Polymer concrete pipe production line

A production line, polymer technology, applied in tubular articles, applications, household appliances, etc., can solve problems such as shedding, limited pressure bearing performance, pipeline damage, etc., to reduce the phenomenon of erosion, enhance the overall adhesion, and improve the yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

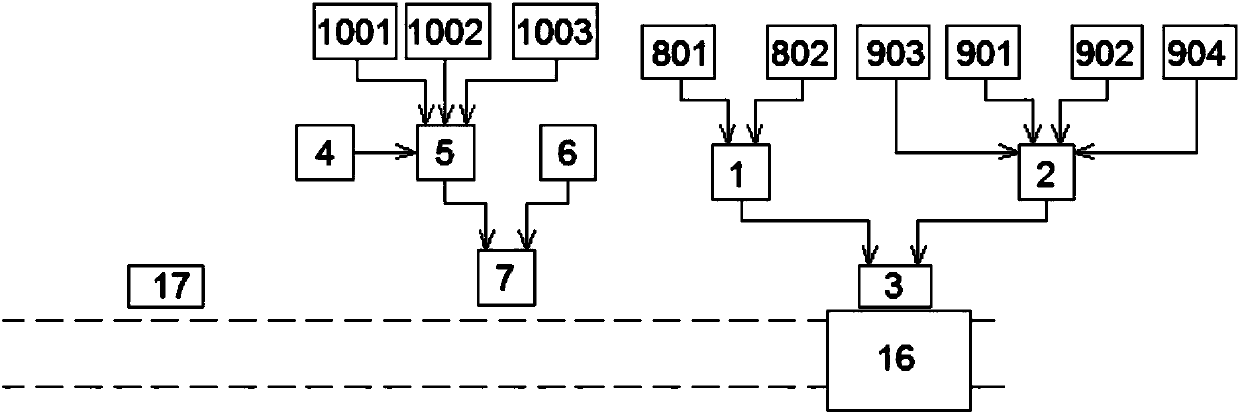

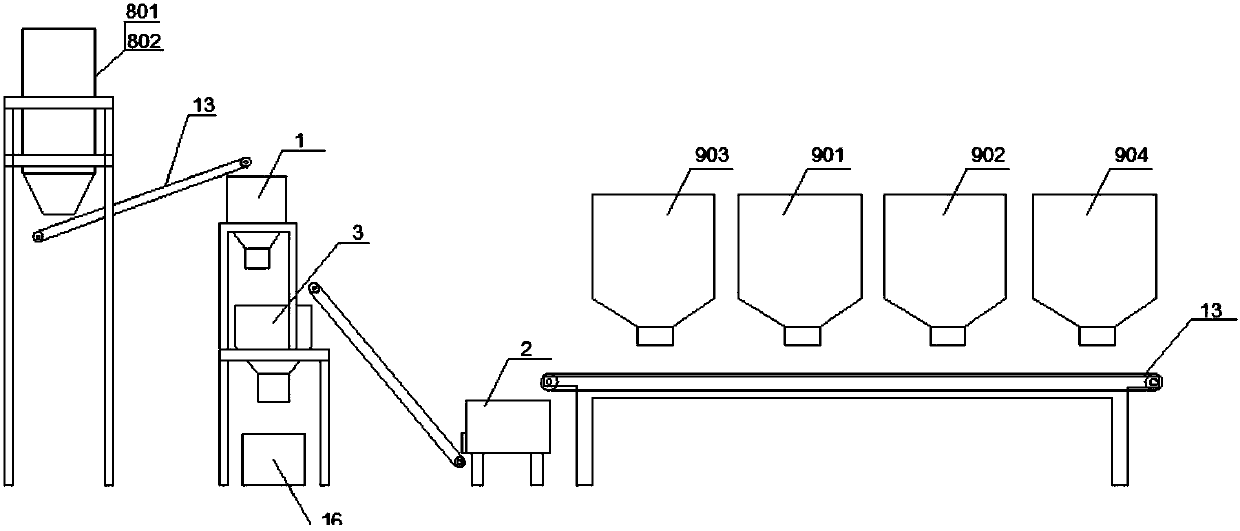

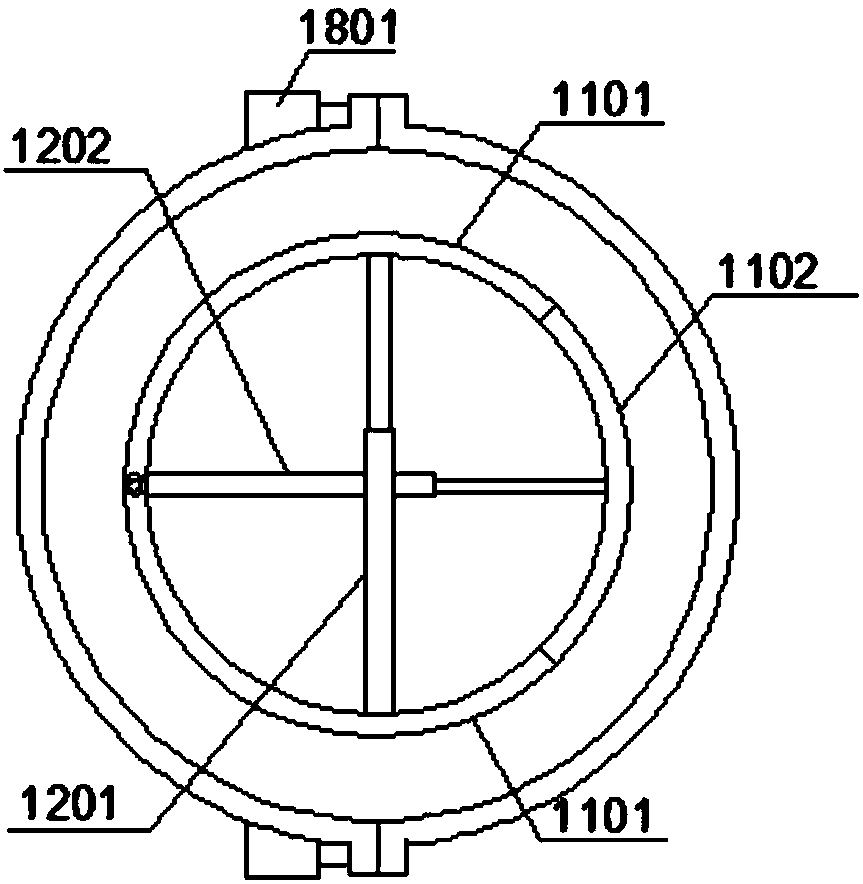

[0021] The invention relates to a polymer concrete pipeline production line, comprising an aggregate supply mechanism, a liquid material supply mechanism, a mixing mechanism and a pouring mechanism. The input ends of the mixing mechanism are respectively corresponding to the output ends of the aggregate supply mechanism and the liquid material supply mechanism. The output end of the mixing mechanism is connected with the input end of the pouring mechanism. The aggregate supply mechanism includes a first mixer 1 and a second mixer 2, and a first mixer 1 and a second mixer arranged in parallel The output ends of 2 are connected to the input end of the third mixer 3. The input end of the first mixer 1 is connected to a group of coarse bins arranged in parallel, and the input end of the second mixer 2 is connected to a group of powders arranged in parallel. Silo; the liquid material supply mechanism includes a set of auxiliary tank, resin tank 4, transfer tank 5, auxiliary material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com