A kind of preparation method of polyurethane composition for shoes and its molded body

A polyurethane and composition technology, applied in the field of polymer materials, can solve the problems of affecting material properties, poor compatibility of polymer materials, and difficulty in achieving ideal results, and achieves short foaming molding time, excellent antistatic performance, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

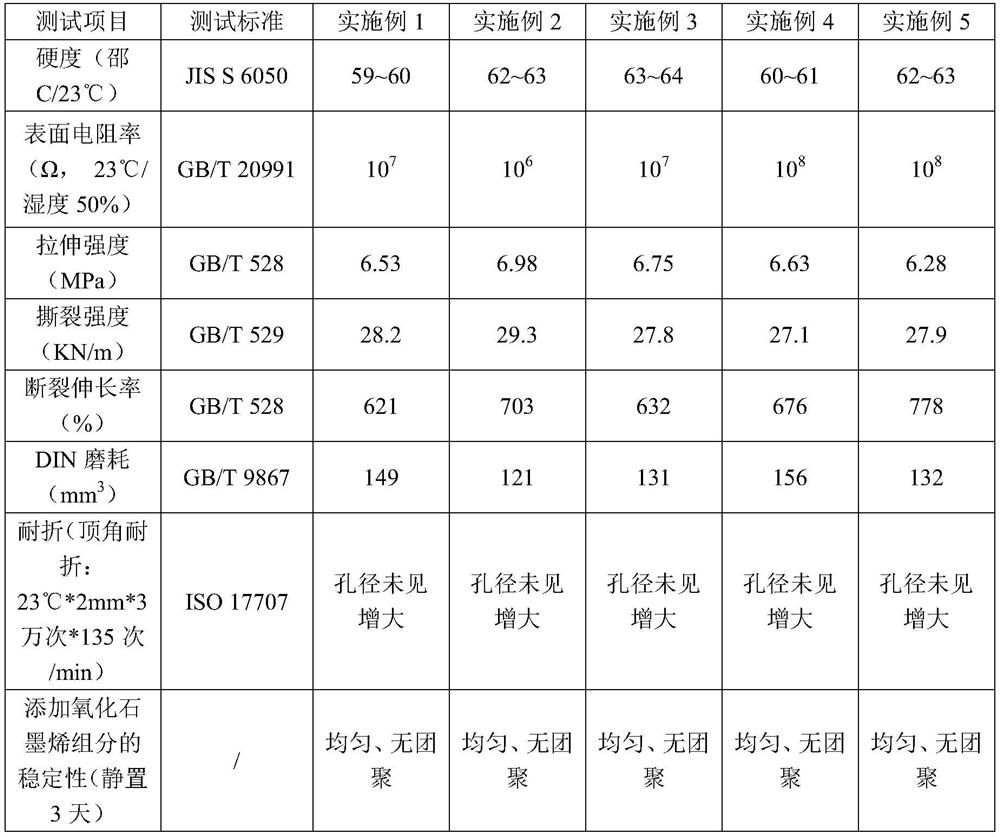

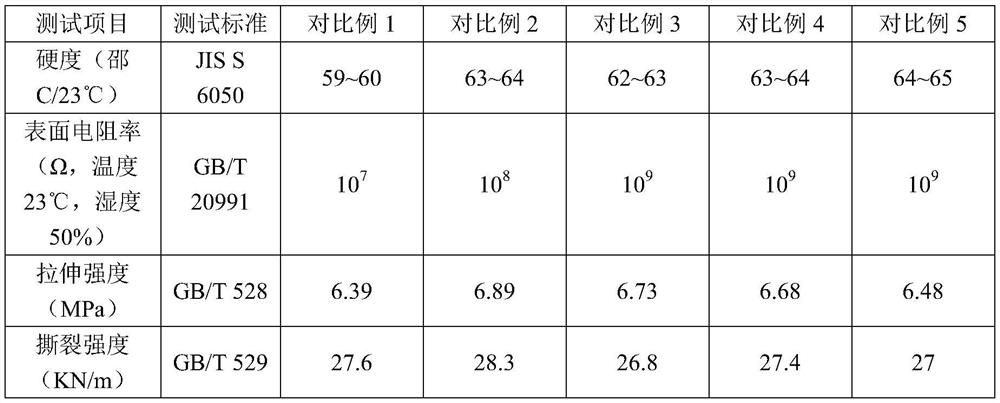

Examples

Embodiment 1

[0033] To prepare Component A:

[0034] Calculated in parts by weight, 90 parts by weight of polyethylene glycol 1,6-adipate polyol (average number average molecular weight 1500, hydroxyl value 74.8), 10 parts by weight of poly1,6-adipic acid Trimethylolpropane diethylene glycol ester polyol (average number average molecular weight 1870, hydroxyl value 62.1), 3 parts by weight of ethylene glycol, in the presence of 0.35 parts by weight of water and 0.35 parts by weight of Dow Corning DC-193, at 40°C After fully mixing for 2 hours, reduce to normal temperature to obtain A component;

[0035] To prepare Part B:

[0036] Calculated in parts by weight, 43 parts by weight of 4,4'-MDI and 10 parts by weight of liquefied MDI will be added to the reaction vessel under nitrogen protection, and 5 parts by weight of dried graphene oxide 2 will be slowly added step by step. Reaction for 1 hour to form a cloudy liquid, add 30 parts by weight of polyethylene glycol 1,6-adipate polyol (ave...

Embodiment 2

[0042] To prepare Component A:

[0043] Calculated in parts by weight, 35 parts by weight of polyethylene glycol 1,6-adipate polyol (average number average molecular weight 1500, hydroxyl value 74.8), 15 parts by weight of poly1,6-adipic acid Trimethylolpropane diethylene glycol ester polyol (average number average molecular weight 1870, hydroxyl value 62.1), 50 parts by weight of polyethylene 1,6-adipate 1,4-butanediol ester polyol (average number average molecular weight 1870, hydroxyl value 62.1) Number-average molecular weight 2000, hydroxyl value 56.1), 5 parts by weight of diethylene glycol, in the presence of 0.35 parts by weight of water and 0.50 parts by weight of Dow Corning DC-193, after fully mixing at 40 ° C for 2 hours, it was lowered to room temperature to obtain Group A Minute;

[0044] To prepare Part B:

[0045] Calculated in parts by weight, 65 parts by weight of 4,4'-MDI will be added and placed in a nitrogen-protected reaction vessel, 10 parts by weight ...

Embodiment 3

[0051] To prepare Component A:

[0052] Calculated in parts by weight, 50 parts by weight of polyethylene glycol 1,6-adipate polyol (average number average molecular weight 1500, hydroxyl value 74.8), 10 parts by weight of poly1,6-adipic acid Trimethylolpropane diethylene glycol ester polyol (average number average molecular weight 1870, hydroxyl value 62.1), 40 parts by weight of polyethylene 1,6-adipate 1,4-butylene glycol ester polyol (average number average molecular weight 1870, hydroxyl value 62.1) Number-average molecular weight 2000, hydroxyl value 56.1), 3 parts by weight of diethylene glycol, in the presence of 0.45 parts by weight of water and 1.05 parts by weight of Dow Corning DC-193, after fully mixing at 30 ° C for 4 hours, it was lowered to room temperature to obtain Group A Minute;

[0053] To prepare Part B:

[0054] Calculated in parts by weight, 75 parts by weight of 4,4'-MDI and 5 parts by weight of liquefied MDI will be added in a reaction vessel protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com