Patents

Literature

76results about How to "Fix scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Electrostatic-resisting rubber board and its production

ActiveCN101074301AWill not polluteWon't change colorOther chemical processesEngineeringPolymer science

An anti-electrostatic rubber plate (desk pad and floor mattress) and its production are disclosed. The anti-electrostatic rubber plate consists of anti-electrostatic layer and conducting layer. It is prepared by preparing anti-electrostatic layer, preparing conducting layer film and vulcanizing to obtain final product.

Owner:浙江一远静电科技有限公司

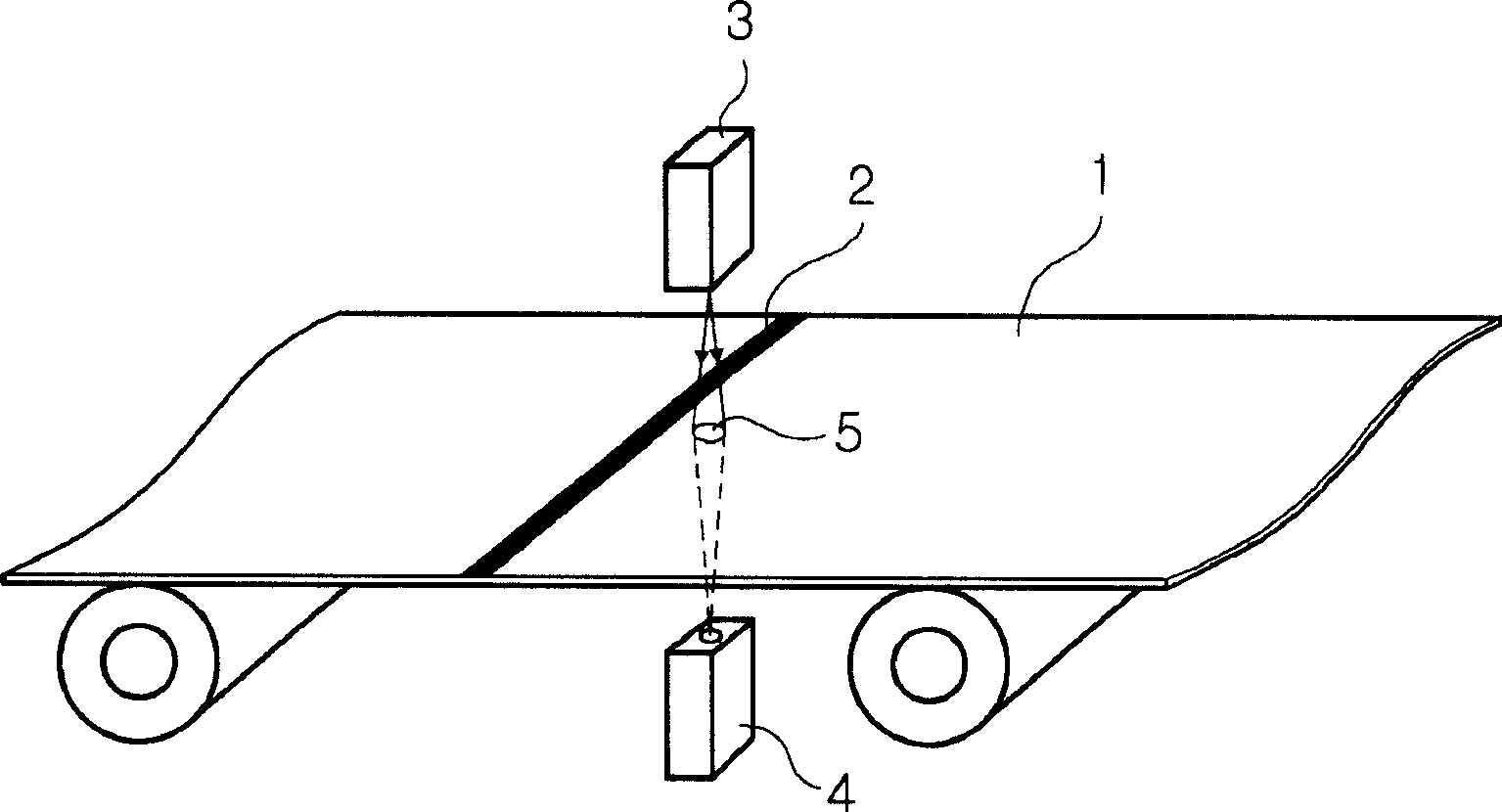

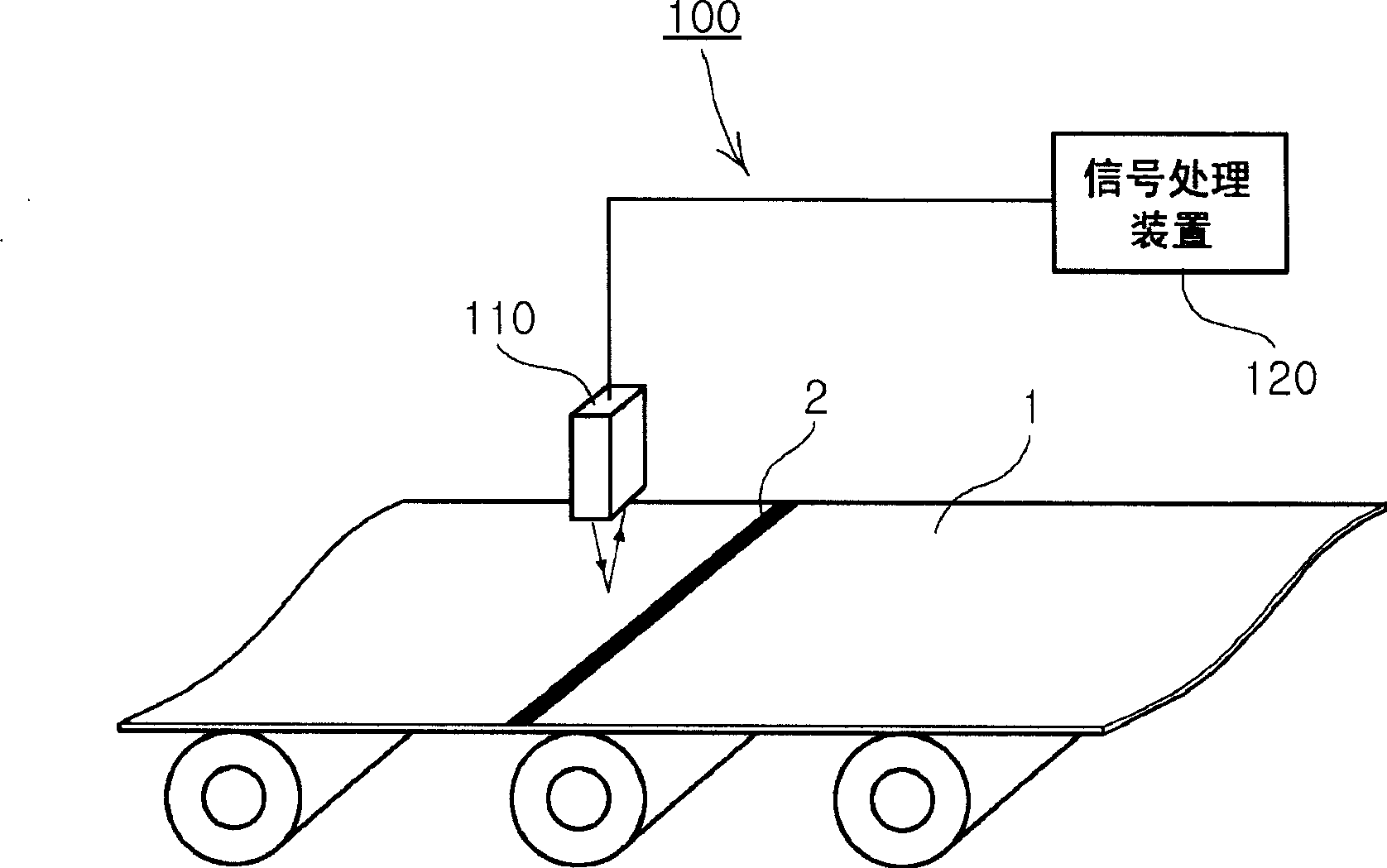

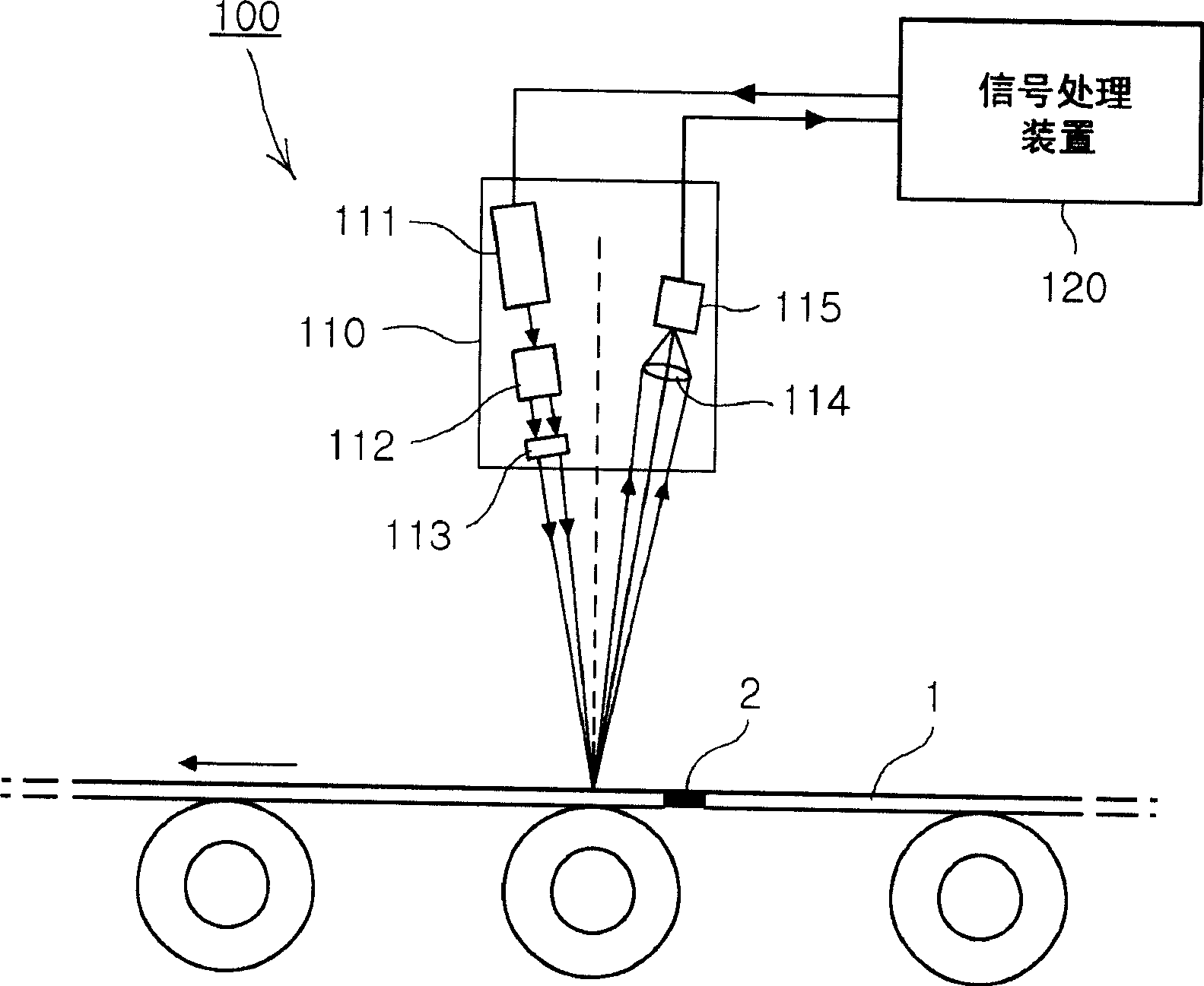

Apparatus and method for on-line detecting welding part of strip

ActiveCN101416044AEasy to detect onlineIncrease productivityScattering properties measurementsOptically investigating flaws/contaminationReflectivity measurementLaser beams

Provided is an on-line detection system and method for a weld of a steel strip, which can emit a laser beam onto the surface of a steel strip moving at a high speed and measure the reflectivity of the laser beam reflecting from the same, thereby detecting the weld of the steel strip easily on-line. In the on-line detection system, reflectivity measuring means emits a laser beam onto a moving steel strip and continuously measuring the reflectivity of the laser beam returning from the surface of the steel strip, and signal processing means detects a weld of the steel strip based on change in the reflectivity measured on the weld.

Owner:POSCO CO LTD

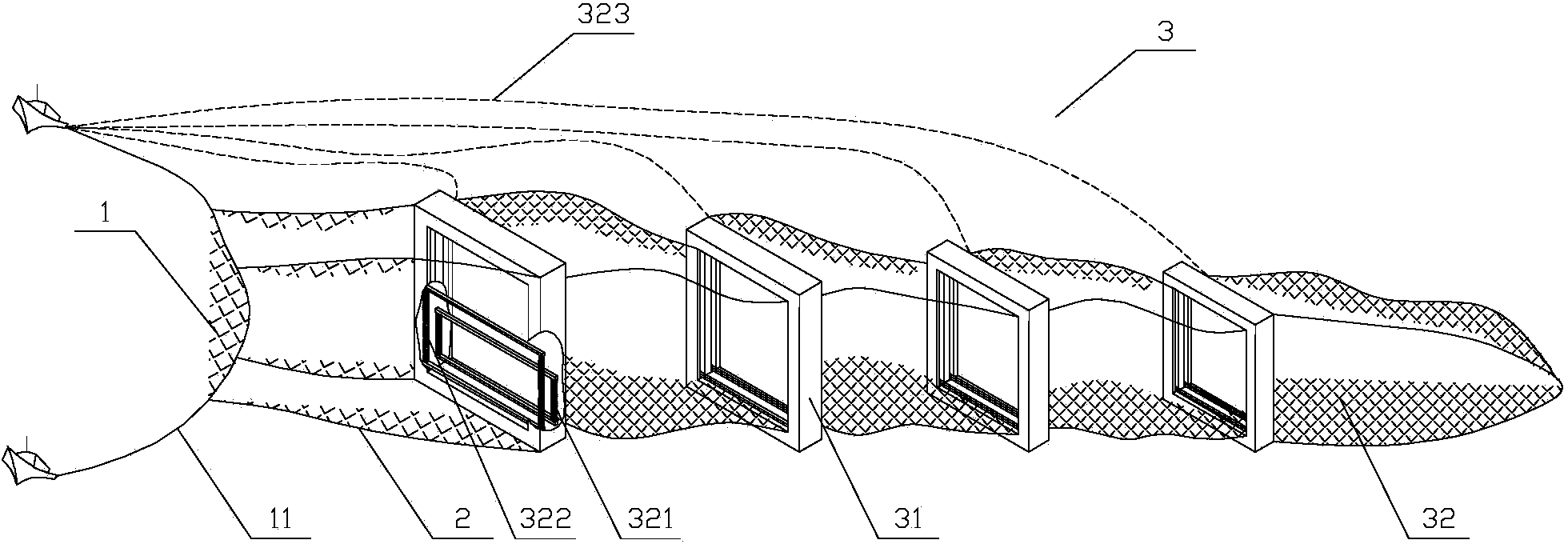

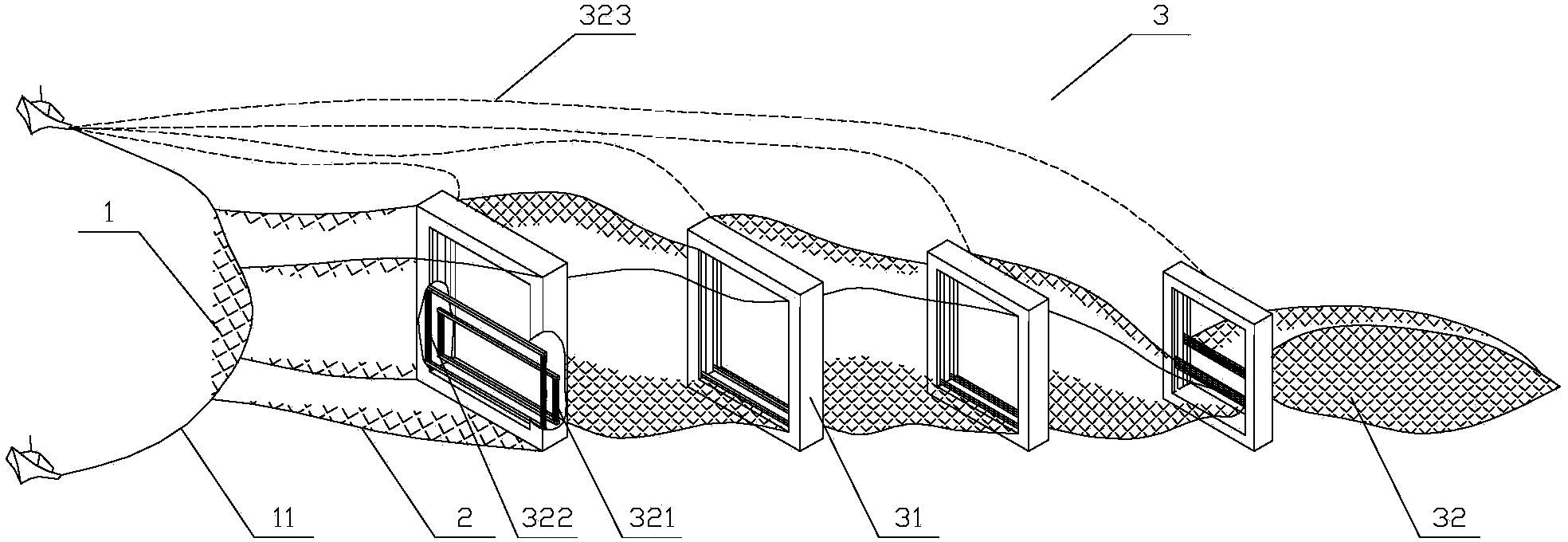

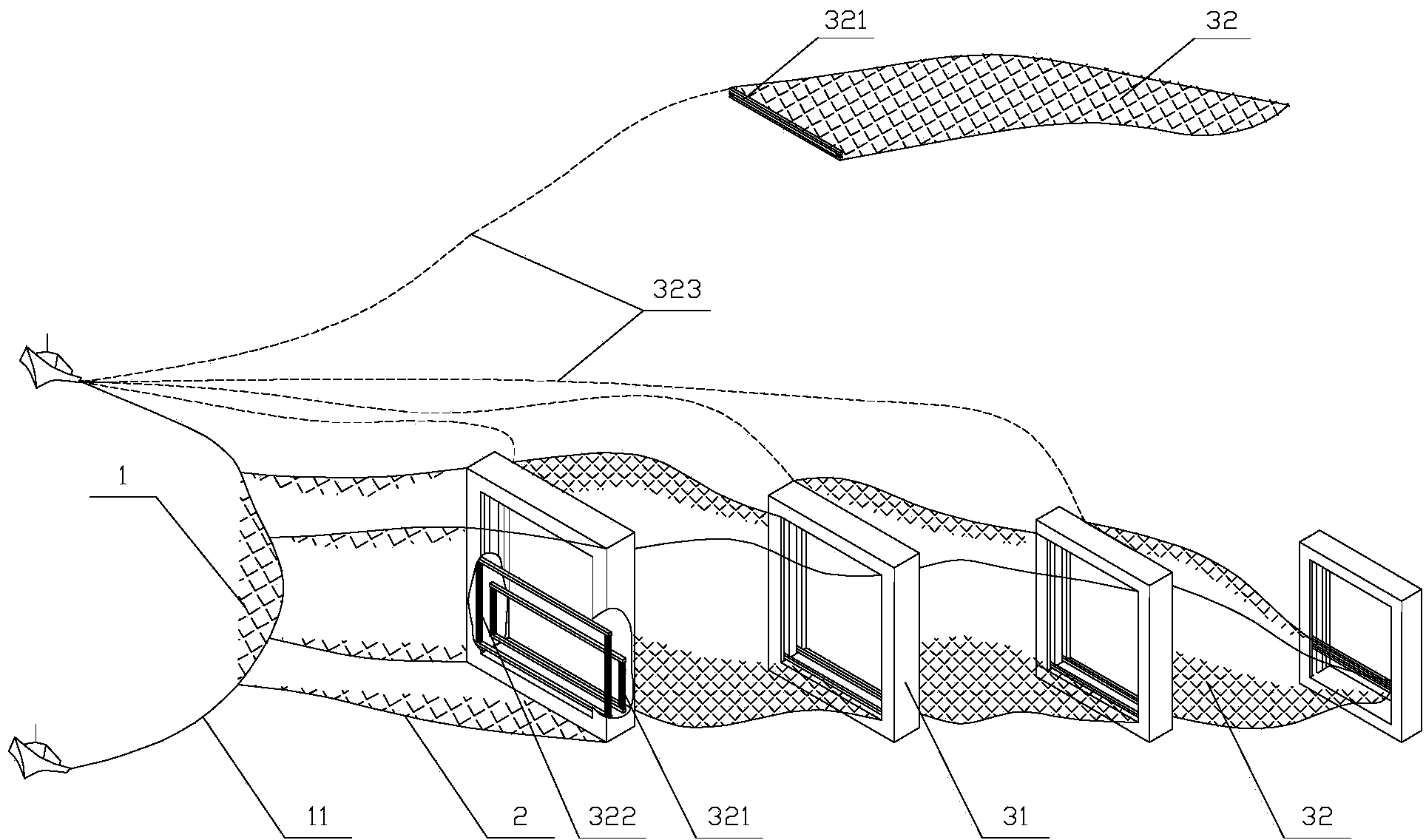

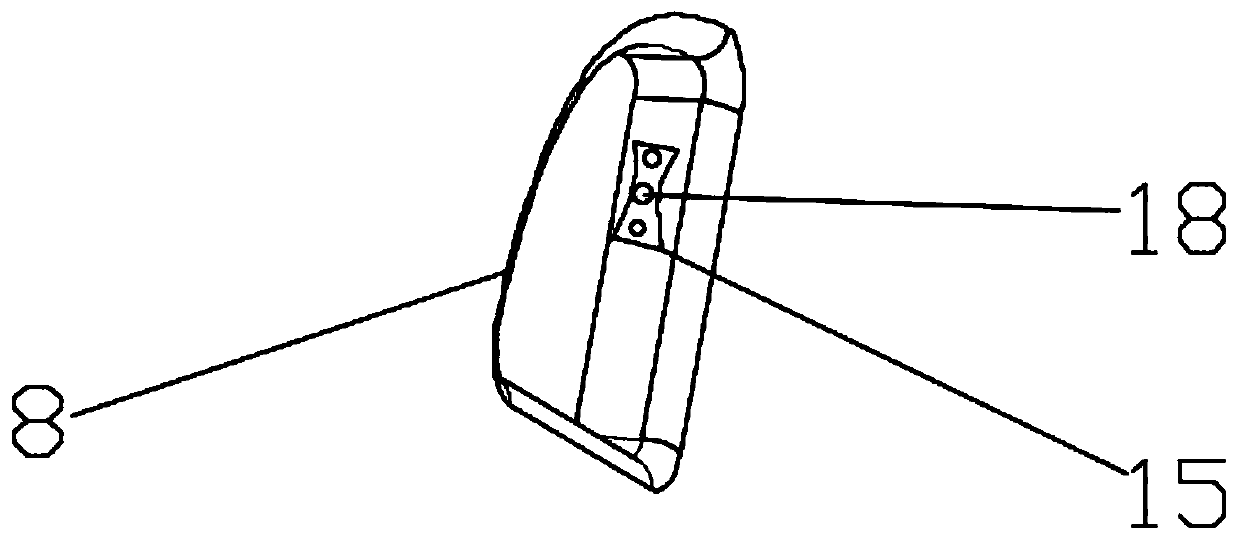

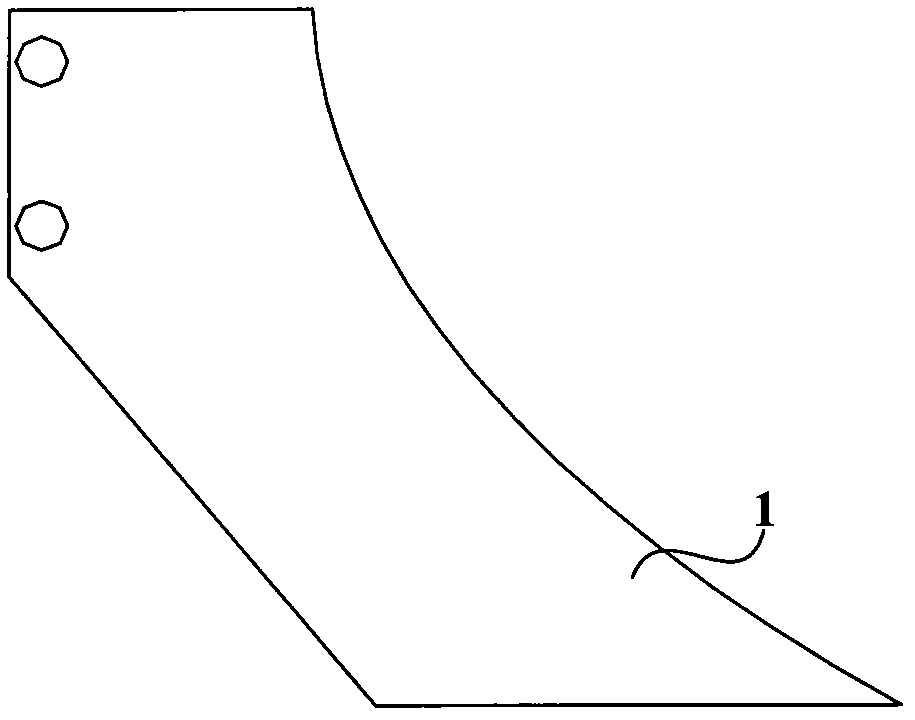

Dragnet with a plurality of serial bags and fishing method using dragnet

The invention discloses a dragnet with a plurality of serial bags and fishing method using the dragnet. The dragnet comprises a net wing, a net body and a net bag. The net bag comprises the plurality of bags which are serially connected end to end and frame. Each frame is provided with a front-rear frame open-close device, a bag separating device and a controller. By the arrangement, fish captured by the dragnet can be gathered in corresponding bags in batches, separated from the net body along with the bags, and dragged and lifted to a fishing boat, the problems of pressing, scratch, death even deterioration, caused by long-term trawling, of the captured fish are solved, survival rate and freshness quality of the captured fish are increased, and power of a fishing boat winch can be relieved due to lifting in batches and light bags.

