Easily adhesive film, method for producing same, polarizing plate, and image display device

A manufacturing method and thin film technology, which is applied in the field of image display devices, can solve the problems of low adhesion, and achieve the effect of not easy to stick and not easy to optical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

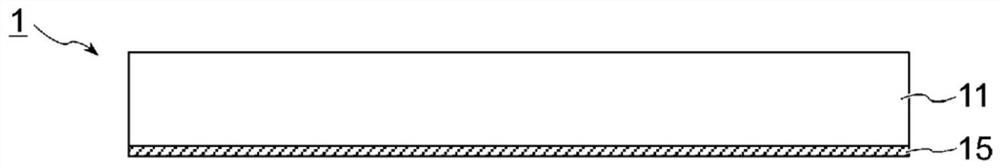

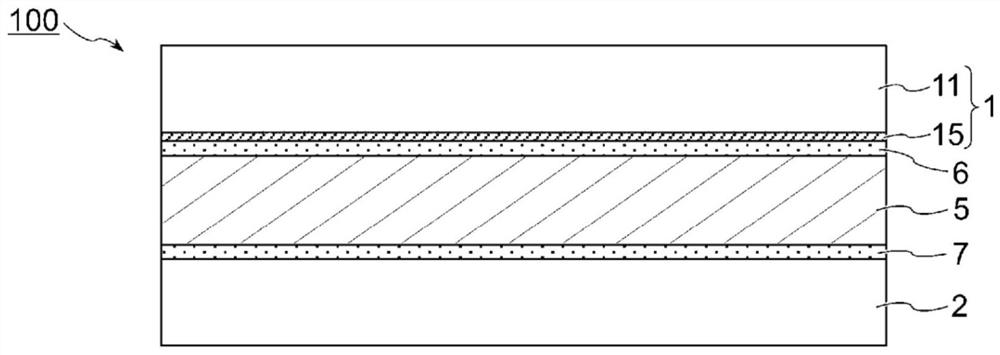

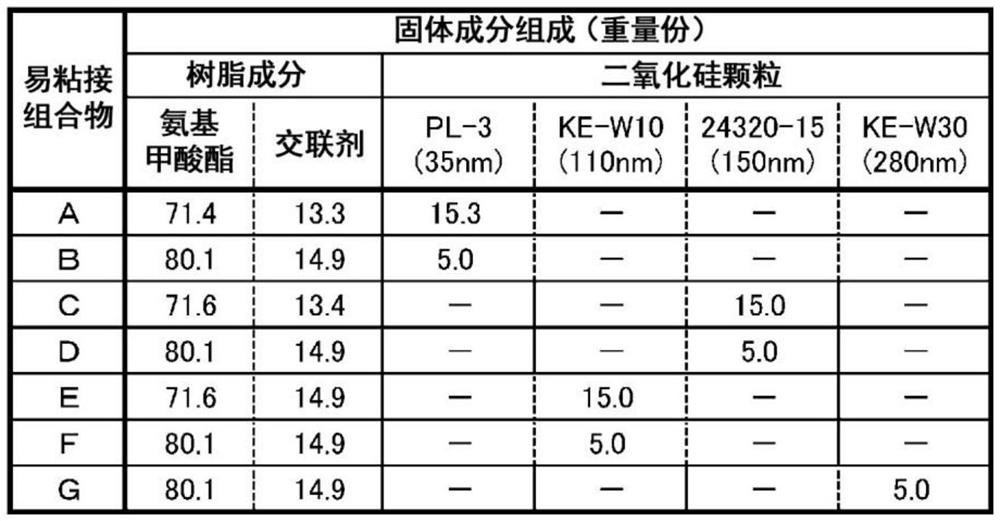

Embodiment 1

[0150] An easily-adhesive film was produced using a film production device equipped with a melt extrusion film forming device, a gravure coater, a tenter-type simultaneous biaxial stretching device, and a winding device. As the acrylic resin, the same imidized MS resin (glass transition temperature: 120°C) as that used in the preparation of "transparent protective film 1A" described in the example of JP-A-2017-26939 was used of pellets. The acrylic resin was melt-extruded from a T-die and formed into a film with a thickness of 160 μm. Using a gravure coater, one side of the film was coated with the above-mentioned easy-adhesive composition C at a wet thickness of about 9 μm. In a heating furnace, use a simultaneous bidirectional stretching tenter to stretch to 2 times along the length direction (MD) and width direction (TD), respectively, to obtain an acrylic film with a thickness of 40 μm on one side of the acrylic film with a thickness of 200 nm. Easy-to-adhesive film for b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com