Patents

Literature

37results about How to "Stable antistatic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

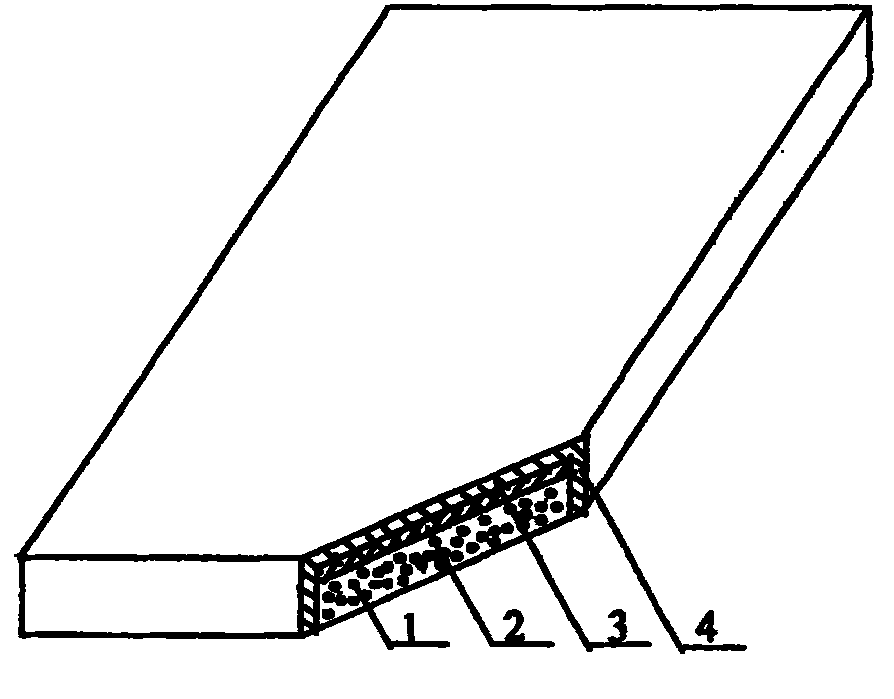

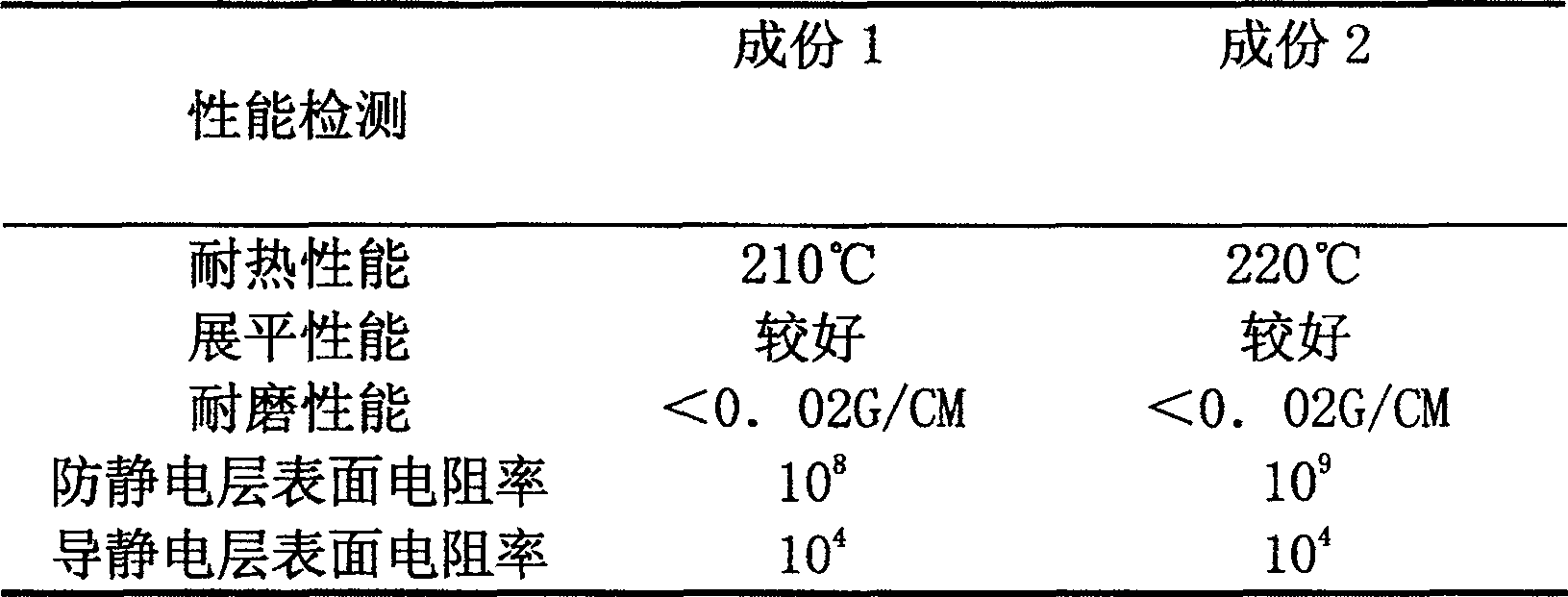

Electrostatic-resisting rubber board and its production

ActiveCN101074301AWill not polluteWon't change colorOther chemical processesEngineeringPolymer science