Owner:ZHEJIANG OCEAN UNIV

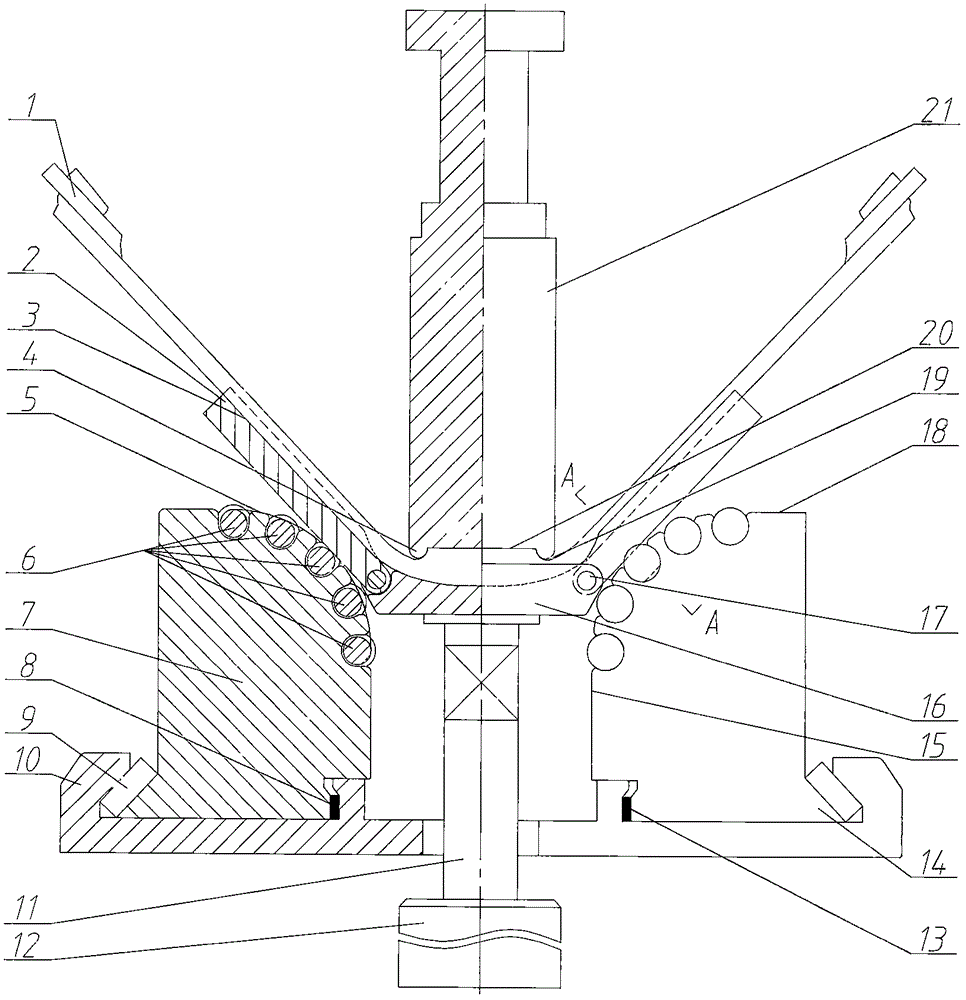

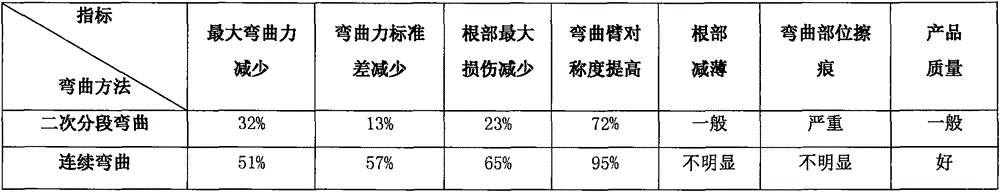

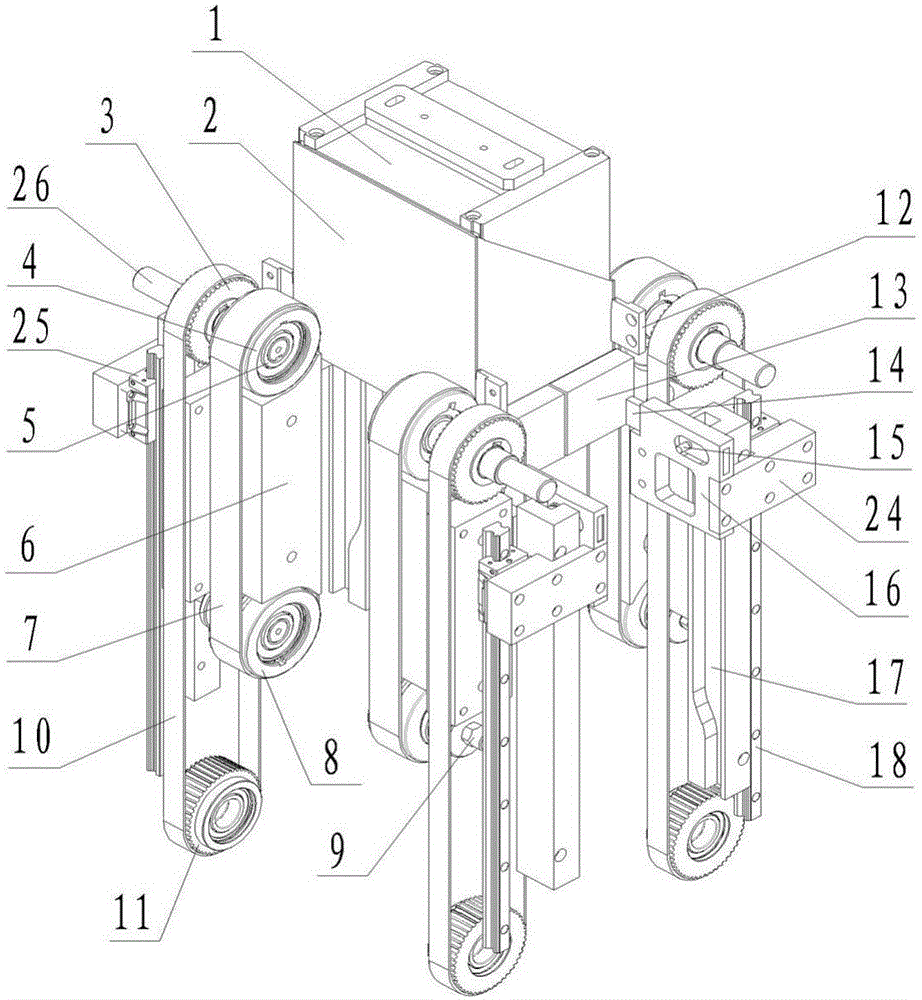

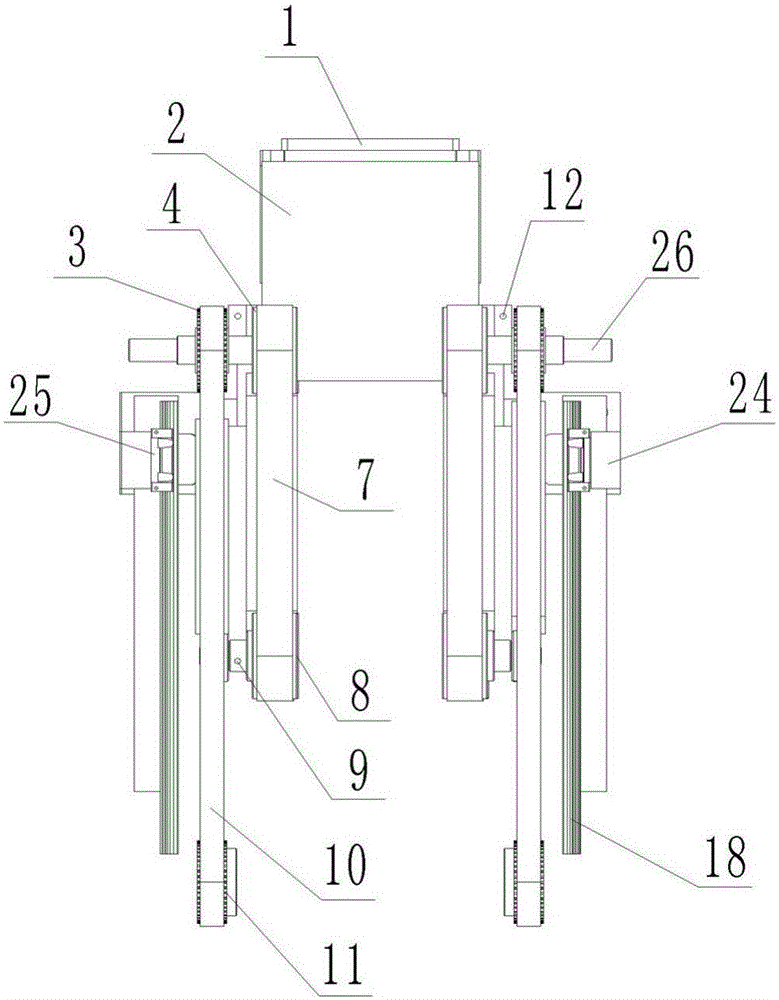

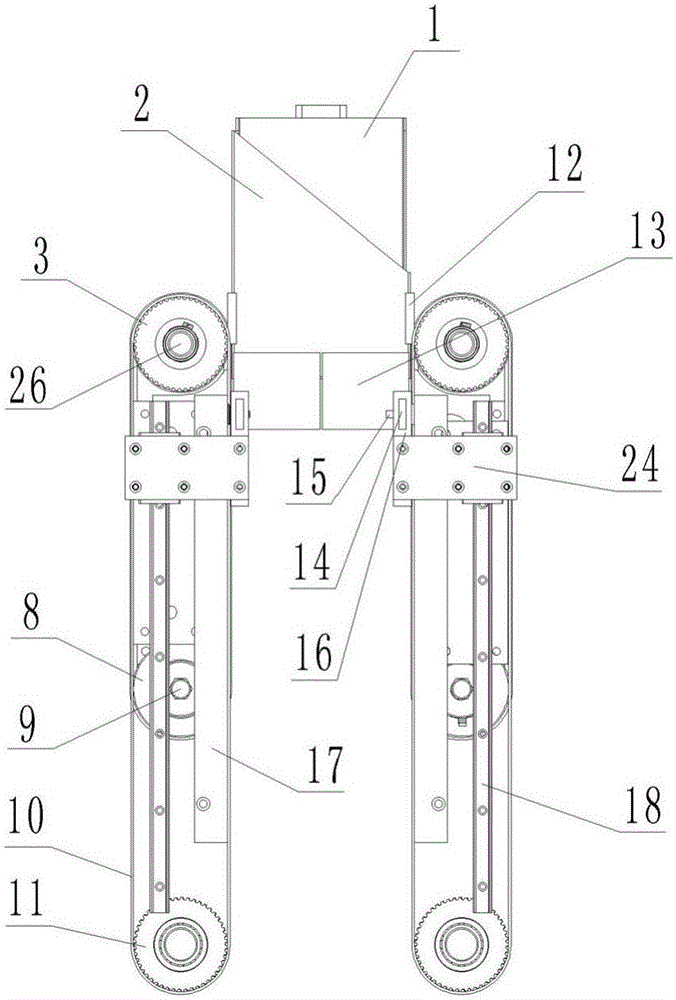

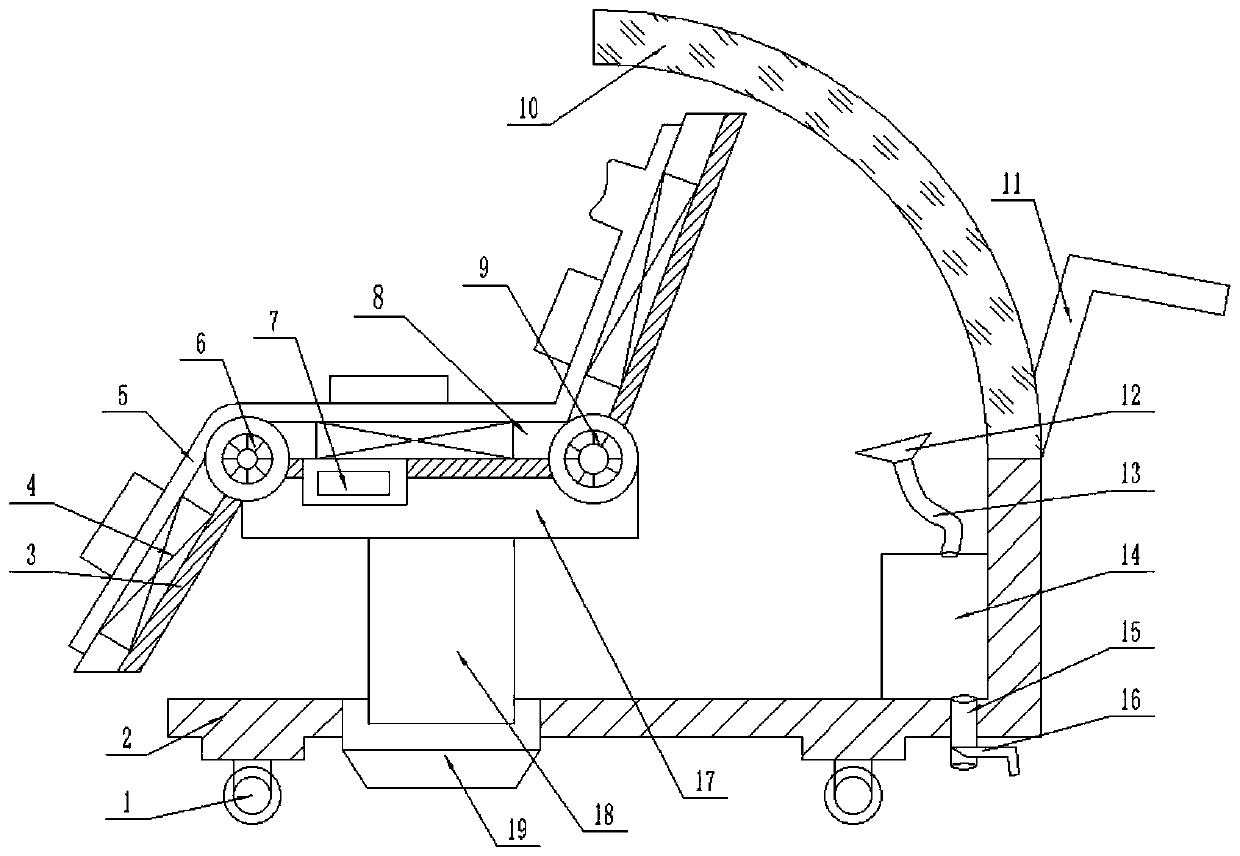

Accurate continuous bending method of U-shaped large forging

InactiveCN106825153AAvoid damageReduce bending loadShaping toolsMetal-working feeding devicesEngineeringBack pressure

The invention discloses an accurate continuous bending method of a U-shaped large forging. The method is realized through an arc-shaped inlet female mold, a male mold matched with the female mold, and a back pressure mold with a bent guiding plate. The method comprises the following steps: heating a forging blank to perform preforging; performing back pressure trimming; performing residual heat accurate positioning; enabling the bent guiding plate to drive the bent part of the forging to move and be bent along the arc-shaped track of a female mold inlet, and the like. The method has the advantages that the surface of the bent part is high in quality and small in damage, and the symmetry of the forging is high.

Owner:SOUTHWEST UNIVERSITY

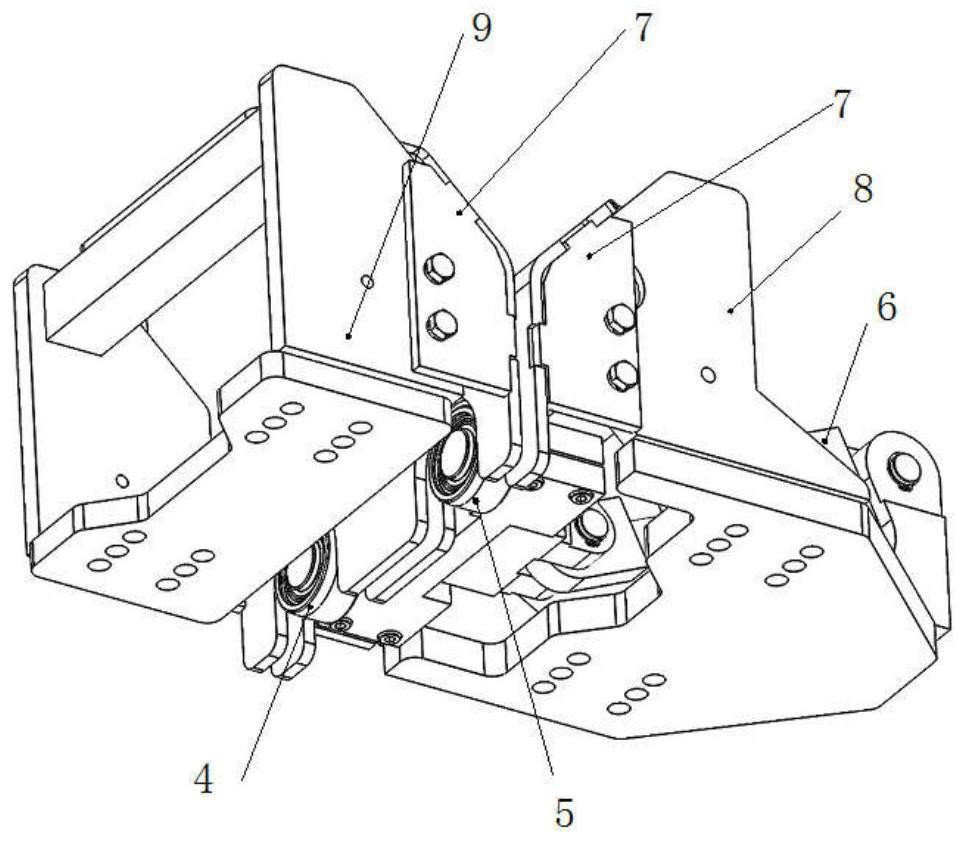

Cavity mechanism

ActiveCN105150595AGood glue spray effectSpray glue sticking effect is goodBoxes/cartons making machineryDrive shaftEngineering

Owner:WENZHOU GAOSHENG MACHINERY CO LTD

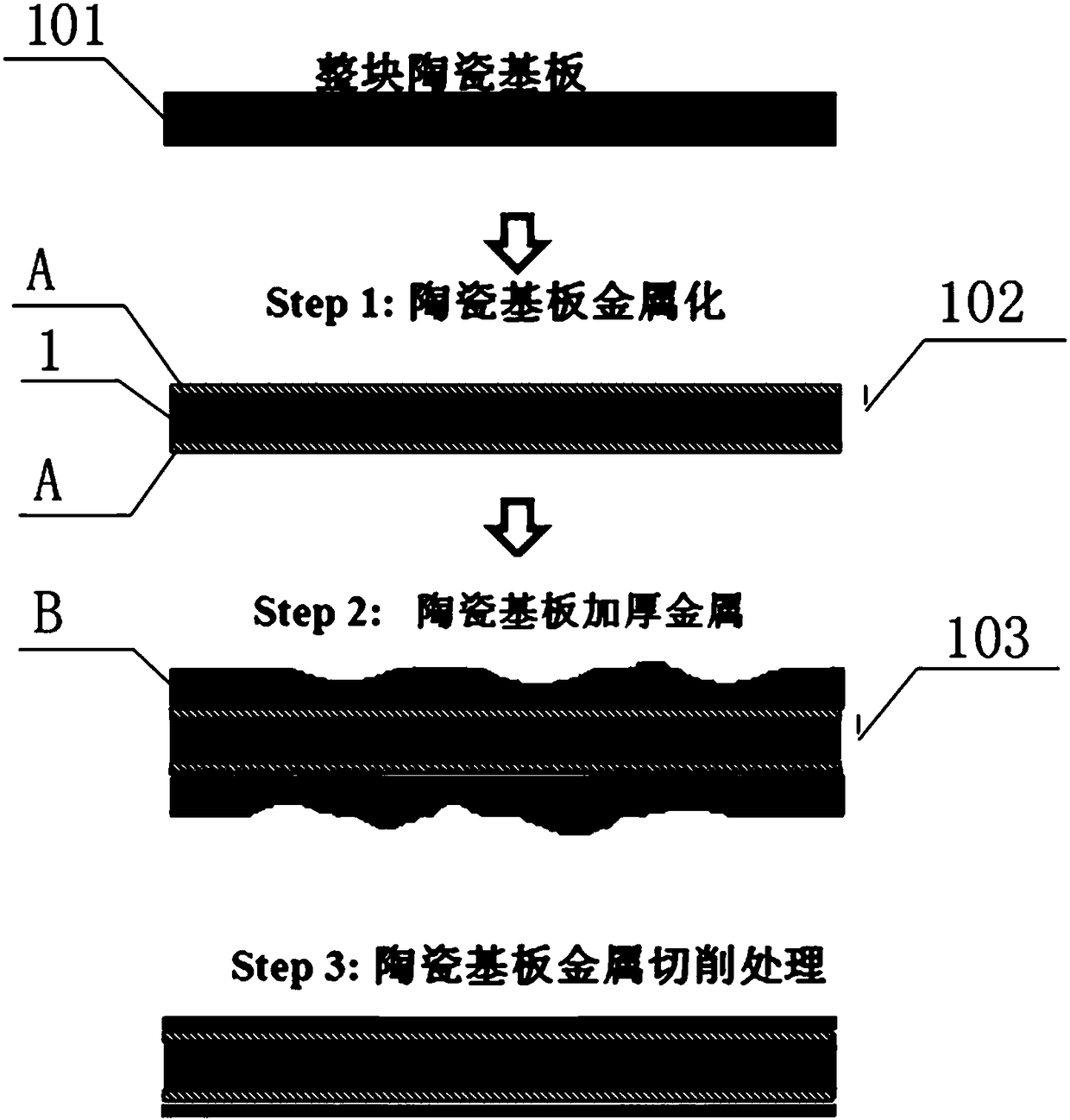

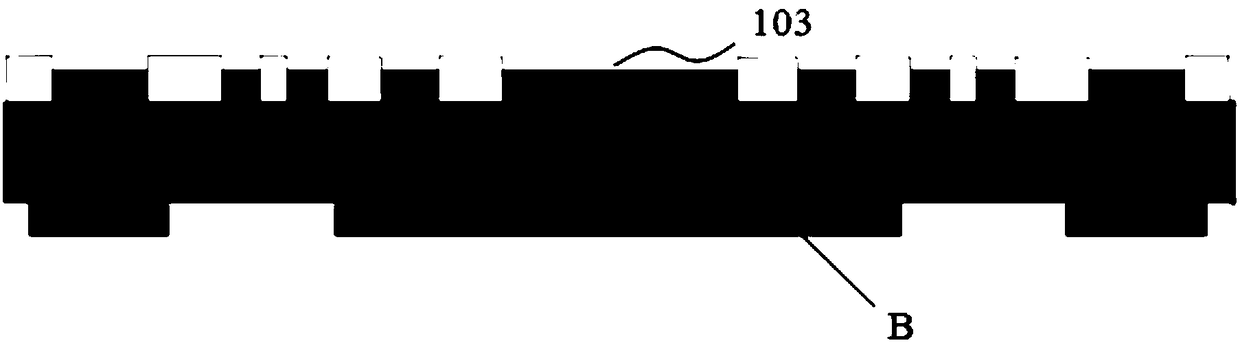

DPC ceramic circuit board and preparation method thereof

InactiveCN108174524AFix scratchesHigh surface flatnessConductive pattern polishing/cleaningCircuit susbtrate materialsRoom temperatureCopper

The invention discloses a DPC ceramic circuit board and a preparation method thereof. The method comprises the following steps: an electroplated thickened ceramic substrate is prepared, wherein the electroplated thickened ceramic substrate includes a ceramic substrate and a metal layer arranged on the ceramic substrate, and there is a copper line on the metal layer; and cutting is carried out: metal cutting is carried out on the surface of the electroplated thickened ceramic substrate, and in the process of cutting, a platform for placing the electroplated thickened ceramic substrate is a shock absorption platform, the ambient temperature and the temperature of the electroplated thickened ceramic substrate are controlled at room temperature, the precision range of temperature is + / -2DEG C,and rotary cutting is adopted. The circuit board preparation method of the invention avoids a certain degree of damage to the substrate caused by grinding and polishing, and the high requirement fora mirror surface can be hardly achieved by the cutting in the prior art. By using the circuit board preparation method of the invention, the DPC ceramic circuit board has a mirror surface, the reflectivity of the circuit board is improved, and the thickness of the circuit board after processing is very uniform.

