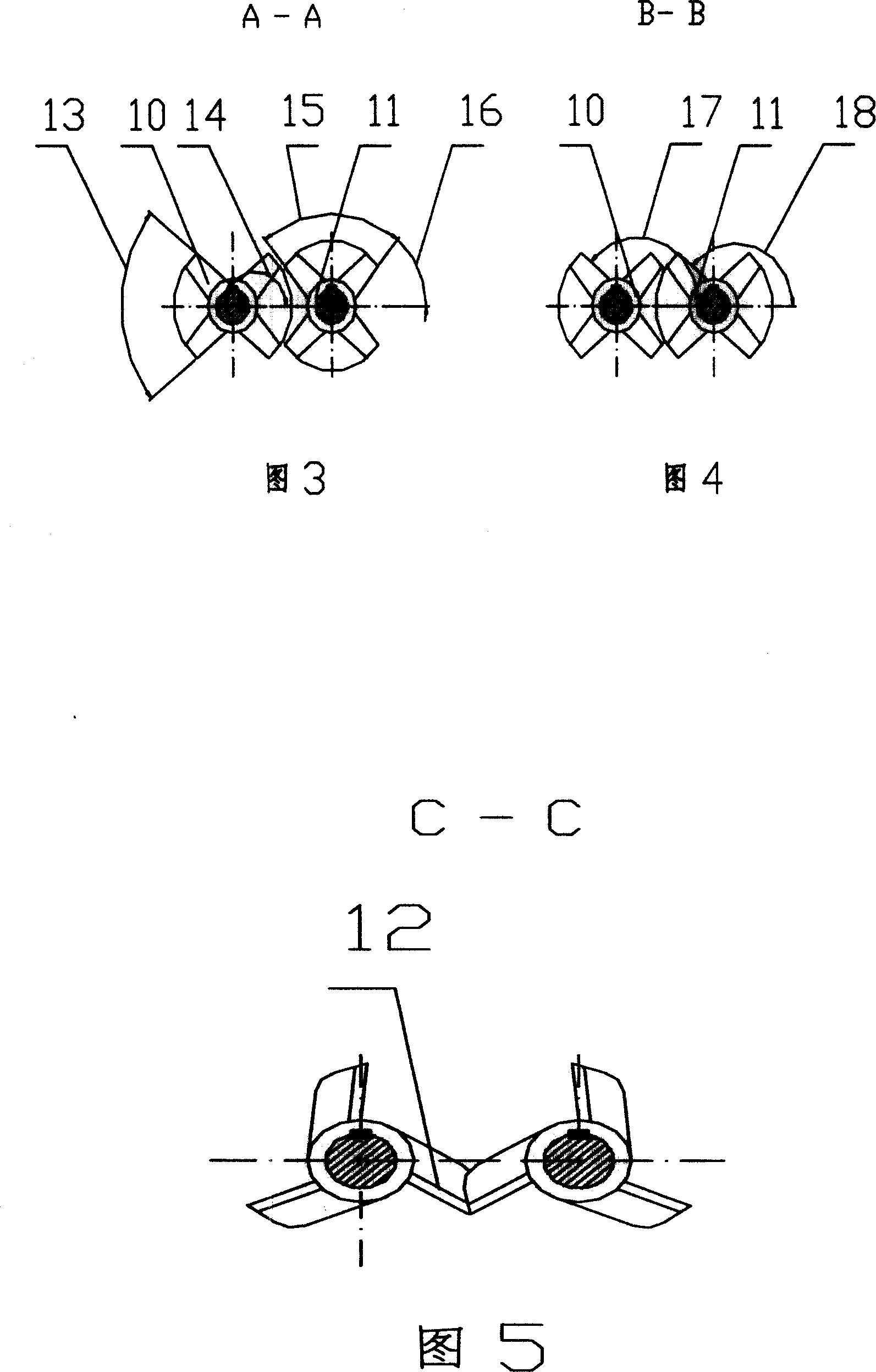

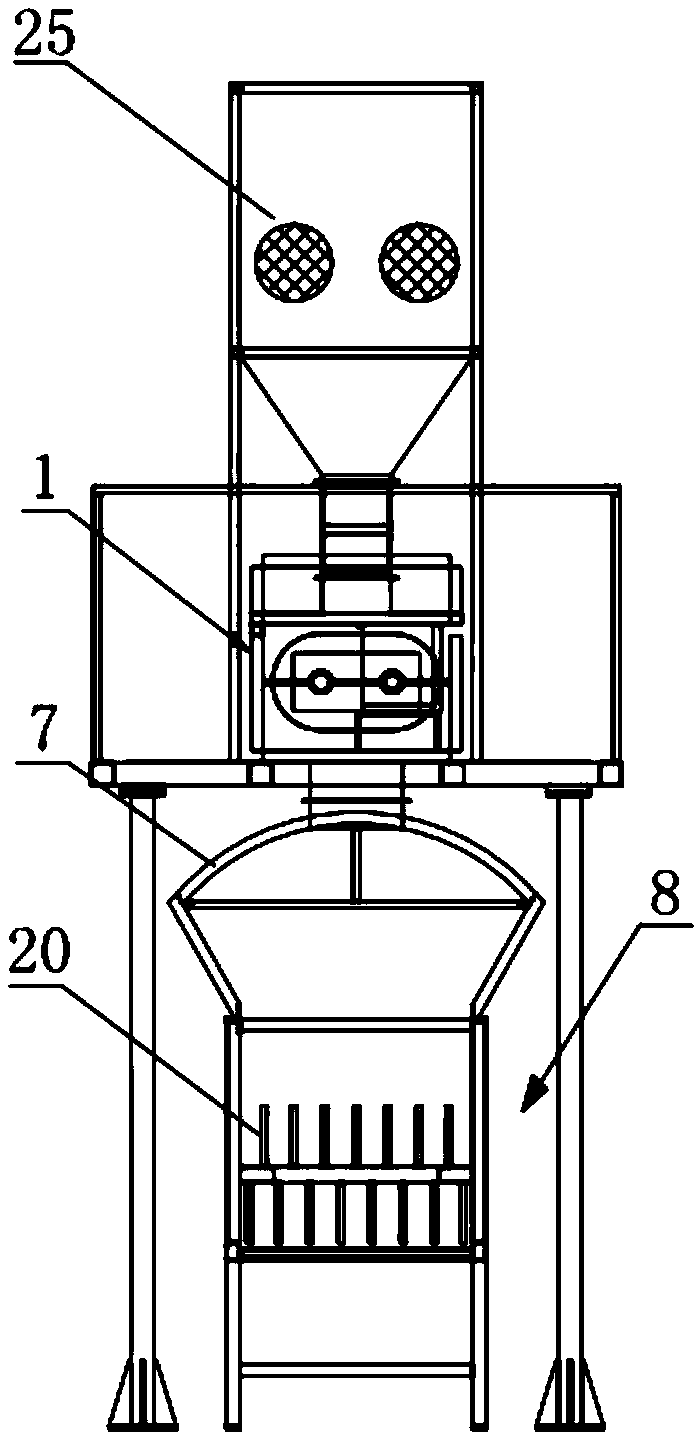

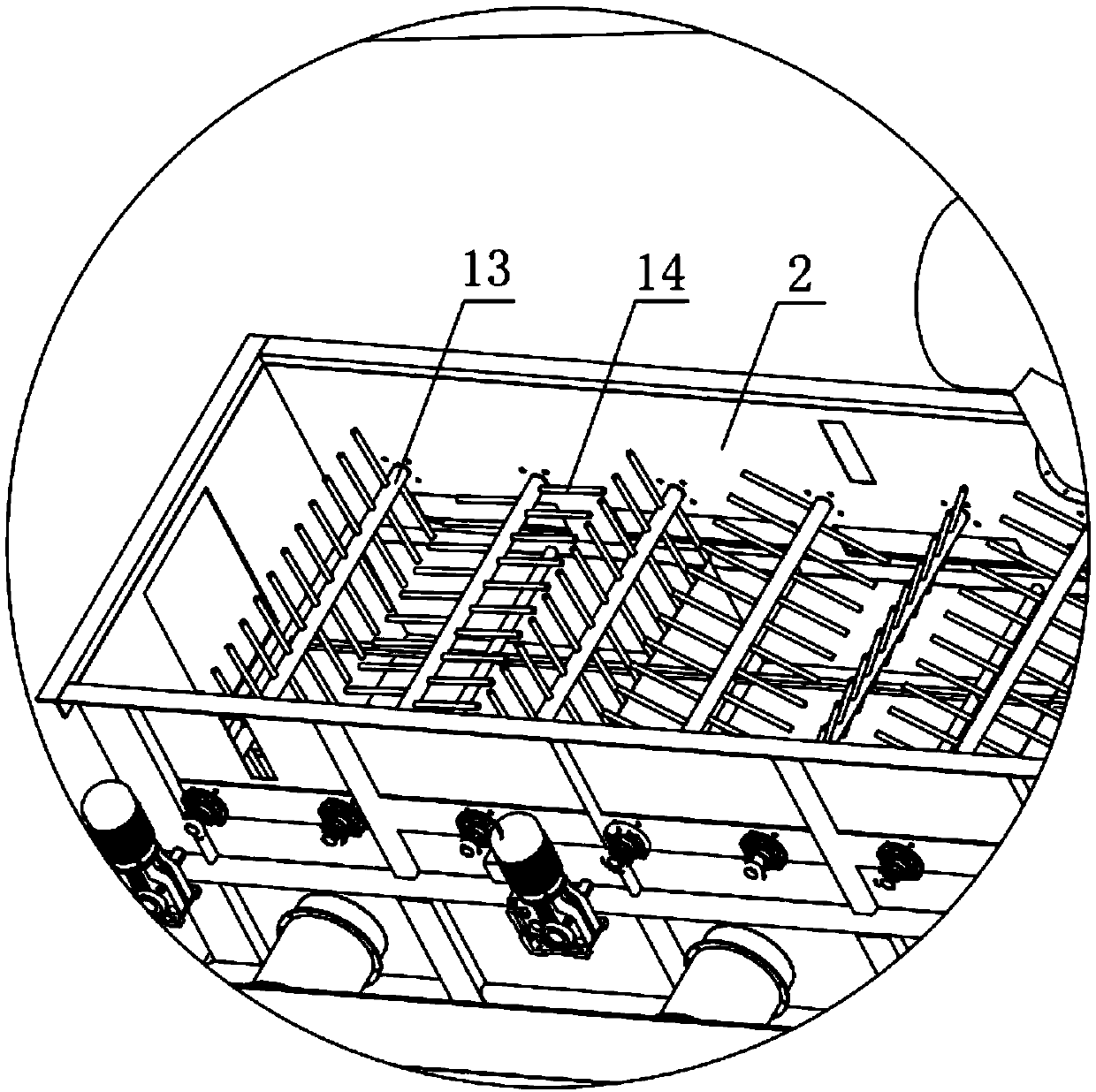

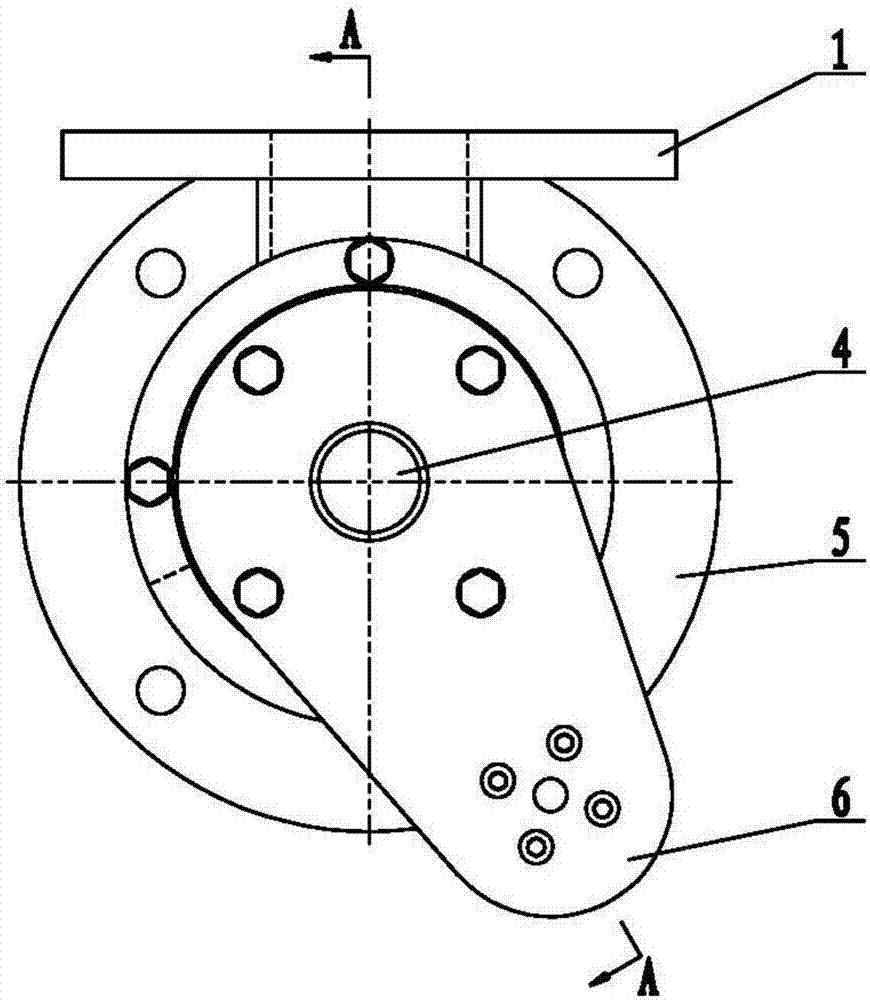

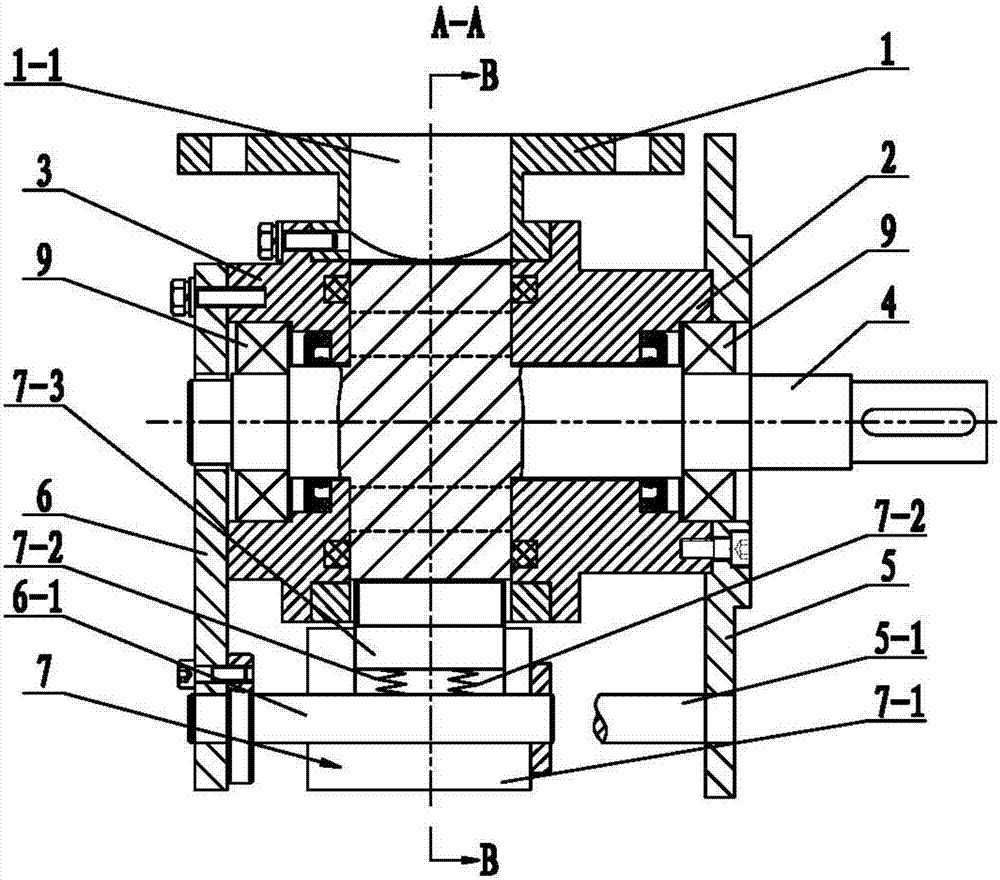

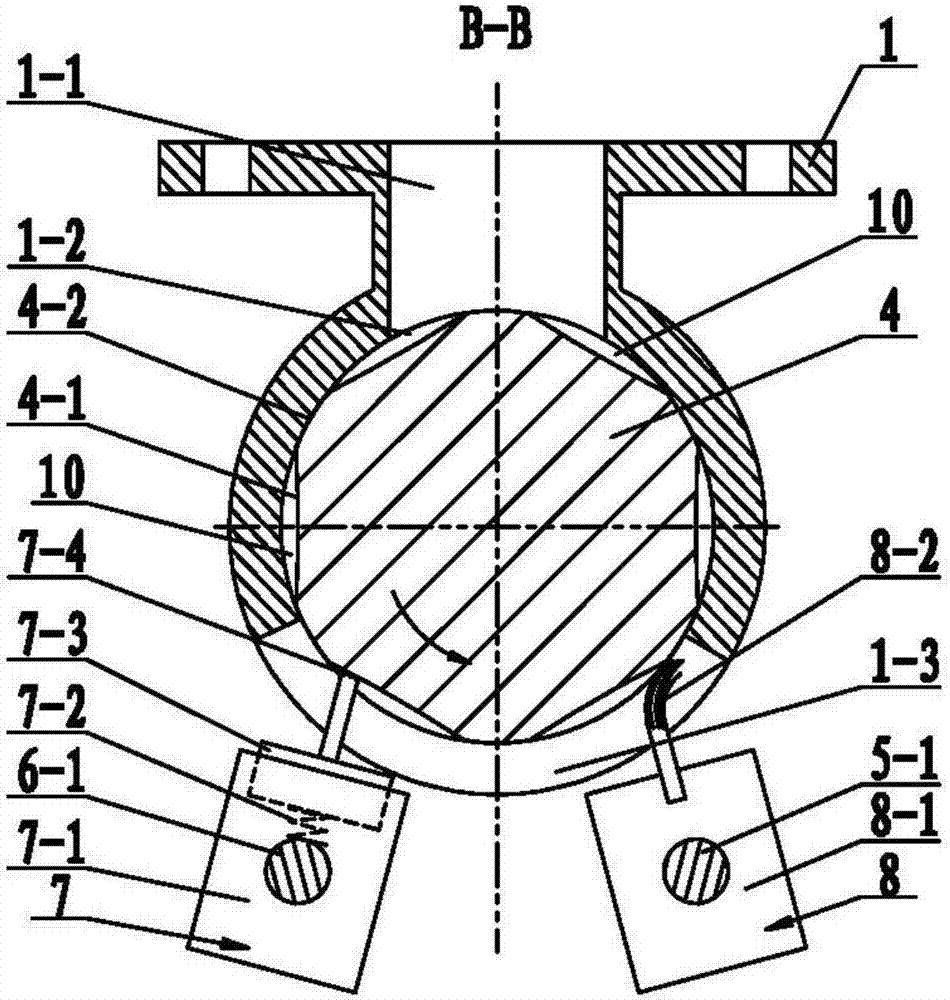

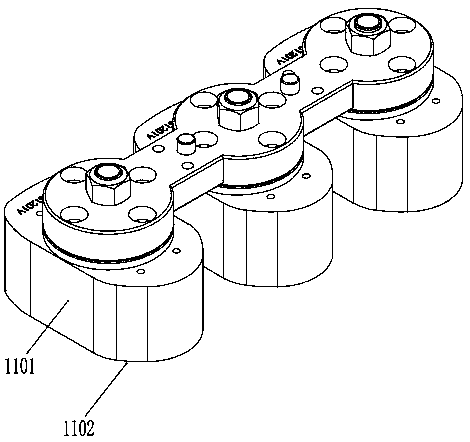

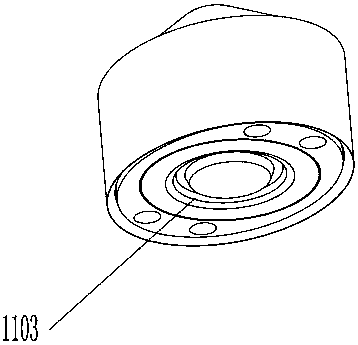

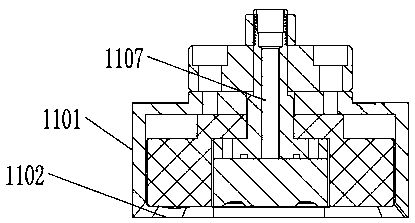

Coal slime rubbing-kneading equipment

ActiveCN101125307AImprove crushing effectNot prone to adhesionGrain treatmentsPulp and paper industryReducer

The present invention relates to a coal slurry twine and the device, wherein, the power source, the reducer, the gear box, the feed bin and the material outlet hopper are arranged on the bottom frame, and the transmission shaft is a pair of shafts rotating in an opposite direction. The two rotating shafts are respectively provided with spiral cutting blades with different rotating direction, and synchronously the two rotating shafts are respectively provided with the non spiral cutting blades. The cutting blade on the crossed part of the phase positions of the left rotating cutting blade and the right cutting blade has the cutting up effect for the coal slurry. The cutting blade on the equal part of the phase positions of the left rotating cutting blade and the right cutting blade has the tearing up effect for the coal slurry. The invention makes cutting and tearing to the coal slurry after dehydration by cutting and tearing methods, and synchronously makes the coal slurry transported along the axial direction. When cutting and tearing the material with certain glutinosity, the phenomenon of glued connecting, agglomeration and blocking is unlikely to be produced, and the invention particularly has good effect for the coal slurry smashing after dehydration.

Owner:光大清洁技术股份有限公司

Alginate fiber non-woven fabric capable of being gelled in water and preparation method and application thereof

ActiveCN110106629AReduce usageImprove gel performanceLiquid/gas/vapor removalNon-woven fabricsFiberPolymer science

The invention discloses an alginate fiber non-woven fabric capable of being gelled in water and a preparation method and application thereof, and belongs to the technical field of non-woven fabric production. The alginate fiber non-woven fabric is prepared from alginate fibers, skeleton fibers and a modified solvent, wherein the mass ratio of the alginate fibers to the skeleton fibers is (30-80):(20-70). The alginate fiber non-woven fabric capable of being gelled in water is soft in texture and is gelled in water, after the alginate fiber non-woven fabric is applied to the skin, the effects ofmoisturizing and whitening can be achieved. The non-woven fabric changes the situation that a traditional facial mask base cloth only can be used as a medium, and the alginate fiber non-woven fabricis convenient to carry and easy to preserve.

Owner:绍兴蓝海纤维科技有限公司

Fully-automatic continuous film-covering drying production line for plastic foam particles