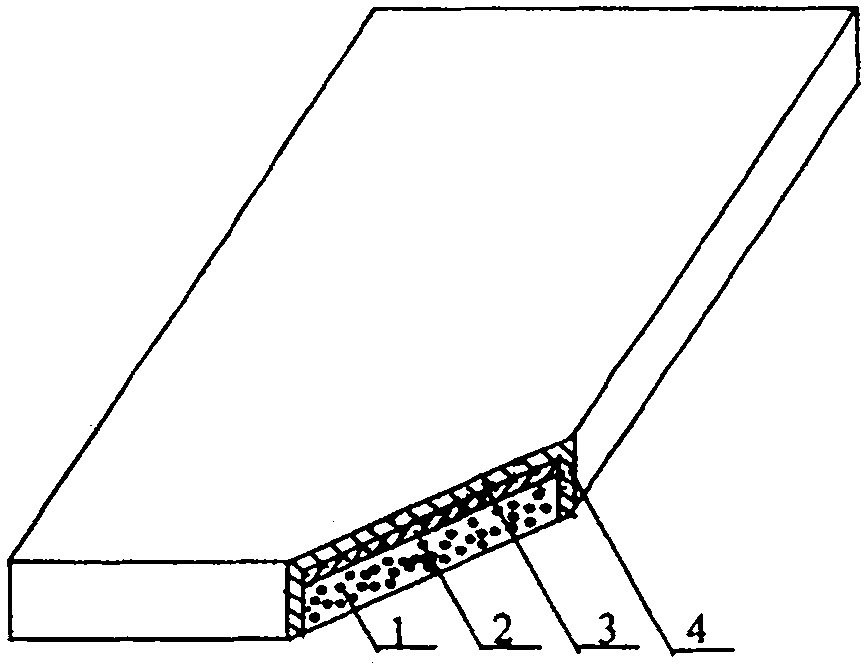

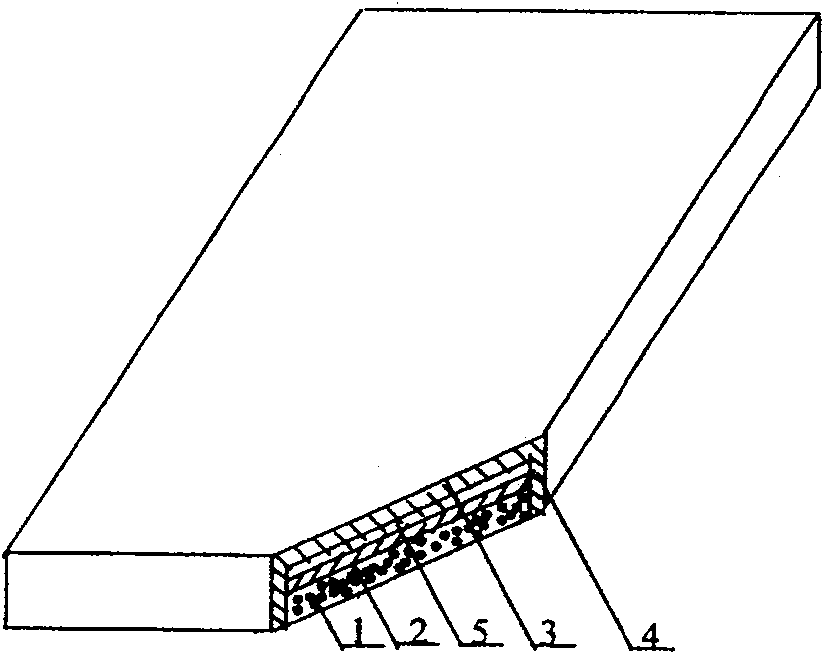

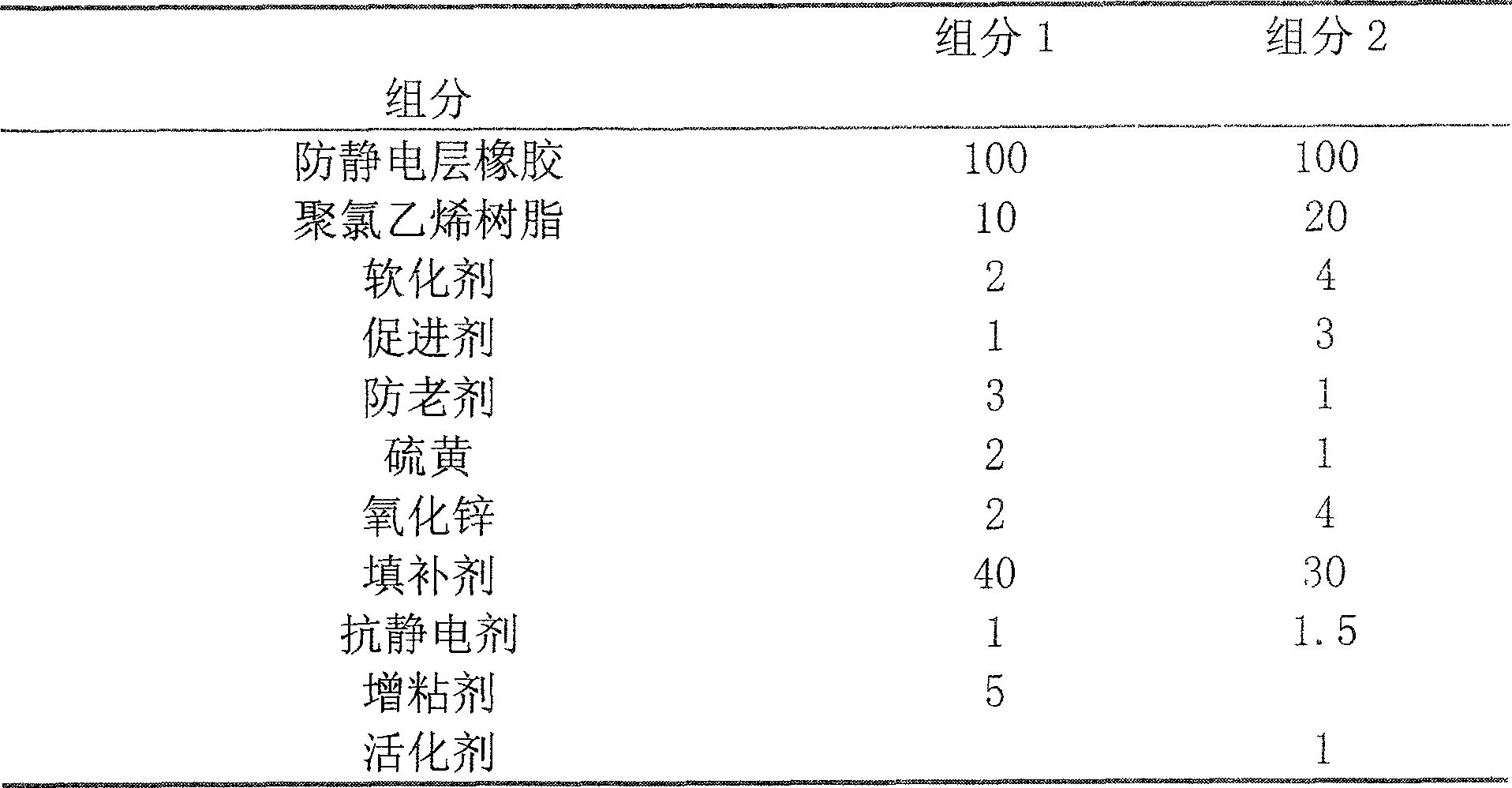

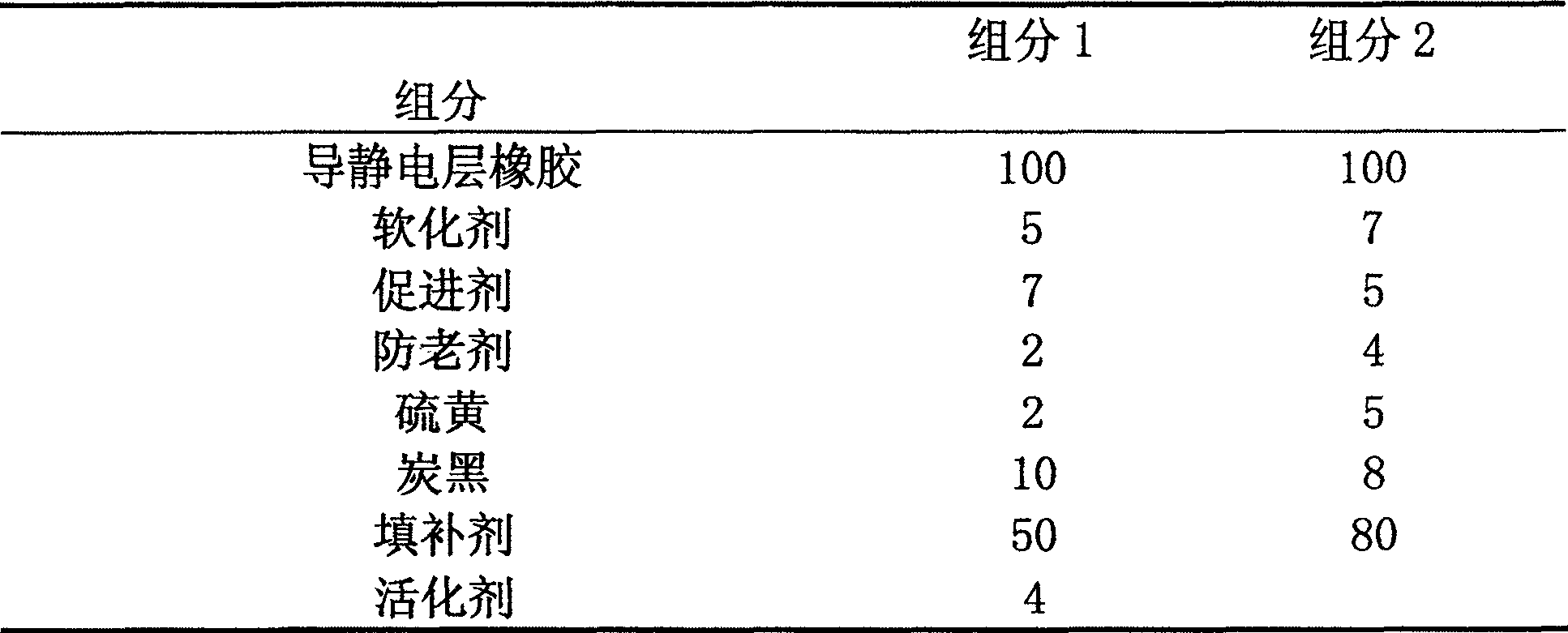

An anti-electrostatic rubber plate (desk pad and floor mattress) and its production are disclosed. The anti-electrostatic rubber plate consists of anti-electrostatic layer and conducting layer. It is prepared by preparing anti-electrostatic layer, preparing conducting layer film and vulcanizing to obtain final product.

Owner:浙江一远静电科技有限公司

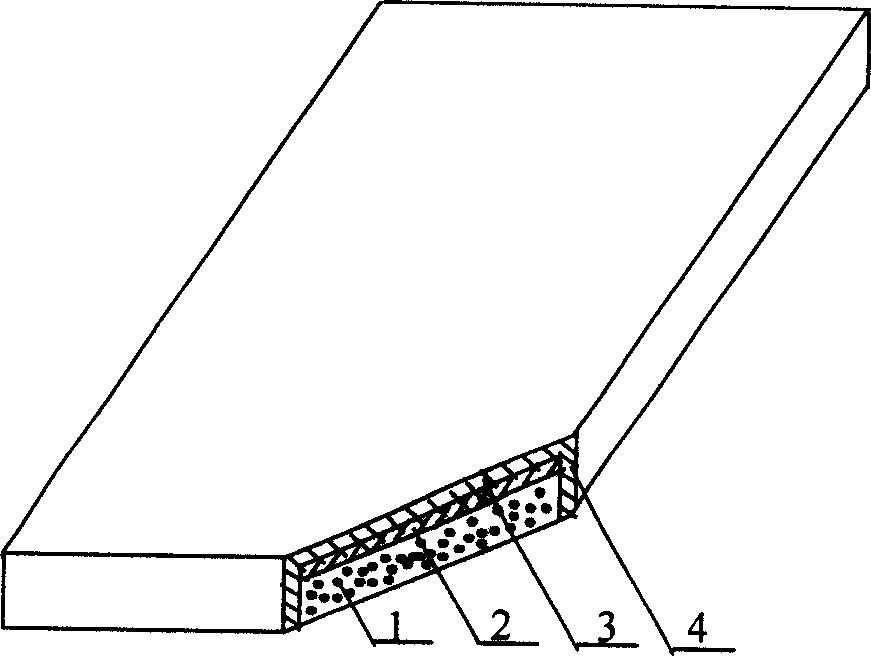

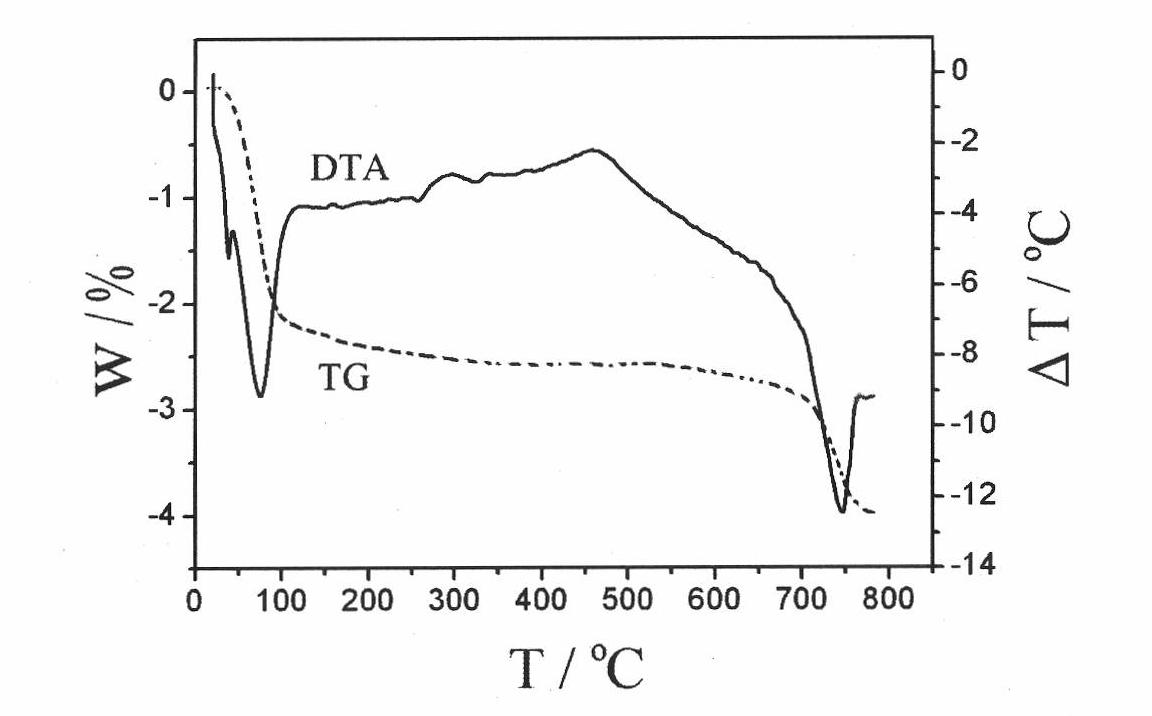

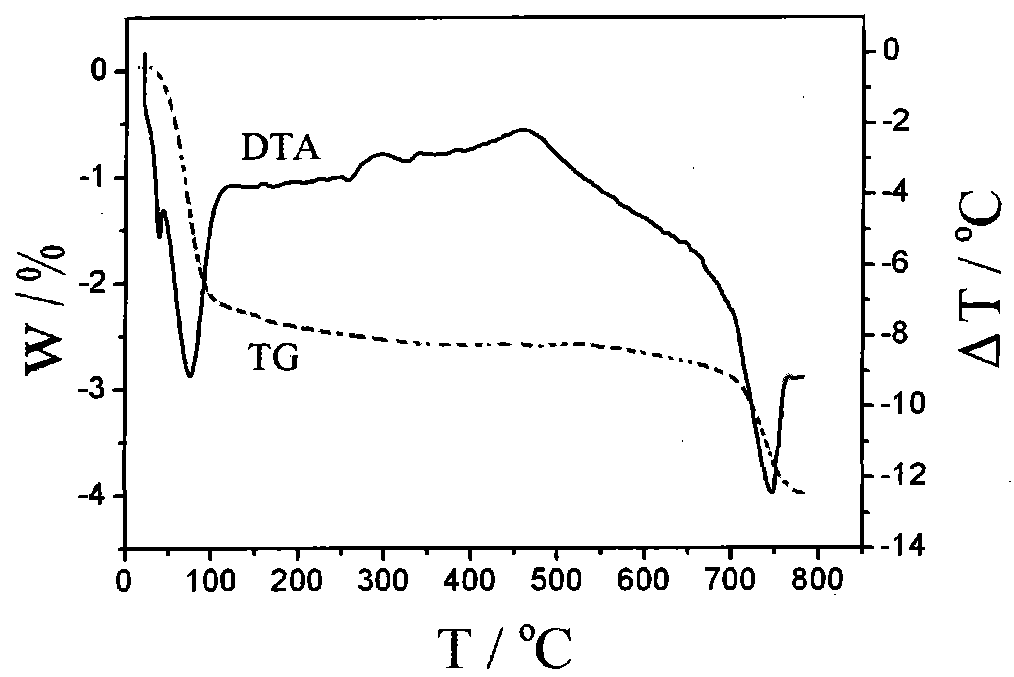

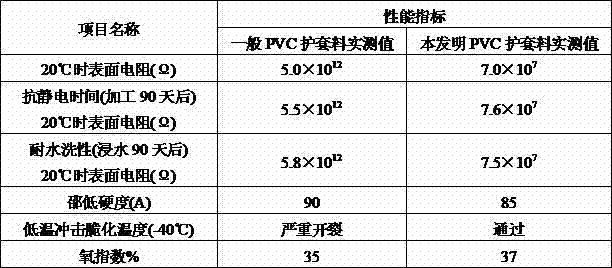

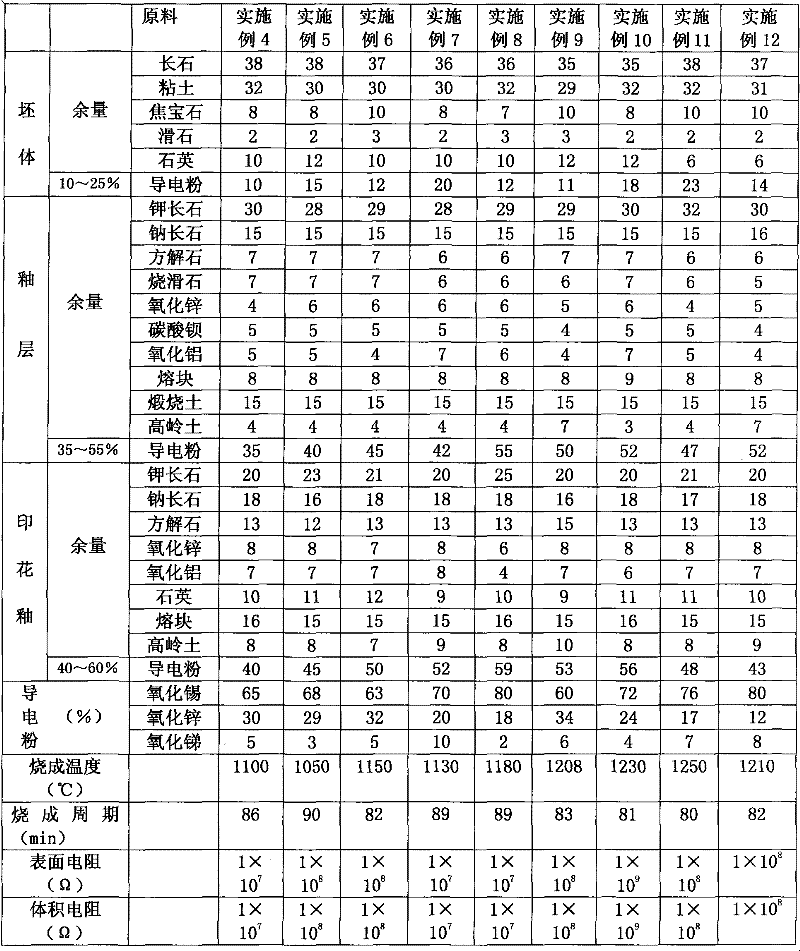

Electrostatic-proof ceramics wall floor tile and preparation method thereof

InactiveCN1693289AStable antistaticLess amount of conductive fillerClaywaresTransition layerSemiconductor

An antistatic ceramic tile for floor or wall is prepared through preparing ceramic blank, preparing antistatic enamel from enamel and semiconductor oxide chosen from SnO2, TiO2 and ZnO through proportional mixing, coating enamel transition layer on the ceramic blank, drying, coating antistatic enamel, drying, coating antistatic enamel on its peripheral surface, and calcining.