Owner:国瓷赛创电气(铜陵)有限公司

Wound treatment device for scratch injury and scuffing injury

InactiveCN107261314AEfficient removalPrevent wound infectionDispersed particle filtrationMedical devicesAir filterEngineering

The invention discloses a device for treating scratches and wounds, a gauze box and a handle. The left side of the gauze box is provided with a sealing cover, the inside of the gauze box is provided with a rotating shaft, and the lower end of the gauze box is provided with a gauze outlet. The upper end of the handle is provided with a water tank and an air filter device. The upper end of the water tank is provided with a water inlet pipe. There is a spray plate, the lower end of the air filter device is connected with an air intake pipe, the lower end of the air intake pipe is connected with a rubber air bag, the outer handle of the rubber air bag is provided with a cavity, and the left side of the rubber air bag is provided with an air outlet pipe. The invention is used for treating scratches and scratches, has a simple structure and is convenient to carry, and solves the problem of difficulty in treating scratches and scratches when going out.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

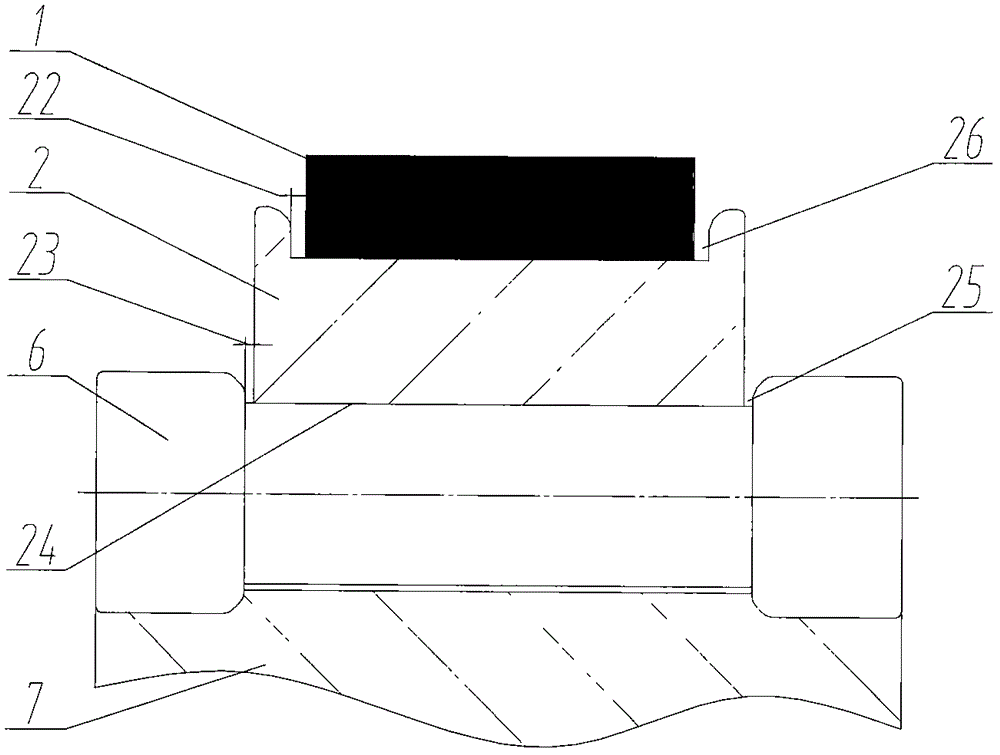

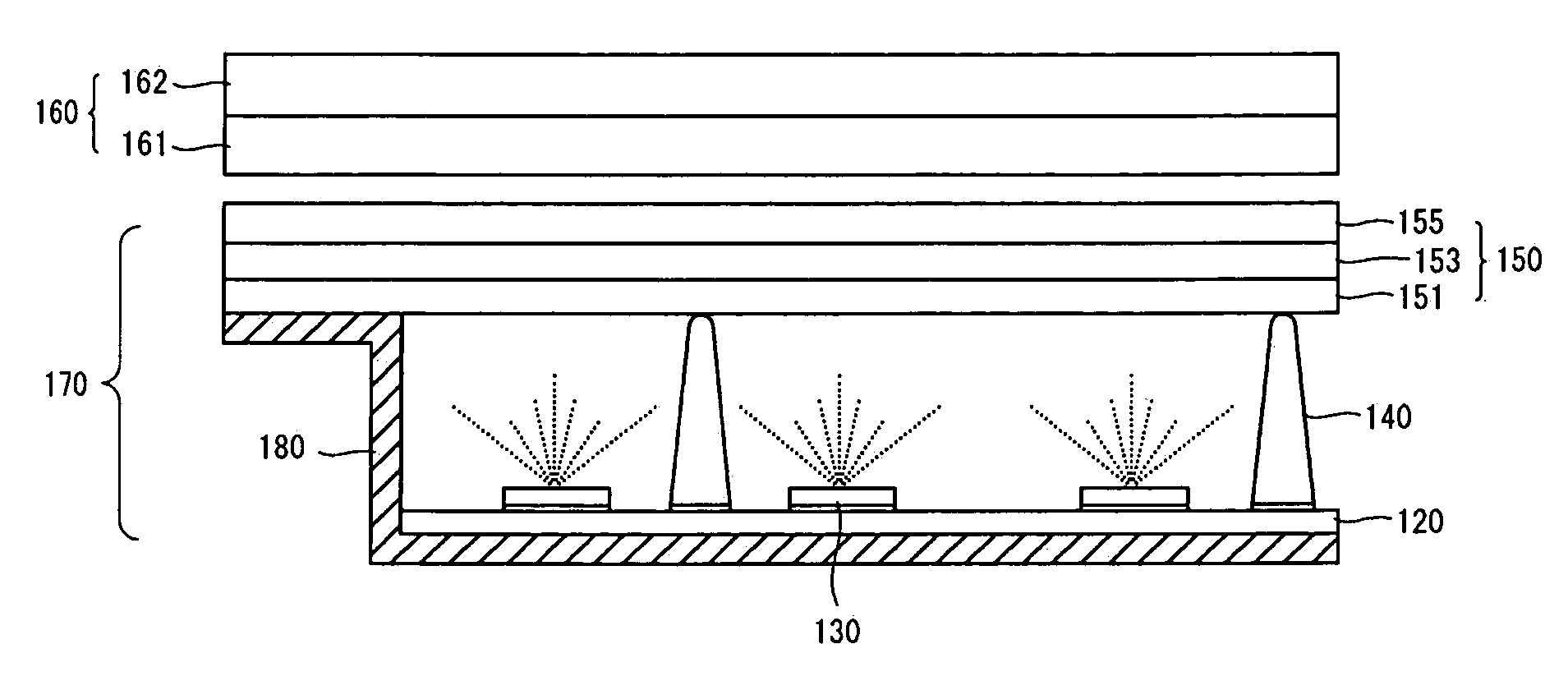

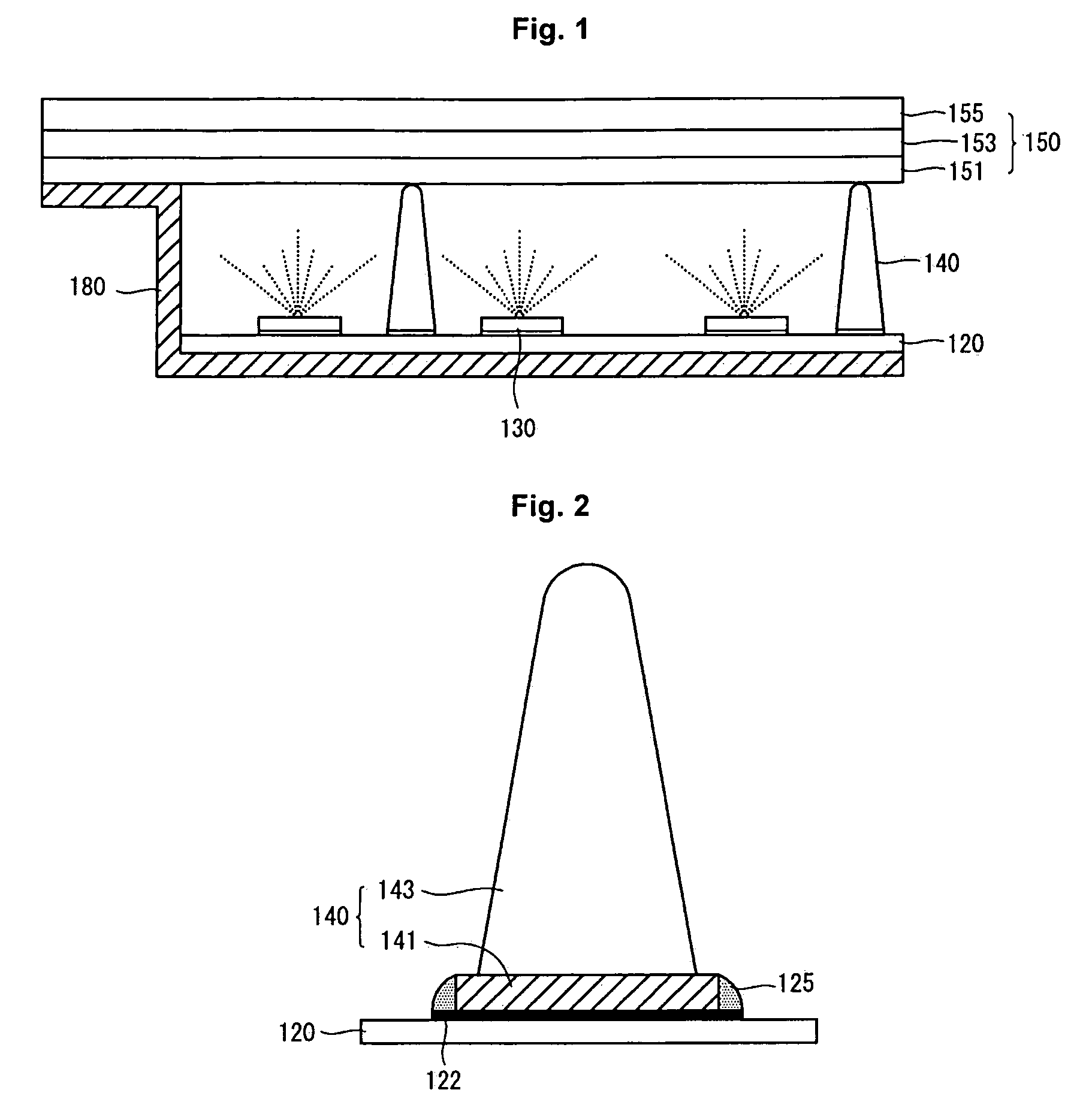

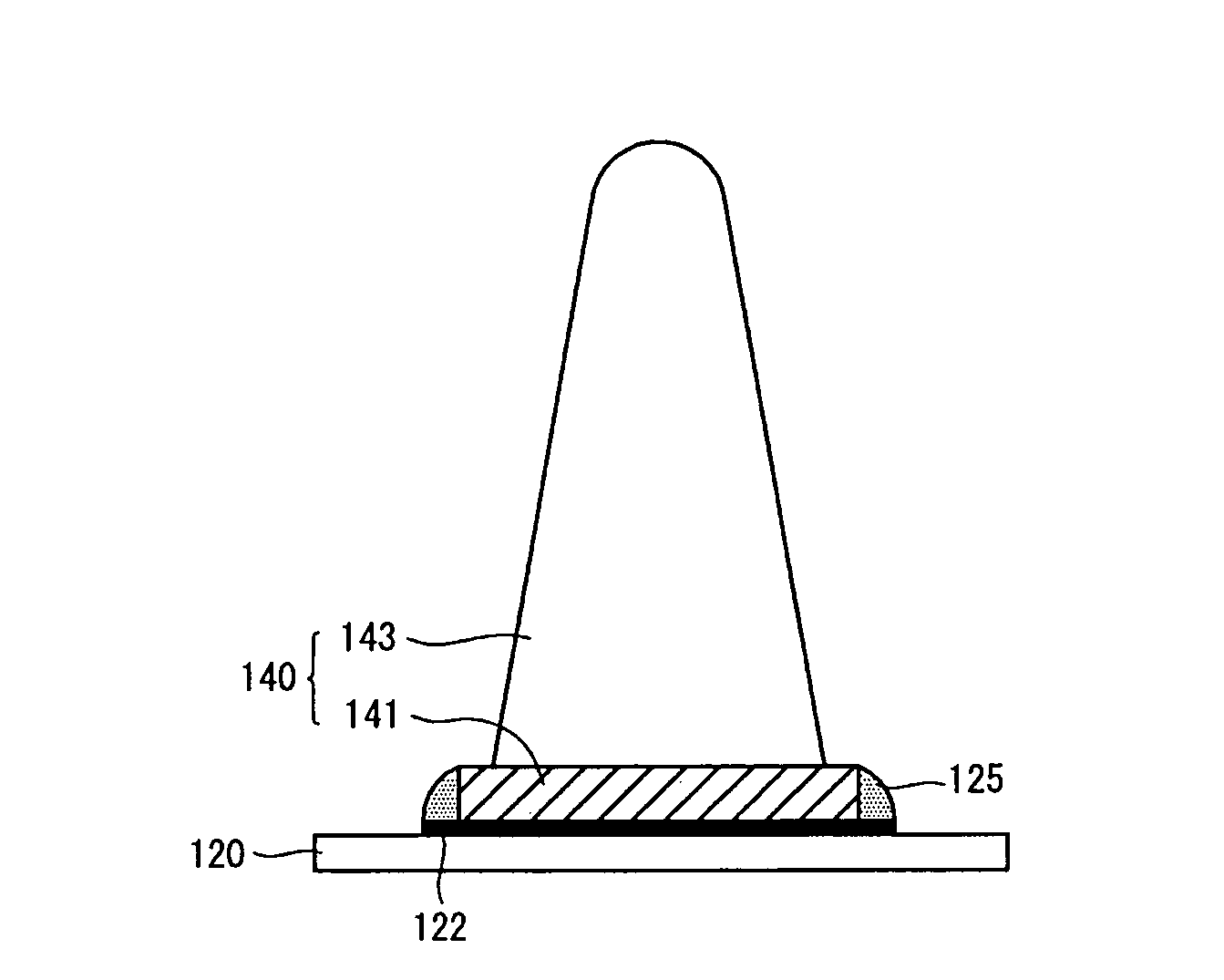

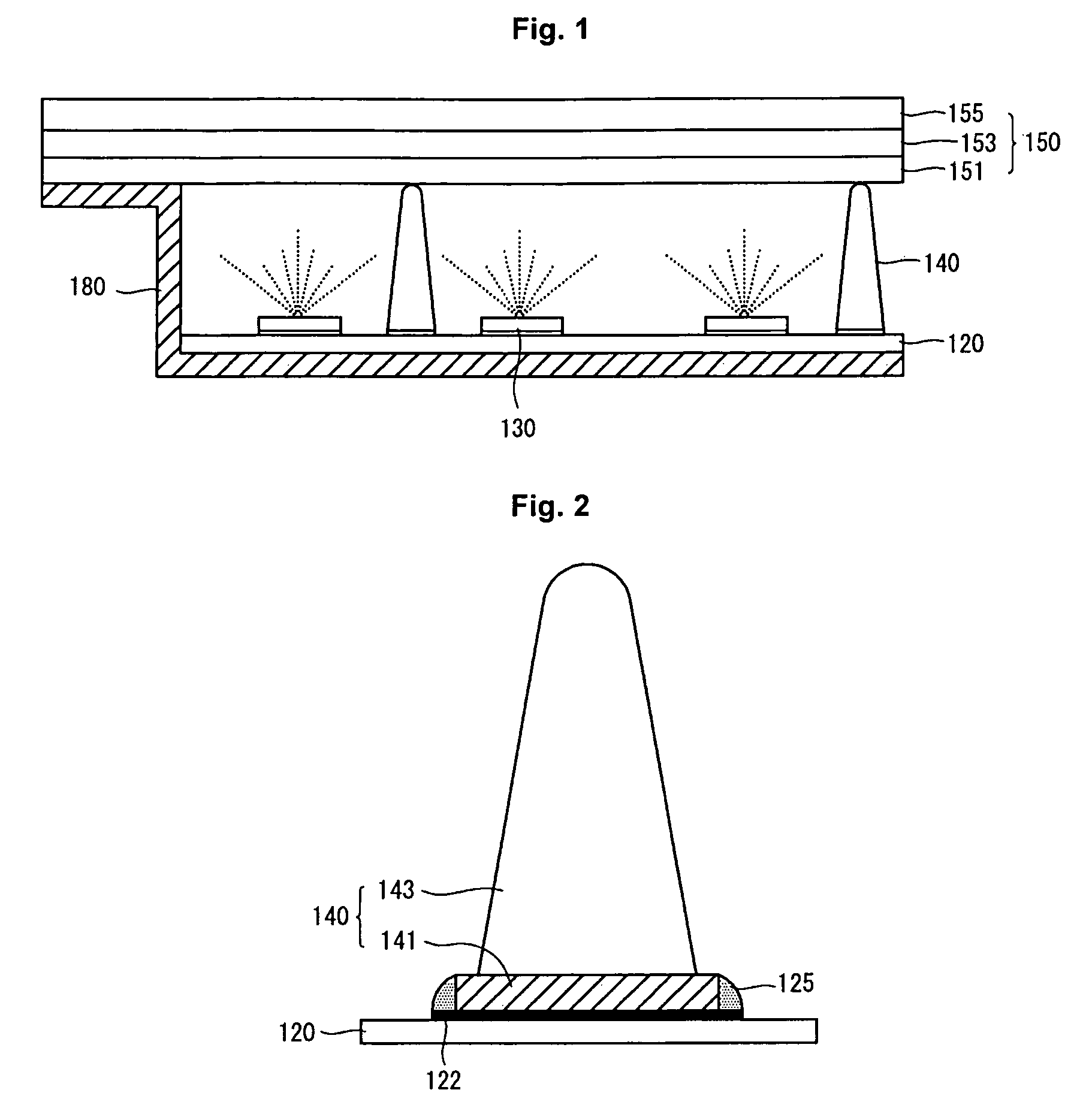

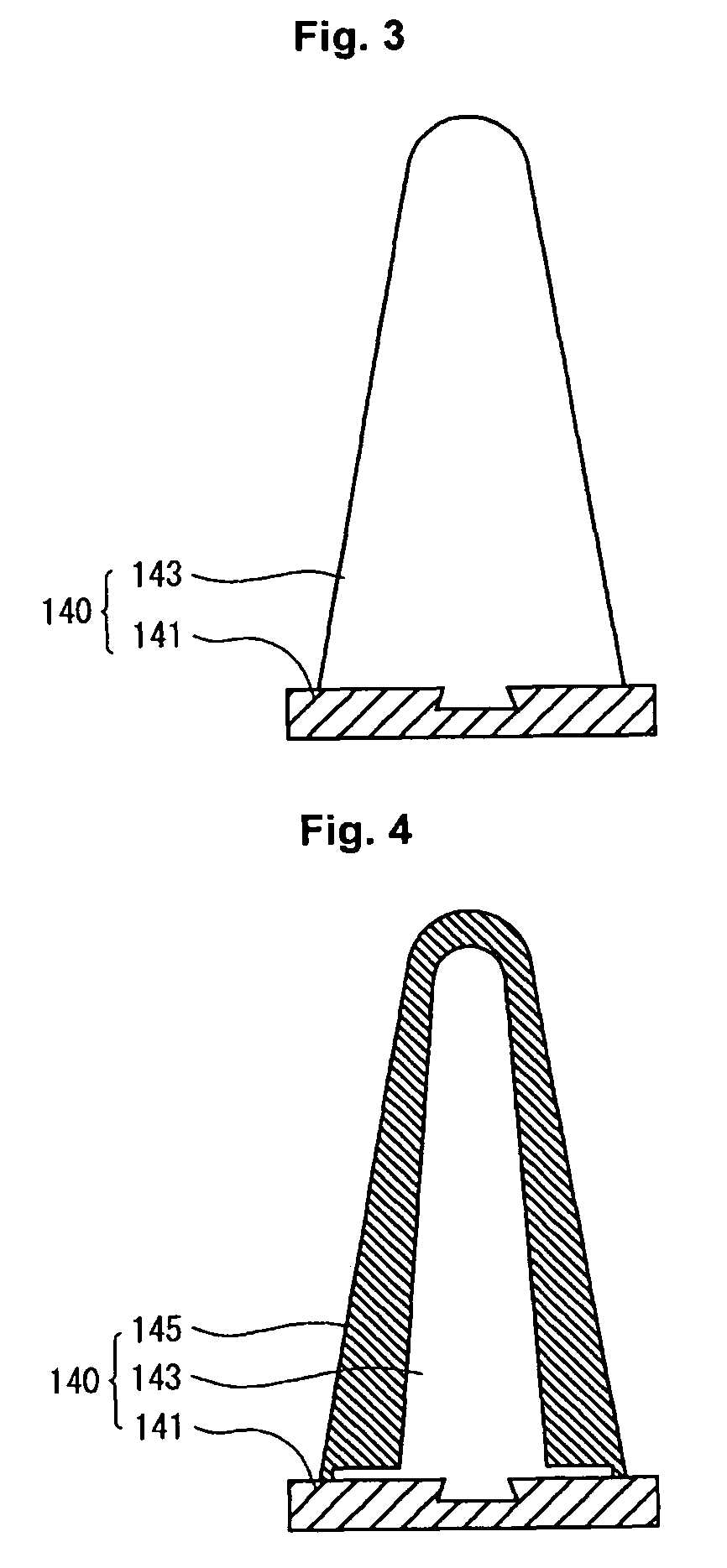

Back light unit and liquid crystal display using the same

ActiveUS20100061084A1Eliminate the problemShorten the time periodShow cabinetsImpedence networksLiquid-crystal displayEngineering

A backlight unit is provided. The backlight unit comprises: a cover bottom: a printed circuit board (PCB) that is supported by the cover bottom; a light emitting element that is positioned on the PCB; an optical film layer that is supported by the cover bottom and that is positioned on the PCB; and a guide that is mounted separately from the light emitting element in a surface of the PCB in order to support the optical film layer.