The invention relates to the technical field of machining machinery for foam particles, and particularly relates to a fully-automatic continuous film-covering drying production line for plastic foam particles. The fully-automatic continuous film-covering drying production line for the plastic foam particles comprises a film-covering mechanism, a feeding mechanism, a spraying device and a drying mechanism, wherein the film-covering mechanism comprises a film-covering box body provided with an inner cavity and a stirring device arranged in the film-covering box body; the stirring device comprises a rotary shaft; spiral sheets are axially arranged on the rotary shaft in the axial direction of the rotary shaft; the spiral sheets comprise continuous spiral sheets used for pushing materials anddiscontinuous spiral sheets used for carrying out uniform and comprehensive stirring on a film-covering liquid and the particles to enable the surfaces of the particles to be uniformly wrapped with the film-covering liquid; each discontinuous spiral sheet is composed of a plurality of tooth sheets in a spiral manner and at intervals; the left tooth side of one tooth sheet of each two adjacent tooth sheets and the right tooth side of the other tooth sheet are arranged on a spiral line; and the outer-side tooth side of each tooth sheet is arranged in a manner of approaching to and being tangential with the inner wall of the film-covering box body. According to the fully-automatic continuous film-covering drying production line for the plastic foam particles, nonintermittent and continuous production is realized by pushing materials while stirring; and the fully-automatic continuous film-covering drying production line for the plastic foam particles is high in yield, uniform in coating, rapid in drying, low in energy consumption, and high in automation degree.

Owner:菲尔普(青岛)新材料有限公司

Making and using method of Fusarium head blight grain fungus strains

ActiveCN108277165ASingle particle size is smallReduce volumeFungiMicroorganism based processesDiseaseBiotechnology

The invention belongs to the field of plant fungous disease pathogen culture, and more specifically discloses a making method and a using method of Fusarium head blight grain fungus strains. The making method is used for solving problems in the conventional fungus inoculation identification method that the method is complex, long time storage of fungus liquid is difficult to realize, and fungus inoculation success rate is low. The making method comprises following steps: grains with husk are immersed in 5% mung bean water to maintain 60% water holding capacity, and are packaged with bags; compacting is carried out, and the bags are sealed to prepare fungus tubes; the fungus tubes are subjected to high temperature high pressure sterilization, and are cooled to room temperature in the air; the two ends of each fungus tube are inoculated with fungus, and culture is carried out at a dark constant-temperature ventilative high humidity environment, and then obtained fungus strains are transferred into ventilative paper bags, are dispersed, are subjected to airing at cold and ventilative places, and are sealed in ziplock bags for low temperature storage in dark. The using method comprisesfollowing steps: activity is detected; after heading before flowering, basal spikelet side floret glumelle is inoculated with the fungus strains, packaging moisture retention is carried out until lemma becomes brown and a packaging layer is removed, and then mist moisture retention is carried out for 28d at high humidity. The advantages are that: 1, the obtained Fusarium head blight grain fungusstrains can be stored for a long term; 2, Fusarium head blight grain fungus strains prepared via one time of preparation can be used in a plurality of times, using amount is low, and transportation isconvenient; and 3, fungus inoculation method is simple, and is high in efficiency, incidence of disease is high, and disease resistance identification results are accurate.

