Non-contact gripper

A non-contact, on-body technology, applied in baking, dough cutting machinery, dough processing, etc., can solve the problems of dough elongation, thinning, dough adhesion, etc., to strengthen the adsorption force, ensure the integrity, and enhance the adsorption effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

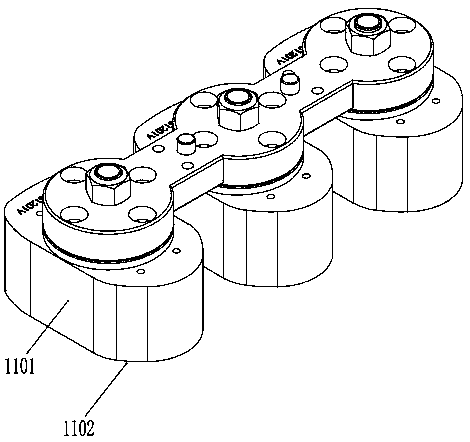

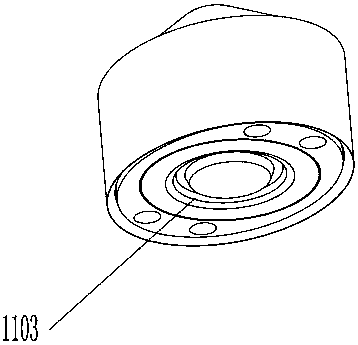

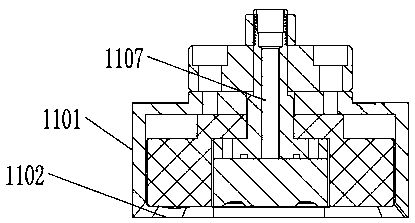

[0026] A non-contact gripper includes a gripper body 1101, a skin cutter is provided on the outer edge of the bottom of the gripper body 1101, a cutting edge 1102 is provided at the bottom of the skin cutter, and an annular groove 1103 is arranged at the bottom of the gripper body 1101 , the side of the annular groove 1103 is provided with an air outlet 1104, and the gripper body 1101 absorbs the dough to the next station by suction. The gripper body 1101 is specifically used to absorb and move the skin-cut dough from the skin-cutting station to the forming mold, and then the forming mold transports the dough to the filling station; it can also directly move the dough to the filling station through adsorption. bit. Since the air outlet 1104 is disposed on the side wall of the annular groove 1103, the negative-pressure airflow will flow along the annular groove 1103, thereby forming a negative-pressure vortex airflow similar to the principle of a tornado. The gripper body 1101...

Embodiment 2

[0028] A non-contact gripper includes a gripper body 1101, a skin cutter is provided on the outer edge of the bottom of the gripper body 1101, a cutting edge 1102 is provided at the bottom of the skin cutter, and an annular groove 1103 is arranged at the bottom of the gripper body 1101 , the side of the annular groove 1103 is provided with an air outlet 1104, and the gripper body 1101 absorbs the dough to the next station by suction. The gripper body 1101 is specifically used to absorb and move the skin-cut dough from the skin-cutting station to the forming mold, and then the forming mold transports the dough to the filling station; it can also directly move the dough to the filling station through adsorption. bit. Since the air outlet 1104 is disposed on the side wall of the annular groove 1103, the negative-pressure airflow will flow along the annular groove 1103, thereby forming a negative-pressure vortex airflow similar to the principle of a tornado.

[0029] The air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com