Electrostatic-proof ceramics wall floor tile and preparation method thereof

An anti-static, wall and floor tile technology, applied in the field of building materials, can solve the problems of poor anti-static performance, large amount of conductive powder added, complex production process, etc., and achieve the effects of stable anti-static performance, easy production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

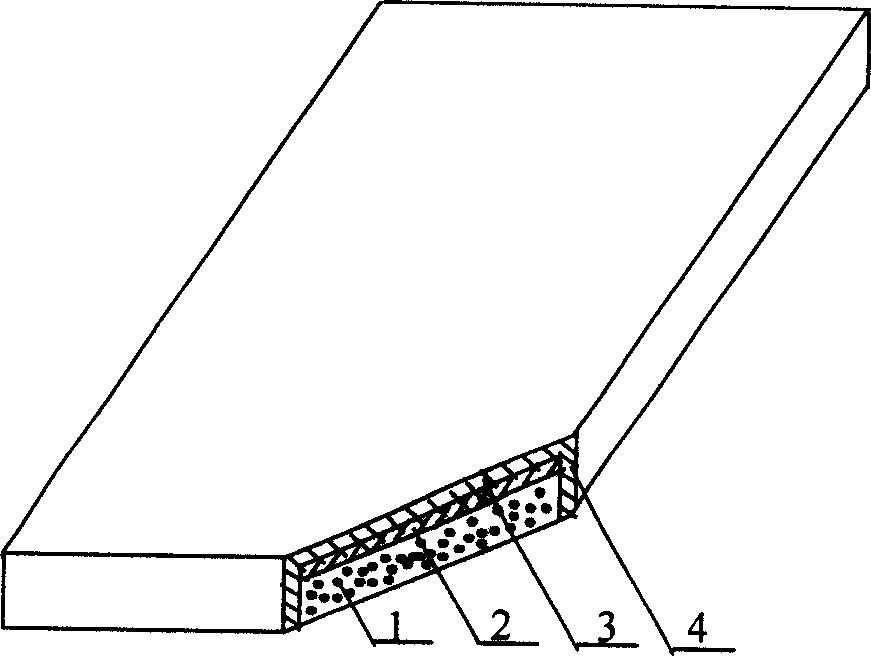

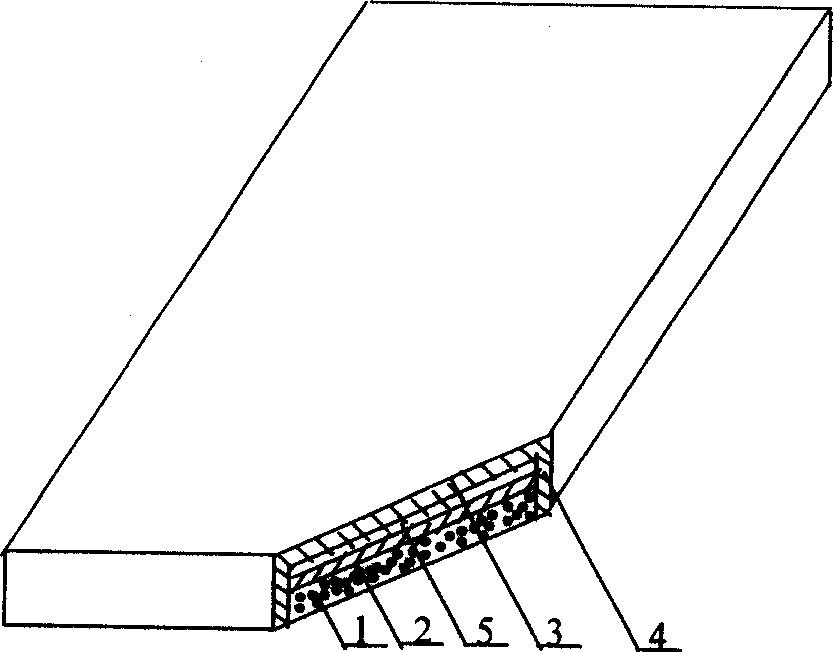

[0025] (1) Glaze preparation: 20% oxide semiconductor powder, 77.5% matt frit, 2.5% clay, plus 0.1% CMC and 0.1% soda ash are added to the ball mill for ball milling;

[0026] (2) Apply a layer of underglaze on the green body that has been bisque fired at about 1170°C by pouring glaze;

[0027] (3) Applying the glaze prepared in step (1) to the base glazed body by pouring glaze;

[0028] (4) apply a layer of glaze slurry prepared in step (1) by brushing or rolling glaze around the glazed base obtained in step (3), and then dry;

[0029] (5) Put the product dried in step (4) into a kiln for firing at a firing temperature of 1020° C. and a firing time of 35 minutes.

[0030] After electrical performance testing, the surface resistivity of the product is 1.5×10 8 Ω.

Embodiment 2

[0032] (1) Glaze preparation: 30% oxide semiconductor powder, 66% matt frit, 4.0% clay, plus 0.15% CMC and 0.1% soda ash are added to the ball mill for ball milling;

[0033] (2) Apply a layer of underglaze on the green body that has been bisque fired at about 1170°C by pouring glaze;

[0034] (3) Applying the glaze prepared in step (1) to the base glazed body by pouring glaze;

[0035] (4) apply a layer of glaze slurry prepared in step (1) by brushing or rolling glaze around the glazed base obtained in step (3), and then dry;

[0036] (5) Put the dried product in step (4) into a kiln for firing at a firing temperature of 10850° C. and a firing time of 25 minutes.

[0037] After electrical performance testing, the surface resistivity of the product is 6.0×10 6 Ω.

Embodiment 3

[0039] (1) Glaze preparation: 30% oxide semiconductor powder, 30% feldspar, 5.0% limestone, 5.0% barium carbonate, 3.0% zinc oxide, 5.0% clay and 22% frit, etc. are added to the ball mill for ball milling;

[0040] (2) Apply a layer of bottom glaze on the ceramic wall and floor tile green body by centrifugally throwing the glaze;

[0041] (3) Applying the glaze prepared in step (1) to the green body with the bottom glaze by means of centrifugal glaze throwing;

[0042] (4) apply a layer of glaze slurry prepared in step (1) by brushing or rolling glaze around the glazed base obtained in step (3), and then dry;

[0043] (5) Put the dried product of step (4) into a kiln for firing at a firing temperature of 1190° C. and a firing time of 50 minutes.

[0044] After electrical performance testing, the surface resistivity of the product is 6.5×10 8 Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com