Owner:CROP SCI RES INST SHANXI ACADEMY OF AGRI SCI

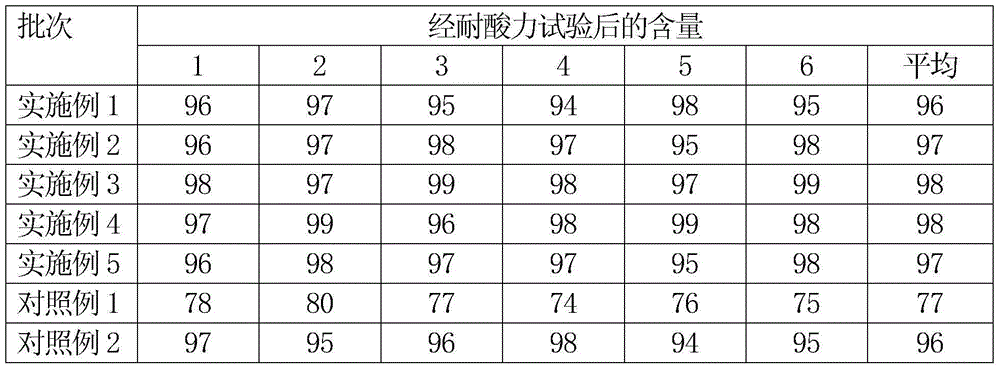

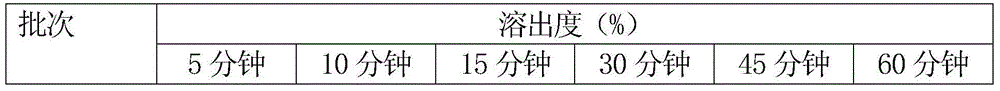

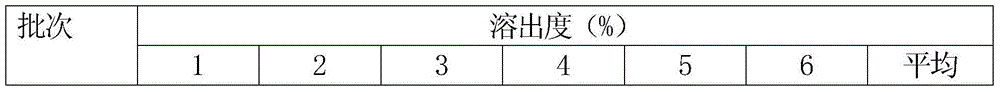

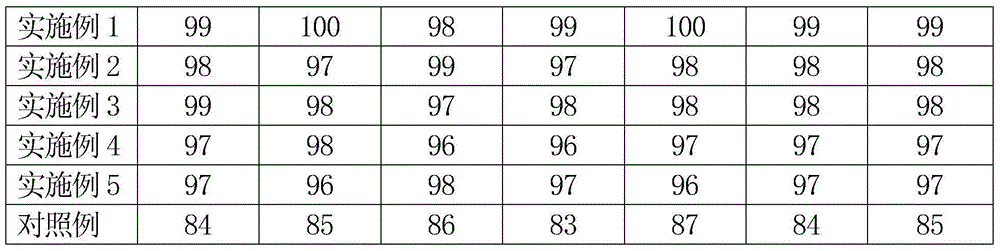

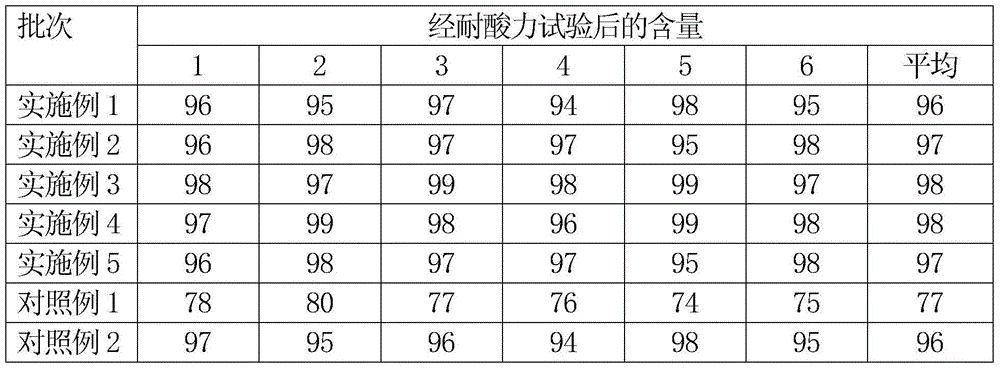

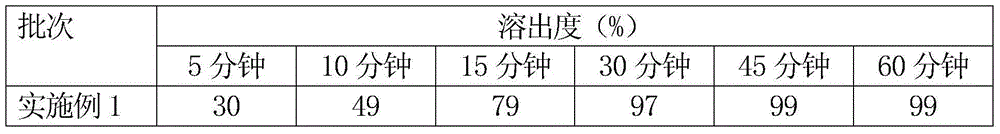

Pellet type pantoprazole sodium enteric capsule and preparation method thereof

InactiveCN104644616AImprove stabilityAvoid photolysisOrganic active ingredientsDigestive systemGranularityIsolation layer

The invention discloses a pellet type pantoprazole sodium enteric capsule and a preparation method thereof. The pellet type pantoprazole sodium enteric capsule is a sustained-release preparation composed of a capsule shell and uniformly mixed pantoprazole sodium pellets held in the capsule shell; the pantoprazole sodium pellet from inside to outside in turn comprises a blank pellet core, a main drug layer, an isolation layer and an enteric layer, wherein the weight of the main drug layer is 14-55% of that of the blank pellet core, the weight of the isolation layer is 9-10% of that of the total weight of the blank pellet core and the main drug layer, the weight of the enteric layer is 28-32% of that of the total weight of the blank pellet core, the main drug layer and the isolation layer; 40-60% of that of the pantoprazole sodium pellet is coated with a pigmented layer on the outside of the enteric layer; the weight of the pigmented layer is 0.5-1% of that of the total weight of the blank pellet core, the main drug layer, the isolation layer and the enteric layer; the diameter of the blank pellet core is 0.8-1.0 mm; the granularity of the pantoprazole sodium pellet is 14-20 mesh; each capsule contains 20-40 mg of the pantoprazole sodium. The pellet type pantoprazole sodium enteric capsule has the advantages of acidproof, rapid release and stable.

Owner:ZHEJIANG CHANGDIAN PHARMA +1

Ball feeding device

ActiveCN102797760AAchieving sports goalsSatisfy the resting position requirements for fetching the ballBearing componentsSteel ballEngineering

A ball feeding device belongs to the technical field of bearing assembly equipment. The ball feeding device comprises a bracket and a ball feeding vibration device, wherein a ball box is arranged on the bracket; a ball feeding pipe matched with the ball box is arranged at the lower part of the ball box; a ball storage pipe is movably inserted into the lower part of the ball feeding pipe; and the ball feeding pipe is matched with the ball feeding vibration device. Through the ball feeding device, balls can be fed efficiently and conveniently, and the stagnation and the disjunction of the steel balls cannot happen in the ball feeding process.

Owner:NINGBO ZHUANGHONGYI BEARING

Mini-pill type nicergoline capsule and preparation method thereof

InactiveCN104622850AImprove solubilityWidely distributedSenses disorderNervous disorderSide effectBiomedical engineering

The invention discloses a mini-pill type nicergoline capsule and a preparation method thereof. The mini-pill type nicergoline capsule is a sustained-release preparation and is prepared from a capsule shell and a nicergoline mini-pill accommodated in the capsule shell, wherein the nicergoline mini-pill sequentially comprises an empty pill core, a main drug layer and a pigmented layer from inside to outside; the main drug layer accounts for 15-60 percent of the empty pill core, and the pigmented layer accounts for 0.5-1 percent of the total weight of the empty pill core and the main drug layer. The mini-pill type nicergoline capsule has the advantages of small stimulation to intestines and stomach, high utilization rate, high stability, less toxic or side effects and capability of fully releasing effective components in time.

Owner:ZHEJIANG CHANGDIAN PHARMA +1

Pellet type omeprazole enteric capsule and preparation method thereof

InactiveCN104546737AWidely distributedIncrease local concentrationOrganic active ingredientsDigestive systemGranularityIsolation layer

The invention discloses a pellet type omeprazole enteric capsule and a preparation method thereof. The pellet type omeprazole enteric capsule is a sustained-release preparation, and is composed of a capsule shell and evenly mixed omeprazole pellets received in the capsule shell; each omeprazole pellet is composed of a blank pill core, a main drug layer, an isolation layer and an enteric layer in order from inside to outside, wherein the weight of the main drug layer accounts for 15-60% of that of the blank pill core, the weight of the isolation layer accounts for 10% of the total weight of the blank pill core and the main drug layer, the weight of the enteric layer accounts for 28-32% of the total weight of the blank pill core, the main drug layer and the isolation layer; besides, the enteric layers of 40-60% of omeprazole pellets are further coated with pigment layers; the weight of the pigment layer accounts for 0.5-1% of the total weight of the blank pill core, the main drug layer, the isolation layer and the enteric layer; the diameters of the blank pill cores are 0.8-1.0mm; the granularity of the omeprazole pellets is 14-20 meshes; each capsule contains 15-30mg of omeprazole. The pellet type omeprazole enteric capsule has the advantages of good acid resistance, sufficient active ingredient release without delay, good stability and the like.