Owner:SOUTH CHINA UNIV OF TECH +1

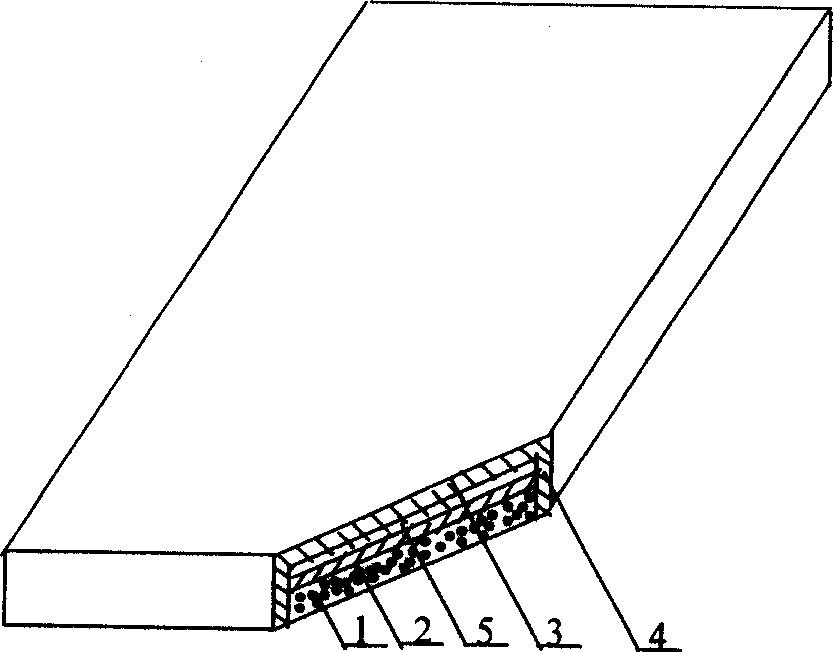

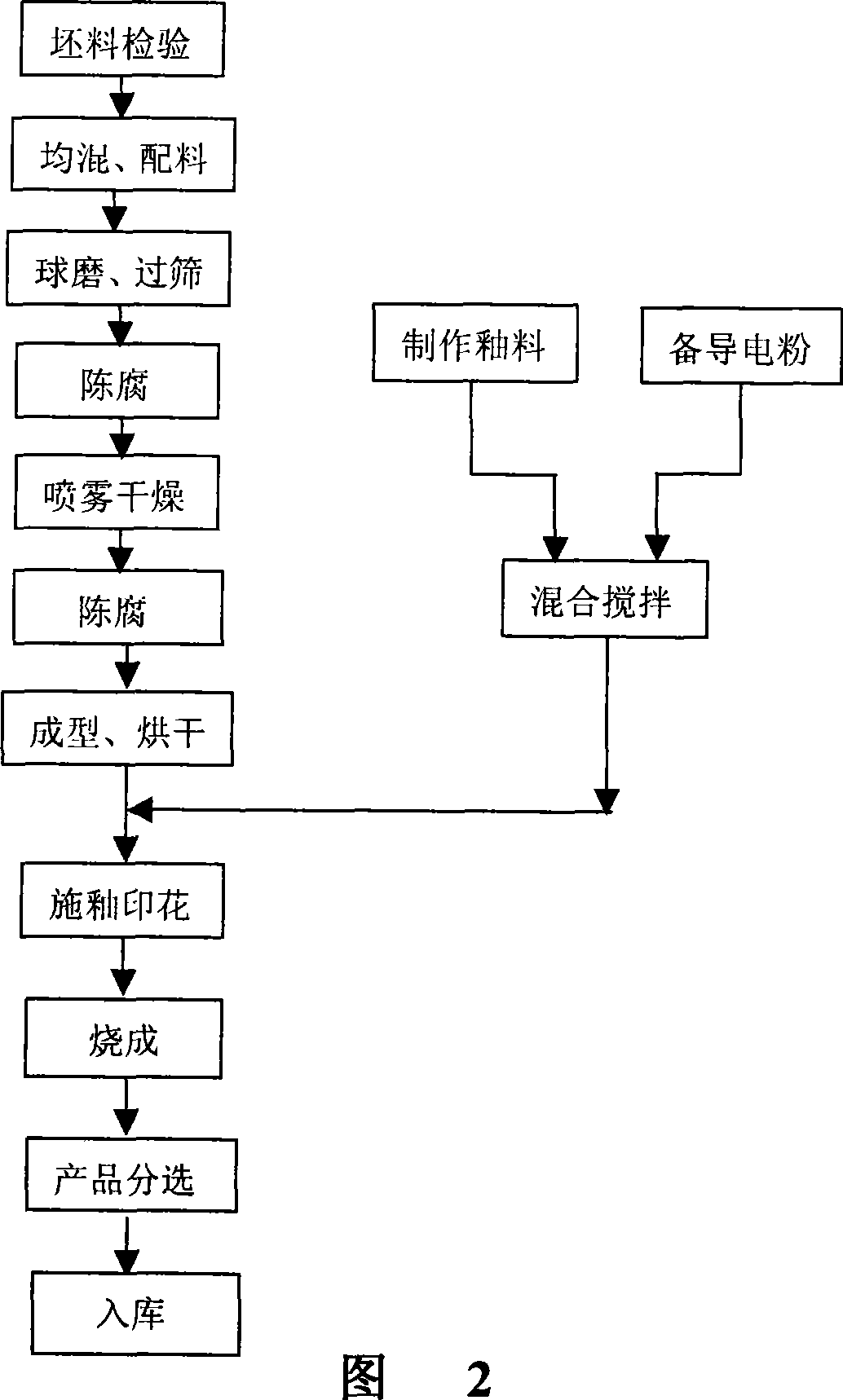

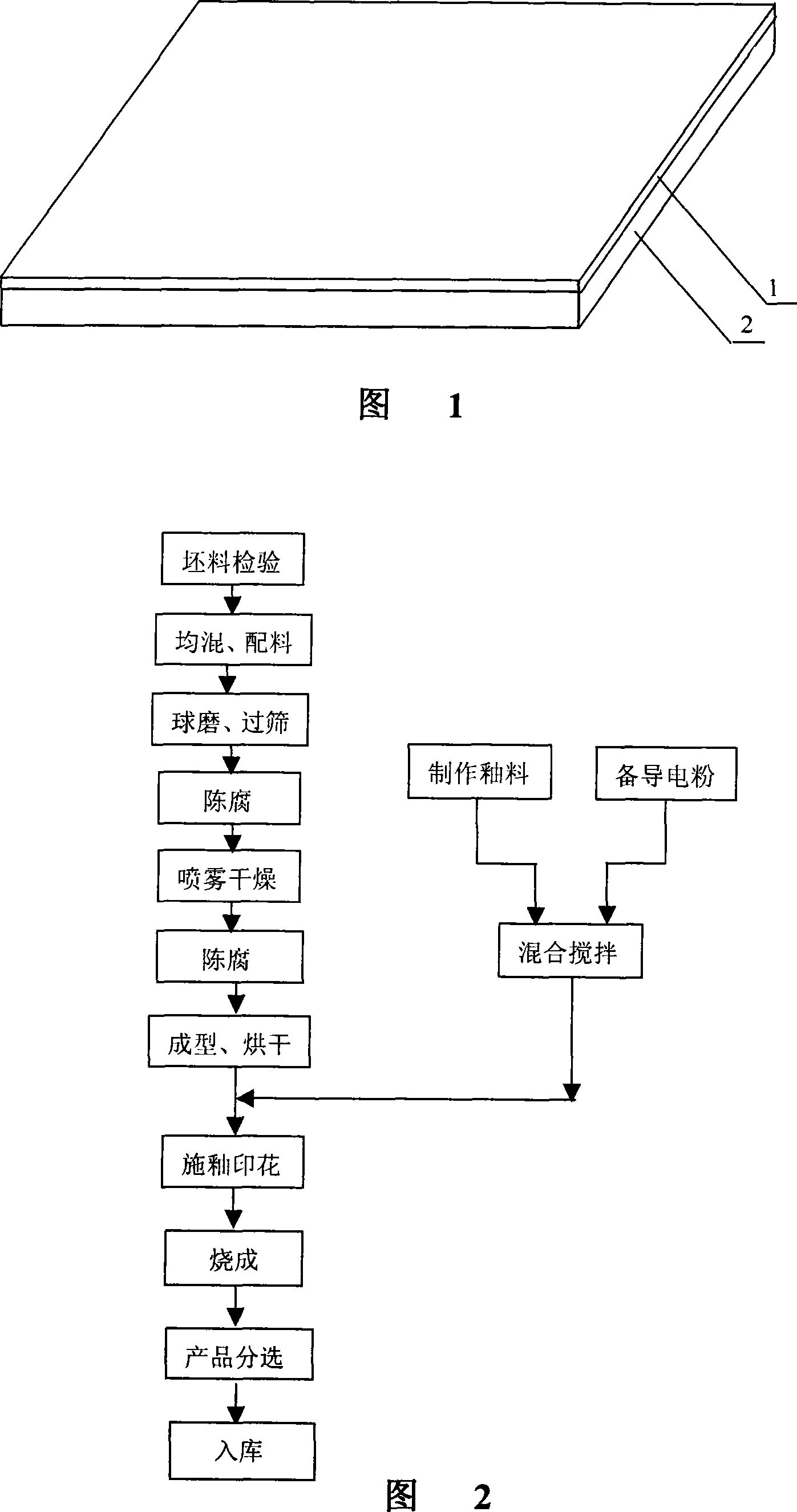

Antistatic ceramic floor and preparing method thereof

The invention discloses an anti-static ceramic floor and a preparation method thereof. The anti-static ceramic floor comprises a body of the ceramic floor, a surface layer of the ceramic floor is baked with a mixed layer of glaze and conductive powder, the conductive powder accounts for 20 to 40 percent of the material weight of the mixed layer, wherein the conductive powder comprises the following compositions in weight percentage: 55 to 90 percent of Sn, 5 to 25 percent of Zn, and 5 to 25 percent of Ti. The preparation method comprises the following steps: the glaze is produced first, and then the conductive powder is added according to the mixing proportion of the glaze and the conductive powder to mix and stir evenly; after a molding process of the ceramic floor is finished, a mixed material of the glaze and the conductive powder is coated on the surface layer of the ceramic floor according to the preset printing proposal; the baking and the separation to finished products are performed to obtain the qualified finished products.