Owner:LG DISPLAY CO LTD

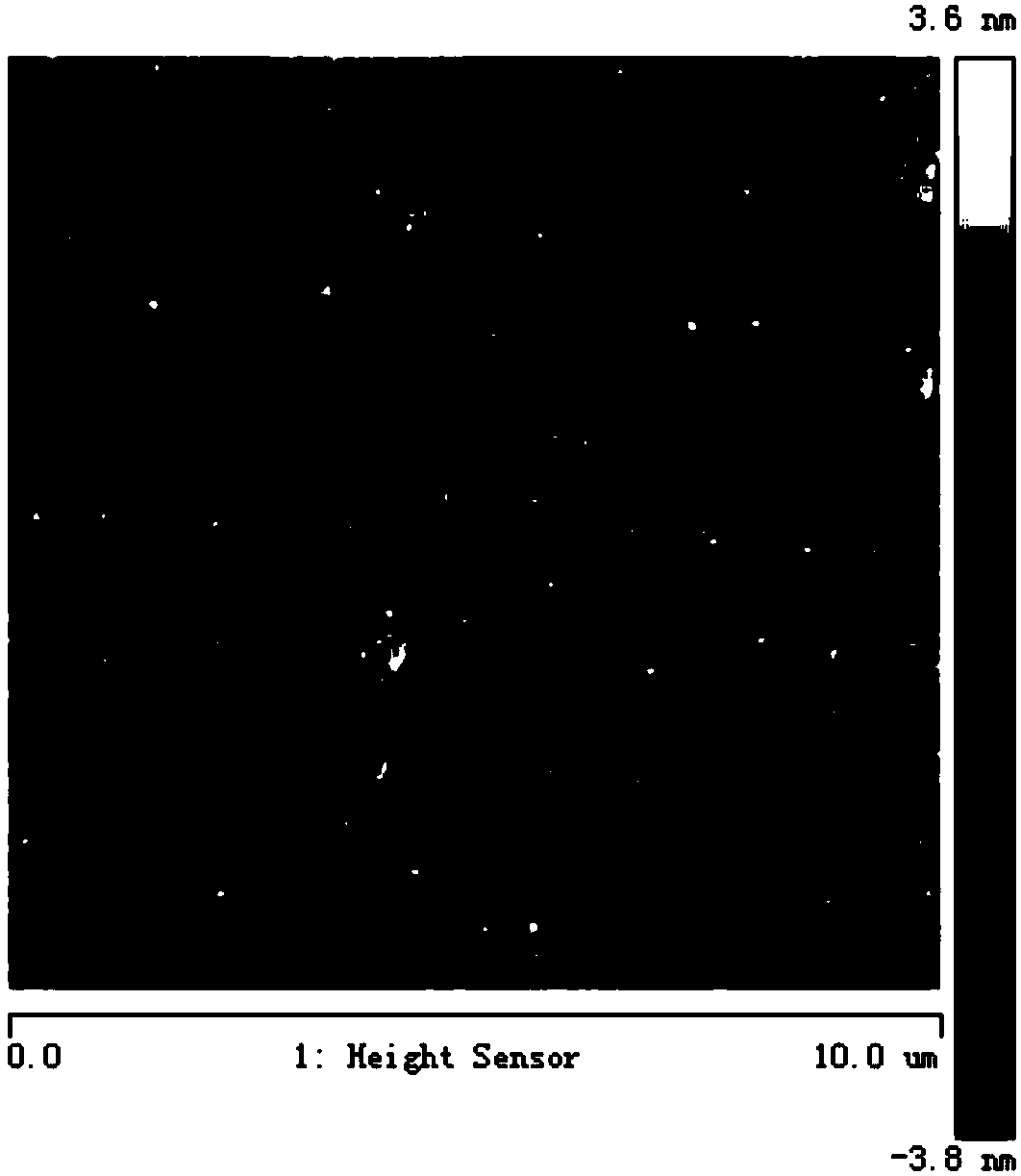

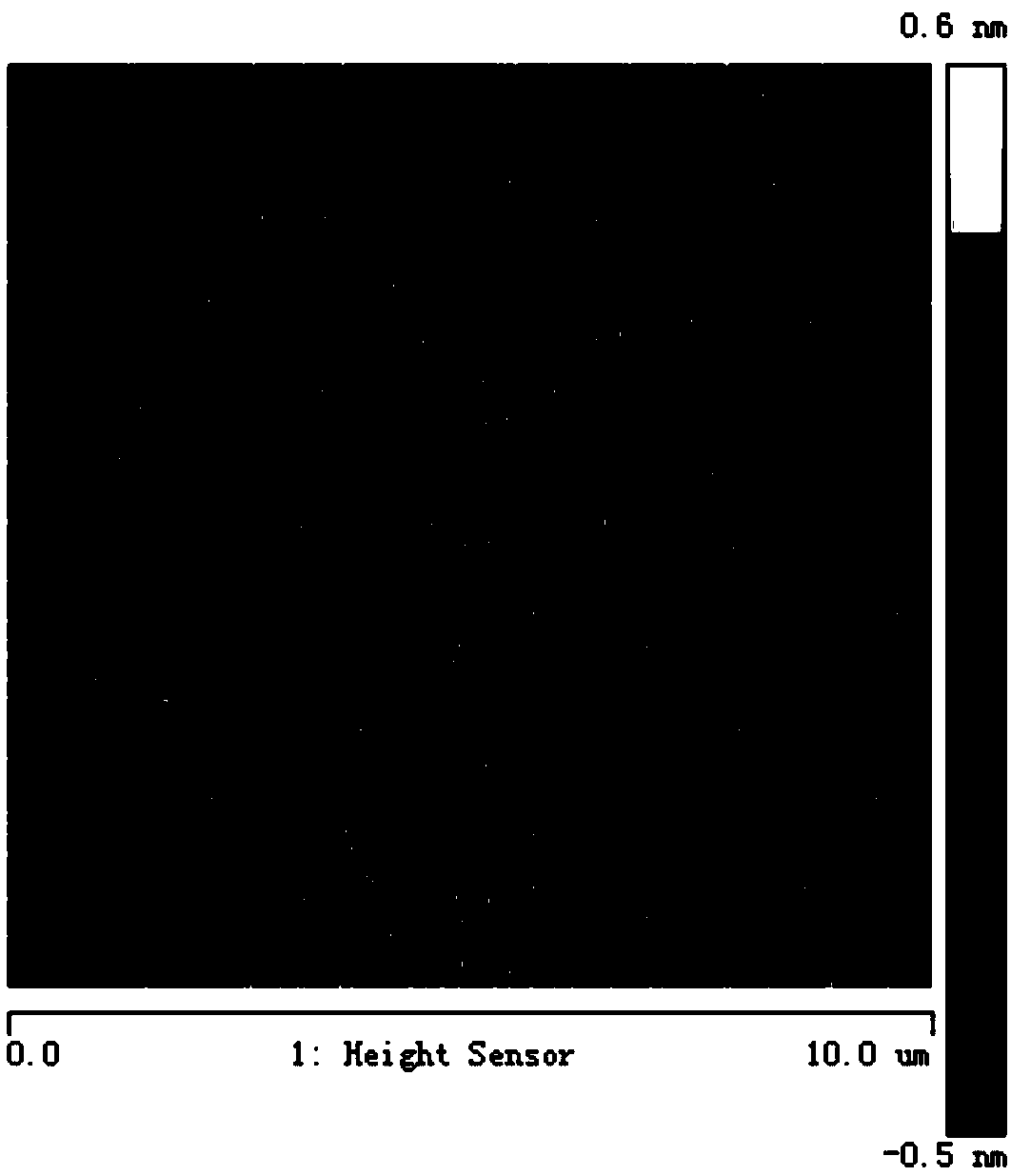

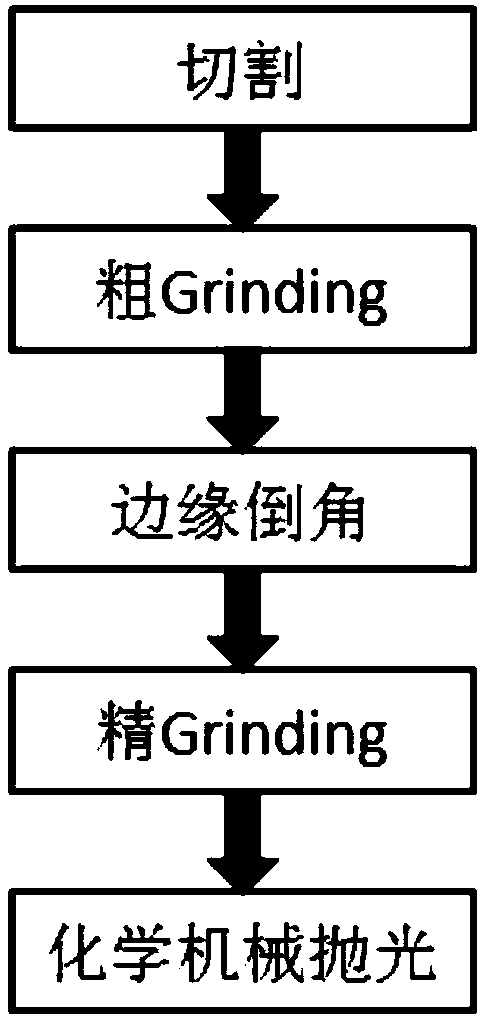

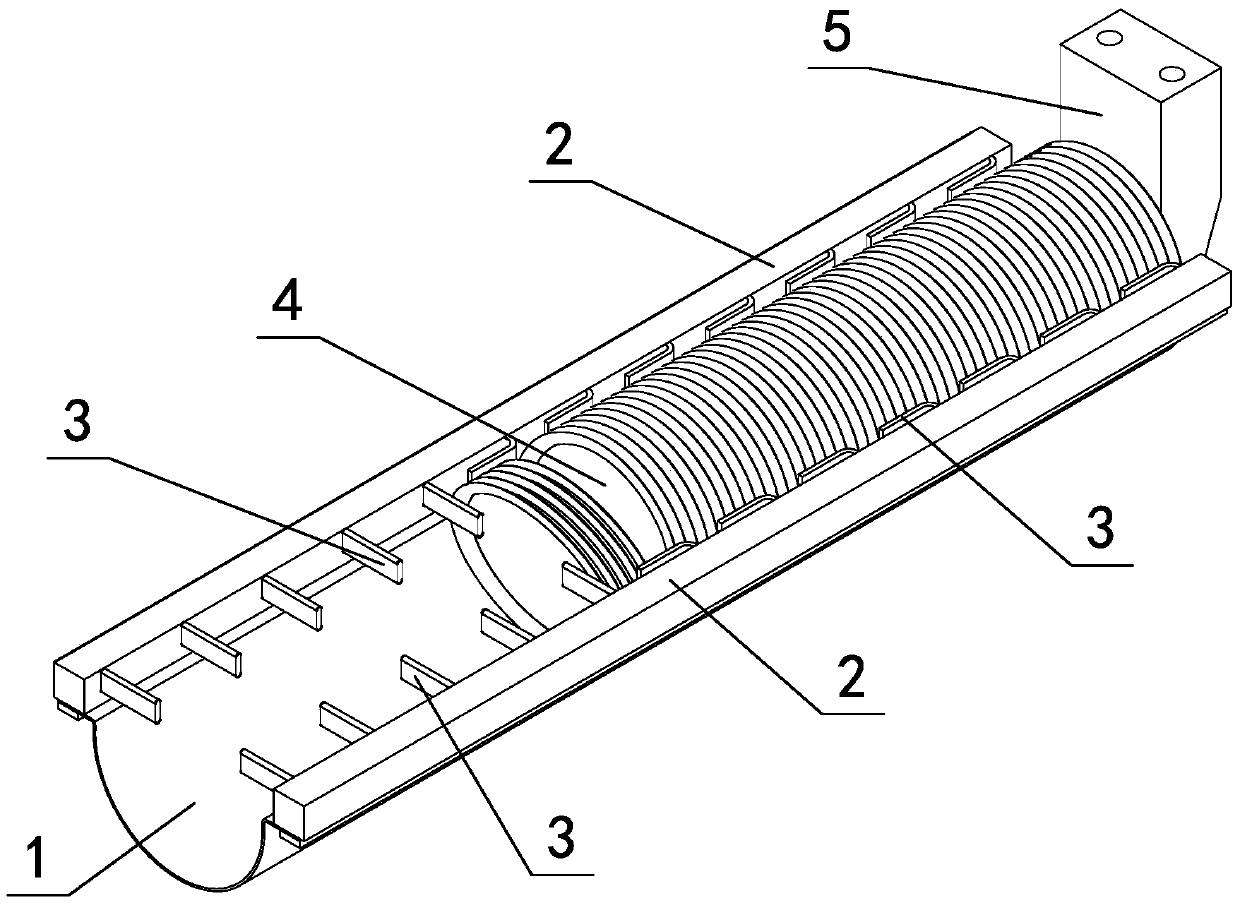

Rapid preparation method of high flatness and low damage single crystal silicon carbide substrate

ActiveCN109545680AImprove flatnessAvoid deformationSemiconductor/solid-state device manufacturingCarbideWire cutting

The invention provides a rapid preparation method of a high flatness and low damage single crystal silicon carbide substrate. The method is characterized by comprising steps that fully-solidified abrasive treatment of the single crystal silicon carbide is performed, chemical mechanical polishing treatment is then performed, the high-flatness and low-damage single crystal silicon carbide substrateis obtained, solidified abrasive treatment includes line cutting and grinding wheel grinding, abrasive particles are consolidated on cutting lines, and the abrasive particles are consolidated on a grinding wheel. The method is advantaged in that surface roughness, a scratch die ratio, a pit ratio and bump of the prepared single crystal silicon carbide substrate are relatively low, surface data isgood, thickness deviation is small, curvature is small, and warpage is small.

Owner:SICC CO LTD

Can cap tipping prevention device

ActiveCN105501909ASmall elastic resistancePouring won'tConveyorsConveyor partsProduction lineEngineering

The invention discloses a can cap tipping prevention device which is arranged on a horizontal cap collection groove of a can cap production line, wherein mounting seats are arranged at the cap collection groove from notches at the two sides of the cap collection groove along the length direction of the cap collection groove; elastic can blocking strips are horizontally arranged at one side, facing to the cap collection groove, of each mounting seat in a spaced manner; one end of each can blocking strip is fixed to one mounting seat correspondingly; the other ends of the can blocking strips are overhung and stretch into the cap collection groove; and the projected lengths of the overhung parts of the can blocking strips on the cross section of the cap collection groove are 30-45% of the width of an opening of the cap collection groove. With the adoption of the can cap tipping prevention device, the problems that in a can collection process in the prior art, can cap tipping happens easily, thereby resulting in that can caps are scratched, a cap pushing resisting force is increased, and a manipulator can not complete a can cap grabbing task can be solved effectively. The can cap tipping prevention device can prevent can caps from tipping effectively, the production efficiency is improved, the product quality is ensured, and the can cap tipping prevention device has very high practical values.

Owner:YIWU EASY OPEN END INDAL CORP

Automotive protective cover

InactiveCN101274588AFix scratchesRemovable external protective coveringsMetal layered productsPolyesterSurface layer

The invention discloses a vehicle shield which is applied to various vehicle models. The product of the invention consists of three layers of materials by adopting a mechanical stitching method. High density PVC polyester pongee materials are selected for the surface layer materials and the bottom layer materials of the product; metal mesh is selected to manufacture the intermediate layer, which is provided with sharp instruments-scratching proof performance, thus thoroughly solving the scratch resistant problem of the vehicle. The present vehicle shields are essentially have single-layer, and can hardly prevent the vehicle from scratch caused by sharp instruments while having certain vehicle-protection effect. By adopting the metal mesh to manufacture the intermediate layer, the scratch caused by sharp instruments can be effectively prevented, thus thoroughly solving the scratch problem of the surface of the vehicle.

Owner:郑维勇

Back light unit and liquid crystal display using the same

ActiveUS8459820B2Shorten the time periodSimple structureShow cabinetsImpedence networksLiquid-crystal displayEngineering

A backlight unit is provided. The backlight unit comprises: a cover bottom: a printed circuit board (PCB) that is supported by the cover bottom; a light emitting element that is positioned on the PCB; an optical film layer that is supported by the cover bottom and that is positioned on the PCB; and a guide that is mounted separately from the light emitting element in a surface of the PCB in order to support the optical film layer.

Owner:LG DISPLAY CO LTD

Kerb protection device during asphalt pavement process, and protection method thereof

InactiveCN105178143AFix scratchesAvoid pollutionPaving gutters/kerbsRoads maintainenceEngineeringRoad surface

The invention discloses a kerb protection device during an asphalt pavement process, and a protection method thereof. The kerb protection device comprises an inner side plate, an upper top plate and an outer side plate, wherein the inner side plate, the upper top plate and the outer side plate are fixedly connected in sequence to form a square upper cover with an open lower part, and the square upper cover covers a kerb; the inner side plate is located at one side close to an asphalt road surface, of the kerb, and the height of the inner side plate is 1-3mm greater than the exposed height of the kerb; the upper top plate is parallel to the upper surface of the kerb, a handle is installed on the upper top plate, the width of the upper top plate is 1-3mm greater than the width of the kerb; and the outer side plate is located at the outer side of the kerb. The kerb protection device disclosed by the invention is capable of effectively solving the problem of scratches caused by a rolling vehicle on the kerb during the asphalt pavement process, and avoiding pollution to the kerb due to the treading of construction personnel on the kerb during the asphalt pavement process; the protected kerb is free from the phenomena of steel wheel extrusion, scratches, treading pollution and the like; and the kerb protection device has a good application effect.

Owner:JINAN URBAN CONSTR GRP

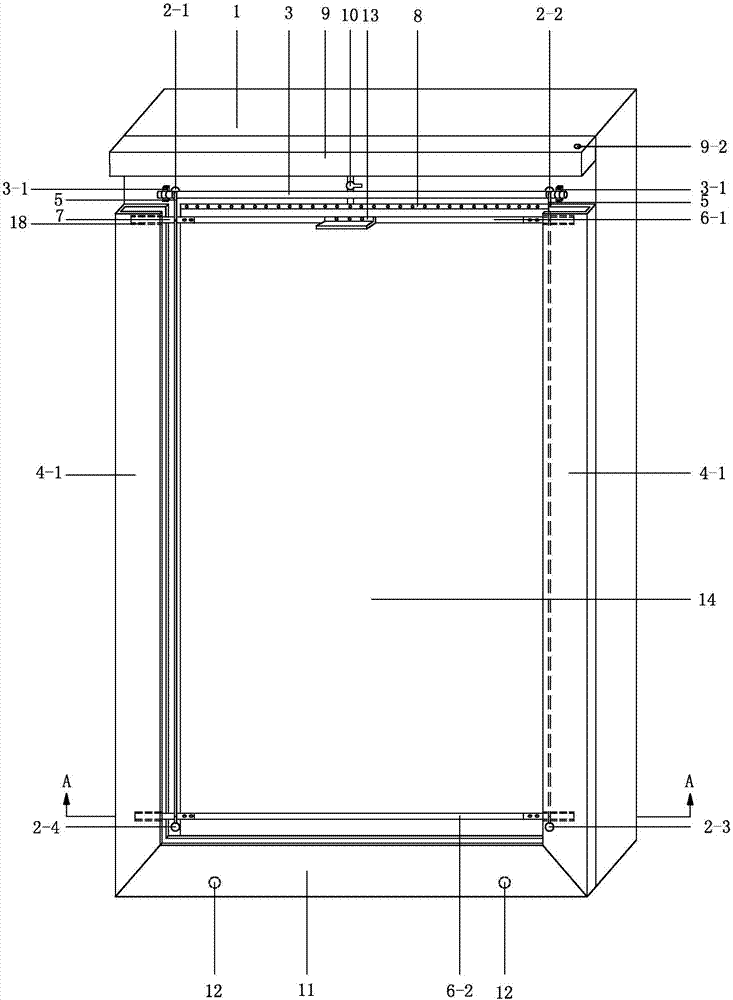

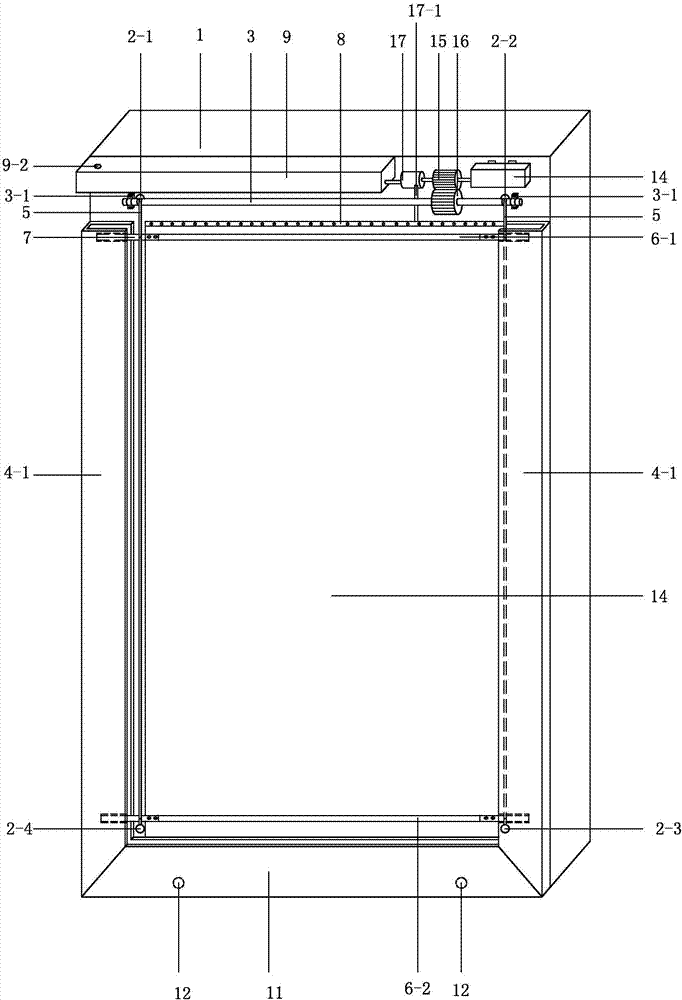

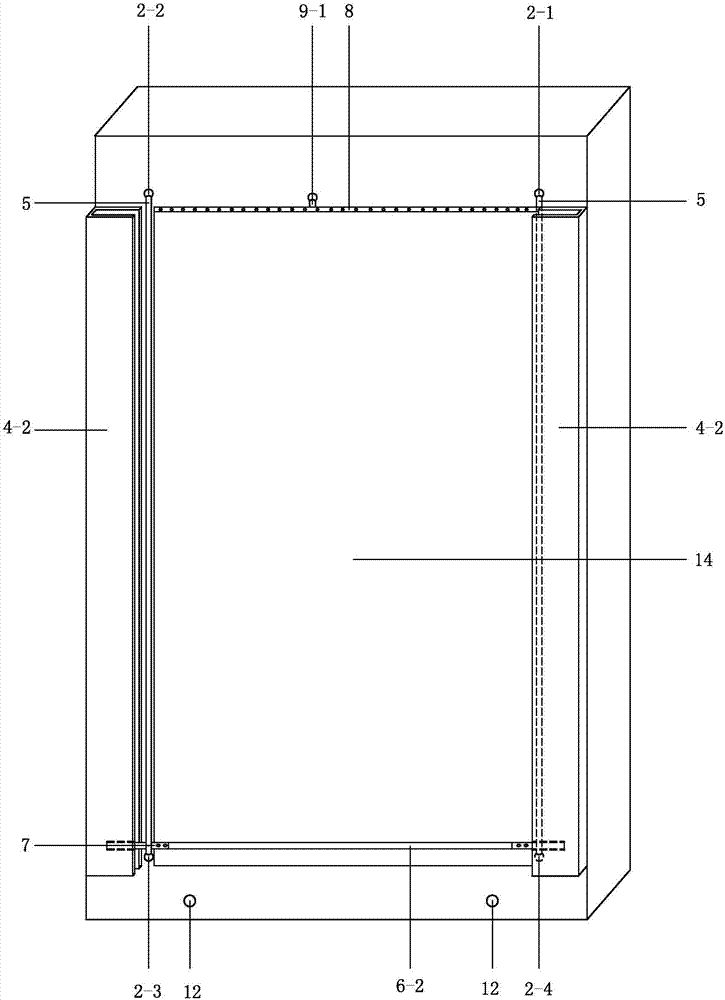

Glass window dual-face cleaner

The invention discloses a glass window dual-face cleaner, and relates to the technical field of glass cleaning tools. The problems that due to an existing glass window cleaning mode, time and labor are wasted, the cleaning efficiency is low, a window provided with a protective guard is difficult to clean, high-rise housing window outer glass is difficult to clean, high-rise building totally-closed window outer glass cannot be cleaned, and potential safety hazards exist are solved. The two ends of a transmission shaft are installed on a window frame through two bearing pedestals, the transmission shaft is in rolling connection with the two bearing pedestals through rolling bearings, two first U-shaped sliding ways and two second U-shaped sliding ways are vertically installed on left and right frames on the inner and outer sides of the window frame respectively, two transmission ropes are wound in the same direction at the two ends of the transmission shaft by the same number of turns, a first water scraping strip is in sliding connection with the two first U-shaped sliding ways through two elastic sliding pieces, a second water scraping strip is in sliding connection with the two second U-shaped sliding ways through two elastic sliding piece, and the first water scraping strip and the second water scraping strip are fixedly connected with the two transmission ropes. The glass window dual-face cleaner is used for cleaning glass of building windows.