Owner:ZHEJIANG CHANGDIAN PHARMA +1

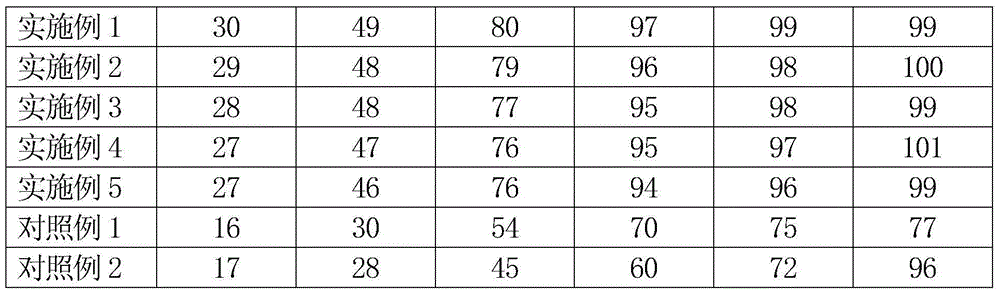

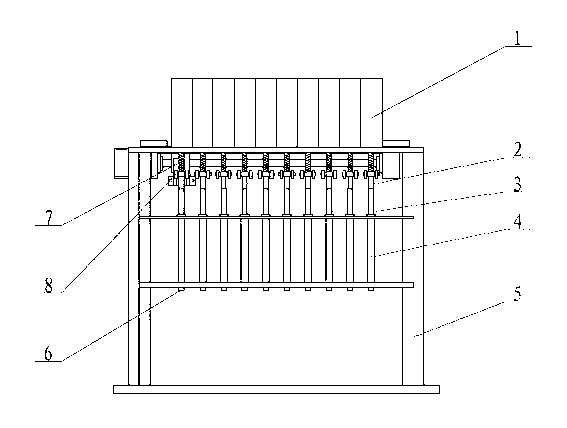

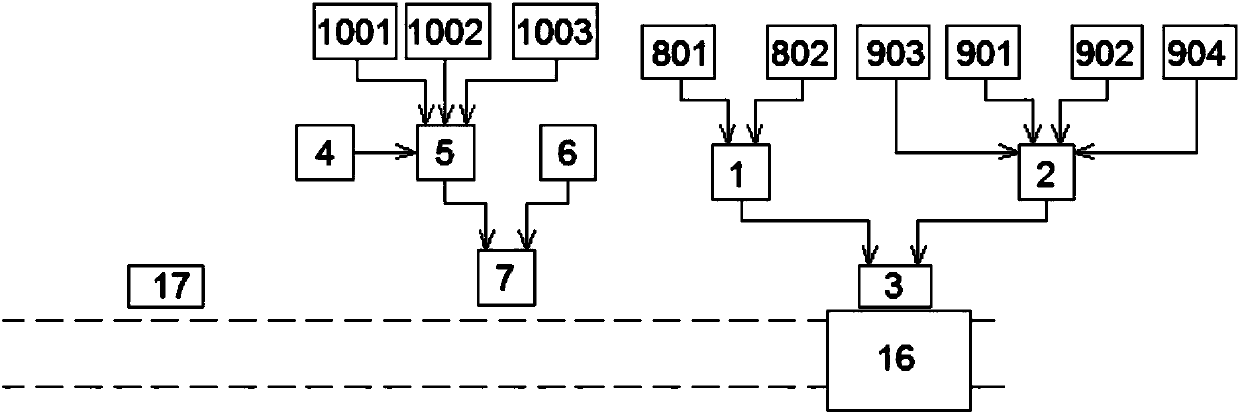

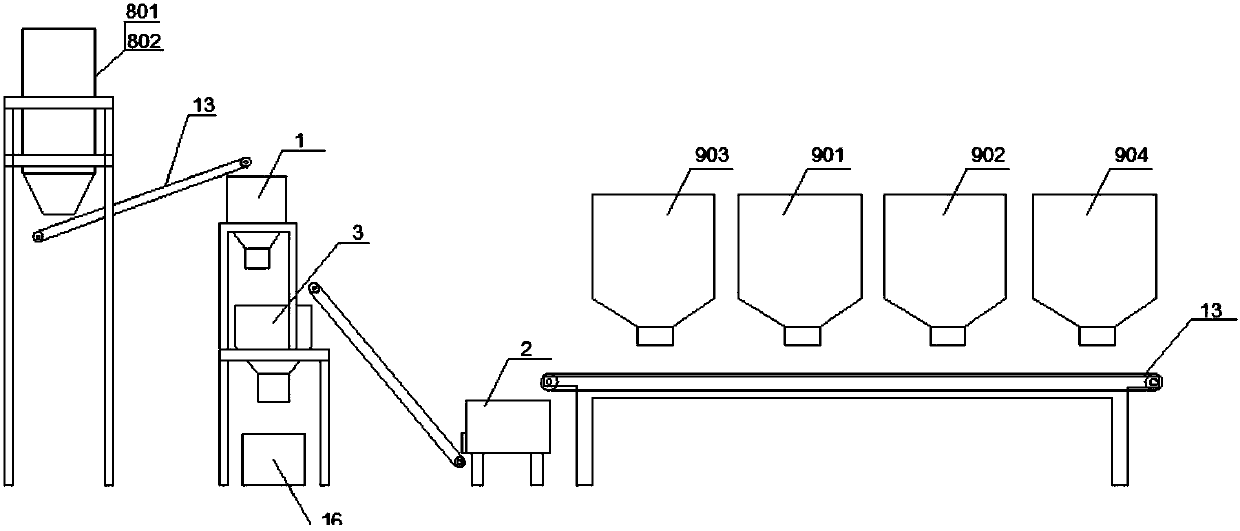

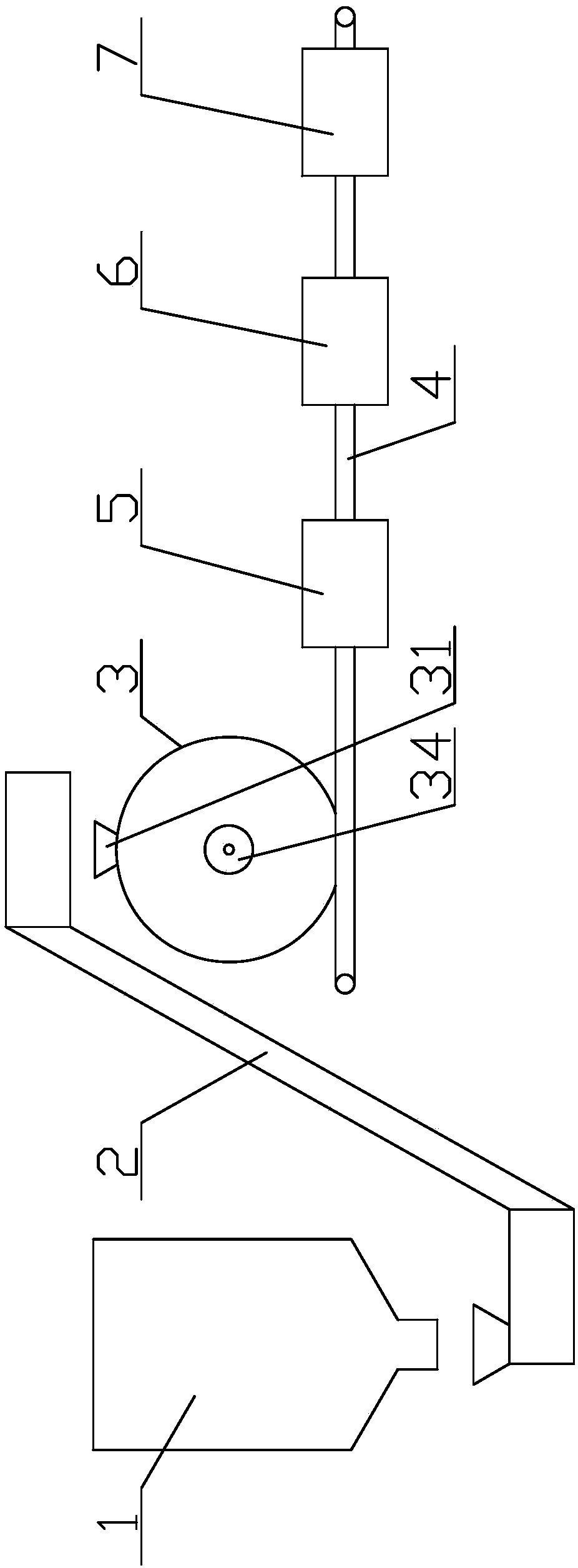

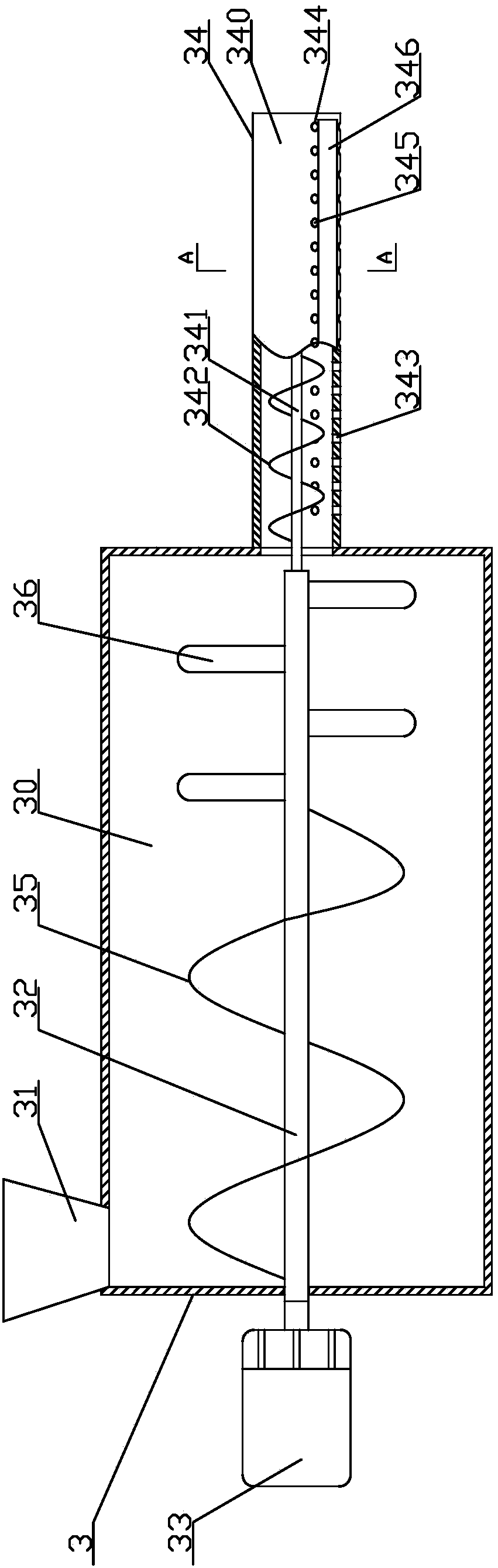

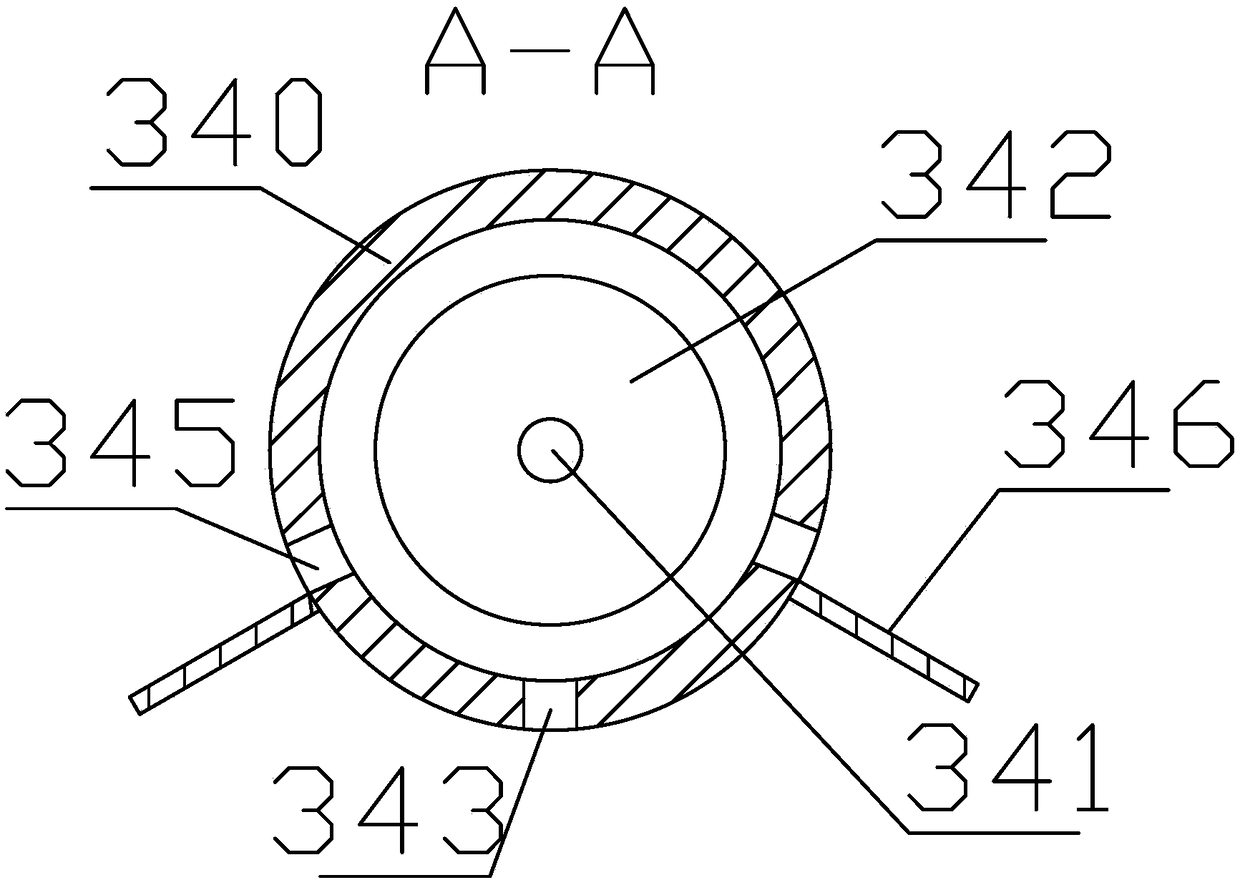

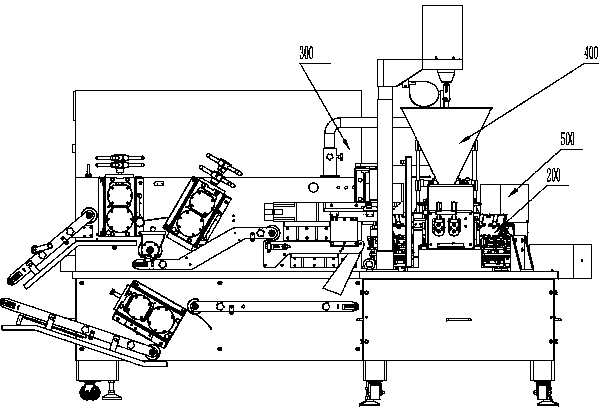

Polymer concrete pipe production line

ActiveCN107599274AImprove adhesionNot prone to adhesionTubular articlesProduction linePolymer concrete

The invention relates to a polymer concrete pipe production line. The polymer concrete pipe production line comprises an aggregate feeding mechanism, a liquid material feeding mechanism, a material mixing mechanism and a pouring mechanism; the input end of the material mixing mechanism is connected with the output end of the aggregate feeding mechanism and the output end of the liquid material feeding mechanism, and the output end of the material mixing mechanism is connected with the input end of the pouring mechanism; the aggregate feeding mechanism comprises a first mixing machine and a second mixing machine which are arranged in parallel, the output ends of the first mixing machine and the second mixing machine are connected with the input end of a third mixing machine, the input end of the first mixing machine is connected with a coarse material bin, and the input end of the second mixing machine is connected with a powdery material bin; the liquid material feeding mechanism comprises an auxiliary tank, a resin tank, a transferring tank, an ingredient tank and a mixing tank, the output ends of the auxiliary tank and the resin tank are connected with the input end of the transferring tank, and the output ends of the transferring tank and the ingredient tank are connected with the input end of the mixing tank; and the pouring mechanism comprises a pouring die and a driving mechanism of the pouring die, and a movable hopper is arranged among the output end of the third mixing machine, the output end of the mixing tank and the input end of the pouring die.

Owner:山东土大力管道工程有限公司

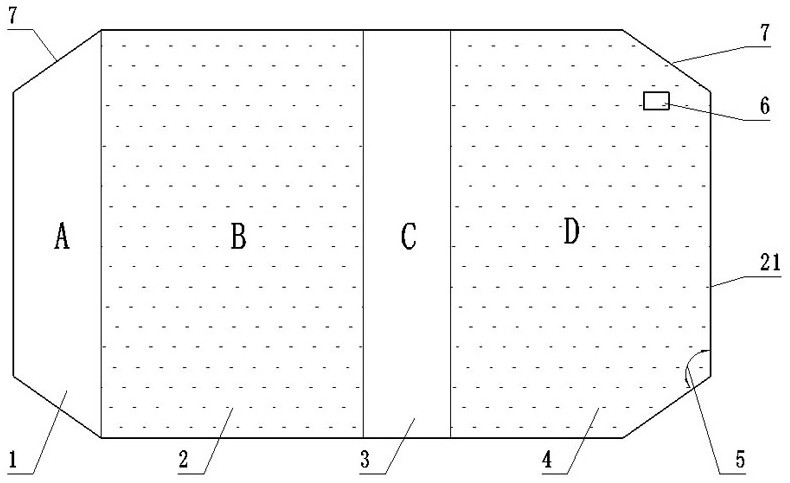

Material formula and production process of automatic winding packaging film

ActiveCN111761899AModerate thicknessStable antistaticFlexible coversWrappersLinear low-density polyethyleneLow-density polyethylene

The invention relates to agricultural harvesting crop packaging materials, and particularly relates to a material formula and a production process of an automatic winding packaging film during harvesting and packaging operation of cotton, silage and the like. The material formula of the automatic winding packaging film material comprises the following raw materials in percentage by mass: linear low-density polyethylene, high-pressure low-density polyethylene, metallocene polyethylene, color masterbatch, an anti-aging agent, an ultraviolet light absorber and an antistatic agent. The productionprocess of the automatic winding packaging film mainly comprises the steps of preparing materials; blowing a film; conducting gluing; manufacturing film rolling units; and connecting the film rollingunits into a finished rolled film. By means of the material formula, the prepared packaging film is moderate in material thickness, stable in anti-aging and anti-static performance, high in anti-buffering strength, good in retraction rate and good in anti-piercing performance. The production process is reasonable in flow design, economical and practical, material bag sealing is enabled to be tightand firm, and the produced packaging film can be rapidly separated in the material packaging process.