Owner:BEIJING YUNHE INDAL & TRADE

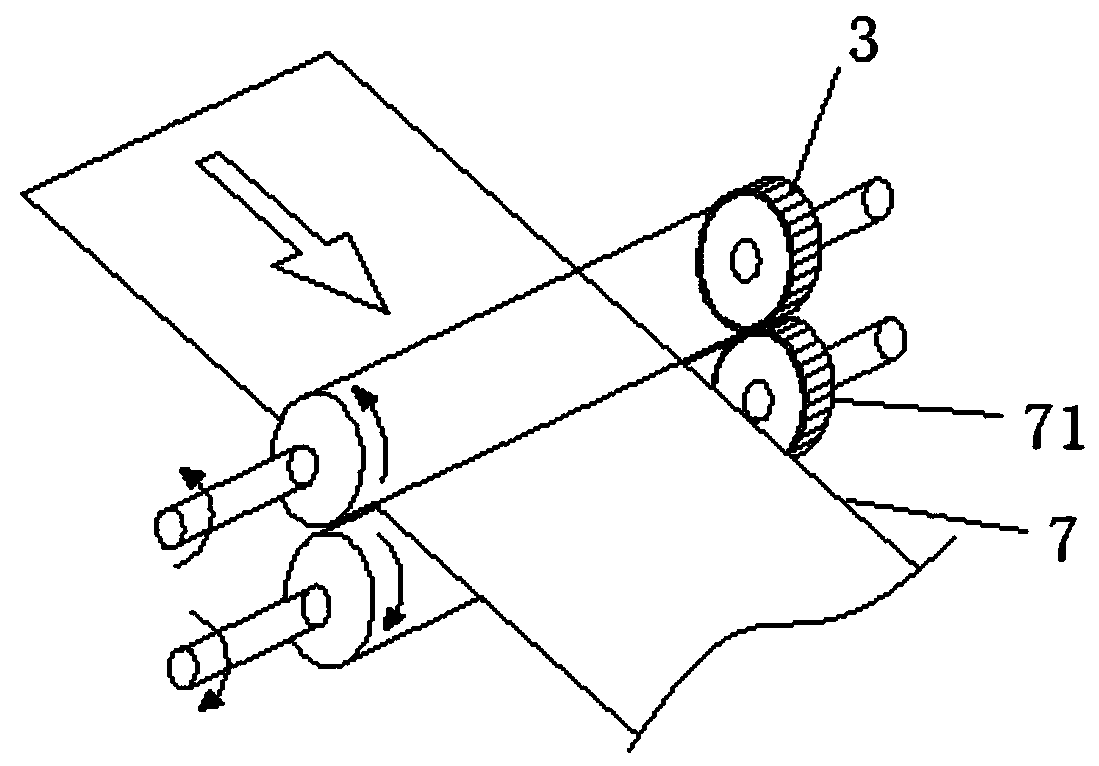

OCA optical cement die cutting technology

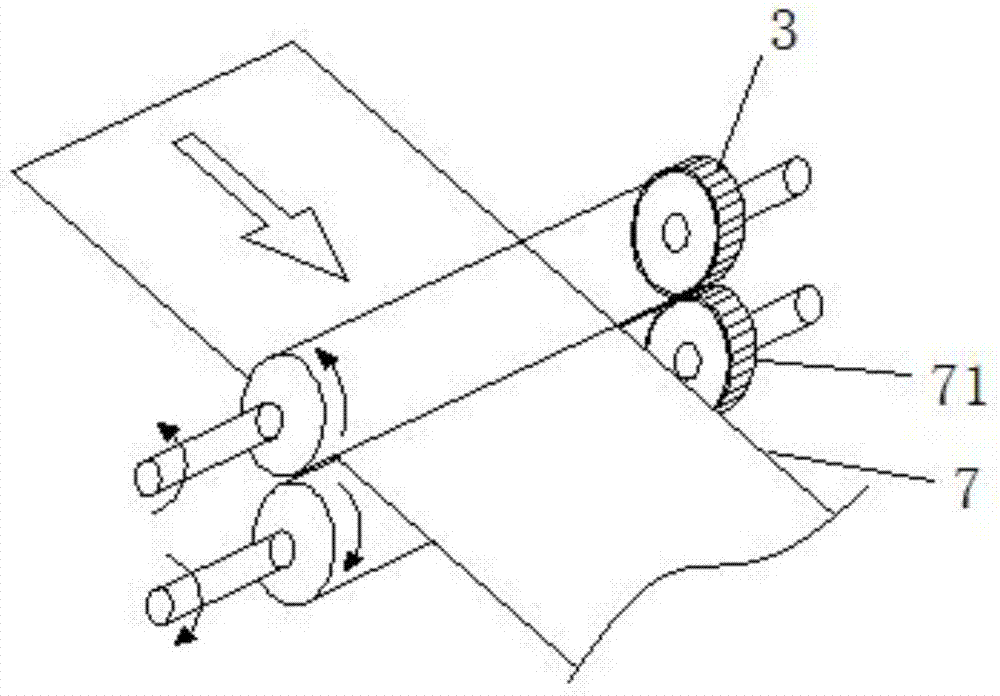

ActiveCN107414929AAvoid gluingAvoid squeezingLamination ancillary operationsLaminationPunchingMaterials science

The invention discloses an OCA optical cement die cutting technology. The OCA optical cement die cutting technology comprises the following steps that die cutting operation is conducted in a thousand-level dust-free room of 80-90 % humidity; after a cutting knife is dedusted, the cutting knife cuts raw materials into small rolls to be hung on a material frame; an upper layer light release film self-contained by OCA optical cement is torn, and an OCA layer is exposed; after anti-sticking processing is conducted on a rolling cutter, the rolling cutter cuts to the two sides of the OCA layer, and a reserved part is formed between a cutting line and the edge of the rolling cutter; after a mylar layer is pasted on the reserved part, and the reserved part and the mylar layer are torn together; an anti-static film is attached to the surface of the OCA layer through a rubber covered roller, and rubber covered roller foam is circumferentially attached to the two sides of the rubber covered roller; the anti-static film is cut off by a punching cutter, and the outer frame edge of a product is greater than the edge of the OCA layer; and cutting is conducted every time the punching cutter rotates one revolution, and neatly-collecting-stacking is conducted. According to the OCA optical cement die cutting technology, the effects that the product has no cement pulling and cement overflowing are achieved.

Owner:昆山威斯泰电子技术有限公司

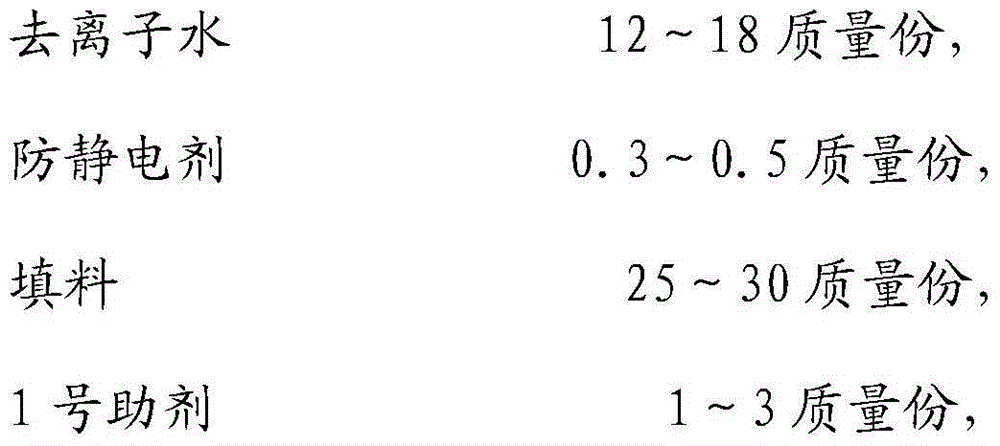

Functional anti-static wall surface paint and preparation method thereof

InactiveCN104140743AImprove surface propertiesPromote environmental protectionEpoxy resin coatingsElectrically-conductive paintsEnvironmental resistanceEmulsion

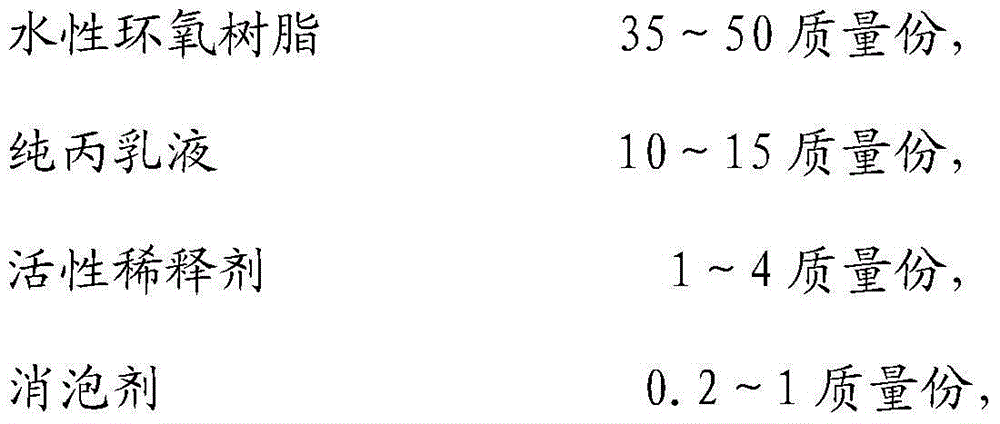

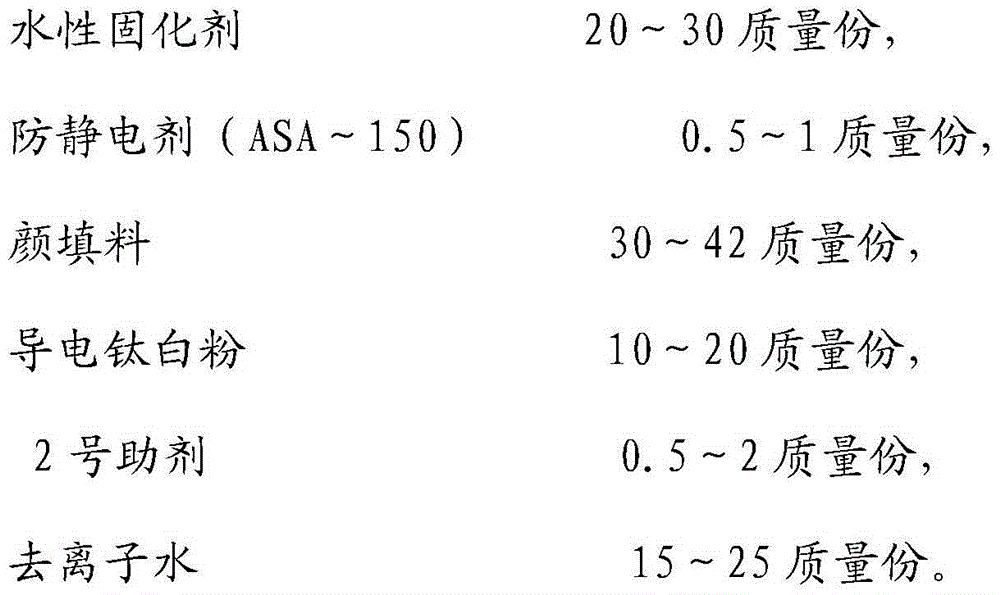

The invention discloses functional anti-static wall surface paint and a preparation method thereof, and aims at providing wall surface paint which is anti-static, environment-friendly, high in stain resistance, good in decoration effect, scrub-resistant, mildew-proof and anti-bacterial. According to the technical key points, the wall surface paint comprises a system A and a system B, wherein the mass ratio of the system A to the system B is 1: 1; the system A is prepared from a system A1 and a system A2; the system A1 is prepared from the following components in parts by mass: 12-18 parts of de-ionized water, 0.3-0.5 part of an anti-static agent, 25-30 parts of fillers and 1-3 parts of an assistant I; the system A2 is prepared from the following components in parts by mass: 35-50 parts of waterborne epoxy resin, 10-15 parts of pure acrylic emulsion, 1-4 parts of a reactive diluent and 0.2-1 part of a defoamer; and the system B is prepared from the following components in parts by mass: 20-30 parts of a waterborne curing agent, 0.5-1 part of an anti-static agent, 30-42 parts of fillers, 10-20 parts of conductive titanium dioxide, 0.5-2 parts of an assistant II and 15-25 parts of de-ionized water. The wall surface paint belongs to the technical field of coatings.

Owner:GUANGZHOU LEOBO PAINT TECH

Anti-static bamboo fiber mould composite material

The invention relates to an anti-static bamboo fiber mould composite material which comprises the compositions as follows: 55 to 70 percent of bamboo fiber, 15 to 55 percent of wood meal, 22 percent of low density polyethylene, and the like. The modified composite material provided by the invention has the effects of environmental friendliness, acoustic insulation, heat insulation, good air tightness, high strength, good tolerance, favorable anticorrosion performance and stable anti-static performance. Corrosion preventive in the plastic-wood composite material can prolong the service life of the plastic-wood composite material and improve the physical and mechanical properties of the plastic-wood composite material. Moreover, the composite material can eliminate static electricity, avoid electric shock phenomena, eliminate discomfort caused by electric shocks and promote physical health.

Owner:CHANGSHU CHANGFU ORGANIC COMPOUND FERTILIZER

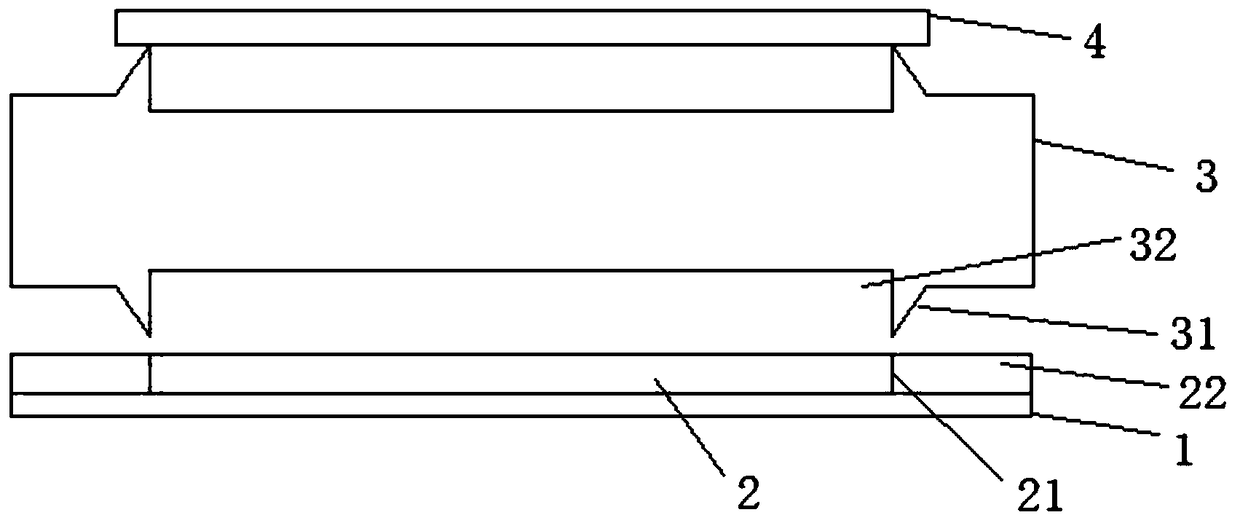

Liquid crystal display with excellent antistatic performance and manufacturing method thereof

InactiveCN104977765ANo static residueStable antistaticNon-linear opticsElectrostatic chargesLiquid-crystal displayEngineering