Owner:张青春

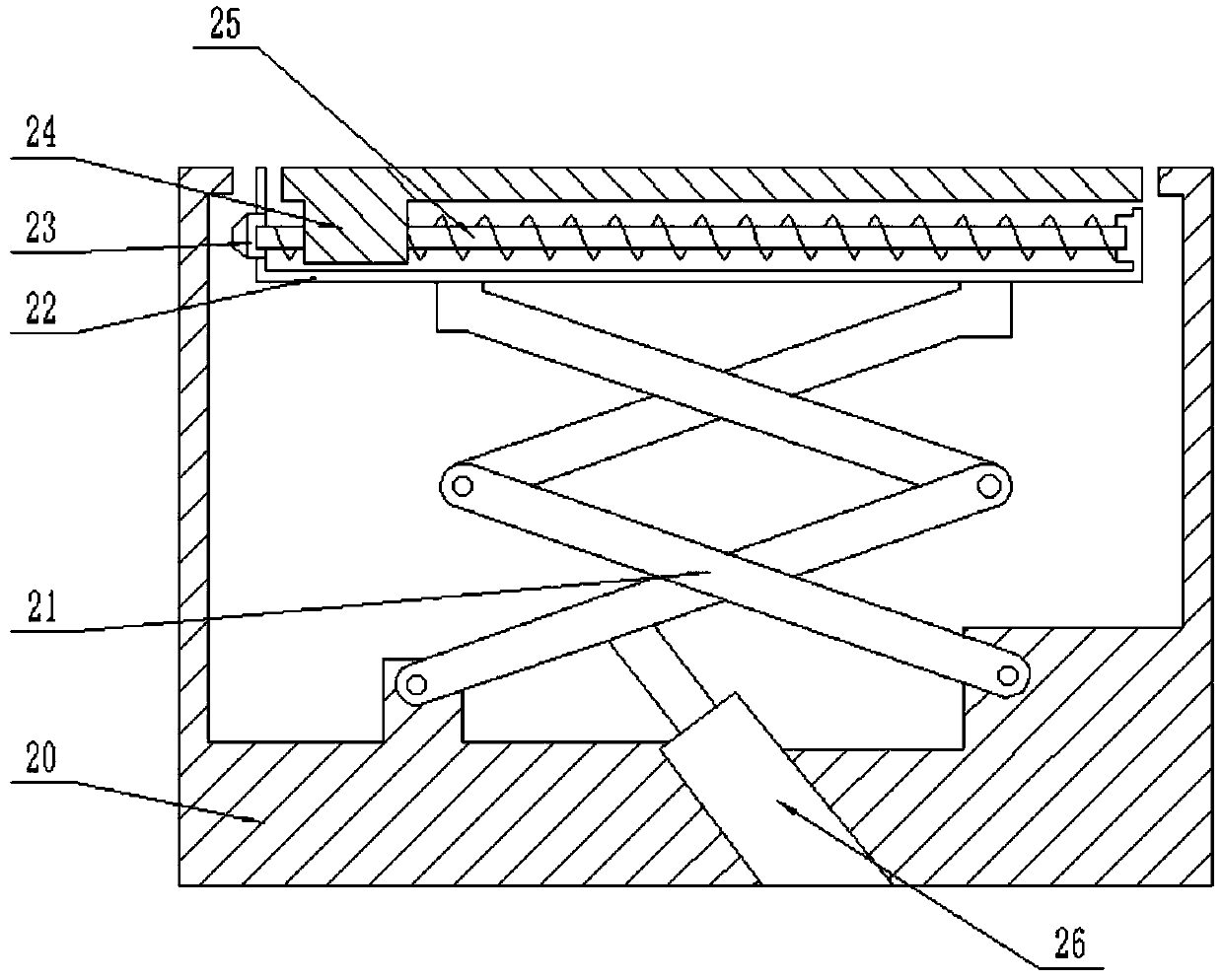

Transition assist device for nursing paralyzed patients

InactiveCN110495999ASimple structureReduce manufacturing costWheelchairs/patient conveyanceNursing bedsHydraulic cylinderPatient need

The invention discloses a transition assist device for nursing paralyzed patients. The transition assist device comprises universal wheels, a device casing, a heating wire, a lifting device, a movablefixed mattress, a first motor, an electric heater, a bed board and the like. If a paralyzed patient needs transition, a bed form is formed by regulating the angle of the bed board through the first motor and a second motor; medical staff pushes the device to a hospital bed, the bed board is driven to rotate through a third motor until the bed board is parallel to the hospital bed, and the patientbody is blocked through a rotary baffle on the mattress; a pin hole is locked by inserting a pin to fix the paralyzed patient, and the paralyzed patient is prevented from falling down; a lifting platform on a lifting bracket is jacked up through a hydraulic cylinder inside the lifting device, the movable fixed mattress is supported against the upper end of the lifting platform, and a fourth motoris used for driving a slide platform on a screw rod to move; the movable fixed mattress is moved into the hospital bed, the hydraulic cylinder is used for driving the lifting platform to descend, thefourth motor is used for drawing out the slide platform, so that the transition is completed with time and labor saving.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV

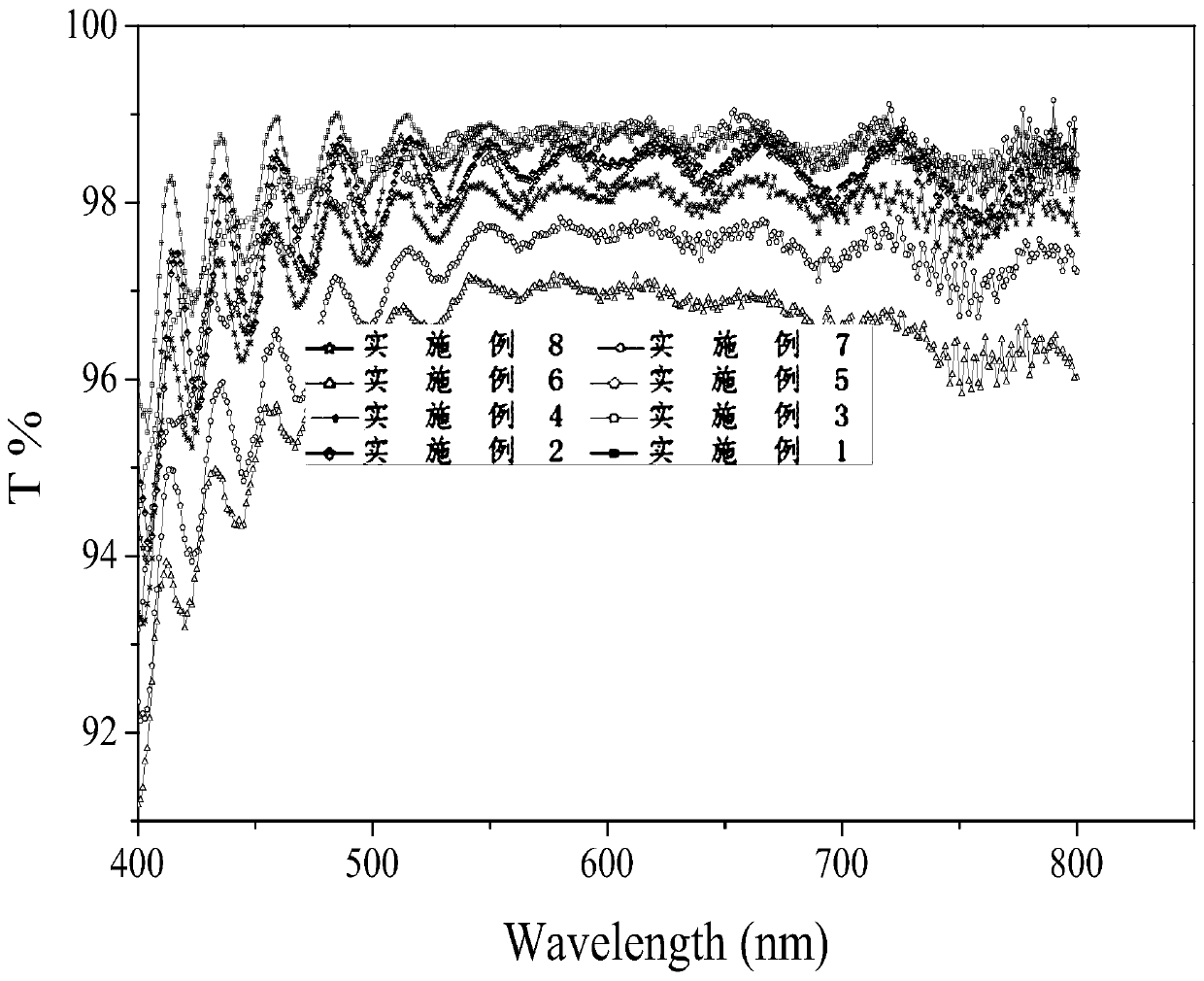

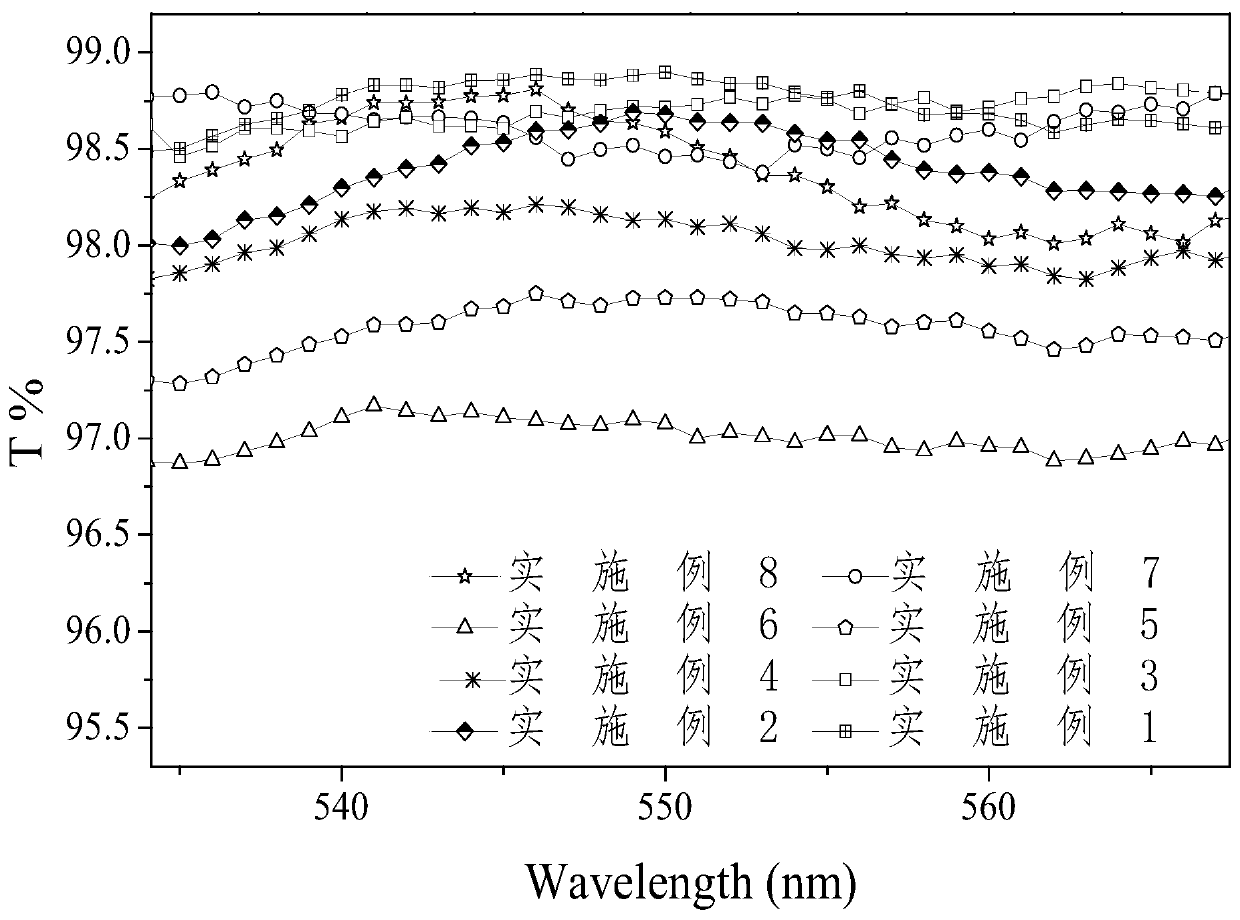

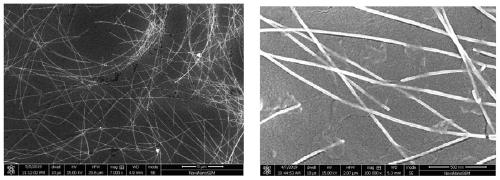

Crosslinkable and chemically sinterable high-cohesiveness silver nanowire conductive ink and conductive film prepared from same

ActiveCN111057414AImprove adhesionSolve the adhesionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersPolymer sciencePolyvinyl alcohol

The invention discloses crosslinkable and chemically sinterable high-cohesiveness silver nanowire conductive ink and a conductive film prepared from the same. The formula of the conductive ink comprises the following components in percentage by mass: 0.1 to 2.0 percent of silver nanowires; 0.01 to 0.5 percent of a bonding agent; 0.001 to 0.008 percent of a dispersing agent; 0.001 to 0.016 percentof a leveling agent, 0.001 to 0.005 percent of a surfactant, 0.1 to 1 percent of a thickening agent, 0.001 to 0.1 percent of a defoaming agent, 0.001 to 0.01 percent of a cross-linking agent and chemical sintering agent, and 96.361 to 99.785 percent of a solvent, and the binding agent is one or a mixture of more of sodium alginate, polyvinyl alcohol, polyurethane, chitosan and the like; and the cross-linking agent and chemical sintering agent is one or a mixture of more of calcium chloride, magnesium chloride, zinc chloride, nickel chloride and the like. According to the invention, the problem of poor adhesiveness of the silver nanowire transparent conductive film on the substrate is solved, and the film has structural stability, high conductivity and high visible light transmittance.

Owner:ZHEJIANG UNIV OF TECH

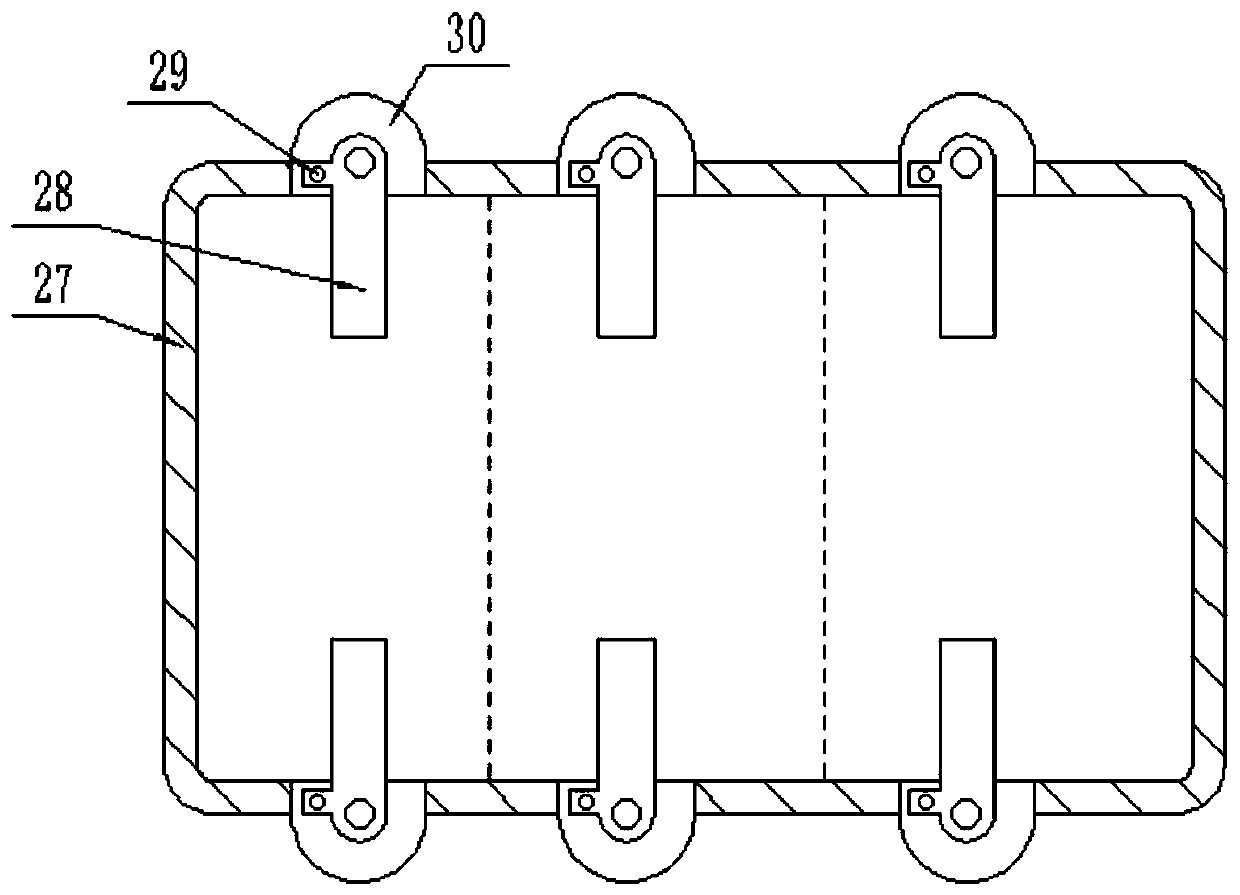

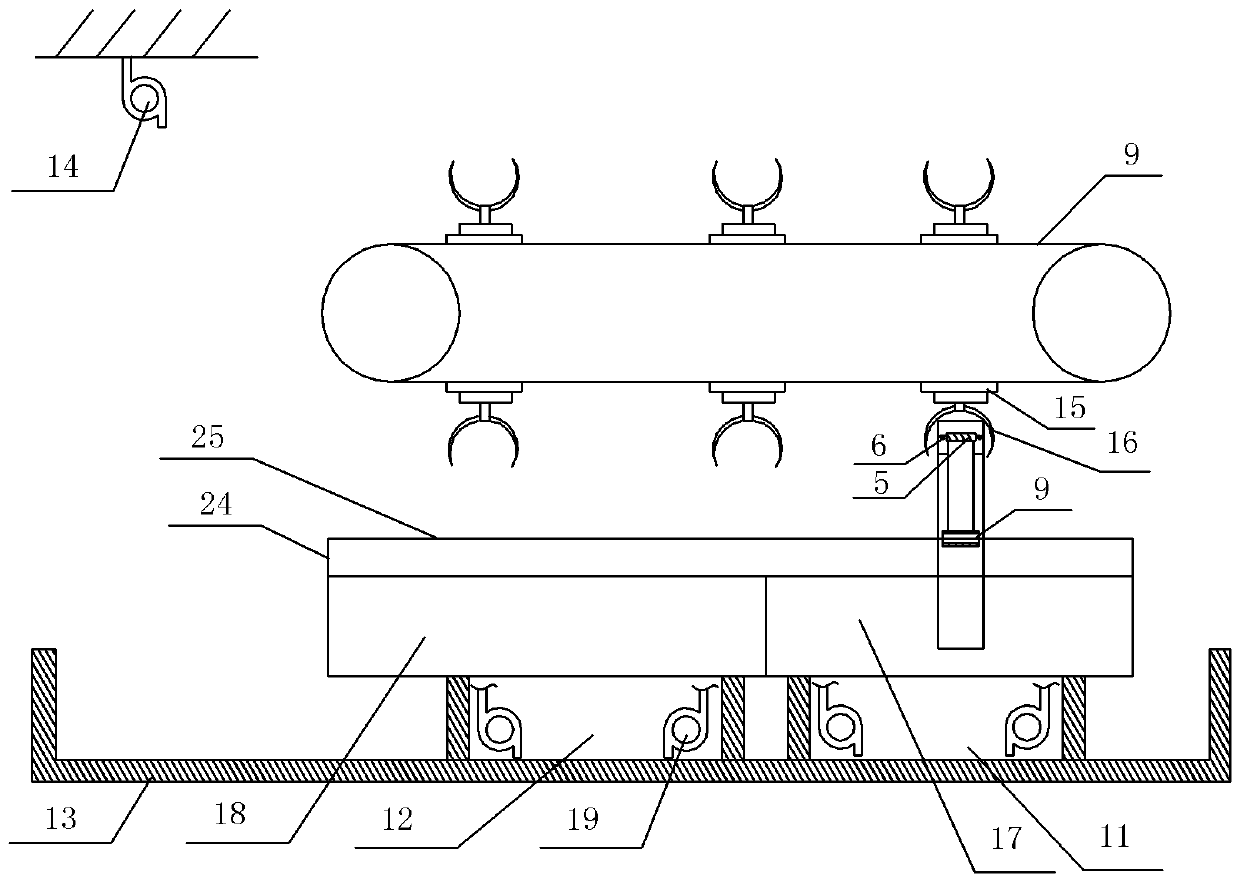

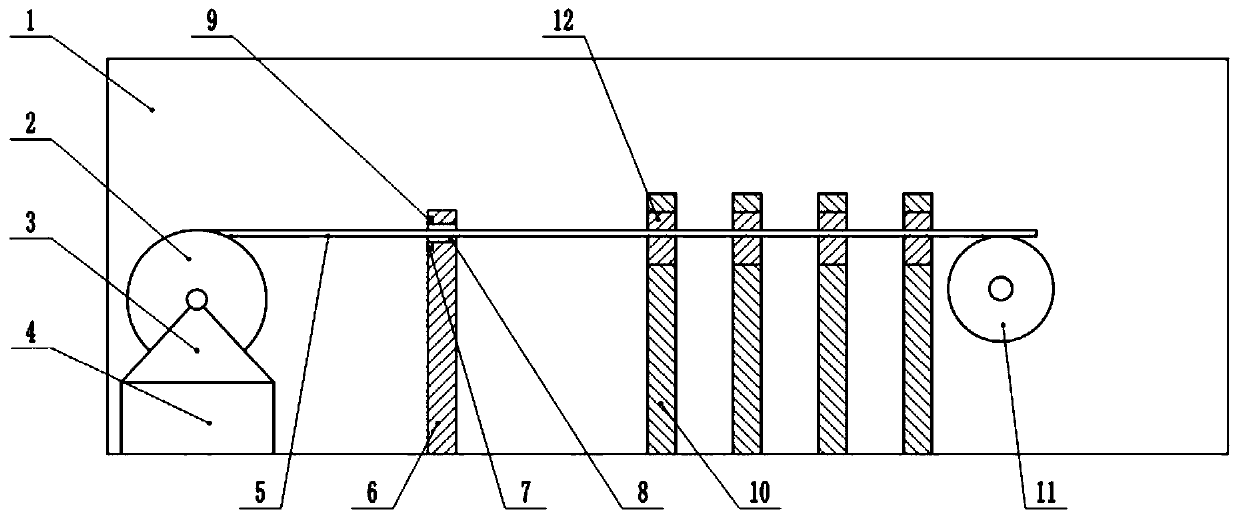

Wire coil bundling angle bead filling anti-scratch device and bundling method

ActiveCN112937984AWon't breakEffectively cut off direct contactBundling machine detailsWire rodPaperboard

The invention provides a wire coil bundling angle bead filling anti-scratch device. The wire coil bundling angle bead filling anti-scratch device comprises material storage boxes, a material taking mechanism, a rotary placing mechanism, an angle bead metal sheet fixing mechanism and a rotary seat. The rotary seat is fixedly mounted on the outer surface of a main vertical plate of a platen truck of a packing machine through a base; one end of the rotary placing mechanism is connected to a central rotating shaft of the rotary seat, and the other end is connected with a sliding block combination of the material taking mechanism; the material storage boxes are internally provided with angle bead metal sheets which are distributed in a layered manner and are fixedly mounted on two sides of the main vertical plate of the platen truck of the packing machine; and according to the angle bead metal sheet positioning mode of the bundling portion, multiple sets of magnetic elements are adopted and fixedly installed on a magnetic element base on a bundling wire guide plate of the packing machine. The angle bead filling anti-scratch device can replace the existing manual operation of filling paperboards or flannelette, the action sequence of the device is braided into a PLC of the packing machine to realize full-automatic operation, and meanwhile, a non-metal angle bead filler is changed into a thin steel sheet or an iron sheet, so that the direct contact between a bundling wire and a coil can be effectively prevented, steel sheet angle beads can directly participate in acid pickling during deep processing of a user and does not need to be taken away by cutting the bundling wire, and safety and operation efficiency of deep processing are improved.