Owner:新疆棉锦农业科技有限公司

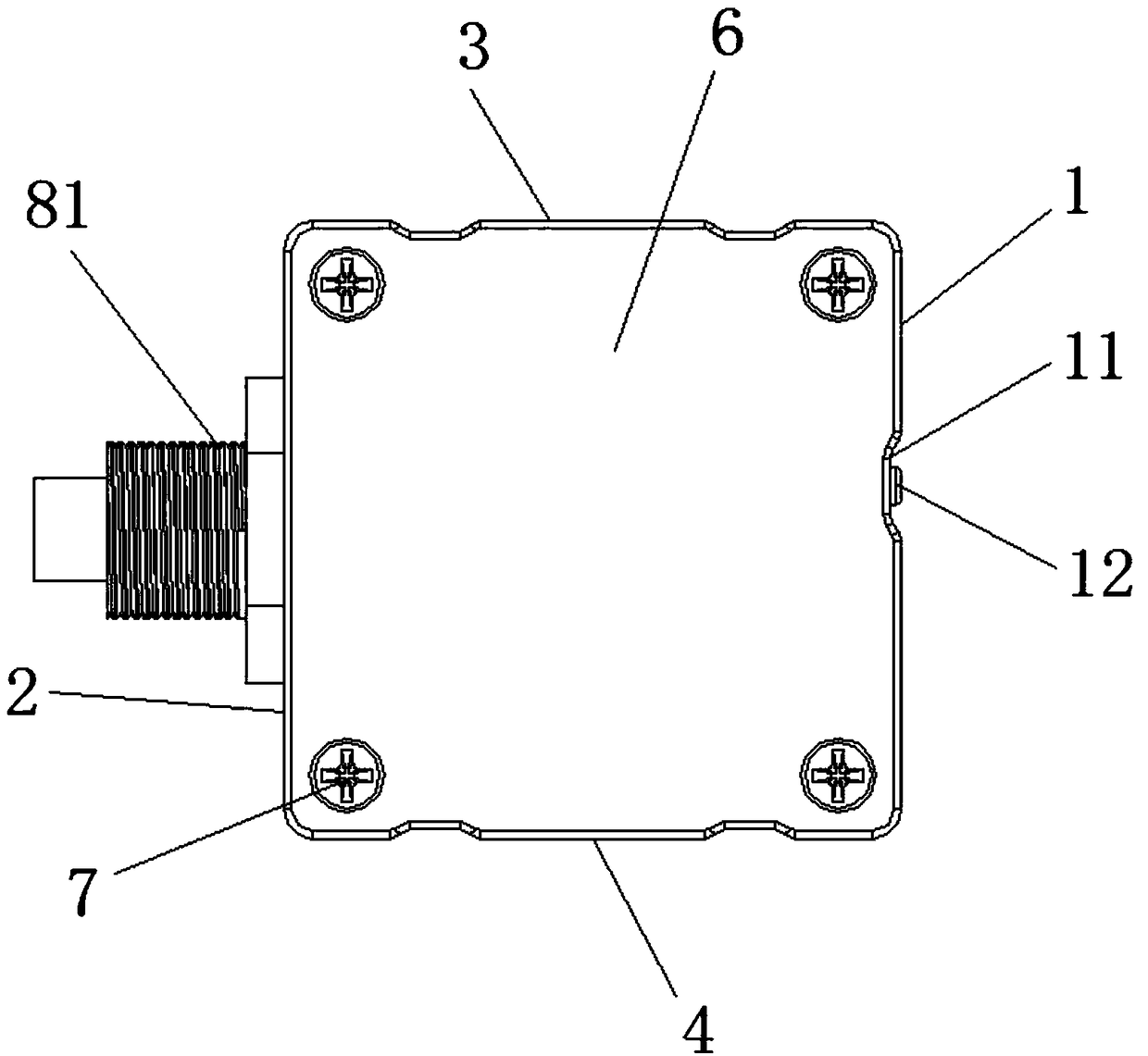

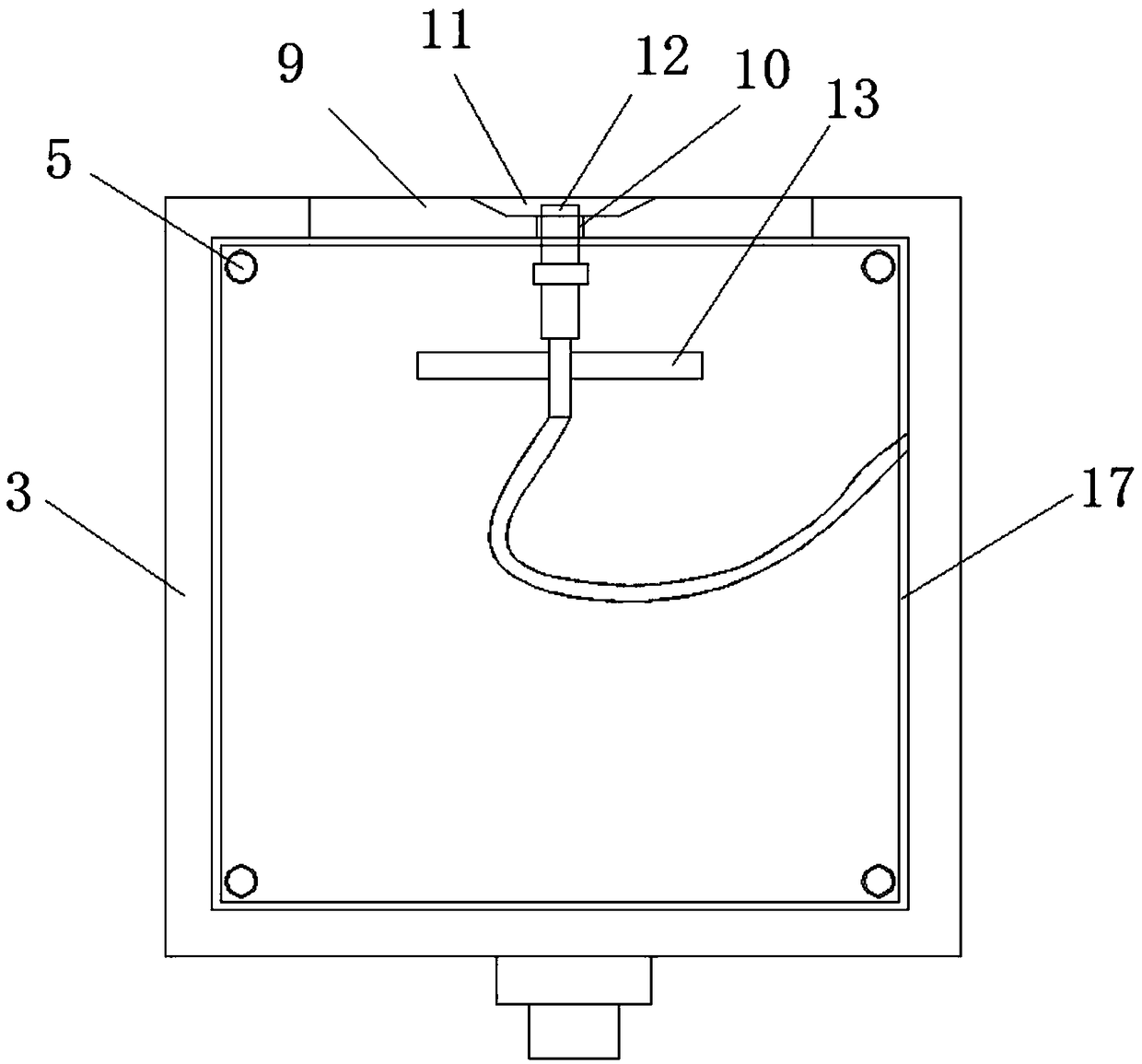

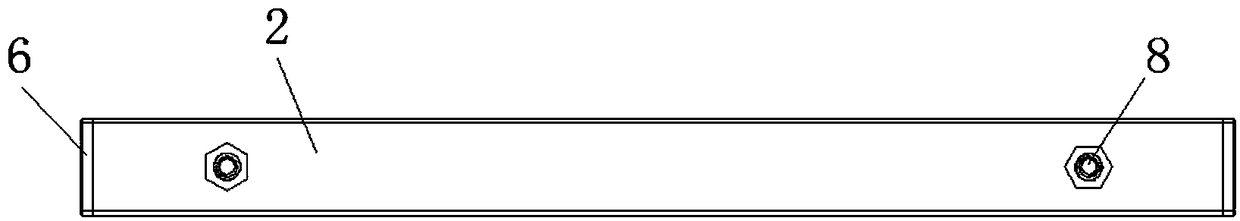

High-precision intelligent electronic water gauge

ActiveCN108072421AAvoid corrosionShorten the timeLevel indicators by physical variable measurementEngineeringAtmospheric pressure

The invention discloses a high-precision intelligent electronic water gauge. The electronic water gauge comprises an electronic water gauge body and an end cover, the two ends of the electronic watergauge body are of cuboid hollow structures with openings, and the electronic water gauge body comprises a first surface, a second surface, a third surface and a fourth surface; end holes are formed inthe two ends of the electronic water gauge body in the length direction, connection threaded openings are formed in the two ends of the second surface in the length direction, and an opening is formed in the middle of the first surface in the length direction; a fixing plate is arranged in the opening, and a fastening bolt is arranged at the bottom of the fixing plate. The high-precision intelligent electronic water gauge is simple in structure and ingenious in design, a user saves a large amount time of threaded field installation, the detection precision is also improved, and the whole leakproofness of the electronic water gauge is improved; measurement errors are not influenced by external factors such as atmospheric pressure, temperature, humidity and sand content, the problems of lowprecision, poor leakproofness and inconvenient installation of existing electronic water gauges are solved, and the electronic water gauge is high in practicability and easy to popularize.

Owner:湖北亿立能科技股份有限公司

Drying system for plastic foam particle film

The invention relates to the technical field of foam particle processing machinery, in particular to a drying system for a plastic foam particle film. The drying system comprises a drying cavity and adrying device, wherein the drying cavity is provided with a top cover, a sealed cavity is formed by the top cover and the drying cavity, and the drying device is arranged in the drying cavity. The drying system further comprises an air inlet device and an air outlet device, wherein the air inlet device is connected with the lower part of one side face of the drying cavity and is used for enablingparticles in the drying cavity to be in a suspended state, air circulation is formed by the air inlet device and the air outlet device to carry out comprehensive and rapid drying, and the air inlet device comprises a plurality of air inlet pipes which are connected through a blast pipeline in series. According to the drying system, the multiple air inlet pipes in the air inlet device are connected through the blast pipeline in series to achieve circulation of heat energy, the energy consumption is reduced, air circulation in the drying cavity is achieved through an induced draft fan and an air blower, the particles are dried by 360 degrees without dead corners, air with moisture in the drying cavity is discharged, the particle speed is high, the particles are not prone to adhering, the drying effect is good, the energy consumption is low, and the working efficiency is high.

Owner:菲尔普(青岛)新材料有限公司

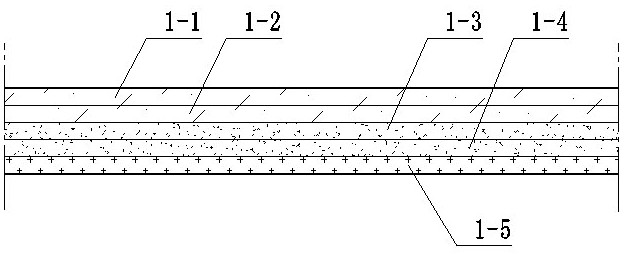

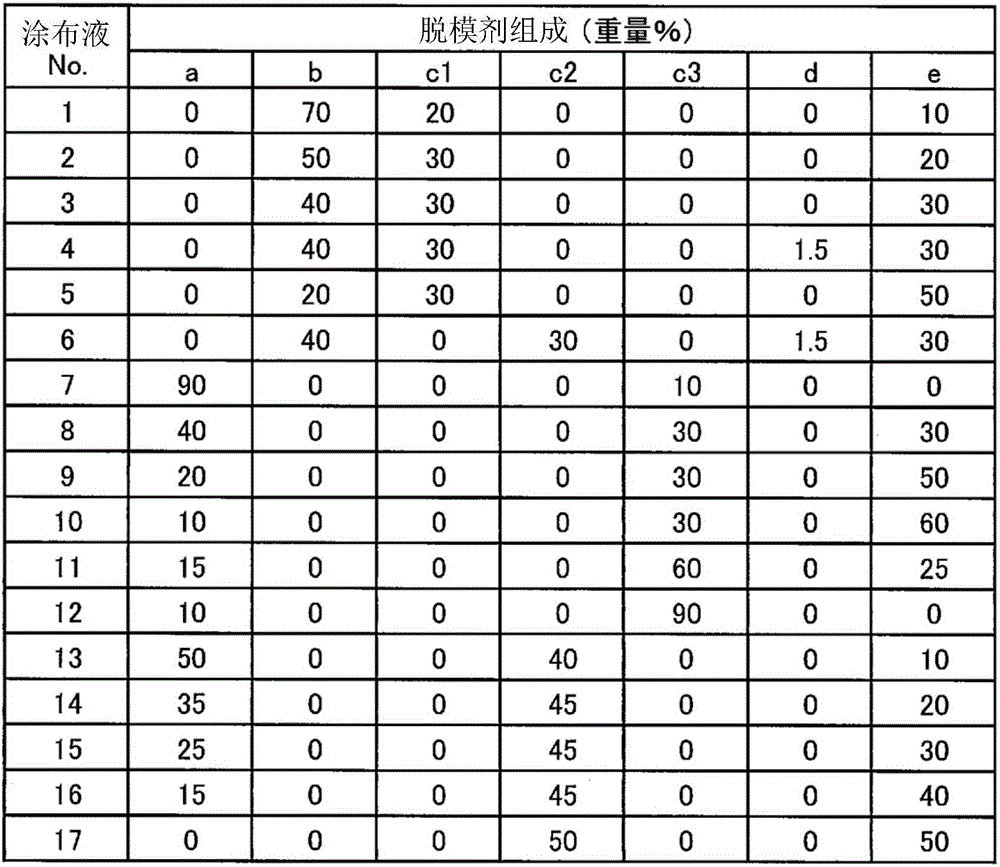

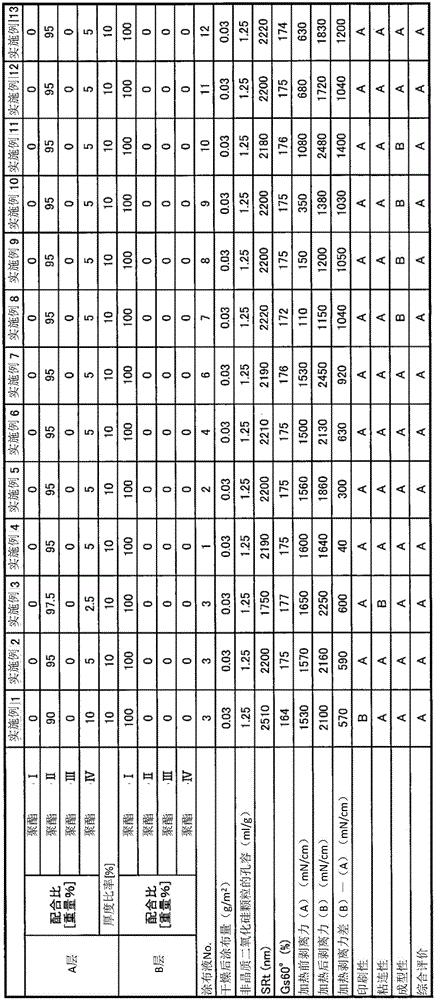

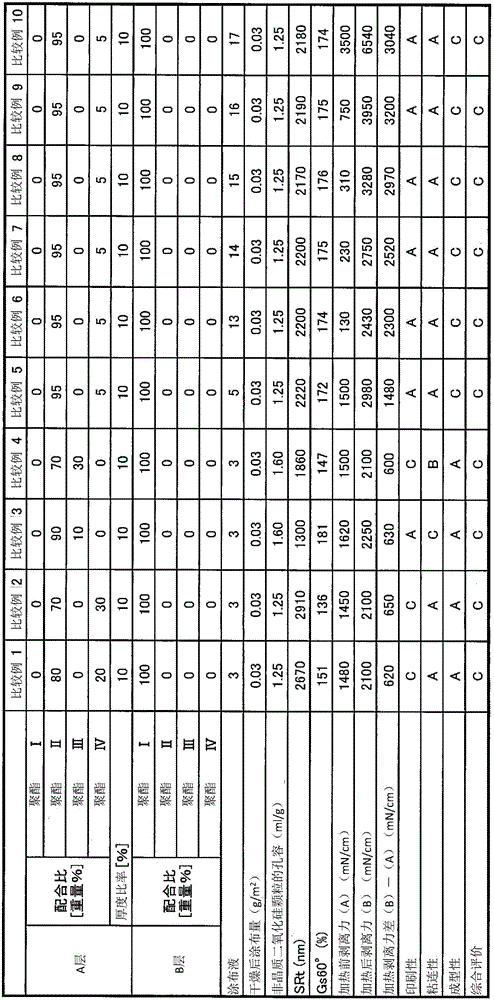

Mold release polyester film for simultaneous molding and transfer

InactiveCN107529335AEfficient printingNot prone to adhesionDecorative surface effectsSynthetic resin layered productsPolyesterPolymer chemistry

Provided is a mold release polyester film for simultaneous molding and transfer, which has excellent gloss, is free from the occurrence of blocking during a processing step of a transfer sheet, and has a function that enables smooth separation at the interface between a mold release layer and a print layer, while maintaining uniform gloss of the surface of a molded article during a transfer sheet separation step after simultaneous molding and transfer. This mold release polyester film for simultaneous molding and transfer has a mold release layer on at least one surface of a multilayer polyester film which is composed of at least three layers, and wherein inert particles contained in both outermost layers have a pore volume of 1.40 ml / g or less. The maximum height of the profile (SRt) of the surface of the mold release layer is 1,700 nm or more; the gloss at 60 degrees of the surface of the mold release layer in the machine direction (MD) is 155% or more; the peel strength (A) of the surface of the mold release layer before heating is 2,000 mN / cm or less; the peel strength (B) of the surface of the mold release layer after heating at 100 DEG C is 2,500 mN / cm or less; and the difference between peel strengths before and after the heating, namely (B-A) is 2,000 mN / cm or less.

