Mold release polyester film for simultaneous molding and transfer

A technology of molded polyester and laminated polyester film, which is applied in the field of mold release polyester film for synchronous transfer printing, can solve the problems of easy peeling, peeling of printing layer, partial peeling, etc., and achieve high industrial value, fine printing, The effect of not easy to stick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

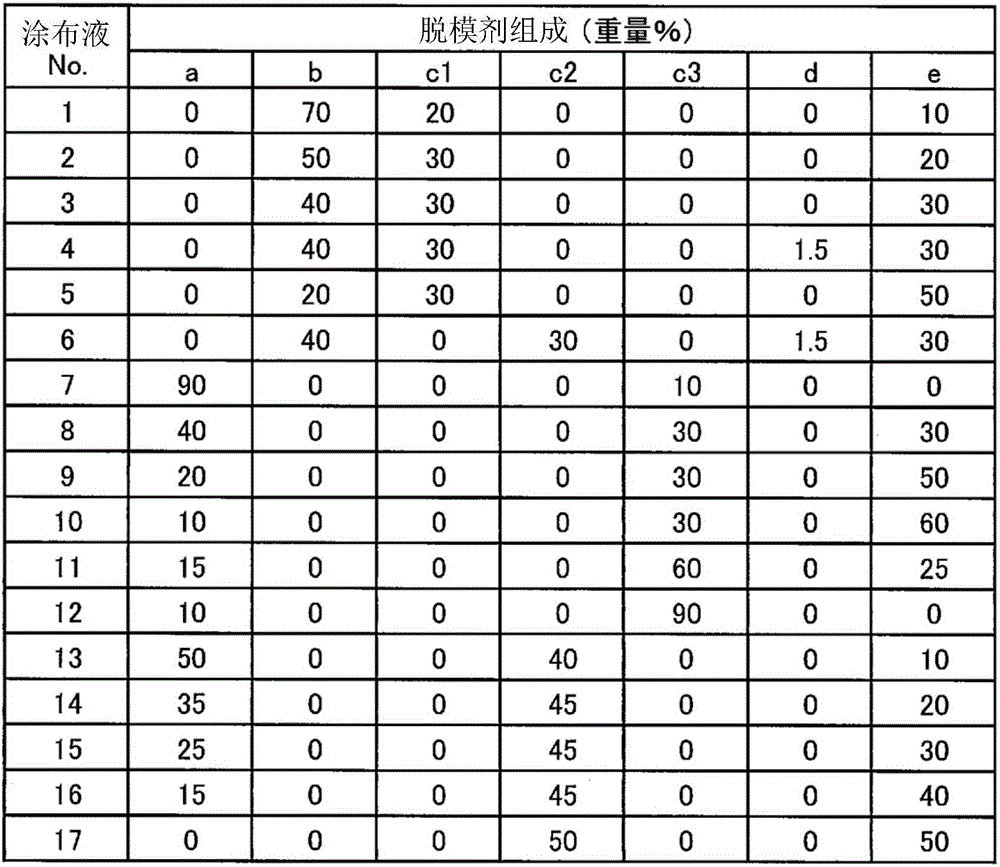

Method used

Image

Examples

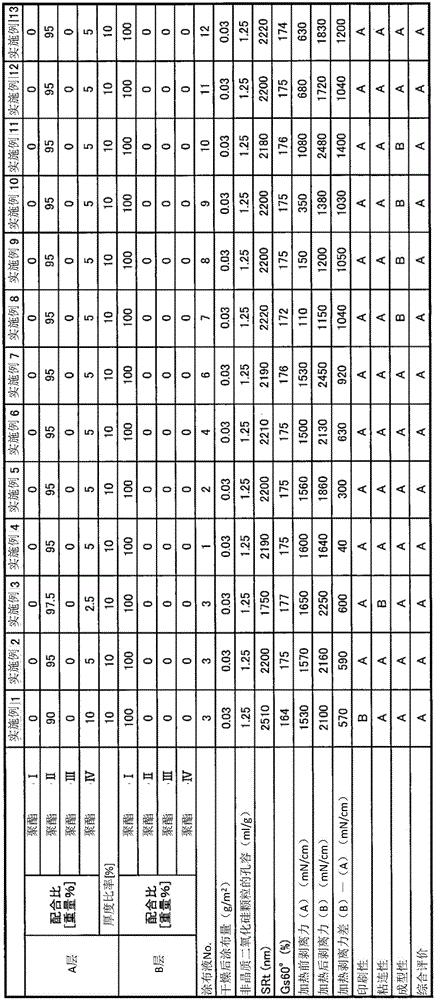

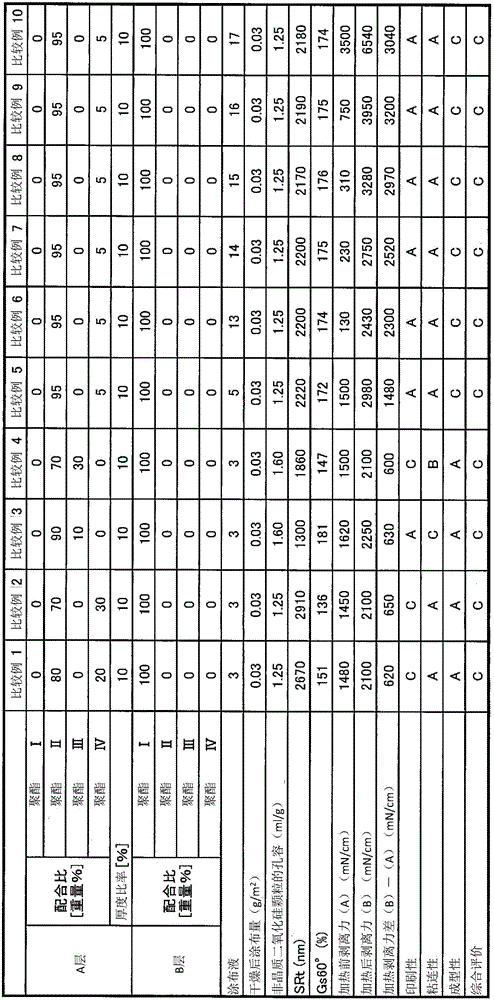

Embodiment 1

[0125] (Manufacture of release polyester film)

[0126] Blend polyester II and polyester IV as shown in Table 2 below, melt them with an extruder, and supply them to the outer layer A of the lamination die, and supply polyester I to the inner layer of the lamination die as shown in Table 2 b. Two types of three-layer laminated polyester resins consisting of outer layer A / inner layer B / outer layer A were extruded into a film and cast on a cooling cylinder at 35°C to produce a quenched and solidified unstretched film. Next, after preheating with a heating roll at 80°C, and stretching 3.4 times in the longitudinal direction between the rolls at 90°C with an infrared heater and a heating roll, apply the coating solution No. 3 in Table 1. Coating solution formulated at a ratio such that the coating amount (after drying) becomes 0.030 g / m 2 . Next, hold the end of the film with clips, introduce it into a tenter, heat it at a temperature of 95°C, and stretch it 4.0 times in the tr...

Embodiment 2

[0130] Polyester II and polyester IV were blended as shown in Table 2, melted by an extruder, and supplied to the outer layer A of the laminated mold, and a release polyester film was obtained in the same manner as in Example 1. The properties of the obtained film are shown in Table 2, showing excellent properties.

Embodiment 3

[0132] Polyester II and polyester IV were blended as shown in Table 2, melted by an extruder, and supplied to the outer layer A of the laminated mold, and a release polyester film was obtained in the same manner as in Example 1. The properties of the obtained film are shown in Table 2. Although there were still problems in the evaluation of blocking properties, excellent properties were comprehensively shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com