Owner:无锡瑞进智能工程有限公司

Hot rolling wire rod production method for improving surface quality

InactiveCN110125177AImprove uneven deformationImprove uneven wearMetal rolling arrangementsWire rodEllipse

The invention relates to a hot rolling wire rod production method for improving the surface quality. The steps include billet preparation, heating processing, pass rolling, reducing and sizing, coil collecting and finishing. Rough rolling, intermediate rolling and pre-finish-rolling are included, the step pitch is increased during the heating processing, the box pass is adopted for billets firstly, exchange in the ellipse pass and the circle pass is then achieved, and the square billets are rolled into semi-finished products with circular fracture surfaces; the box pass, ellipse pass and circle pass combined pass is adopted for the rough rolling, the square billets are compressed under large pressure, the box pass is adopted for the first three passes of the rough rolling, box type hole base angles are increased, the ellipse pass and the circle pass are adopted for the fourth pass and the fifth pass of the rough rolling, and the circular shape is achieved after the rough rolling; and induction heating is added between the rough rolling and the intermediate rolling, and the problem that the head and tail temperature difference of red steel heads is large is solved. A spiral guide pipe is added to a lifting spiral pipe structure for the coil collecting, the circle shape of tail portions is regularized through the spiral guide pipe after the tail portions lose tension during the coil collecting, and therefore the circle shape of the tail portions is controlled and the problem that the tail portions are scratched is solved. The hot rolling wire rod production method meets the zero defect quality requirement.

Owner:WUXI XINGCHENG HUAXIN STEEL

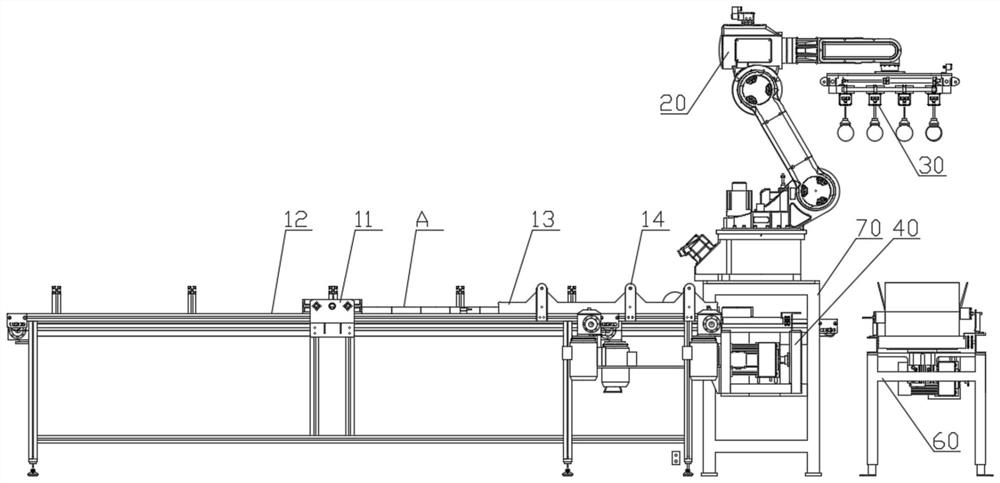

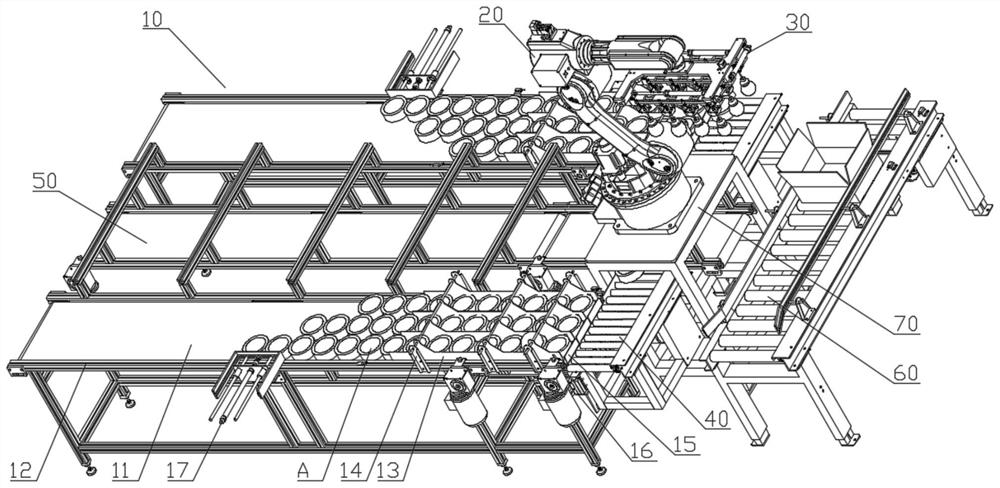

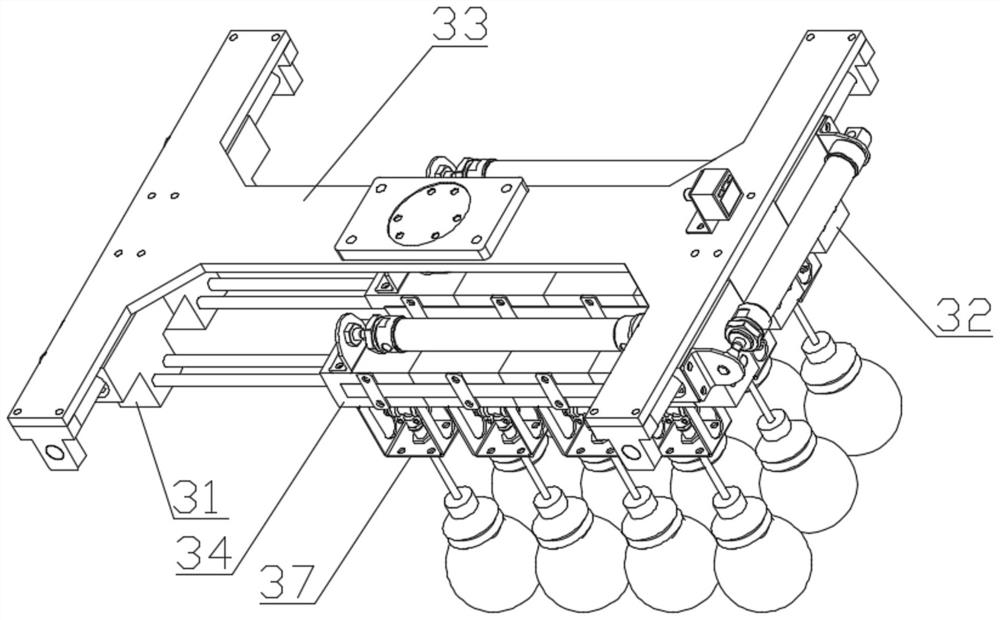

Carrying and boxing processing system for spherical products

PendingCN114476209AFix scratchesReduce manual operationsIndividual articlesStructural engineeringMachining system

The invention relates to a carrying and boxing processing system for spherical products. The carrying and boxing machining system for the spherical products comprises a feeding conveying device, a carrying robot and a claw device. The carrying robot is arranged on one side of the feeding conveying device, and the claw device is installed at the end of the carrying robot. The claw device comprises a supporting top frame, a first connecting mechanism, a second connecting mechanism, a first sliding tensioning mechanism and a grabbing assembly. The first connecting mechanism and the second connecting mechanism are installed at the two ends of the supporting top frame respectively. The two ends of the first sliding tensioning mechanism are installed on the first connecting mechanism and the second connecting mechanism correspondingly. The first sliding tensioning mechanism comprises a first guide rod, a first sliding block, a first tensioning cylinder, a first fixing block and an elastic bandage. The carrying and boxing machining system for the spherical products has the beneficial effects of being efficient and accurate in carrying.

Owner:GUANGZHOU CHANGREN IND TECH CO LTD

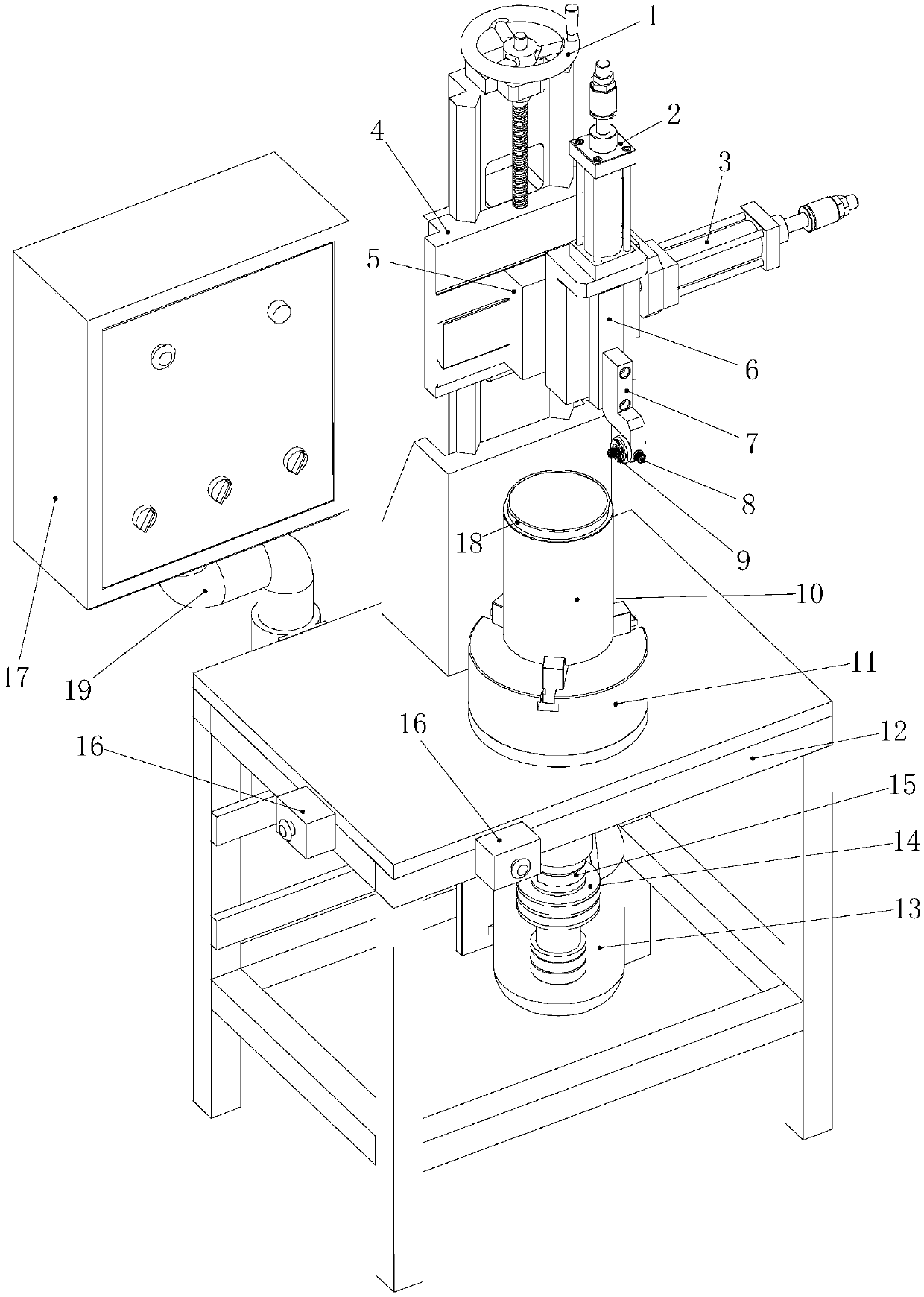

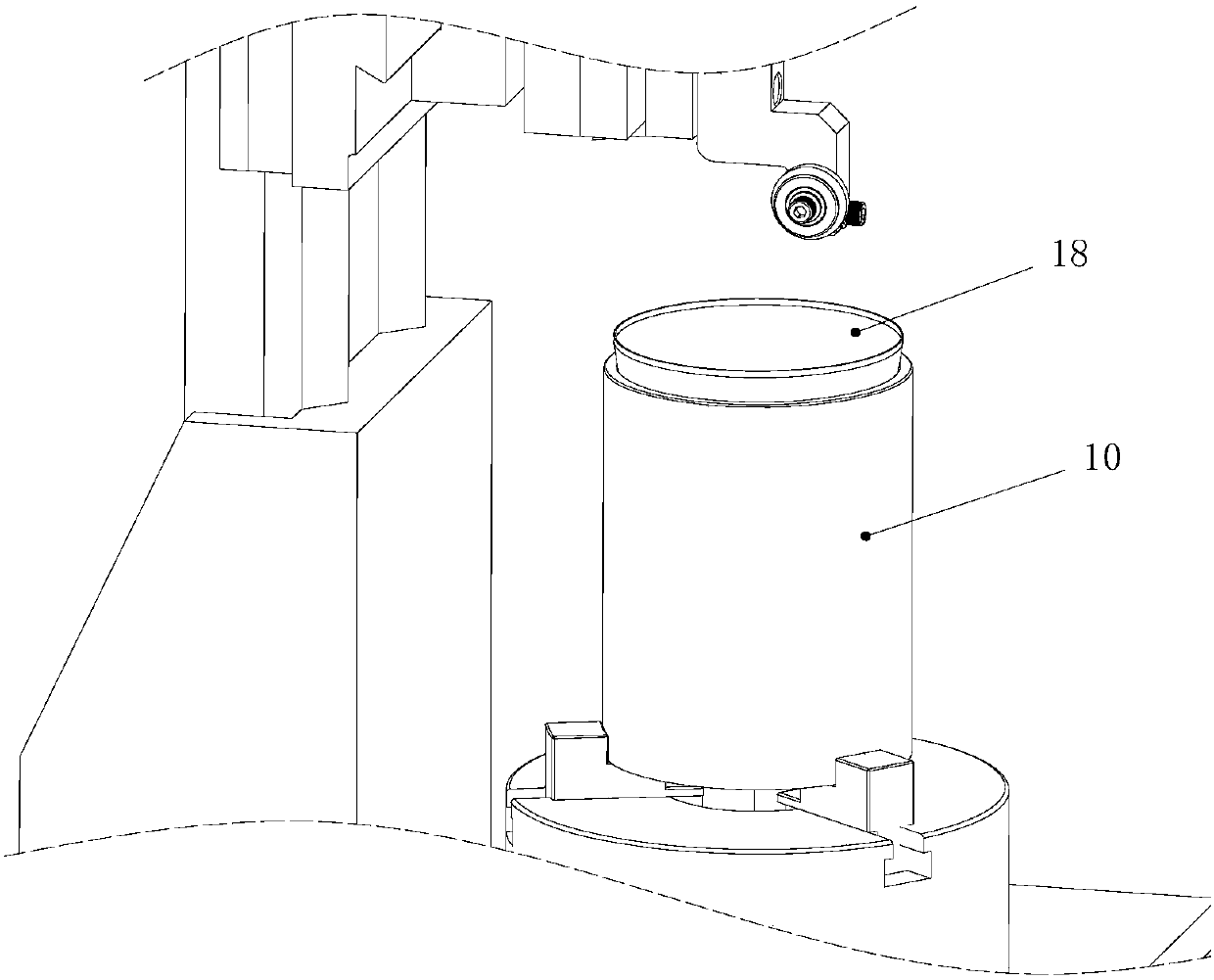

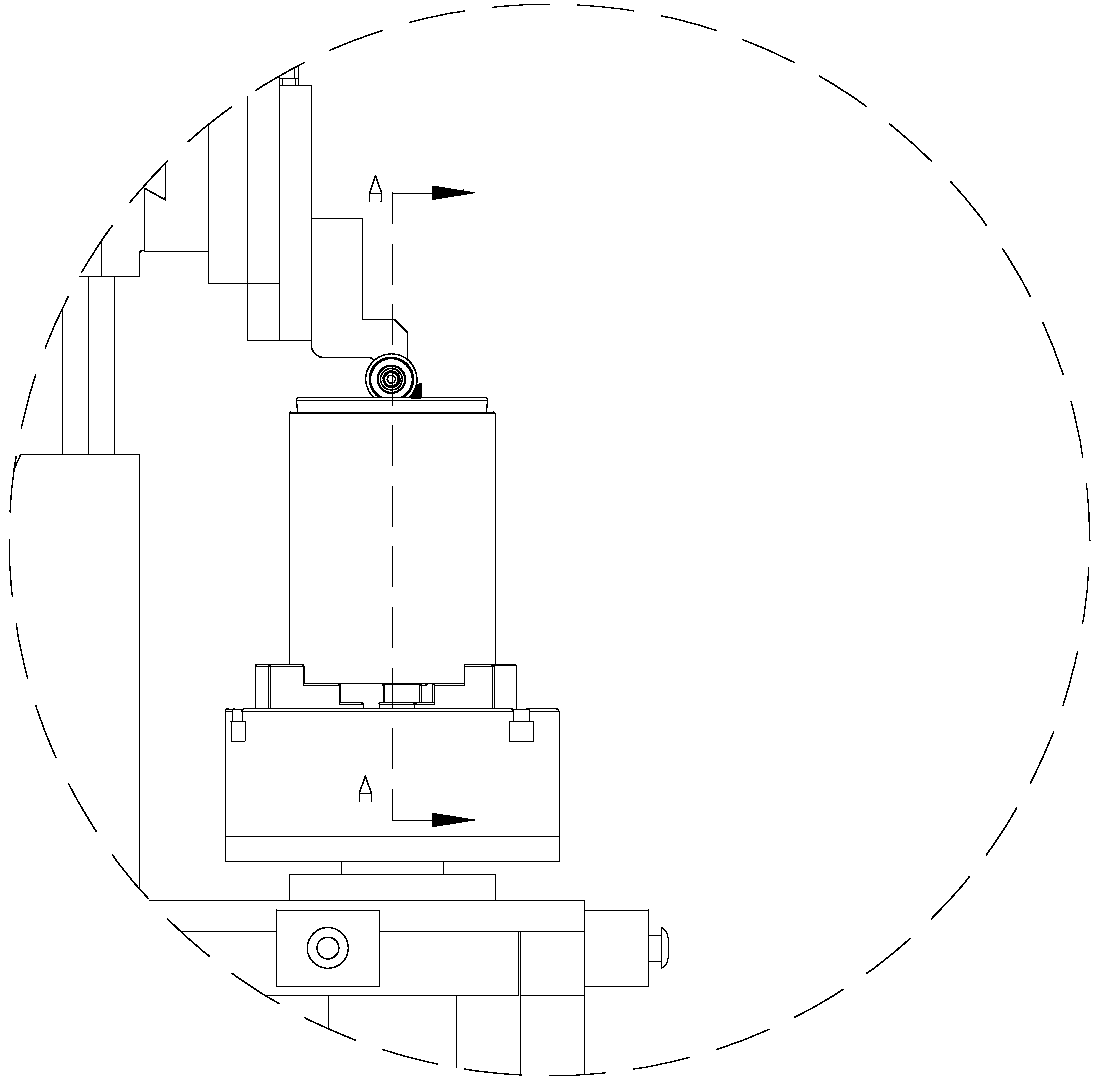

Heat preservation container metal shell barrel body surface machining and automatic edge curling equipment and machining process

The invention relates to heat preservation container metal shell barrel body surface machining and automatic edge curling equipment and a machining process. The heat preservation container metal shellbarrel body surface machining and automatic edge curling equipment and the machining process are characterized in that a working table is provided with an edge curling female die and a three-claw chuck, an edge curling wheel is fixedly connected to the working table through an edge curling fixing arm and an edge curling wheel sliding block, an adjusting mechanism is arranged on the edge curling wheel sliding block, the up-and-down distance of the edge curling wheel is adjusted through an adjusting hand wheel of the adjusting mechanism and the edge curling wheel sliding block, and the distancebetween the edge curling wheel and a metal shell barrel body is automatically controlled and adjusted depending on SCJ air cylinders A and B. The process comprises the steps that the adjusting hand wheel enables the up-and-down distance of the edge curling wheel to meet the machining condition and requirement; a variable frequency motor is started to enable the metal shell barrel body to rotate at a constant speed along with the edge curling female die; and the SCJ air cylinders A and B are started to enable the metal shell barrel body to do yield deformation until edge curling is completed.The heat preservation container metal shell barrel body surface machining and automatic edge curling equipment and the machining process have the beneficial effects that a male die is not needed, themetal shell barrel body outer surface cannot be abraded and scratched, and deformation, pressing damage and scratching of metal shell barrel body surface quality are avoided. The cost is low, maintenance is convenient, and the product quality and production quality are greatly improved.

Owner:SHANGHAI WANSHENG VACUUM FLASK & VESSEL

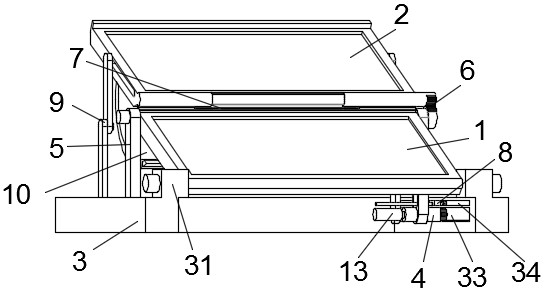

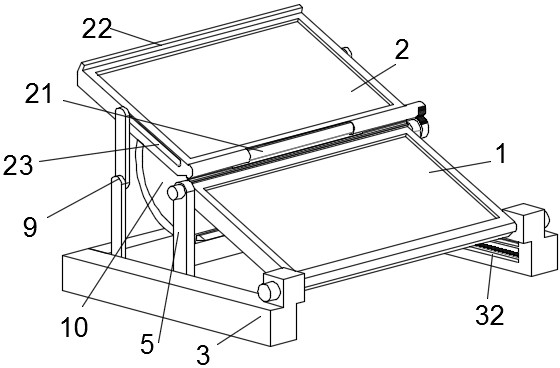

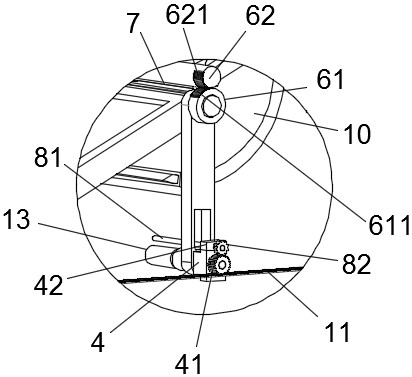

Solar photovoltaic panel assembly

PendingCN114866003AAvoid shockPrevent penetrationPhotovoltaic supportsSolar heating energyMechanical engineeringSevere weather

The invention discloses a solar photovoltaic panel assembly, which belongs to the technical field of photovoltaic equipment and comprises longitudinal bottom plates arranged in parallel, horizontal T-shaped grooves are formed in opposite side surfaces of the longitudinal bottom plates, a first photovoltaic panel is rotationally connected with a connecting support lug and an adjusting plate, the connecting support lug is arranged at one end of each longitudinal bottom plate, and the adjusting plate is arranged on a guide sliding block. The guide sliding blocks are connected with the horizontal T-shaped grooves in a sliding and clamping mode, one guide sliding block is provided with a driving mechanism, the adjusting plate arranged on the same side of the driving mechanism is connected with a linkage piece, a connecting hinge is arranged between the second photovoltaic plate and the first photovoltaic plate, and the second photovoltaic plate is further connected with a supporting and folding plate. And the linkage piece rotates along with the rotation of the adjusting plate and drives the second photovoltaic panel piece to rotate. According to the invention, a split type structure is adopted, the solar photovoltaic panel assembly can be self-protected in rainy and snowy severe weather, and damage is reduced; and meanwhile, the requirements of customers on the use angle of the solar photovoltaic module are met.