Owner:MITSUBISHI CHEM CORP

Steel scrap preheater and preheating method of electric-arc furnace step disturbance culvert

ActiveCN103196296BImprove heat transfer efficiencyImprove heat transfer effectPreheating chargesElectric arc furnaceCulvert

The invention discloses a scrap preheater of an electric-arc furnace step disturbance culvert. The scrap preheater comprises a heat-exchanging culvert, the low side of the heat-exchanging culvert is connected with a furnace, the high side of the heat-exchanging culvert is respectively connected with a smoke-collecting and dust-removing pipe and a feed sealing device, the heat-exchanging culvert comprises a material- conveying groove and a smoke guide cover, the material-conveying groove is used for conveying steel scrap materials to the electric-arc furnace, the smoke guide cover is covered on the material- conveying groove and is used for guiding smoke, the heat-exchanging culvert is provided with at least one cross-section abrupt change structure in the height-extending direction, and the cross-section abrupt change structure is used for disturbing the steel scrap material flow state and the smoke flow state. The invention further discloses a preheating method of the electric-arc furnace step disturbance culvert, and the steel scrap materials can be added to the material-conveying groove by the feed sealing device; the steel scrap material flow state is disturbed under the combined action of the cross-section abrupt change structure on the heat-exchanging culvert and horizontal vibration, so that the steel scrap materials have air permeability in a certain area; and the smoke flow state can be disturbed in the smoke guide cover, so that the smoke and the steel scrap materials can be subjected to heat exchanging fully.

Owner:CISDI ENG CO LTD

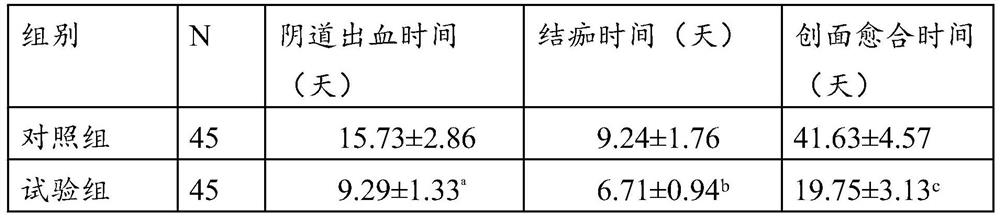

Liquid dressing with cervical postoperative hemostasis function and infection prevention function and application

InactiveCN113546212AStable in natureInhibition of reproductionPharmaceutical delivery mechanismAdhesive dressingsTriclosanGlycerol

The invention discloses a liquid dressing with a cervical postoperative hemostasis function and an infection prevention function. The liquid dressing is prepared from the following components in parts by weight: 1-2 parts of carbomer, 2-25 parts of microporous bioactive glass, 30-70 parts of medical glycerol, 25-60 parts of propylene glycol, 0.5-2.5 parts of chitosan, 0.1-1.0 part of sodium hyaluronate, 0.05-0.25 part of triclosan and 0.01-0.2 part of recombinant human epidermal growth factor; wound exudate is absorbed through the adsorption effect of the microporous bioglass; the bioactive glass and the chitosan have the functions of stopping bleeding and promoting healing, and bleeding is reduced; and the triclosan has the sterilization and bacteriostasis effects, so that infection is prevented, wound healing is promoted, and the liquid dressing is a functional medical product with a wide application prospect.

Owner:克尔维特(福州)医疗科技有限公司

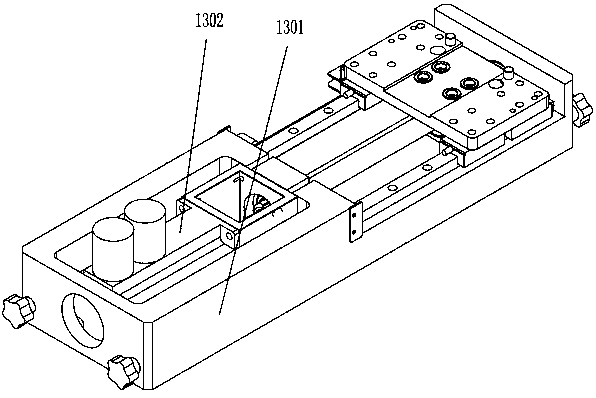

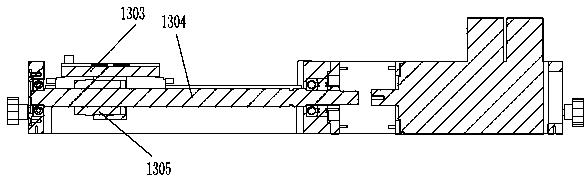

Making method and system of alum-free vermicelli

ActiveCN108056456AEvenly dispersedNot prone to adhesionFood thermal treatmentFood ingredientsMolding machineEngineering

The invention discloses a making method and system of alum-free vermicelli. The making system of the alum-free vermicelli comprises a stirring machine, a feeding machine, an extrusion molding machineand a conveying belt, which sequentially communicate, wherein the conveying belt penetrates through a pregelatinization boiling water basin, an electromagnetic wave heating device and a cold water basin sequentially. The making method of the alum-free vermicelli comprises the following steps of (1) making flocculent starch; (2) performing extrusion molding; (3) performing pregelatinization to obtain pregelatinized vermicelli; (4) performing electromagnetic wave heating on the pregelatinized vermicelli for gelatinization; and (5) performing cooling. The making method and system have the advantages that the whole process is completely mechanical, the condition that the vermicelli is broken off cannot occur, and the making method and system are suitable for large scale production; and the extrusion molding machine designed in the making method disclosed by the invention is used for performing stirring and extrusion, and the vermicelli is pregelatinized through an electromagnetic wave heating manner, so that alum and alum substitutes are not needed, the mouth feel and the toughness of the vermicelli can still be guaranteed, and all indexes conform to Chinese standards.

Owner:鄂尔多斯市诚创食品科技有限公司

Oil resistant rubber clamp pipe

The invention relates to an oil resistant rubber clamp pipe consisting of the following components: 150 parts of an ethylene-propylene-diene monomer, 40 parts of epichlorohydrin rubber, 12 parts of polyamide wax micro powder, 5 parts of polycaprolactone, 15 parts of nano sepiolite, 1 part of zinc oxide, 2 parts of an anti-aging agent, 40 parts of reinforcing filler and 6 parts of modified fly ash. Furthermore, the oil resistant rubber clamp pipe also includes 2 parts of dioctyl maleate, and 3 parts of dinitrosopentamethylene tetramine. The produced oil resistant rubber clamp pipe is good in oil resistance and is difficult to degrade or break bonding, thus reducing seepage or leakage of fuel oil, and overcoming a shortcoming of general rubber that oil resistance cannot meet requirements.

Owner:QINGDAO BOYUTE RUBBER & PLASTIC PRODS

Simple powder quantitative material feeder

ActiveCN106927223AKeep it cleanQuantitatively accurateCleaningIncreasing energy efficiencyStructural engineeringMechanical engineering

The invention relates to the technical field of powder feeding device, in particular to a simple powder quantitative material feeder. The simple powder quantitative material feeder is provided with a valve body, wherein the valve body comprises a material inlet, a valve chamber and a material outlet; a first end cover and a second end cover are respectively fixed on two sides of the valve body; a main shaft valve core is supported on the first end cover and the second end cover in a rotatable manner; the cross section of a working section, which is located in the valve chamber, of the main shaft valve core is regularly prismatic, and a transitional arc section is formed between every two adjacent edges; each transitional arc section is in tiny clearance fit with the inner wall of the valve chamber; a material accommodating cavity is formed between each edge and the inner wall of the valve chamber; a material clearing device and a sweeping device are arranged at the material outlet; and when the main shaft valve core rotates, the material clearing device and the sweeping device clear away powder attached on all the edge surfaces of the working section of the main shaft valve core. The material feeder is simple in structure, quantitative and accurate, can clear away the powder attached on the walls of the material accommodating cavities and the main shaft valve core, and difficultly damages the surface of the main shaft valve core.

Owner:CHANGZHOU INST OF LIGHT IND TECH

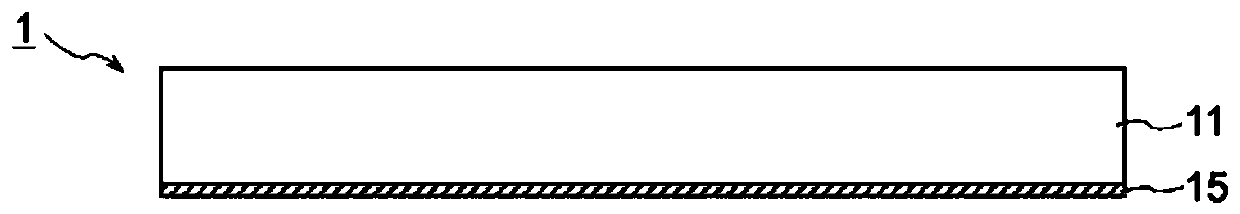

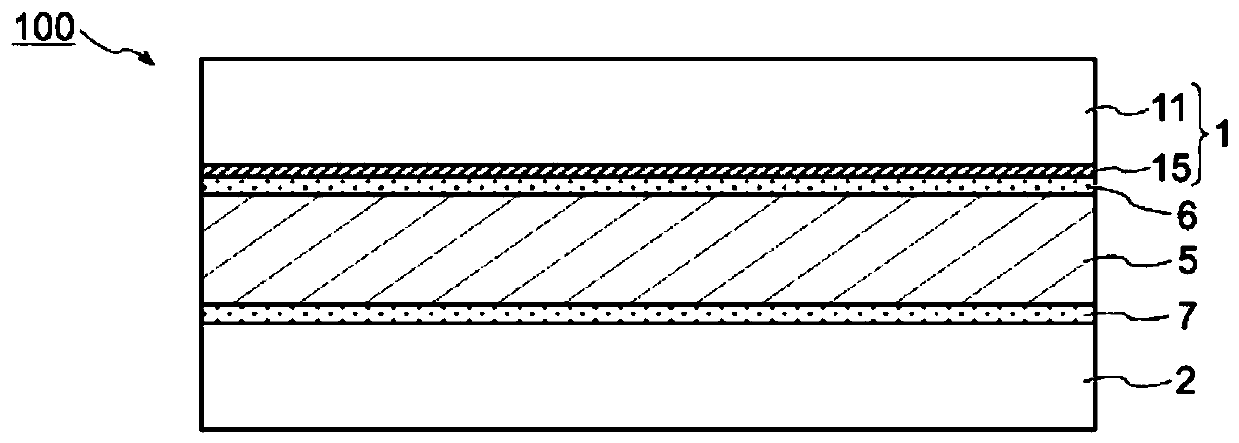

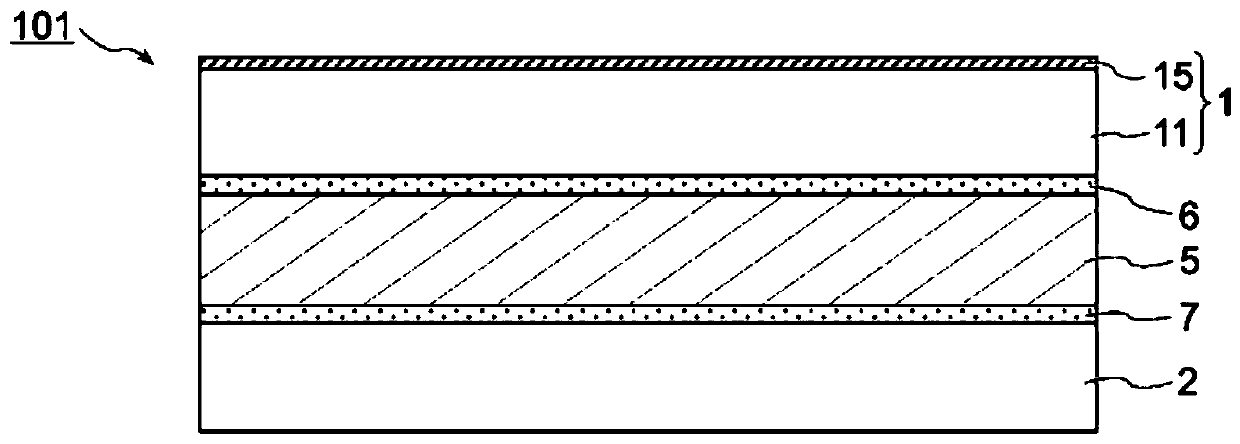

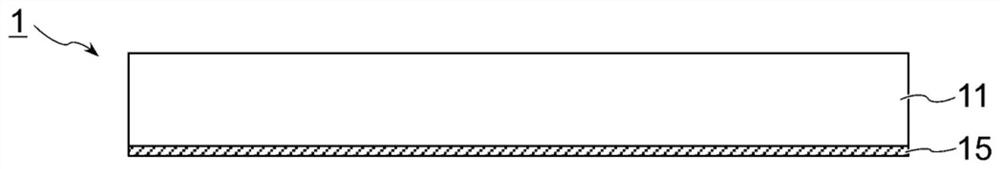

Optical film, production method thereof, polarizer, and image display device

ActiveCN111448246AGood adhesionNot prone to adhesionFilm/foil adhesivesSynthetic resin layered productsOptical thin filmPolarizer

An optical film (1) is provided with a slippery layer (15) on the surface of a transparent film substrate (11). The slippery layer (15) contains a binder resin and fine particles. The alkali componentcontent of the slippery layer (15) is 5-75 ppm. The slippery layer can be formed by applying a composition for forming the slippery layer which contains the binder resin or a precursor thereof, the fine particles, the alkali component, and a solvent onto the transparent film substrate, and heating the substrate. The optical film can be used as a polarizer protective film.