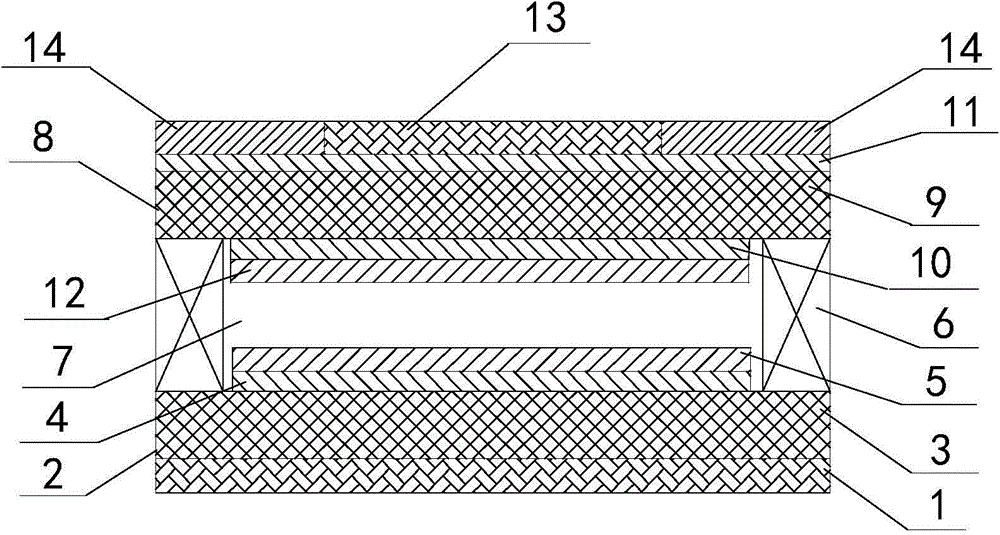

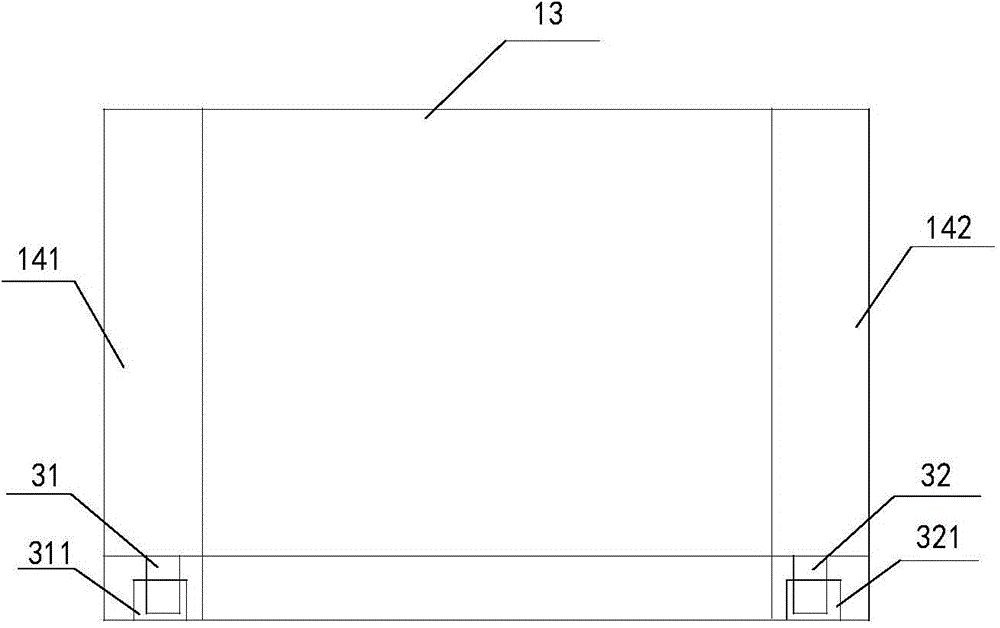

The invention discloses a liquid crystal display with excellent antistatic performance and a manufacturing method thereof. The liquid crystal display comprises double-faced ITO glass, a frame, bottom ITO glass and bottom polaroid. A liquid crystal is arranged in the space formed by the double-faced ITO glass, the frame and the bottom ITO glass. The double-faced glass comprises face glass, a first ITO conductive layer arranged on the surface of the face glass and a second ITO conductive layer arranged on the lower surface of the face glass and etched with a first ITO pattern. The bottom ITO glass comprises bottom glass and a third ITO conductive layer arranged on the upper surface of the bottom glass and etched with a second ITO pattern. A polaroid is arranged in a vision area on the upper part of the first ITO conductive layer. A piece of conductive cloth is arranged outside the vision area of the upper part of the first ITO conductive layer and is connected with a static electricity lead-out device. According to the invention, via the 8KV discharge, there is no static electricity left in the LCD; the antistatic performance of the product is stable; and service lifetime of the product can reach 100000 hours.

Owner:江苏骏成电子科技股份有限公司

Preparation method of antistatic composite fabric

The present invention discloses a preparation method of an antistatic composite fabric. The method is characterized by comprising the following steps of 1, preparing conductive fibers; 2, cleaning theobtained antistatic fibers with warm water, and drying the antistatic fibers until the water content is below 10%; 3, knitting blended yarns of the antistatic fibers and cotton fibers in different proportions on a knitting machine to form knitted grey cloth; 4, sequentially performing a bleaching process, a dyeing process, an antibacterial process and a setting process on the knitted grey cloth to obtain the antistatic knitted fabric. According to the method, the fibers are combined with antistatic modification liquid, a hydrophilic soft finishing agent and absolute ethanol and are blended with the cotton fibers, and the blended yarns are subjected to bleaching, dyeing, antibacterial treatment and setting, so that the fabric has the excellent antistatic performance, the problem that the knitted composite fabric generates static electricity in the prior art and the problem of relatively difficult antistatic care of the fabric are effectively solved, the fabric is soft in hand feeling,comfortable and breathable, the skin affinity of the composite fabric is improved, and the use comfort is improved.

Owner:宁波太平鸟潮服饰营销有限公司

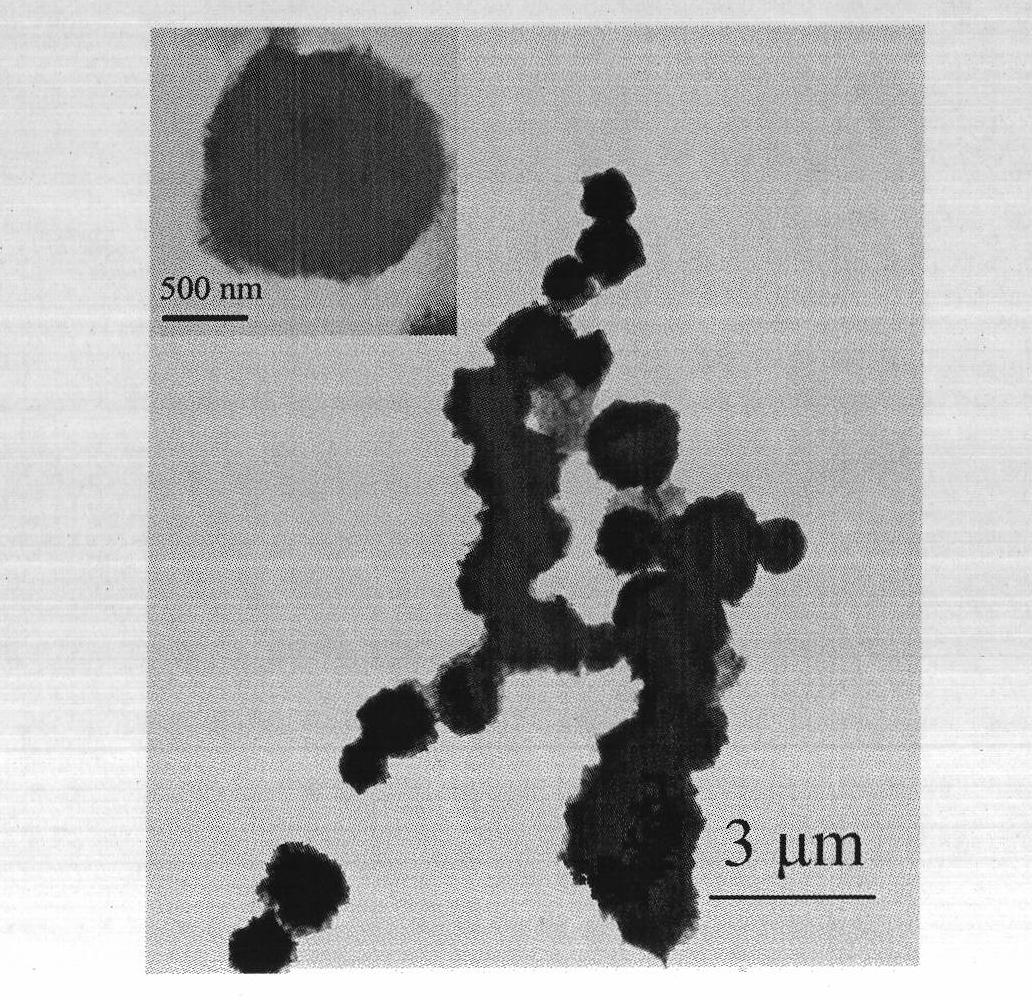

Calcium carbonate/nickel composite conductive material matrix antistatic coating and preparation method thereof

ActiveCN101921528AEasy to obtainGuaranteed antistatic effectEpoxy resin coatingsElectrically-conductive paintsMetallic materialsEconomic benefits

The invention discloses a calcium carbonate / nickel composite conductive material matrix antistatic coating and a preparation method thereof. The antistatic coating comprises the following main components in percentage by weight: 10-70 percent of composite conductive material, 0.5-3.0 percent of dispersant, 0.5-3.0 percent of wetting dispersant, 0.1-2.0 percent of deformer, 0.1-2.0 percent of leveling agent, 10.0-50.0 percent of resin and the balance of mixed thinner. In the invention, the antistatic coating is prepared by adding the calcium carbonate / nickel composite conductive material with favorable conductivity so that the antistatic effect of the antistatic coating is equivalent to that of a metal matrix antistatic coating and is stable and unchanged along with the changes of temperature, time, moisture, and the like. Compared with the metal matrix antistatic coating, the prepared antistatic coating greatly decreases the production cost, improves the economic benefits of enterprises, simultaneously solves the problems of excessive metal material consumption, and the like, accords with the sustainable development strategy and can be widely applied to the fields of electronic equipment, container pipelines, indoor decoration, furniture finishing, and the like.

Owner:池州市贵兴非矿新材料有限公司

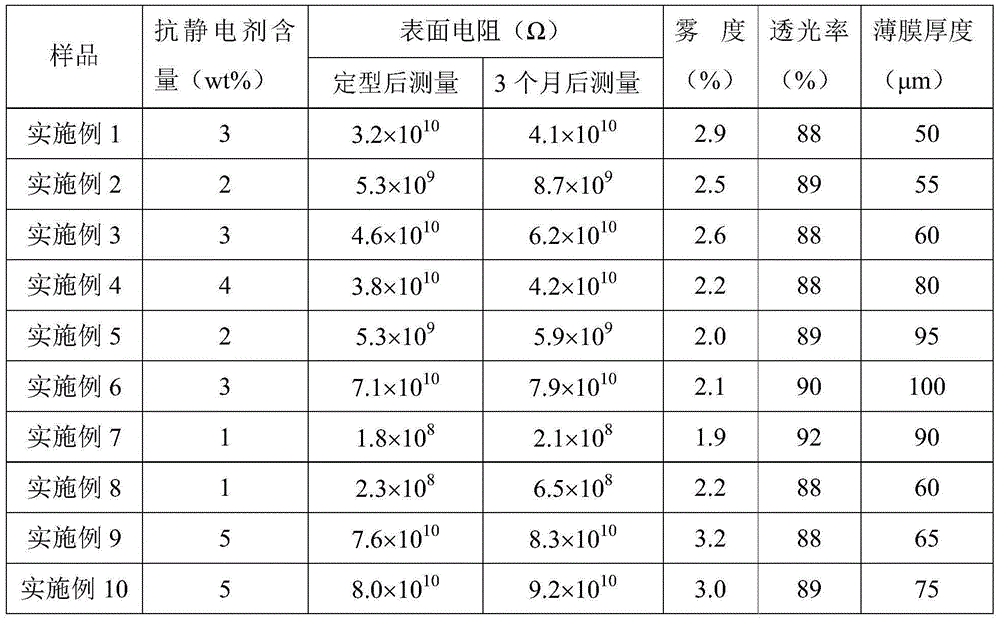

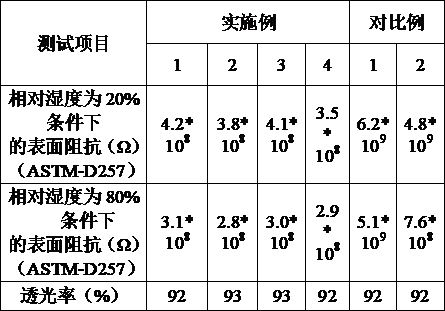

A kind of highly transparent antistatic PET polyester film and preparation method thereof

ActiveCN104086957BImprove antistatic performanceHigh transparencyPolyethylene terephthalate glycolAntistatic agent

The invention discloses a high transparent anti-static PET (polyethylene terephthalate) polyester thin film and a preparation method thereof. The high transparent anti-static PET polyester thin film comprises the following components: PET, an anti-static agent and an antioxidant at a mass ratio of (95-99):(1-5):0.1. Block copolymerization is carried out on terephthalic acid, ethylene glycol and polyether, and the obtained copolymer is subjected to twin-screw extrusion pelletizing, so that an anti-static master batch, namely the anti-static agent, is prepared; a PET polyester is chipped, the anti-static master batch is subjected to vacuum drying, the anti-static master batch and the PET polyester chips are uniformly mixed, the antioxidant is added and mixing is carried out; then a thick film is obtained by virtue of twin-screw extrusion, and the thick film is subjected to two-way stretching and then is sized, so that the high transparent anti-static thin film is obtained. The PET polyester thin film has the advantages that the anti-static function of the thin film is improved, the surface resistance of the PET polyester thin film can be reduced to 108-1010 ohm, and high transparency is also maintained; by adopting the anti-static master batch, a long-time and stable anti-static function can be played.