Owner:徐州日托光伏科技有限公司

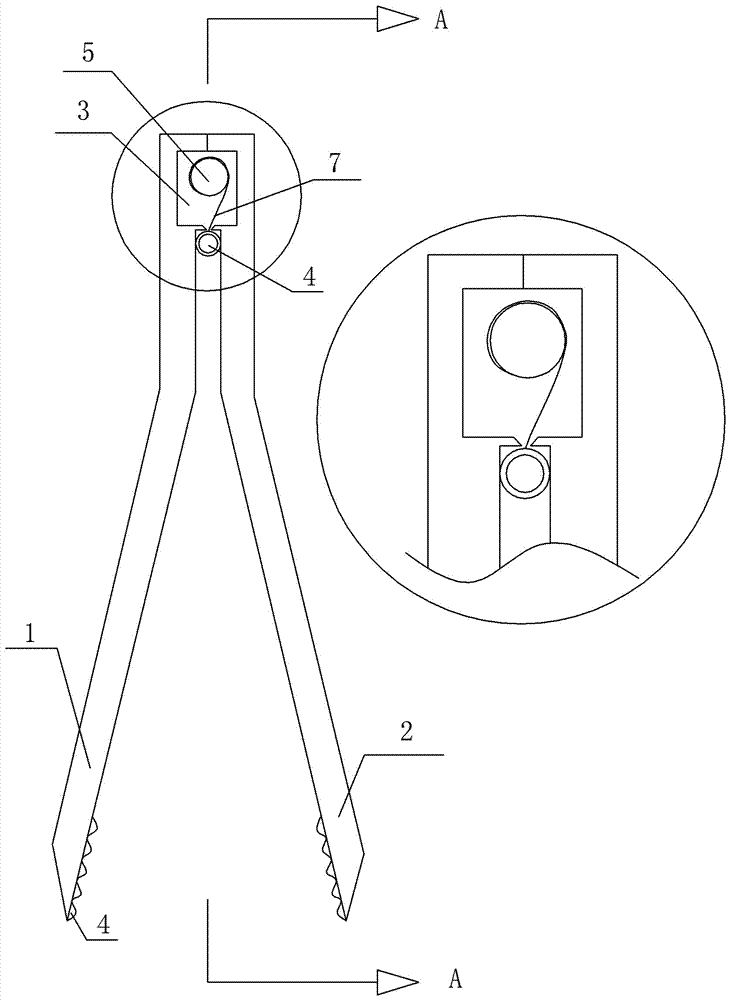

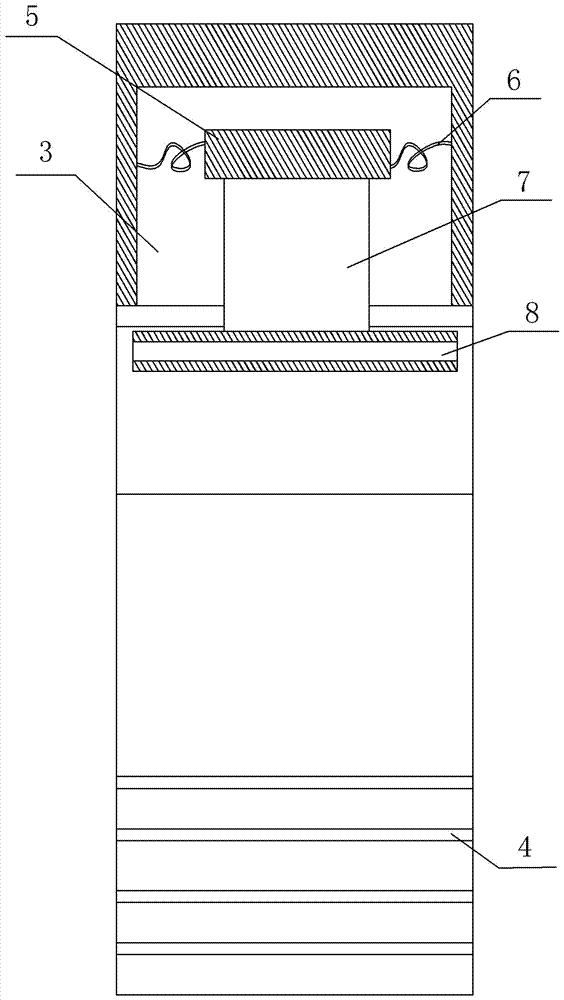

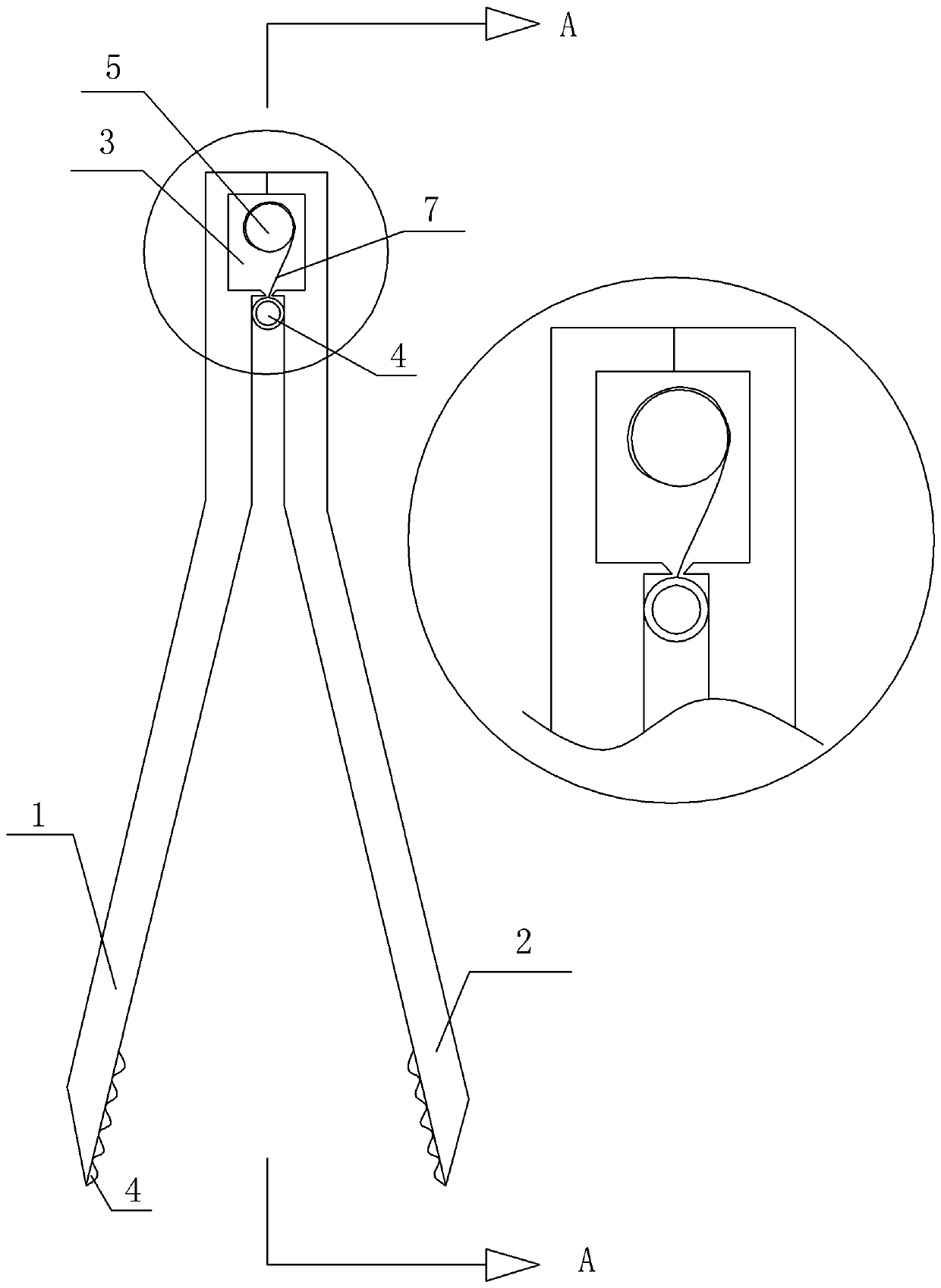

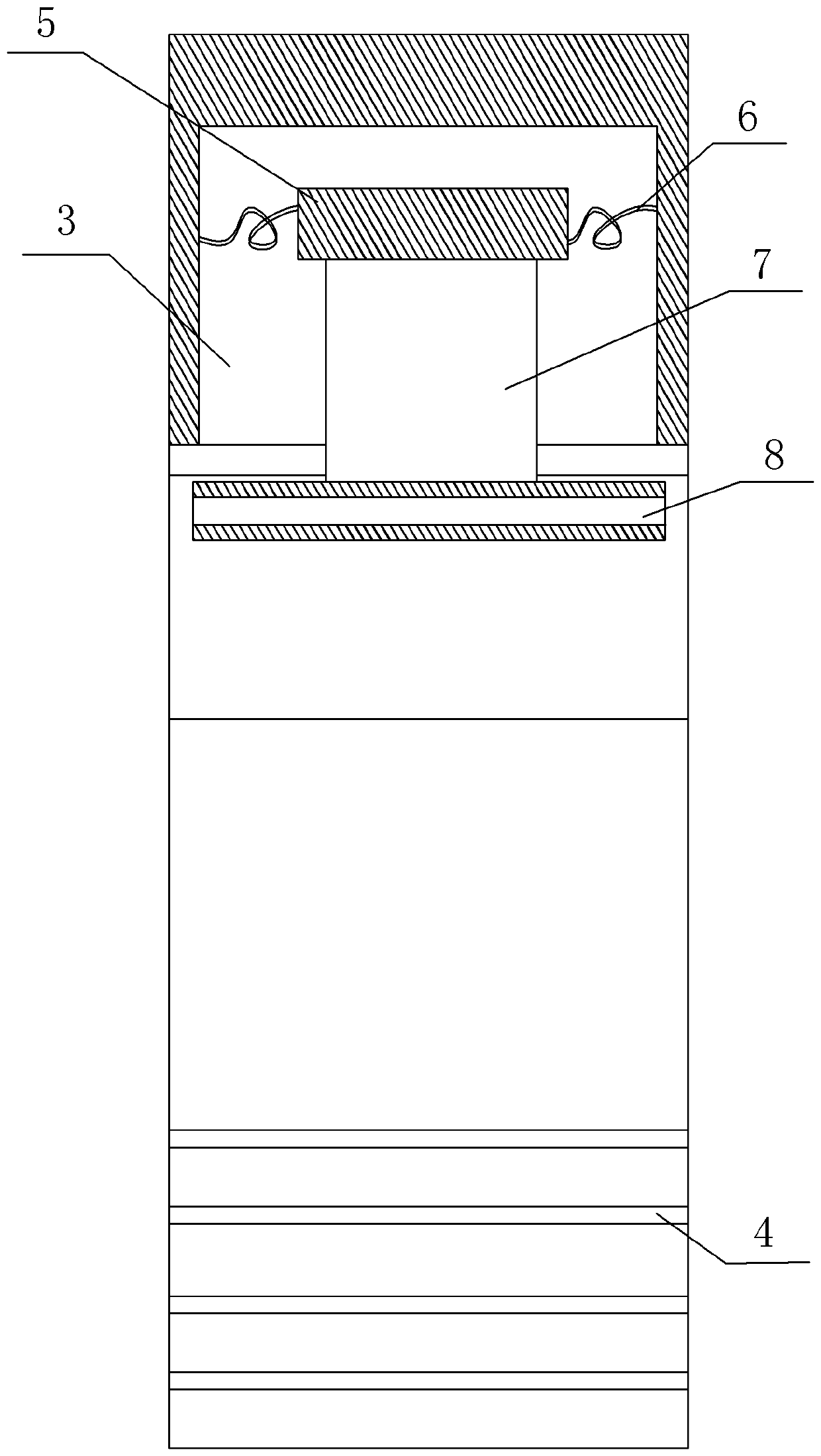

Tweezers and disinfecting device thereof

ActiveCN107414692AIncrease intensitySolve the problem that the spacing is small and cannot be cleanedMetal-working hand toolsChemicalsMedical equipmentEngineering

The invention relates to the field of medical equipment and cleaning, and particularly relates to a pair of tweezers and a disinfecting device thereof. The pair of tweezers comprises a first clamping arm and a second clamping arm, wherein a first cavity is formed in one end of the first clamping arm, a second cavity is formed in one end of the second clamping arm, one end of the first clamping arm is fixedly connected with one end of the second clamping arm, and the first cavity communicates with the second cavity; rotating rods and torsion springs are arranged in the first cavity and the second cavity, cleaning cloth is arranged on the circumferential walls of the rotating rods, and one end of the cleaning cloth is fixedly connected with the circumferential walls of the rotating rods; and a circular post is located between the first clamping arm and the second clamping arm, and the other end of the cleaning cloth is fixedly connected with the circumferential wall of the circular post. By adopting the technical scheme, the problem of incapability of cleaning due to small spacing between the first clamping arm and the second clamping arm is effectively solved, and additionally, the force of the pair of tweezers can be increased by the circular post, so that the pair of tweezers is easy to control when in use, and the use comfort is increased.

Owner:宁波隆锐机械制造有限公司

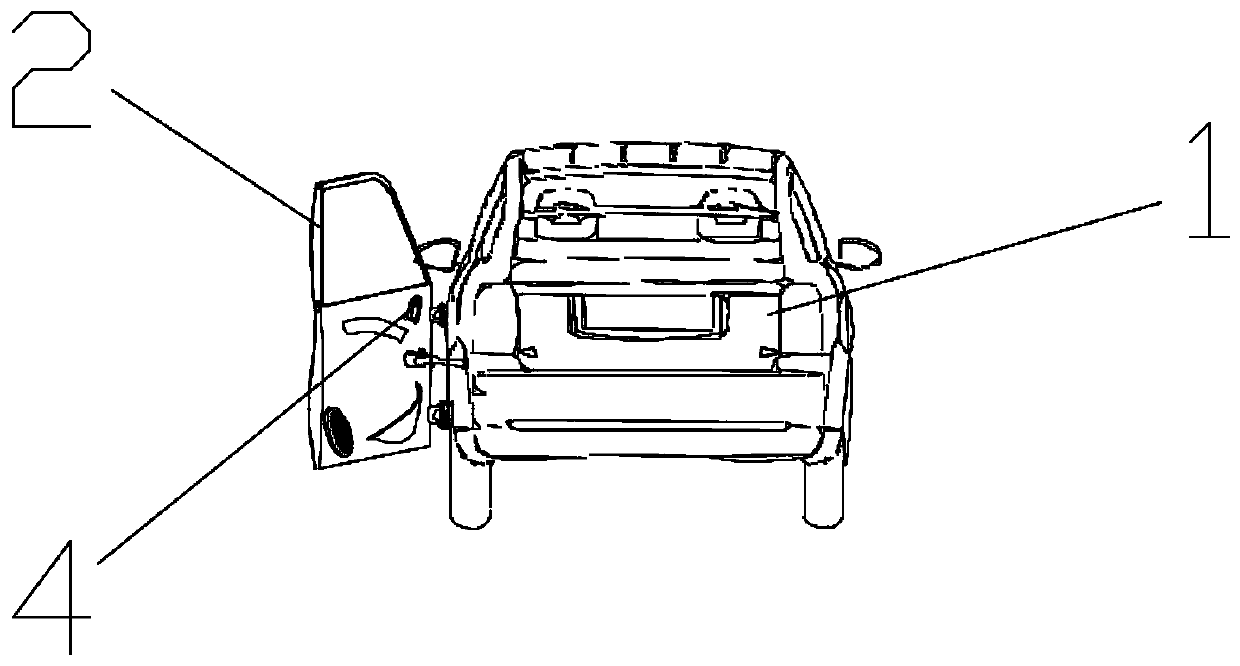

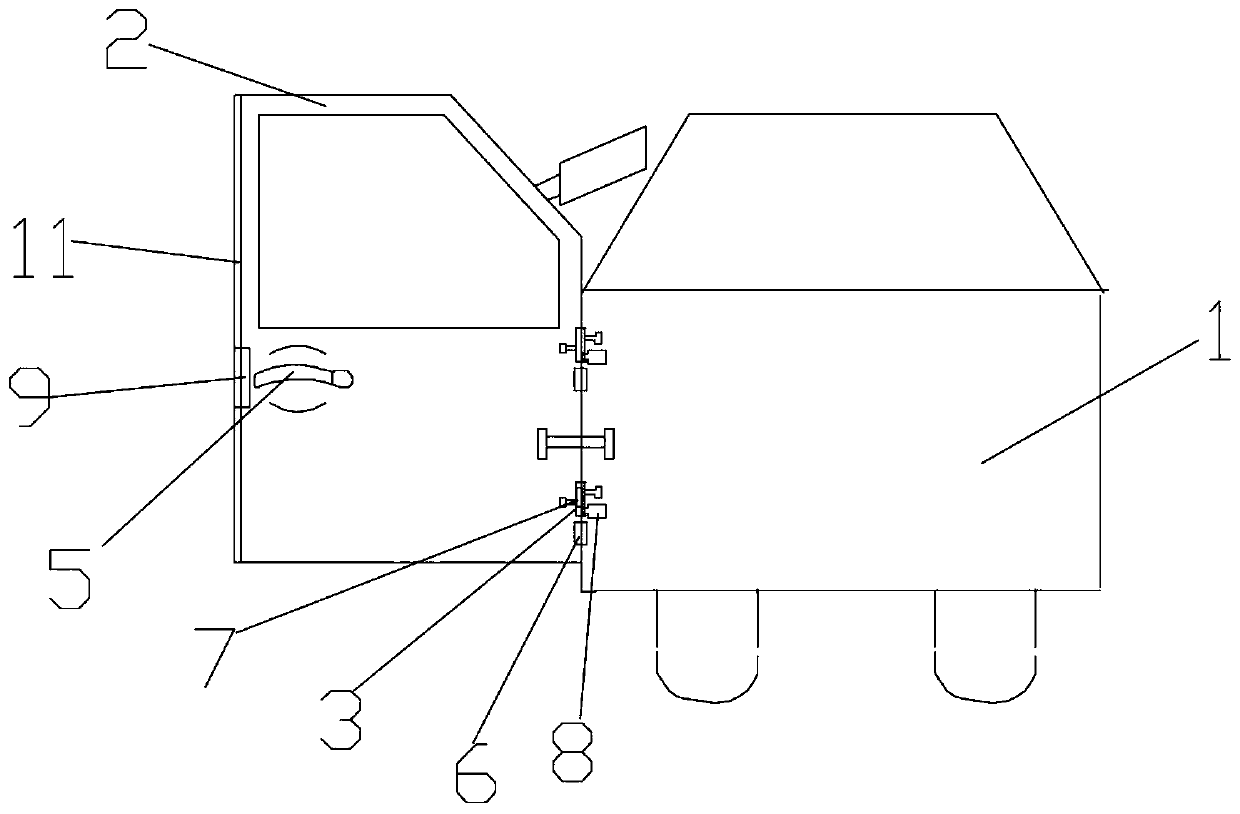

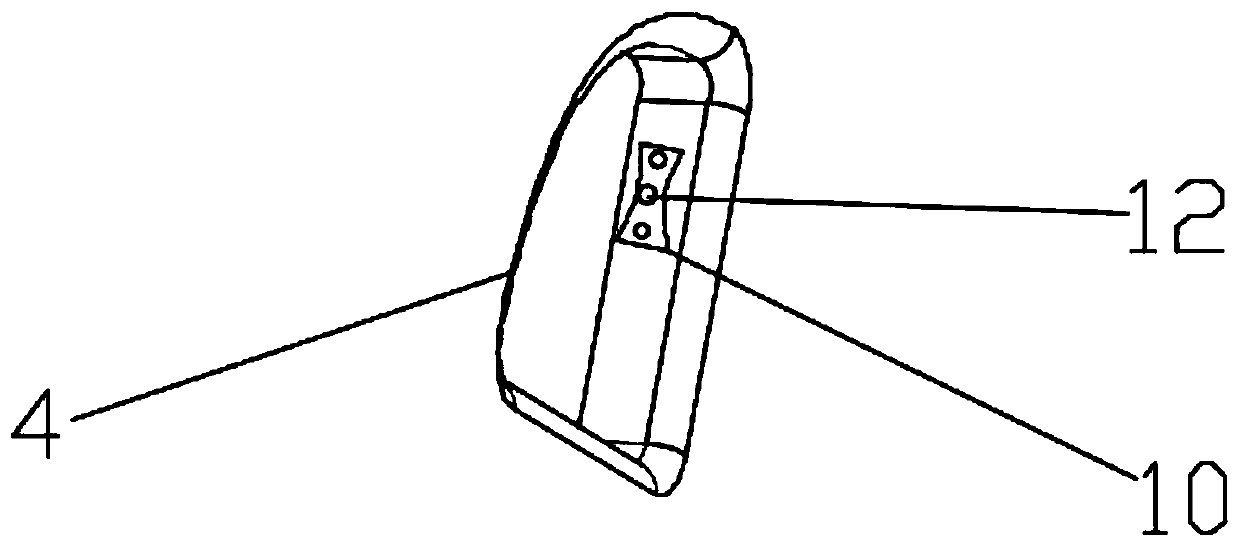

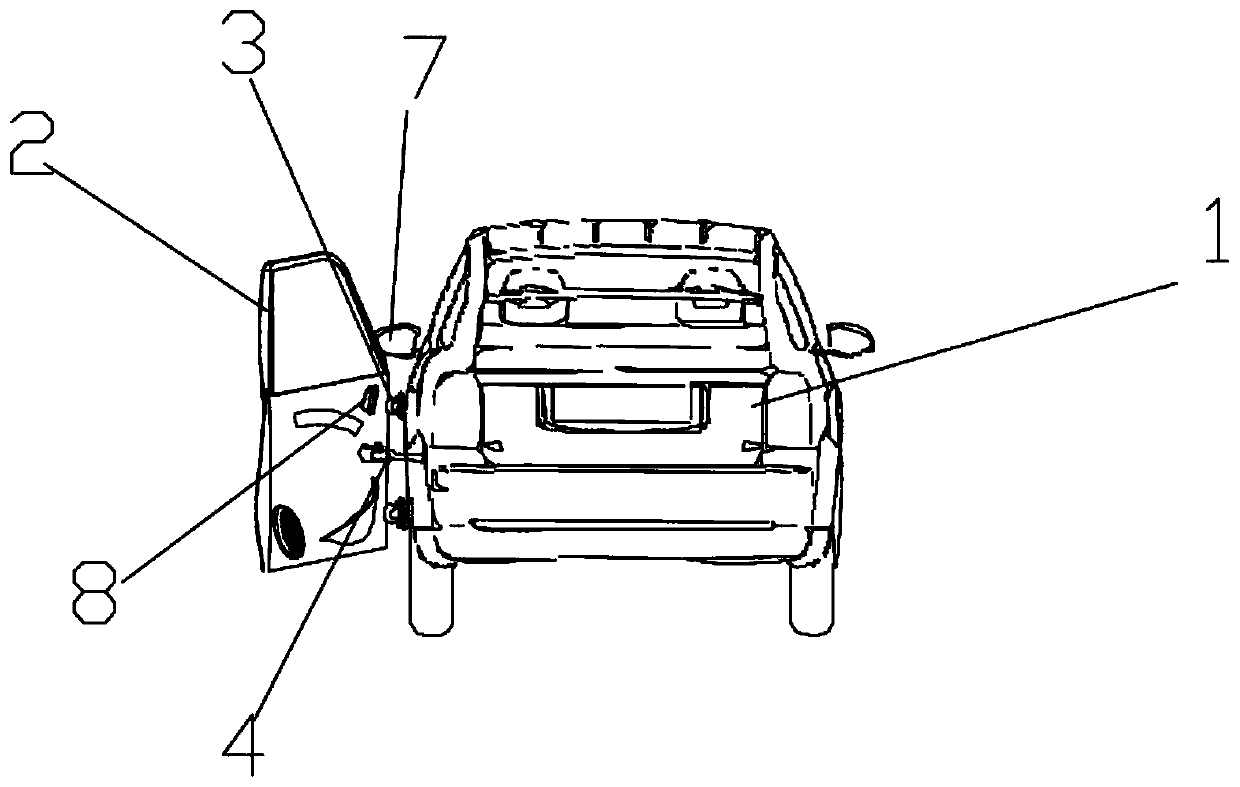

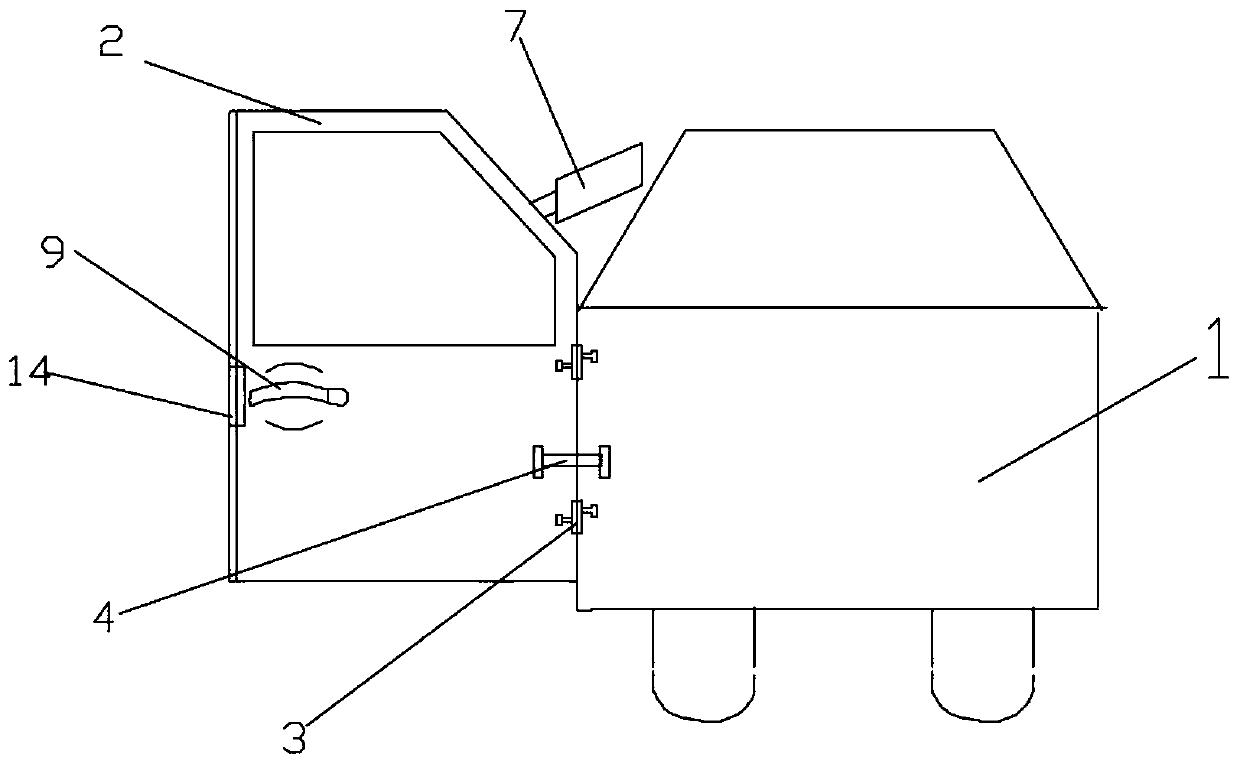

Automobile door preventing collision in case of opening automobile door

InactiveCN110303857ASolve the impactFix scratchesSignalling/lighting devicesDoorsRear-view mirrorCar door

The invention relates to an automobile door opening preventing collision in the case of opening the automobile door. According to the automobile door, an automobile body and an automobile door body are involved, wherein the automobile door body is installed on the automobile body through a hinge, a rearview mirror and an automobile door handle are arranged on the automobile door body, the automobile door handle is divided into an inner handle and an outer handle, a rotating shaft of the hinge is provided with a stepping motor and a sensing device for starting the rotating shaft to rotate, an electromagnetic locking device is arranged on the inner side of the hinge, a distance measuring sensor is arranged at the position, close to the edge of the automobile door body, of the outer handle end, a switch controller is arranged on the inner handle, the distance measuring sensor is connected with an input end of the switch controller, and an output end of the switch controller is connected with the stepping motor and the electromagnetic locking device. The automobile door opening preventing collision in the case of opening the automobile door can effectively solve the problem that the automobile doors of adjacently parked automobiles are collided against each other and scratched due to the fact that after parking, the automobile doors are opened too quickly or the span of automobiledoor opening is too large.