Owner:NITTO DENKO CORP

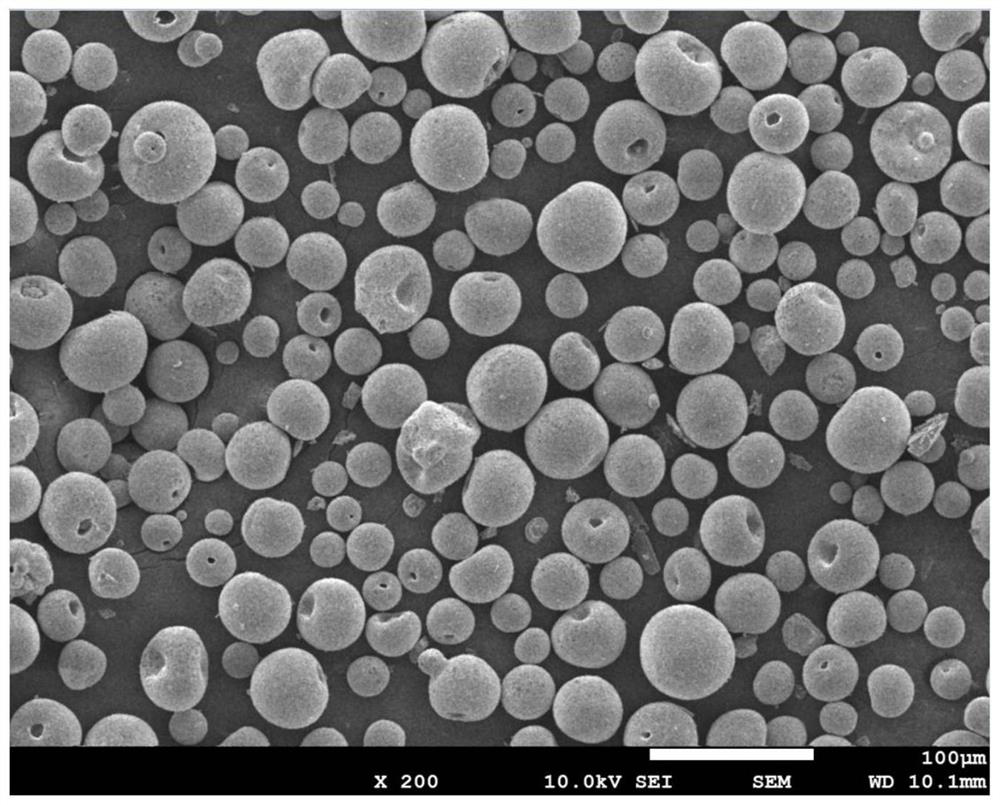

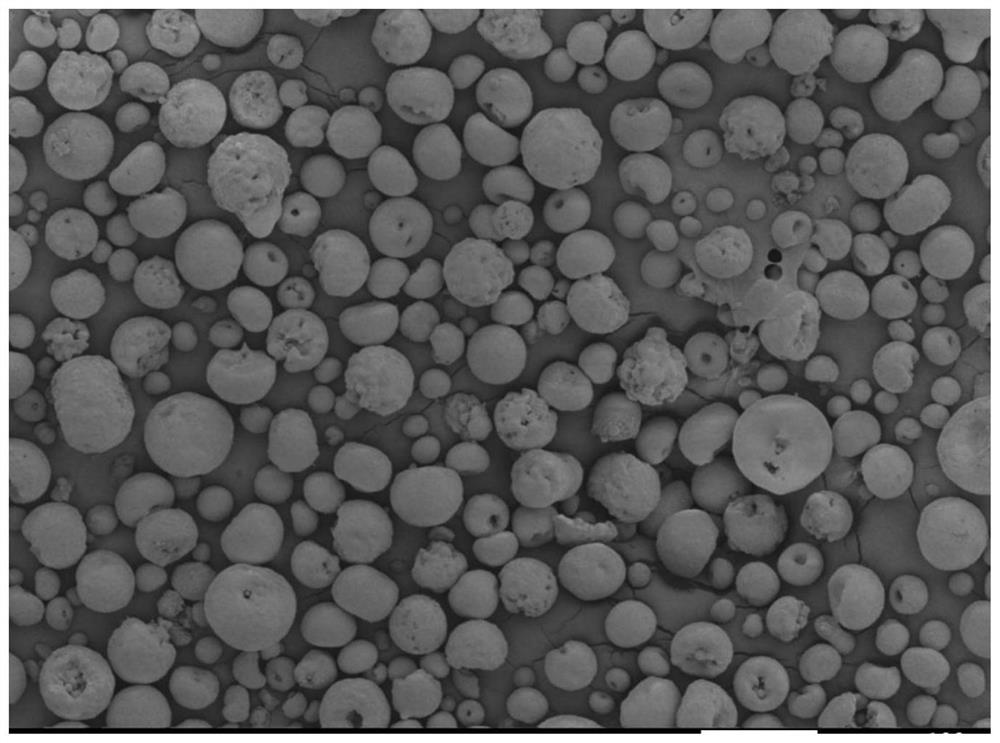

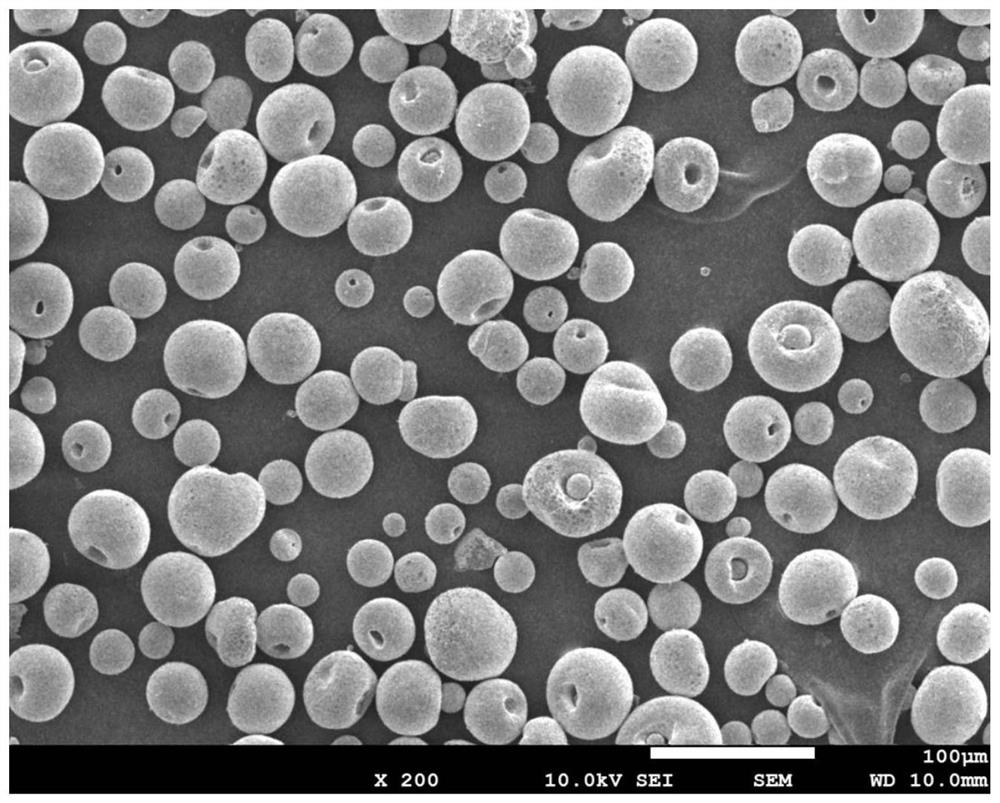

Bird nest-like structure aluminum oxide as well as preparation method and application thereof

PendingCN114573012AGood thermal conductivityLower interface thermal resistanceAluminium compoundsCell component detailsOxideHeat transmission

The invention relates to the field of alumina powder production, and discloses a nest-like structure alumina, the nest-like structure alumina is a hollow sphere structure, the hollow sphere is provided with an inwardly recessed large hole, and the surface of the hollow sphere is a network structure fully distributed with small holes. The preparation method of the aluminum oxide with the bird nest-like structure comprises the following steps: 1) adding spherical superfine aluminum oxide into water, and uniformly dispersing to obtain dispersion liquid; 2) carrying out standing settlement treatment on the dispersion liquid, and after standing settlement is finished, collecting an upper-layer suspension to obtain an aluminum oxide dispersion liquid; and (3) carrying out spray granulation on the aluminum oxide dispersion liquid obtained in the step (2) to obtain a particle aggregate, and sintering the particle aggregate at 1180-1250 DEG C to obtain the aluminum oxide with the bird nest-like structure. According to the aluminum oxide filler with the bird nest-like network structure, the continuous network structure provides a continuous transmission path for heat transmission, and interface thermal resistance caused by adding of the filler is reduced.