Owner:HANGZHOU HUASU IND

Arc-proof fabric and preparation method thereof

InactiveCN111235721AAntistatic long-lastingImprove antistatic performanceWoven fabricsYarnTextile technologyPolymer science

The invention relates to the field of textile technology, and disclose arc-proof fabric. The arc-proof fabric comprises warp yarn and weft yarn, wherein the warp yarn is composed of following raw materials in part by weight: 20-30 parts of modal fiber, 15-25 parts of nylon fiber, 13-20 parts of bamboo fiber, 10-15 parts of aramid fiber and 2-5 parts of conductive fiber; and the weft yarn consistsof the following raw materials in part by weight: 25-35 parts of vinylon fiber, 20-30 parts of flame retardant PTFE fiber, 15-25 parts of polysulfone amide fiber, 13-20 parts of bamboo charcoal fiberand 8-15 parts of polyurethane fiber. According to the arc-proof fabric, through various ratio of fiber content, a synergistic effect between materials is played, reasonable compatibility design is realized, on the basis of meeting the arc protection performance of the fiber, the fabric is enabled to have soft hand feeling, abrasive resistance, antibacterial property, no melting drops meeting fireand the other excellent features; and the fabric antistatic performance is long-acting, lasting and stable, the mechanical strength and toughness are increased, after repeated washing, the effect offlame-retarded and antistatic properties is not affected, a wearer can wear more comfortably, and the comprehensive performance is high.

Owner:宁波太平鸟潮服饰营销有限公司

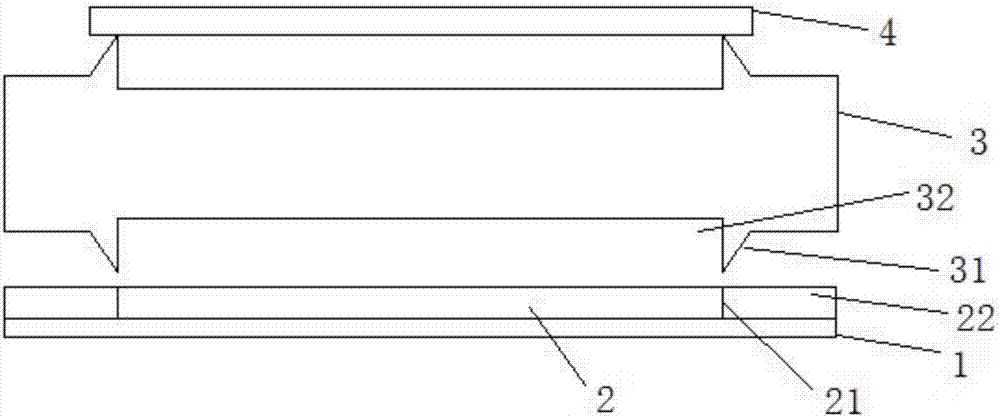

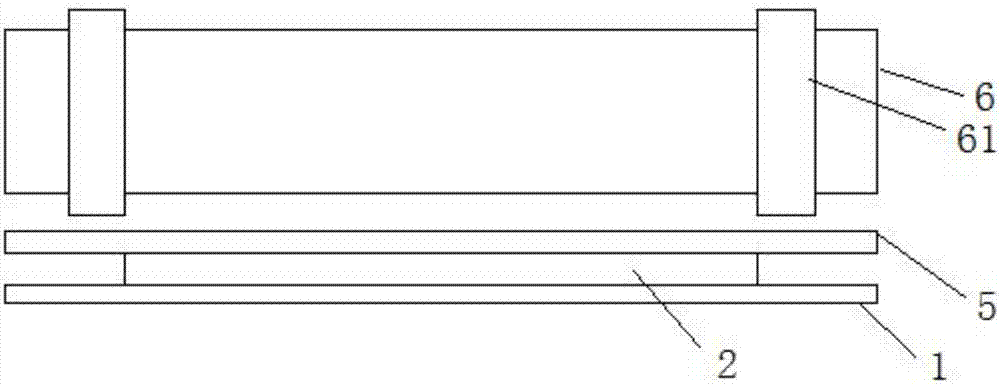

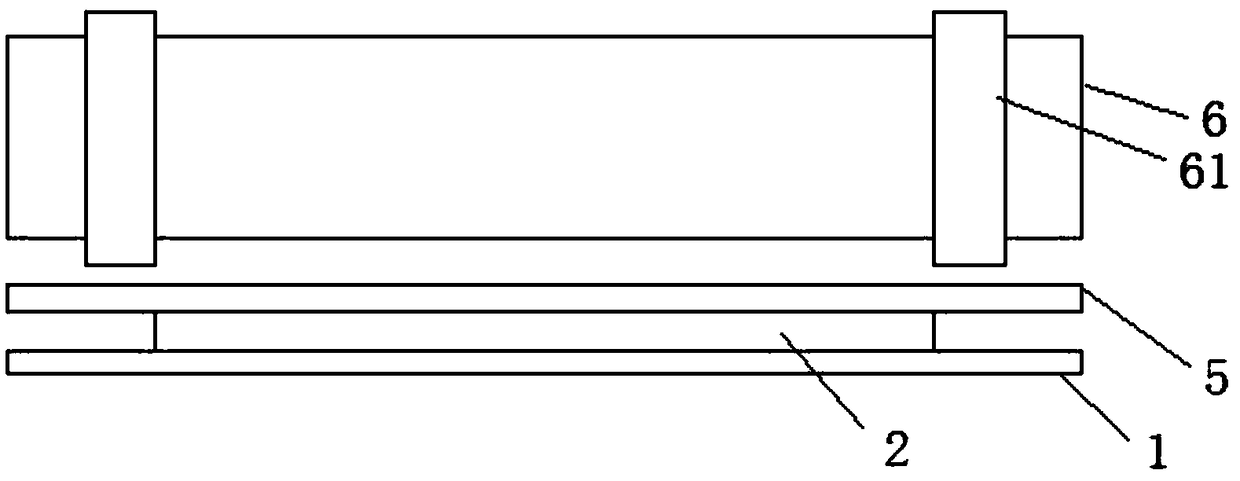

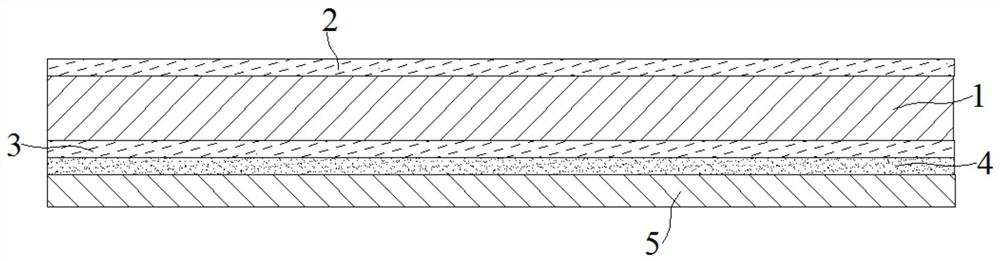

Preparation process for anti-static film used for electronic products

ActiveCN111978582AReduce the chance of injurySmall change in surface resistancePolyurea/polyurethane coatingsElectrically-conductive paintsMethylanilinePolyvinyl alcohol

The invention discloses a preparation process for an anti-static film used for electronic products. The preparation process comprises the following steps: step I, mixing and evenly stirring 100 partsof polyurethane resin, 40-60 parts of polyvinyl alcohol, 2-4 parts of sodium octyl sulfate, 1-3 parts of sodium 3-(N-ethyl-3-methylanilino)propanesulfonate, 8-12 parts of dioctyl terephthalate, 40-60parts of n-butyl alcohol, 20-30 parts of isobutyl acetate, 0.5-1 part of castor oil polyoxyethylene ether, 0.3-0.8 part of triethylenetetramine, 0.5-1.5 parts of silane coupling agent, 0.6-2 parts ofantioxidant and 0.4-1 part of leveling agent to obtain a coating solution; and step II, uniformly applying the coating solution obtained in step I onto a substrate layer (1) through coating, and performing baking and drying to obtain the anti-static film. Not only is the anti-static performance of the anti-static film prepared by the preparation process improved, but also the change of the surfaceresistance of the anti-static film is almost very small, and the anti-static performance is stable under the condition that the change of the anti-static performance is relatively large under the influence of environment humidity, and accordingly, the anti-static film is suitable for the complex electronic product process flow and climate.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Method for preparing anti-radiation anti-static thin film

InactiveCN106188603AGood radiation resistanceEffectively shield electromagnetic radiationChemistryDopamine hcl

Owner:张静

oca optical glue die-cutting process

ActiveCN107414929BAvoid gluingAvoid squeezingLamination ancillary operationsLaminationPunchingEngineering

The invention discloses an OCA optical cement die cutting technology. The OCA optical cement die cutting technology comprises the following steps that die cutting operation is conducted in a thousand-level dust-free room of 80-90 % humidity; after a cutting knife is dedusted, the cutting knife cuts raw materials into small rolls to be hung on a material frame; an upper layer light release film self-contained by OCA optical cement is torn, and an OCA layer is exposed; after anti-sticking processing is conducted on a rolling cutter, the rolling cutter cuts to the two sides of the OCA layer, and a reserved part is formed between a cutting line and the edge of the rolling cutter; after a mylar layer is pasted on the reserved part, and the reserved part and the mylar layer are torn together; an anti-static film is attached to the surface of the OCA layer through a rubber covered roller, and rubber covered roller foam is circumferentially attached to the two sides of the rubber covered roller; the anti-static film is cut off by a punching cutter, and the outer frame edge of a product is greater than the edge of the OCA layer; and cutting is conducted every time the punching cutter rotates one revolution, and neatly-collecting-stacking is conducted. According to the OCA optical cement die cutting technology, the effects that the product has no cement pulling and cement overflowing are achieved.

Owner:昆山威斯泰电子技术有限公司

Electric control dimming glass

InactiveCN105759530BHigh transparencyImprove self-cleaning abilityNon-linear opticsTin dioxideMethacrylate

The invention discloses electrically-controlled switchable glass. According to the technical scheme, the glass comprises a first transparent glass substrate layer, a first transparent conducting layer, an ion storage layer, an ion conductor layer, an electrochromism layer, a second transparent conducting layer, a second transparent glass substrate layer and a protective layer, the second transparent glass substrate layer is connected with the protective layer through transparent adhesive, and the transparent adhesive comprise, by weight, 5-55% of metacrylic acid ester, 3-50% of liquid polybutadiene, 0.5-5% of ultraviolet light initiator, 0.5-5% of thermal initiator, 8-65% of plasticizr and 5-15% of a nanometer antistatic base material; the nanometer antistatic base material is composed of, by weight, 50 parts of acrylic resin, 25 parts of antimony-doped tin dioxide nanometer powder, 10 parts of isopropanol, 12 parts of butanone and 3 parts of diphenyldimethoxysilane, wherein the mole ratio Sb: Sn of doped antimony to the antimony-doped tin dioxide nanometer powder is 9: 50. The electronically-controlled switchable glass has the advantages of being high in transparency, stable in antistatic performance and high in self-cleaning performance.

Owner:南京富特莱数码科技实业有限公司

An antistatic protective film

ActiveCN107502122BReduce surface resistanceImprove antistatic performanceElectrically-conductive paintsPolyesterPolymer science

