Stuffed food forming machine with non-contact dough-cutting mechanism

A non-contact, forming machine technology, applied in the fields of dough slitting machinery, dough handling, food science, etc., can solve the problems of dough sticking, thinning, and stretching of the dough, to enhance the adsorption effect, ensure the integrity, and be easy to control. and the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

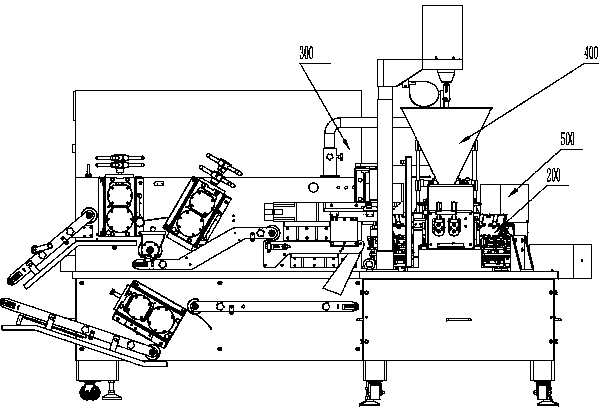

[0075] A stuffed food forming machine with a non-contact noodle cutting mechanism, comprising an annular track 100 and a forming mold 200 that can slide on the annular track 100, a dough conveying mechanism 300 and a stuffing mechanism are sequentially arranged around the annular track 100 400. Forming mechanism 500 and take-out mechanism 600, the corresponding position of the dough conveying mechanism 300 is the skin receiving station, the corresponding position of the filling filling mechanism is the filling station, the corresponding position of the forming mechanism is the forming station, the The corresponding position of the take-out mechanism is the take-out station; after the dough belt is processed by the dough conveying mechanism 300, it is cut into multiple independent dough pieces by the non-contact claw cutting device, and the dough is absorbed by the non-contact claw cutting device and then put into On the forming mold 200 on the circular track 100, the skinning o...

Embodiment 2

[0079] A stuffed food forming machine with a non-contact noodle cutting mechanism, comprising an annular track 100 and a forming mold 200 that can slide on the annular track 100, a dough conveying mechanism 300 and a stuffing mechanism are sequentially arranged around the annular track 100 400. Forming mechanism 500 and take-out mechanism 600, the corresponding position of the dough conveying mechanism 300 is the skin receiving station, the corresponding position of the filling filling mechanism is the filling station, the corresponding position of the forming mechanism is the forming station, the The corresponding position of the take-out mechanism is the take-out station; after the dough belt is processed by the dough conveying mechanism 300, it is cut into multiple independent dough pieces by the non-contact claw cutting device, and the dough is absorbed by the non-contact claw cutting device and then put into On the forming mold 200 on the circular track 100, the skinning o...

Embodiment 3

[0084] A stuffed food forming machine with a non-contact noodle cutting mechanism, comprising an annular track 100 and a forming mold 200 that can slide on the annular track 100, a dough conveying mechanism 300 and a stuffing mechanism are sequentially arranged around the annular track 100 400. Forming mechanism 500 and take-out mechanism 600, the corresponding position of the dough conveying mechanism 300 is the skin receiving station, the corresponding position of the filling filling mechanism is the filling station, the corresponding position of the forming mechanism is the forming station, the The corresponding position of the take-out mechanism is the take-out station; after the dough belt is processed by the dough conveying mechanism 300, it is cut into multiple independent dough pieces by the non-contact claw cutting device, and the dough is absorbed by the non-contact claw cutting device and then put into On the forming mold 200 on the circular track 100, the skinning o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com