Owner:HUANGHUAI UNIV +1

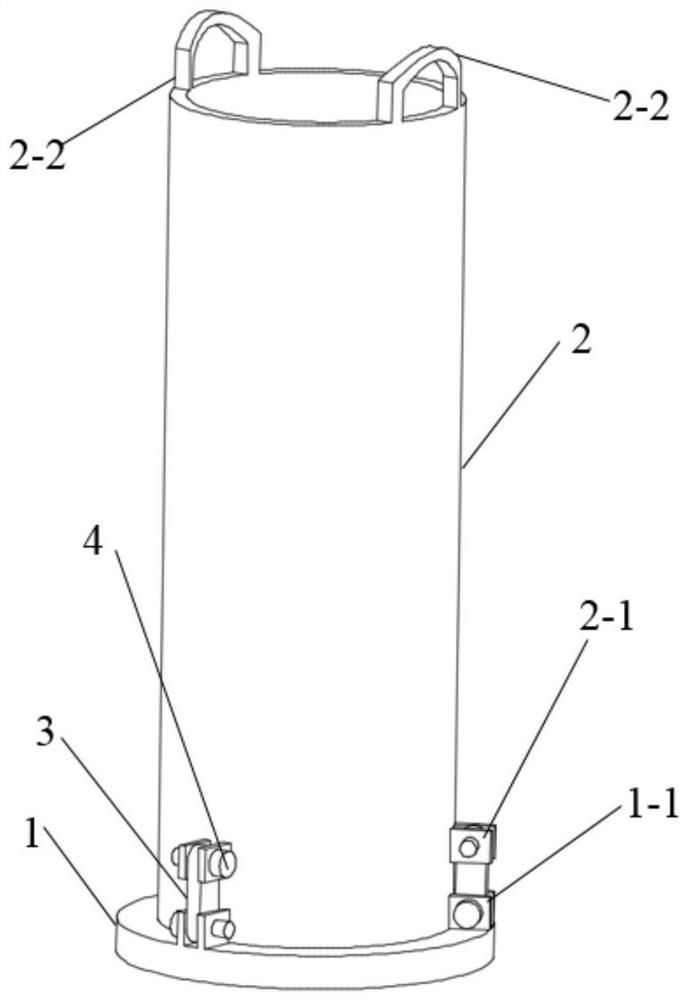

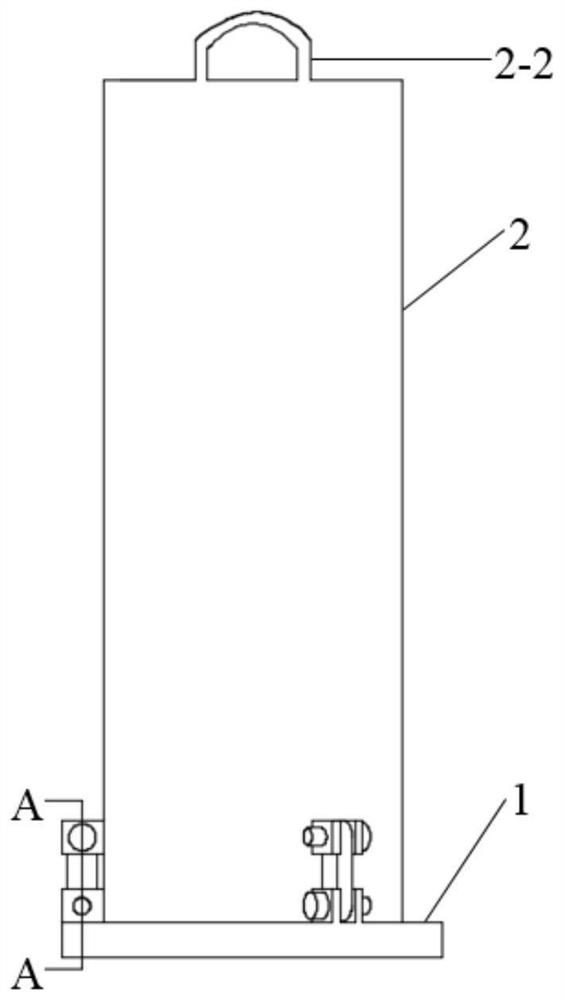

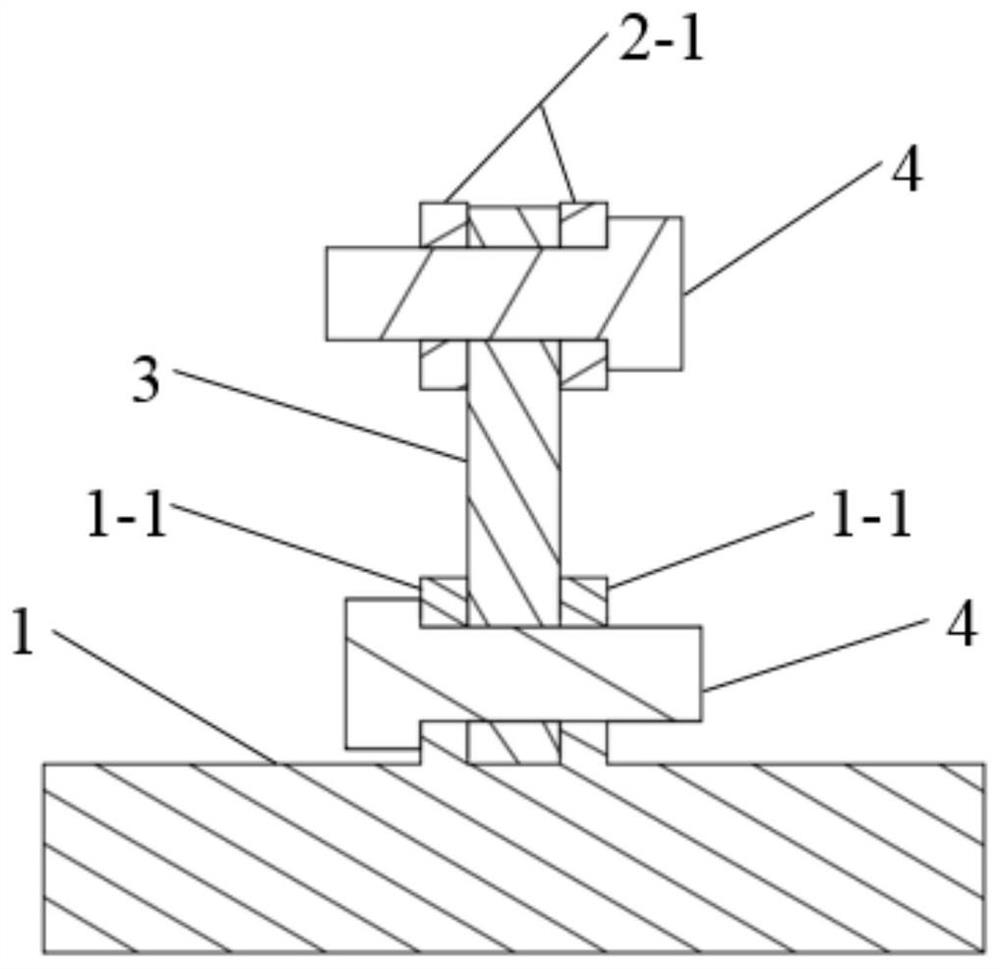

A bottom-loading boat for sintering porous metal materials

The invention discloses a bottom-loading material boat for sintering metal porous materials, which comprises a base and a boat tube detachably connected to the base. The material space is used to accommodate the metal porous material green body. In the present invention, the boat is detachably connected to the base, so that the porous metal material green body can be loaded above the base first, and then the boat is loaded from above the porous metal material green body, which solves the problem of the porous metal material green body Loading above the boat can easily cause the problem of breaking or fragmentation, and reduces the difficulty of loading the metal porous material green body, and improves the sintering efficiency.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

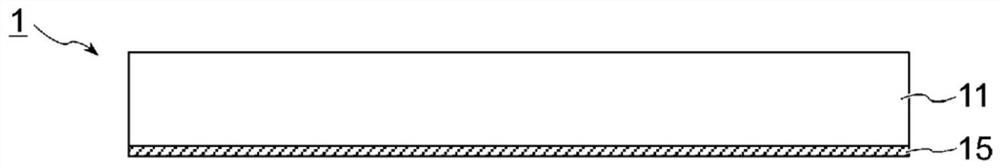

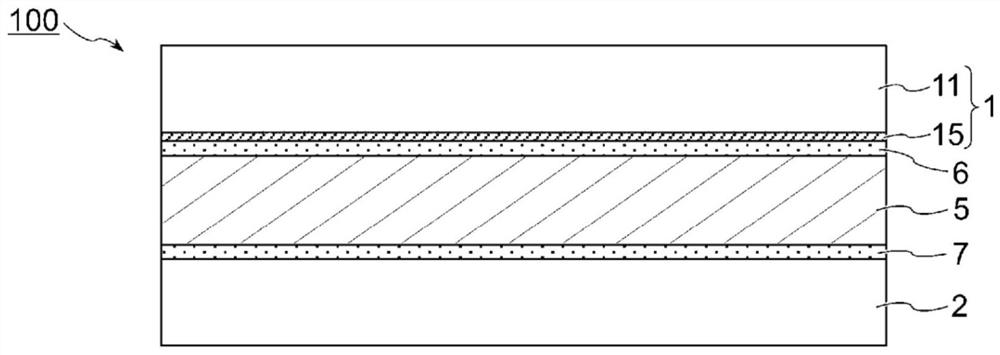

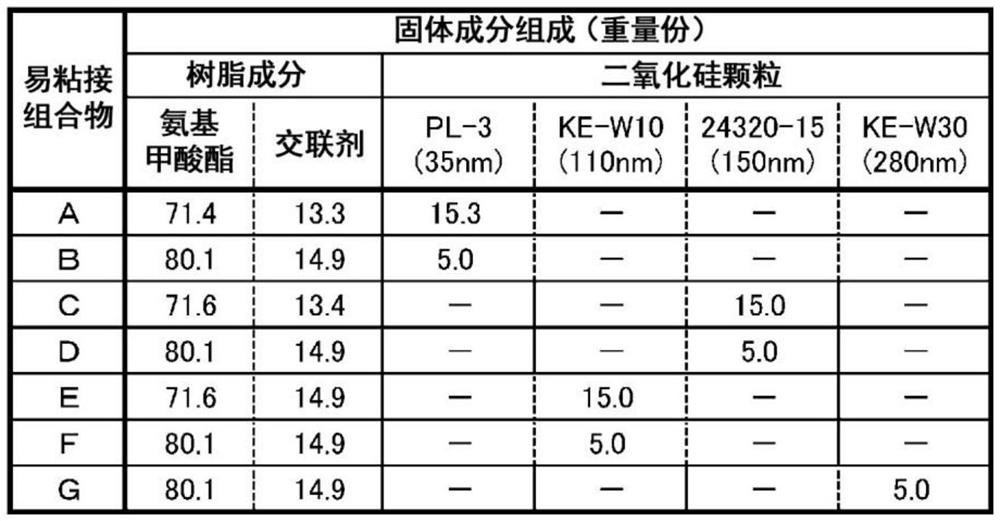

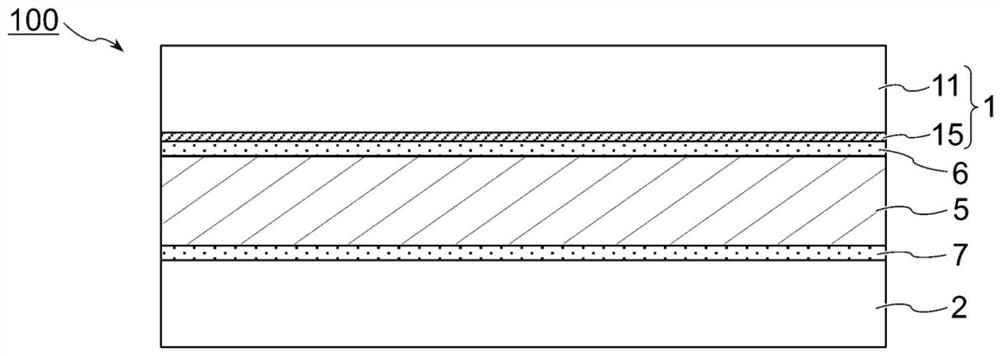

Easily adhesive film, method for producing same, polarizing plate, and image display device

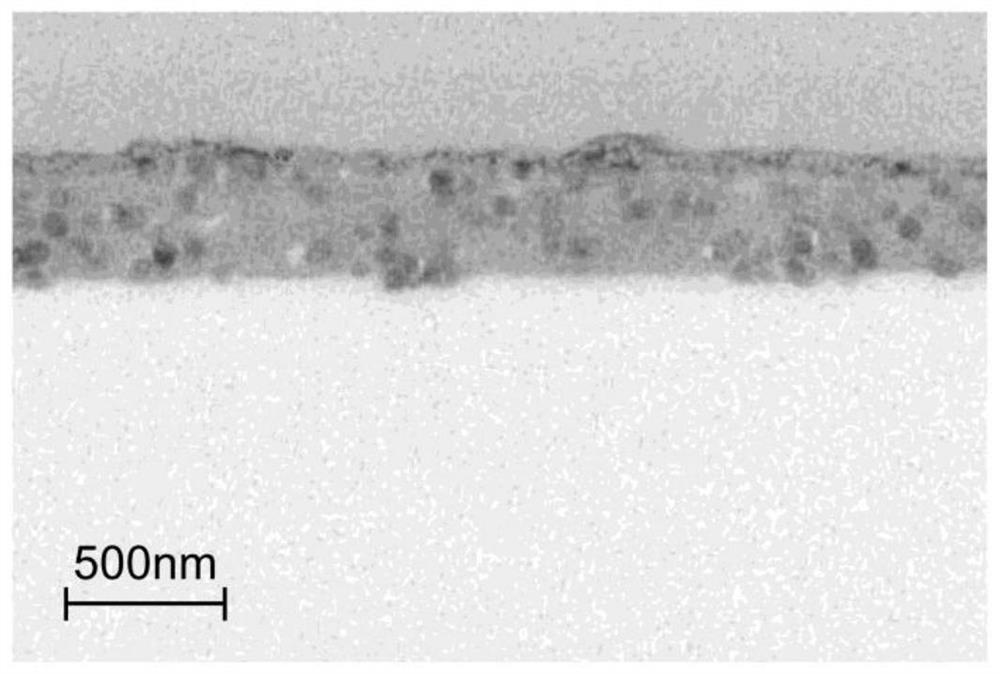

PendingCN114207485ANot prone to adhesionNot prone to optical defectsLayered product treatmentFilm/foil adhesive primer layersPolymer scienceThin membrane

A highly adhesive film (1) is provided with a highly adhesive layer (15) on the surface of a transparent film substrate (11). The easily adhesive layer (15) contains a binder resin and fine particles. The thickness of the easy-to-adhere layer is preferably 120-260 nm, and the average primary particle diameter of the fine particles is preferably 0.1-0.9 times the thickness of the easy-to-adhere layer. The highly adhesive layer can be formed by applying and heating a highly adhesive composition containing a binder resin or a precursor substance thereof, fine particles, an alkali component, and a solvent on a transparent film substrate.

Owner:NITTO DENKO CORP

Easy-to-adhere film and method for manufacturing the same, a polarizing plate, and an image display device

ActiveCN111890762AGood adhesionNot prone to adhesionSynthetic resin layered productsPolarising elementsThin membraneComposite material

The invention provides an easy-to-adhere film, and a method for manufacturing the same, a polarizing plate, and an image display device. The easy-to-adhere film (1) is provided with an easy-to-adherelayer (15) on the surface of a transparent film substrate (11). The easy-to-adhere layer (15) contains a binder resin and inorganic fine particles having an average primary particle diameter of 10-100nm. The content of the basic component in the easy-to-adhere layer (15) is 5-75 ppm. An easy-to-adhere layer can be formed by applying an easy-to-adhere composition containing a binder resin or a precursor thereof, inorganic fine particles, an alkaline component, and a solvent to a transparent film substrate and heating the composition.

Owner:NITTO DENKO CORP

Non-contact gripper

PendingCN109303086ANot prone to adhesionThe skin of those who are not easy to appear is stretchedDough dividingDough processingGrippersEngineering

The invention belongs to the technical field of non-contact grippers, in particular to a non-contact gripper. The non-contact gripper comprises a gripper body, wherein the outer edge of the bottom ofthe gripper body is provided with a cutting edge; the bottom of the gripper body is provided with a ring-shaped groove; the side edge of the ring-shaped groove is provided with an air outlet; the gripper body is used for adsorbing wrappers to a next station through suction force. The gripper body can horizontally move the wrappers from a wrapper cutting station to a wrapper receiving station directly instead of vertically pushing the wrappers downwards to the next station according to a non-transmission method, so that the whole non-contact gripper has higher extensibility. When the processedwrappers are larger in moisture content, the wrappers are prevented from adhering or getting long and thin by stretching.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Paper-based upper cover tape and preparation method thereof

InactiveCN107672265AEasy to cutEasy to rollLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolyester

The invention relates to the technical field of electronic component packaging, in particular to a upper cover tape matched with a paper carrier tape for use. The paper-based upper cover tape comprises a thin paper base material layer and an ethylene-vinyl acetate copolymer layer attached to the thin paper base material layer; the ethylene-vinyl acetate copolymer layer contains a non-ionic antistatic agent with mass of 0.3% to 3.0%; a thickness of the copolymer layer is 10 to 18 mu m; surface resistivity is smaller than or equal to 1*E10. Thin paper is used as a base material, the thin paper contains certain moisture, the surface resistivity is smaller than or equal to 1*E10, and the thin paper per se does not have static electricity, is difficult to adhere and does not need to be coated with an antistatic agent; the thin paper can be directly compounded with a low-density polyethylene layer or the ethylene-vinyl acetate copolymer layer after being subjected to corona processing, and does not need to utilize an adhesive; the thin paper has certain stiffness with respect to a polyester film, and a finished product is easy to part off and wind.

Owner:浙江洁美电子信息材料有限公司

Stuffed food forming machine with non-contact dough-cutting mechanism

PendingCN109303088AEasy to controlEasy to adjustDough dividingDough processingEngineeringMechanical engineering

The application belongs to the technical field of food processing, in particular to a stuffed food forming machine with a non-contact dough-cutting mechanism. The stuffed food forming machine comprises an annular rail and a forming mold which can slide on the annular rail, wherein a wrapper conveying mechanism, a stuffing mechanism, a forming mechanism and a take-out mechanism are arranged aroundthe annular rail in sequence; the wrapper conveying mechanism corresponds to a wrapper receiving station; the stuffing mechanism corresponds to a stuffing station; the forming mechanism corresponds toa forming station; the take-out mechanism corresponds to a take-out station. After being rolled for a plurality of times, sheeted dough can reach the bottom of a non-contact gripper stably to realizewrapper cutting and adsorption. MroeoverMoreover, the wrapper adsorbed to an annular station is easier to control and adjust, so that the stuffed food forming machine has the advantages that other matched equipment can be mounted reasonably and easily compared with the conventional stuffing equipment.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Mildew-proof wax for outer packing of corrugated carton and preparation method of mildew-proof wax

InactiveCN113832777AGood anti-mildew effectNot prone to adhesionFlexible coversWrappersParaffin waxPolymer science

The invention discloses mildew-proof wax for outer packing of a corrugated carton and a preparation method of the mildew-proof wax, and the mildew-proof wax is prepared from the following components in parts by mass: 15-19 parts of semi-refined paraffin, 2-5 parts of polyvinyl butyral, 2-5 parts of stearic acid, 15-20 parts of semi-refined paraffin and 1-4 parts of an additive Awe-2. The prepared mildew-proof wax is good in mildew-proof effect, capable of being stored and transported for a long time, not prone to adhesion, free of toxic substances and free of corrosion.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com