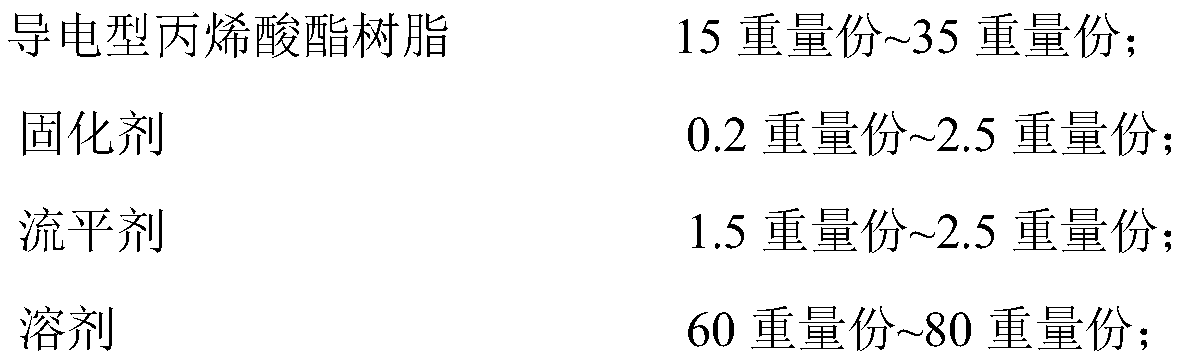

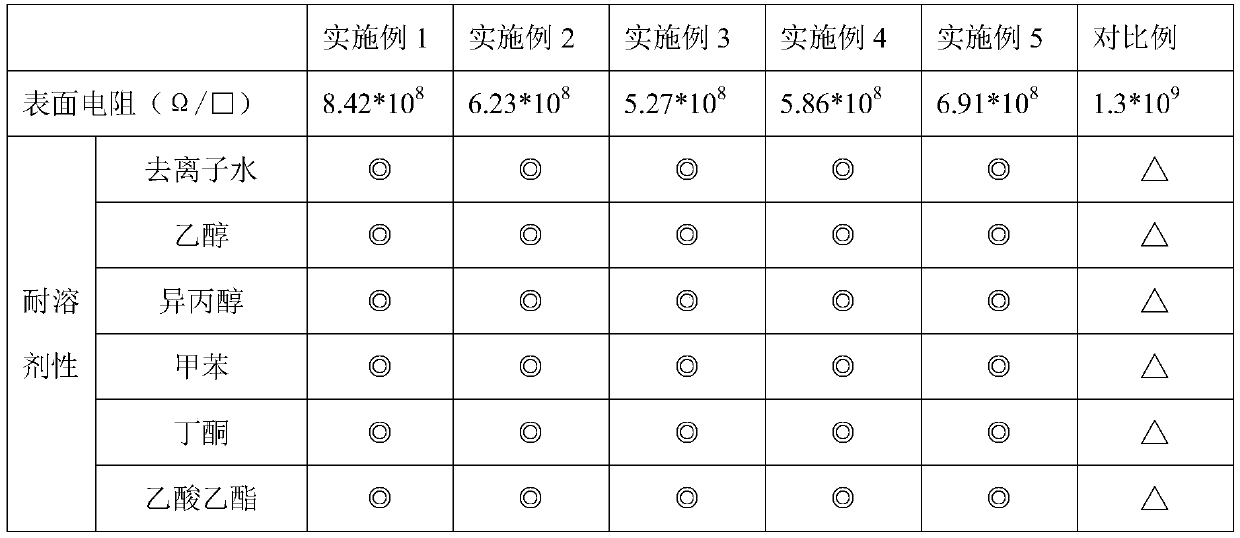

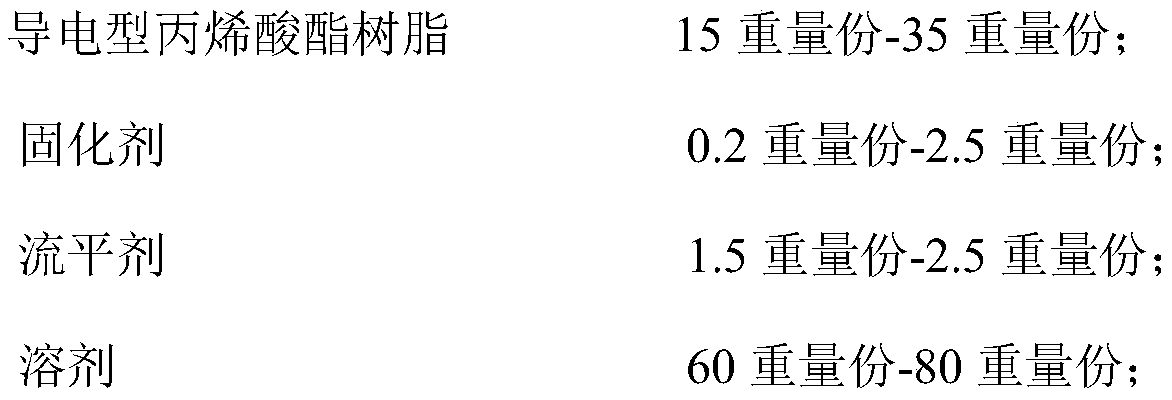

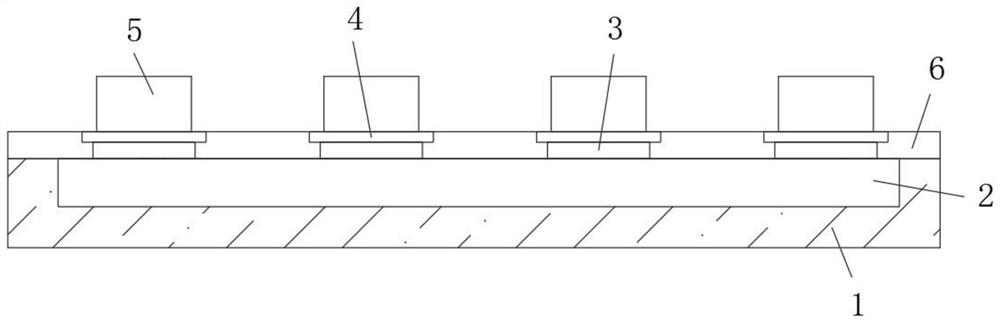

The invention relates to an antistatic protective film, which coats a layer of antistatic coating on the surface of a polyester film, and the antistatic coating is composed of a conductive acrylic resin, a curing agent, a leveling agent and a solvent, wherein the conductive acrylic The content of the ester resin is 15-35 parts by weight, the curing agent is 0.2-2.5 parts by weight, the leveling agent is 1.5-2.5 parts by weight, and the solvent is 60-80 parts by weight. The antistatic coating of the antistatic protective film is wiped with deionized water, ethanol, isopropanol, toluene, butanone and ethyl acetate, and the antistatic coating does not fall off, and has solvent resistance.

Owner:HEFEI LUCKY SCI & TECH IND

Antibacterial antistatic blended fabric and preparation method thereof

InactiveCN108532090ASolve static problemsSolve the difficult problem of anti-static carePhysical treatmentProtective fabricsYarnPolyester

The invention discloses an antibacterial antistatic blended fabric. The fabric comprises an antistatic modified antibacterial fiber, a nano silver antibacterial fiber and a polyester. The antistatic modified antibacterial fiber, the nano silver antibacterial fiber and the polyester are blended in different proportions and twisted into a yarn to further form the blended fabric by a weaving process.The antibacterial antistatic blended fabric is formed by antibacterial processing of natural antibacterial fibers such as a kapok fiber, a chitosan fiber, a jute fiber, a bamboo fiber and a carbonized cotton fiber, has excellent antistatic performance and antibacterial performance, and effectively solves the problem in the prior art that the blended fabric generates static charge and the antistatic treatment of the fabric is difficult. The antistatic performance of the fabric is long-lasting, durable, stable and environmentally friendly, and the fabric has excellent stable long-lasting antibacterial performance after blended with the nano silver antibacterial fiber.

Owner:佛山慧创正元新材料科技有限公司

Flexible transparent LED display screen capable of being crimped at will

PendingCN112201173APrevent precipitationAvoid the situationPrinted circuit assemblingIdentification meansLED displayAdhesive

The invention discloses a flexible transparent LED display screen capable of being crimped at will, belonging to the field of LED display screens. The flexible transparent LED display screen comprisesa modified PET film layer, wherein a copper-plated circuit layer is arranged on one side of the modified PET film layer, a low-temperature solder paste layer is arranged on the outer side of the copper-plated circuit layer, an SMT patch is arranged on the outer side of the low-temperature solder paste layer, LED lamp beads are fixedly connected to the outer side of the SMT patch, and one side ofthe modified PET film layer is coated with a protective layer. According to the invention, the modified PET film layer is adopted, and the modified PET film layer is a flexible transparent thin film,so the display screen of the invention can be crimped at will; a macromolecular anti-precipitation layer and a pressure-sensitive adhesive layer are arranged on the modified PET film layer; the modified PET film layer is allowed to resist a high temperature of 180 DEG C through the arrangement of the pressure-sensitive adhesive layer, and reflow soldering of the low-temperature solder paste layeris facilitated; the macromolecular anti-precipitation layer can prevent the modified PET film layer from precipitation, fogging and the like at high temperature, the LED lamp beads can be protected against pollution, and meanwhile, the softness of the modified PET film layer is not affected.

Owner:深圳市前海恒云联科技有限公司

Antistatic board and preparation method thereof

The invention provides an antistatic board and a preparation method thereof, belonging to the technical field of high polymer materials. The antistatic board is prepared from the following raw materials: polyvinyl chloride, vegetable fiber, dibutyl sebacate, brominated epoxy resin, a plasticizer, a dispersant, diatomite, conductive china clay powder and water. The antistatic board provided by theinvention has outstanding resistance to chemical solvents and impact and stable antistatic performance. The test data of the antistatic board shows that the antistatic force of the board is very stable and surface resistance is 100-110 omega, so the antistatic board has an excellent anti-static function.

Owner:HEFEI LANGSHENG NOVEL MATERIAL CO LTD

Non-electrostatic isolating plate

InactiveCN1412086AEasy to manufactureStable antistaticOther chemical processesStorage devicesFiberPolyolefin

An antistatic separate sheet is provided. The antistatic separate sheet comprises a polyolefin-based resin and a composition comprising a polymer resin essentially having both polyolefin-based skeleton and a hydrophilic polymer skeleton; and it has a surface inherent resistivity of 10 not 11 Ohm or less. A separate sheet of better performance can be acquired by mixing conductive fiber member into the composition, and it has a surface inherent resistivity of 10 not 7 Ohm or less.

Owner:NIPPON PETROCHEMICAL CO LTD

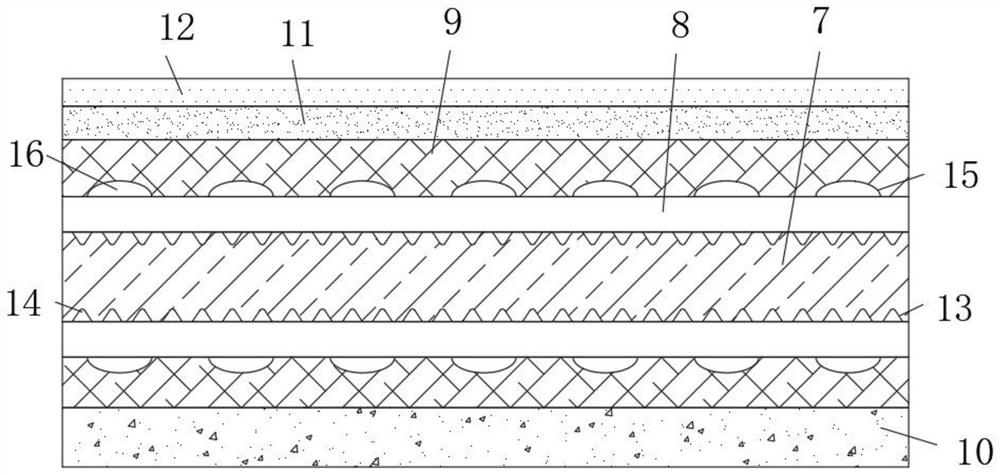

A cold-resistant flame-retardant antistatic polyvinyl chloride sheath material for coal mine cables

ActiveCN103113692BLower surface resistance valueImprove antistatic performanceInsulated cablesInsulated conductorsPhosphatePolyvinyl chloride

The invention discloses a cold-resistance flame-retardant anti-static polyvinyl chloride sheathing material for coal mine cable; the sheathing material is characterized by consisting of the following raw materials: polyvinyl chloride resin SG3, tri(2-chloroethyl) phosphate, an anti-static agent, dioctyl sebacate, dioctyl phthalate, tricresyl phosphate, antimonous oxide, zinc borate, tribasic lead sulfate, bibasic lead sulfate, light calcium carbonate, bisphenol A, 2-mercapto benzimidazole, vinyl tri(beta-methoxyl ethyoxyl) silane, accelerant TMTD and modified asbestos powder; the polyvinyl chloride sheathing cable material provided by the invention has the following characteristics of being low in surface resistance value and high in anti-static property; by adopting the compound high-concentration anti-static agent consisting of TCEP (trichloroethyl phosphate), quaternary ammonium salt cationic surface active agent and nonionic surface active agent, the excellent anti-static synergistic effect can be brought; the surface resistance value of the sheathing material is no higher than 108ohms, and thus the sheathing material has excellent anti-static property.

Owner:安徽龙庵电缆集团有限公司

Antistatic ceramic floor and preparing method thereof

Owner:BEIJING YUNHE INDAL & TRADE

Antistatic powder for antistatic ceramic tile

The invention relates to antistatic powder for an antistatic ceramic brick, is used for producing the antistatic ceramic brick, and belongs to the technical field of architectural ceramics. The antistatic powder comprises the following components in mass percentage: 60 to 80 percent of tin oxide, 10 to 39 percent of zinc oxide and 0.2 to 10 percent of antimony oxide. The antistatic powder can be conveniently used for producing the antistatic ceramic brick to eliminate the static electricity, promote the human health, and protect a high precision apparatus.

Owner:山东电盾科技股份有限公司

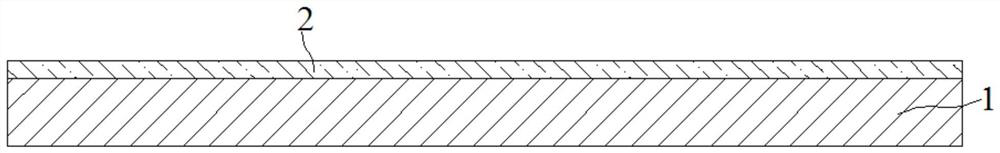

Solvent-resistant antistatic film

ActiveCN111978879BSmall change in surface resistanceReduce the chance of injuryOther chemical processesFilm/foil adhesive primer layersMethylanilinePolymer science

The invention discloses a solvent-resistant antistatic film, which comprises a substrate layer, a first antistatic coating and a second antistatic coating, and the first antistatic coating and the second antistatic coating are respectively located on the base The upper surface and the lower surface of the material layer, a pressure-sensitive adhesive layer is located between the release layer and the second antistatic coating; the first antistatic coating and the second antistatic coating are dried by the coating liquid Obtained, this coating solution is made up of the following components by weight: polyurethane resin, polyvinyl alcohol, sodium octyl sulfate, N-ethyl-N-(3-sulfopropyl)-3-methylaniline sodium salt, p- Dioctyl phthalate, n-butanol, isobutyl acetate, castor oil polyoxyethylene ether, triethylenetetramine, silane coupling agent, antioxidant, leveling agent. The invention not only improves the antistatic performance, but also enables the solvent-resistant antistatic film to have a small change in surface resistance and stable antistatic performance under the condition of large changes in environmental humidity, so that it is suitable for complex electronic product processes and climates. Greatly reduces the chance of damage to electronic products.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

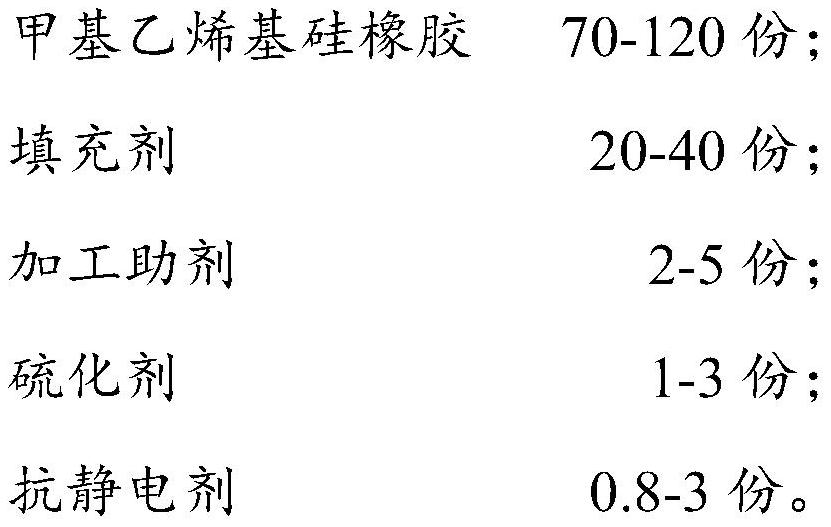

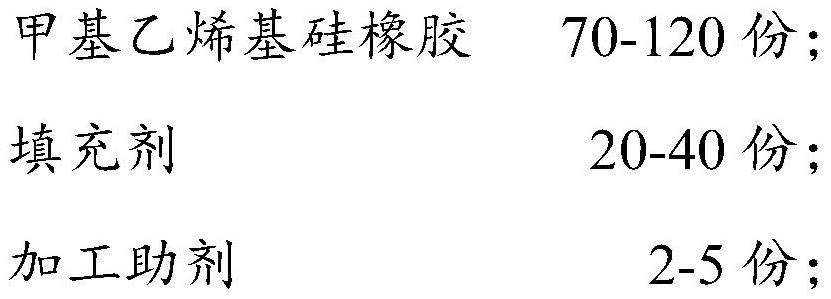

Antistatic fading-free rubber and preparation method thereof

The invention provides antistatic fading-free rubber. The antistatic fading-free rubber is prepared from the following raw material components in parts by weight: 70-120 parts of silicone rubber, 20-40 parts of a filler, 2-5 parts of a processing aid, 1-3 parts of a vulcanizing agent and 0.8-3 parts of an antistatic agent. The antistatic fading-free rubber has stable antistatic performance, does not leave black traces on contact substances, greatly improves the use performance of the product, and is especially suitable for antistatic products which cannot fade or be blackened.

Owner:苏州力达精密配件有限公司

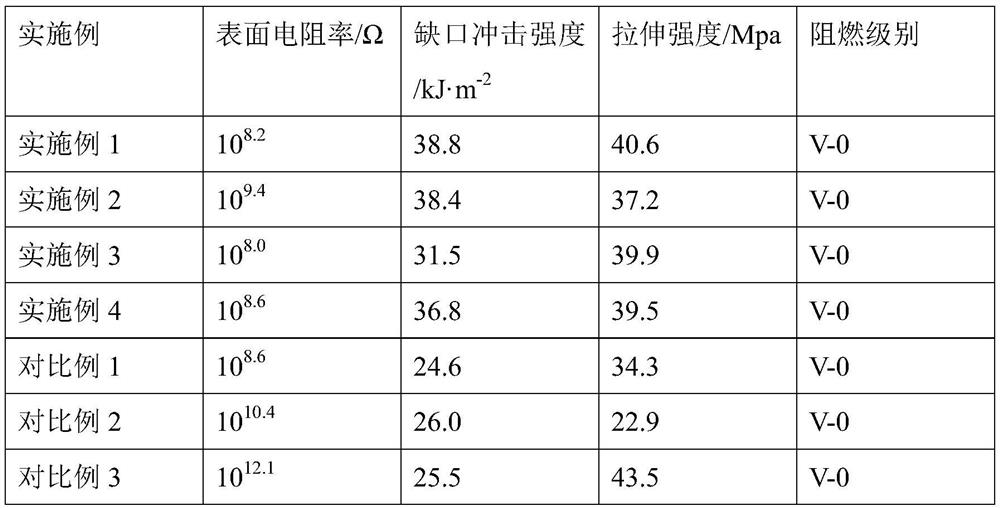

ABS flame-retardant composite material with high impact resistance and low volume resistance and preparation method thereof

ActiveCN114656747AImprove antistatic performanceGood antistatic property/stablePlastic recyclingButadiene DioxideUltimate tensile strength

The invention discloses a high-impact low-volume-resistance ABS (Acrylonitrile Butadiene Styrene) flame-retardant composite material which is prepared from the following raw materials: ABS resin, a styrene-butadiene copolymer, a flame retardant, an antistatic agent, a structural strength enhancer and an adaptive modifier, the raw materials comprise, by mass, 100 parts of ABS resin, 20-30 parts of a styrene-butadiene copolymer, 3-10 parts of a flame retardant, 1-4 parts of an antistatic agent, 0.5-2 parts of a structural strength reinforcing agent, and 1-5 parts of an adaptive modifier. According to the ABS flame-retardant composite material with high impact resistance and low volume resistance, the styrene-butadiene copolymer is added, so that the antistatic performance of the antistatic agent in the composite material is improved, and meanwhile, the toughness of a composite material system is improved; by adding the structural strength reinforcing agent, the impact resistance, tensile resistance and other mechanical properties of the composite material are improved; the antistatic agent and the flame retardant do not interfere with each other, and the obtained ABS flame-retardant composite material has excellent impact strength, good / stable antistatic performance and excellent flame retardant performance.

Owner:苏州新华美塑料有限公司

Electrostatic-proof ceramics wall floor tile and preparation method thereof

InactiveCN1693294BStable antistaticLess amount of conductive fillerClaywaresSemiconductorTransition layer

An antistatic ceramic tile for floor or wall is prepared through preparing ceramic blank, preparing antistatic enamel from enamel and semiconductor oxide chosen from SnO2, TiO2 and ZnO through proportional mixing, coating enamel transition layer on the ceramic blank, drying, coating antistatic enamel, drying, coating antistatic enamel on its peripheral surface, and calcining.

Owner:SOUTH CHINA UNIV OF TECH +1

Electrostatic-resisting rubber board and production thereof

ActiveCN100509936CLow heat resistancePoor flatteningOther chemical processesPolymer scienceVulcanization

The present invention relates to a kind of antistatic rubber plate (such as table mat, ground mat) and production method thereof, this antistatic rubber plate comprises antistatic layer and static conduction layer; This antistatic rubber plate is prepared by a, antistatic layer film ; b, the preparation of the static conductive layer film; c, prepared by the vulcanization step.

Owner:浙江一远静电科技有限公司

Antistatic wool blended fabric and preparation method thereof

The invention discloses an antistatic wool blended fabric. The fabric comprises antistatic fiber, adhesive fiber, wool and polyester, wherein the antistatic fiber, the viscose fiber, the wool and thepolyester are blended in different proportions and twisted into yarn, and the wool blended fabric is formed through a weaving technology. The antistatic wool blended fabric has excellent antistatic performance, the problem that wool blended fabrics in the prior art generate static electricity is effectively solved, and the problem that antistatic caring of the fabrics is difficult is solved; besides, the fabric is lasting in antistatic performance, durable and environmentally friendly.

Owner:佛山慧创正元新材料科技有限公司

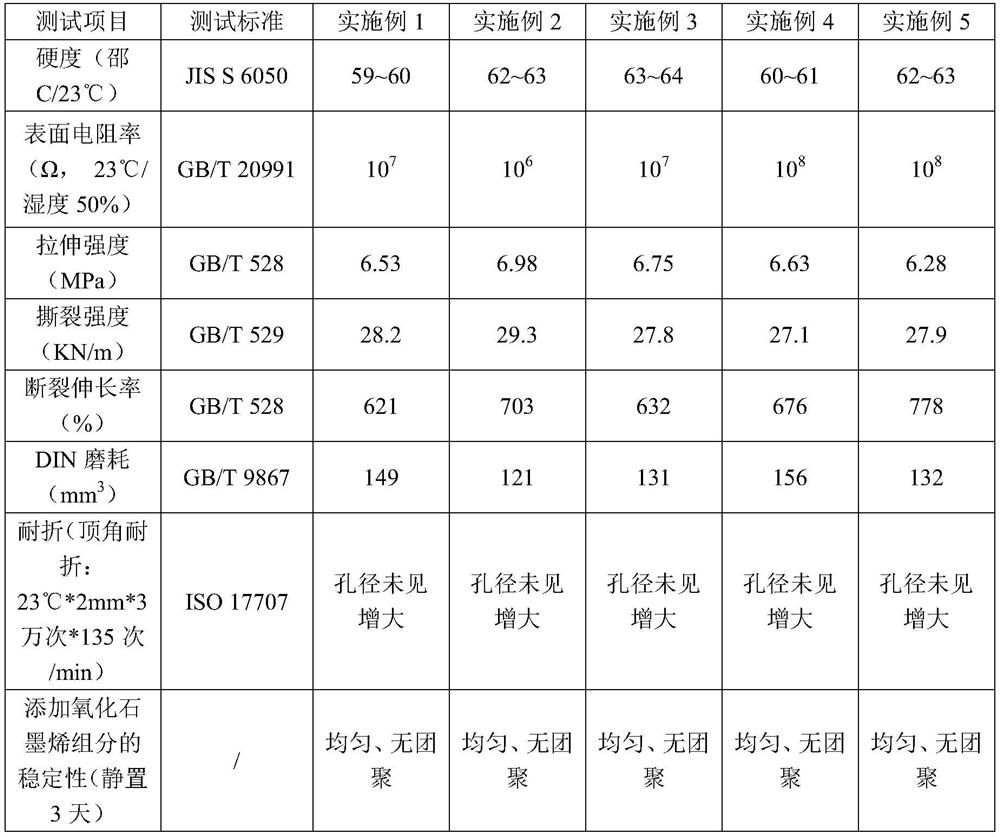

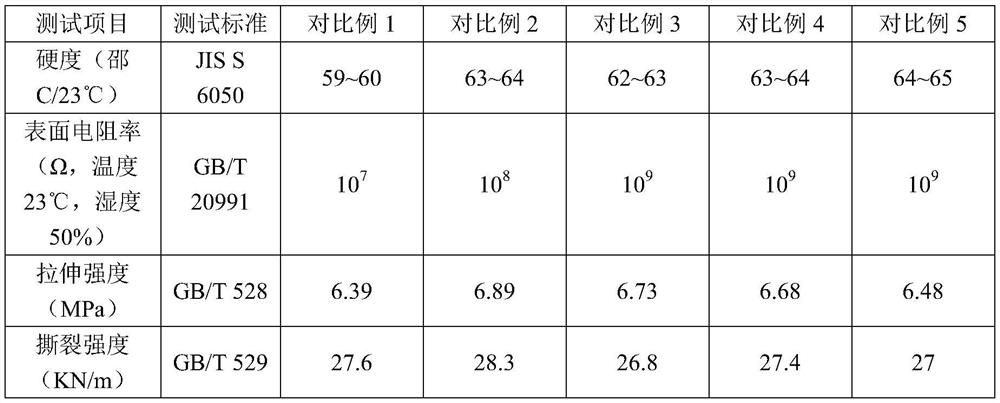

A kind of preparation method of polyurethane composition for shoes and its molded body

ActiveCN111808263BStable storageOvercome the pitfalls of constant migrationSolesPolymer scienceWear resistance

The present invention relates to a preparation method of a polyurethane composition for shoes and a molded body thereof. The polyurethane composition for shoes includes separated A component, B component and C component. After mixing the various components, it is prepared by foaming molding: the A and C components are mixed uniformly at a ratio of 100:1 to 100:3 by weight at 40 to 60 ° C to obtain a mixture of components A and C, and the mixture is controlled. The ratio of the number of moles of active hydrogen in the component to the number of moles of ‑NCO in component B is 1:1. After mixing in a two-component casting machine, it is injected into a mold at 40-60°C for 2-5 minutes to form, and demolded. The polyurethane molded body is obtained by post-curing in an oven at 60-70° C. for 24 hours. The polyurethane molded body prepared by the product can be used to prepare the sole components of labor insurance shoes and safety shoes, has excellent antistatic properties, and significantly improves its mechanical properties such as tensile strength, tear strength and wear resistance.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com