Owner:宁波金特信钢铁科技有限公司

Method for disinfection of tweezers

ActiveCN107583070ARealize moving up and downPrevent rustCleaning using toolsCleaning using liquidsMedical equipmentBiochemical engineering

The invention specifically relates to a method for disinfection of tweezers, belonging to the field of medical equipment and cleaning thereof. The method comprises the following steps: step 1, preparing disinfection equipment; step 2, fixing tweezers; step 3, fixing a ring column; step 4, cleaning and disinfecting the tweezers; step 5, relieving the spacing of the ring column; step 6, drying the tweezers; and step 7, taking off the tweezers. With the method in the invention, tweezers can be thoroughly cleaned and disinfected.

Owner:宁波隆锐机械制造有限公司

Cable production device

The invention relates to the field of cable processing, in particular to a cable production device. The cable production device comprises a cable wire winding mechanism, a positioning and calibrationmechanism and a wire drawing mechanism, wherein the cable wire winding mechanism sequentially comprises a cable wire winding wheel, a base and a telescopic air cylinder; the cable wire winding wheel is rotationally connected with the base, the positioning and calibrating mechanism comprises a calibration plate, a cable wire through hole is formed in the calibration plate, the cable wire drawing mechanism comprises a cable wire drawing plate, a cable wire drawing die hole is formed in the cable wire drawing plate, and the cable wire drawing die hole and the center line of the cable wire throughhole are located on the same horizontal line; the cable production device further comprises a control circuit used for controlling a telescopic rod to ascend and descend, the control circuit is a disconnected circuit, breakpoints are respectively arranged at the bottom of a port of one end of an inlet wire of the cable wire through hole and the top of a port of one end of the inlet wire of the wire through hole. In this way, the problem that a wire core is scratched due to the fact that the metal wire core cannot be automatically calibrated in the cable wire drawing process is solved, and thecable production device is mainly used for cable production factories.

Owner:CHONGQING RUIPU CABLE

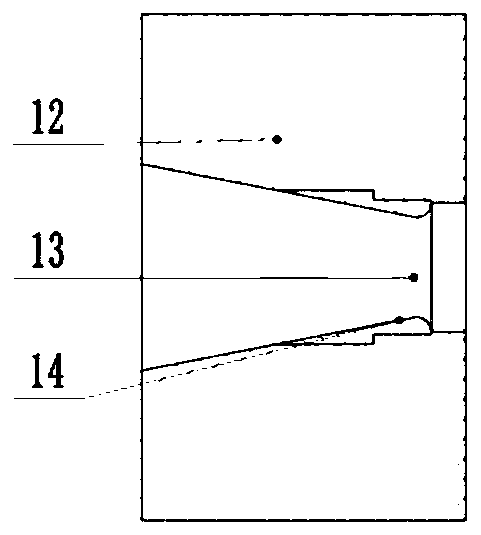

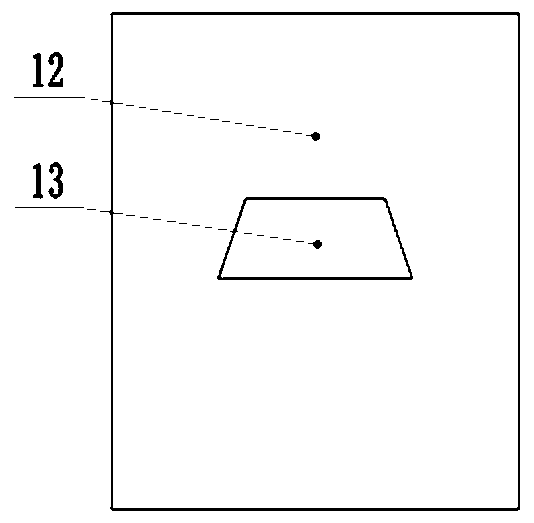

Automobile door capable of preventing collision during door opening

InactiveCN110316057ASolve the impactFix scratchesWing fastenersSignalling/lighting devicesCar doorDoor handle

The invention relates to an automobile door capable of preventing collision during door opening. The automobile door involves an automobile body and the automobile door, wherein the automobile door isinstalled on the automobile body through hinges, a limiter is further arranged between the automobile body and the automobile door, the limiter is composed of a limiting rod and a base, a rearview mirror and automobile door handles are arranged on the automobile door, the automobile door handles comprise the inner handle and the outer handle, a motor and an induction device are fixedly arranged on the base of the limiter, a telescopic clamping shaft is arranged on the motor, a distance measuring sensor is arranged close to the edge of the automobile door and at the end where the outer handleis located, a switch controller is arranged on the inner handle, the distance measuring sensor is connected with an input end of the switch controller, and an output end of the switch controller is connected with the motor and the induction device. According to the automobile door capable of preventing collision during door opening, the problem that the automobile door is collided and scratched with an automobile door of an adjacently-parked automobile when the automobile door is opened too fast or the automobile door is too large in opening span after the automobile is parked can be effectively solved.

Owner:宁波金特信钢铁科技有限公司

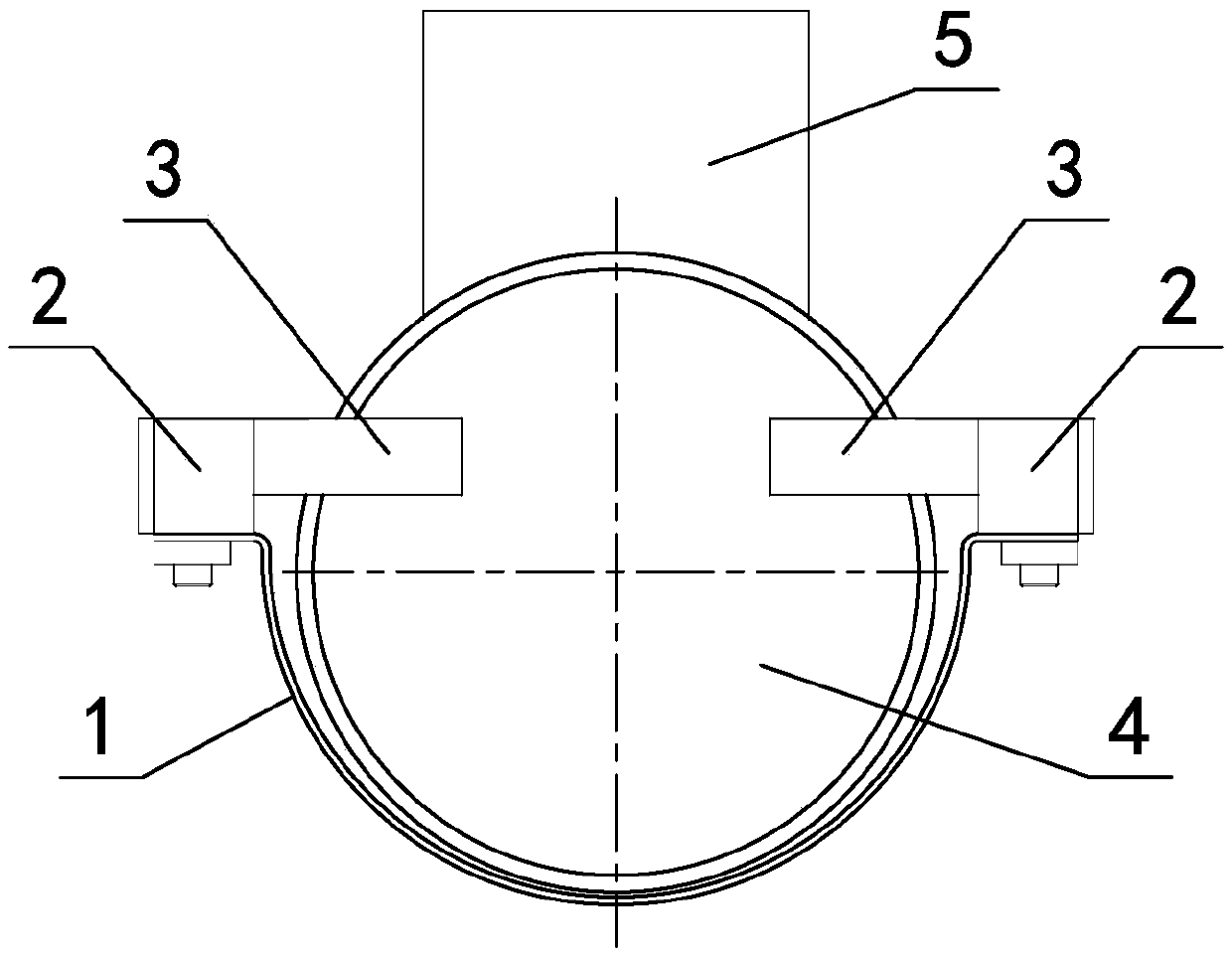

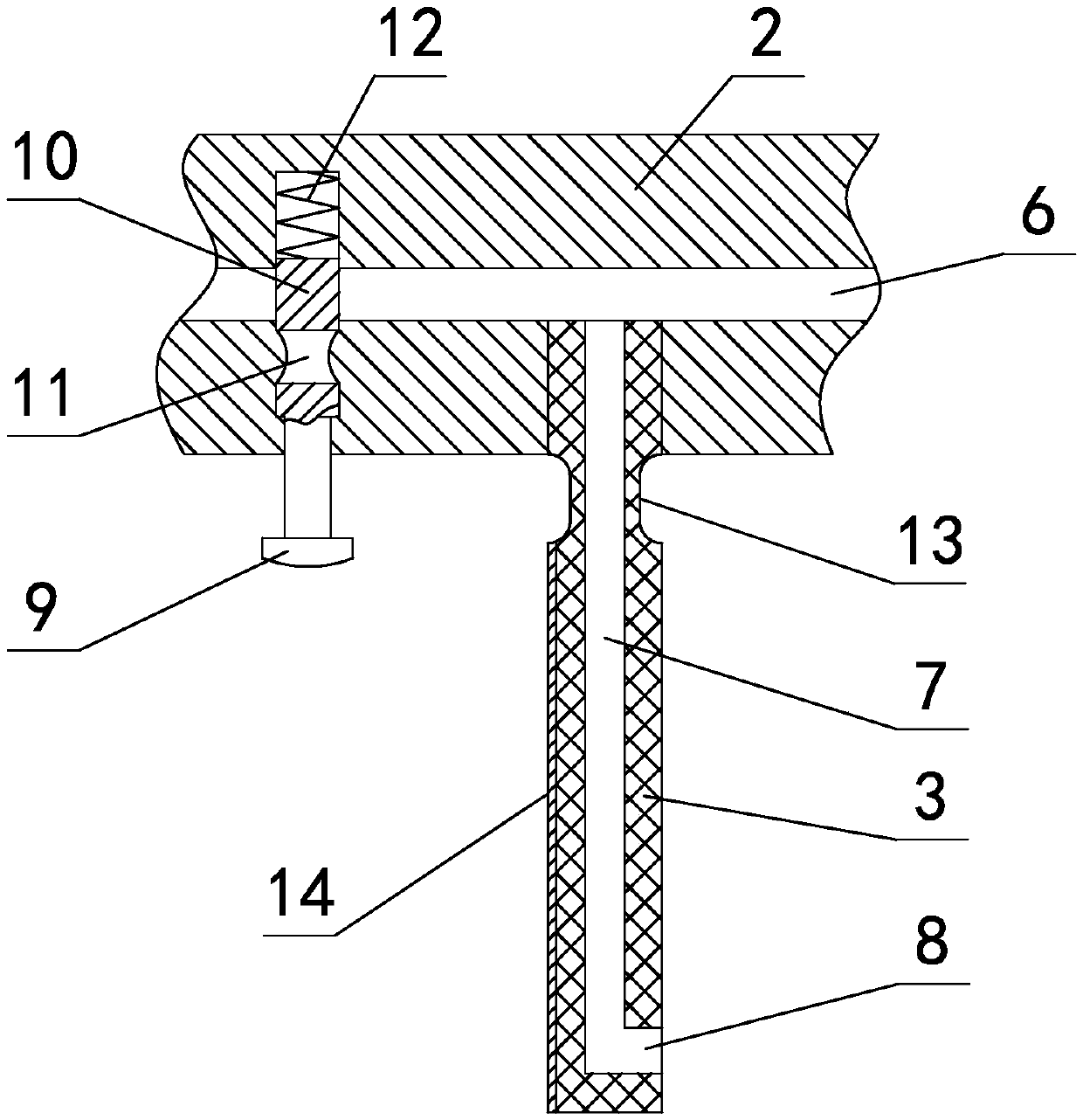

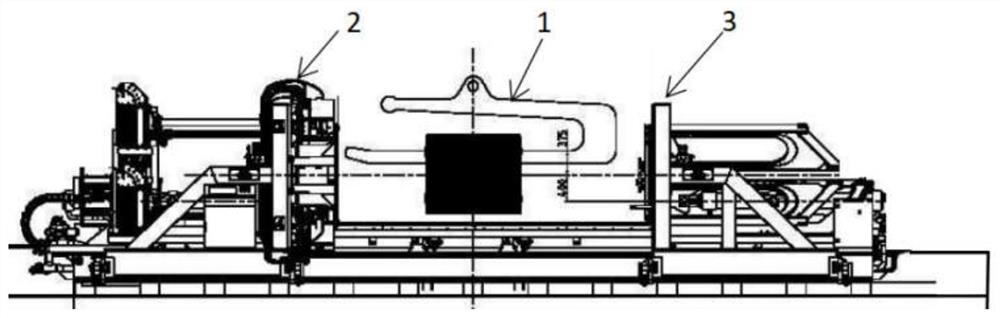

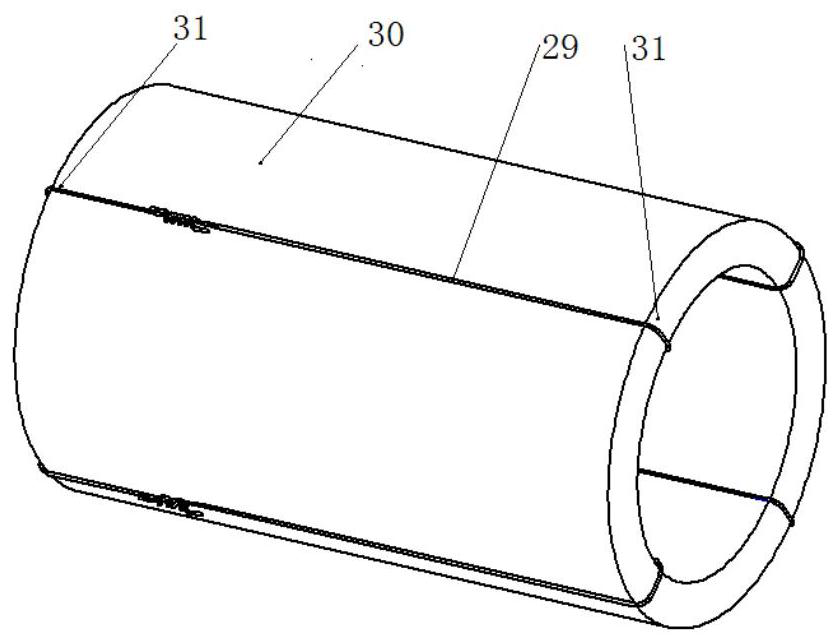

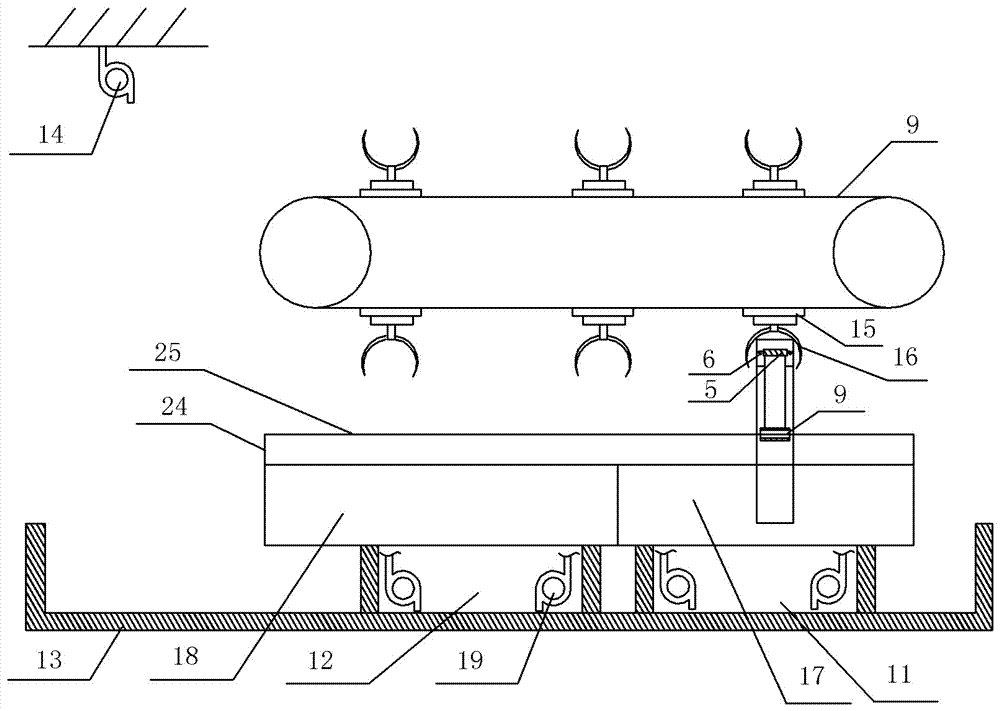

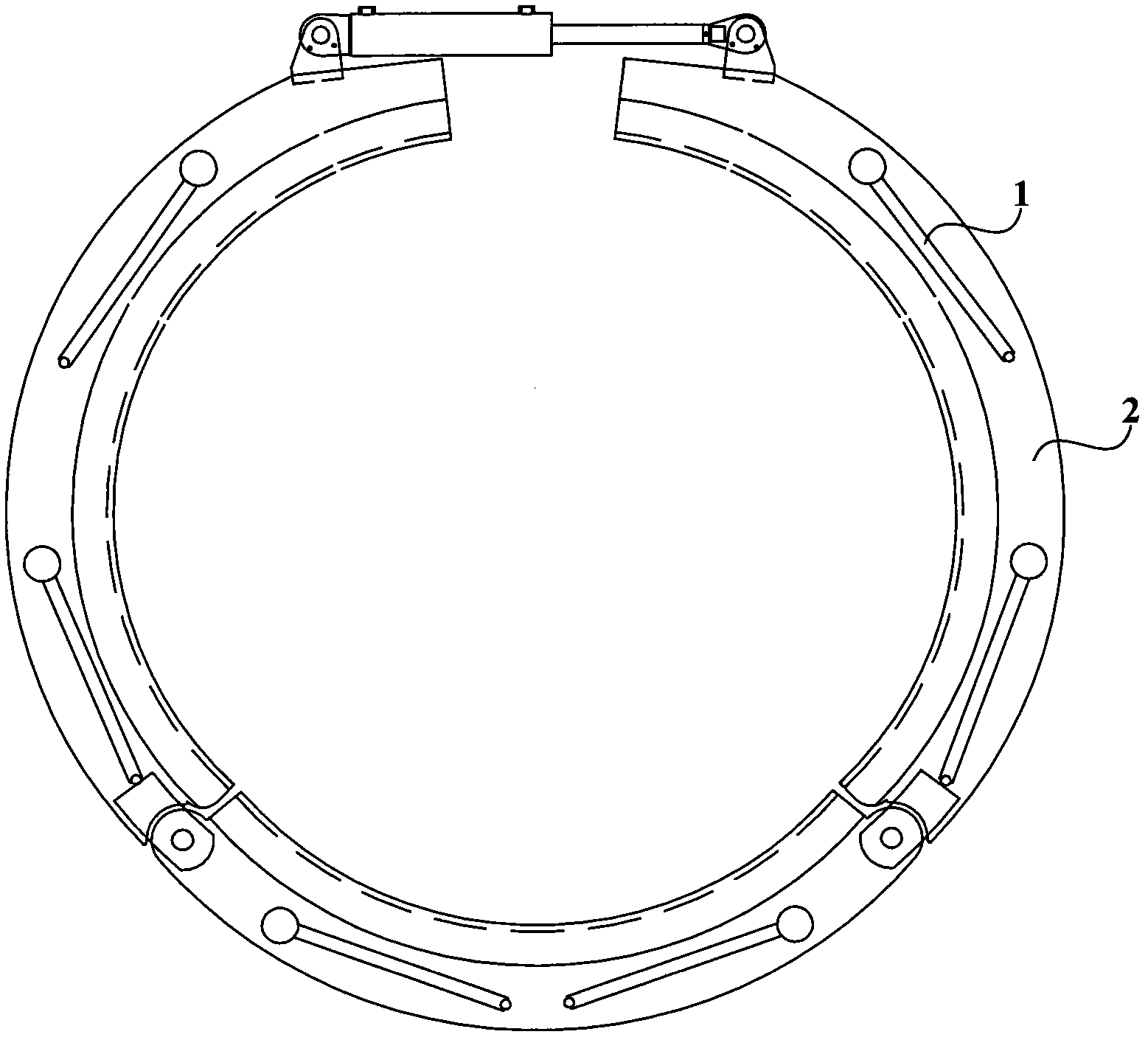

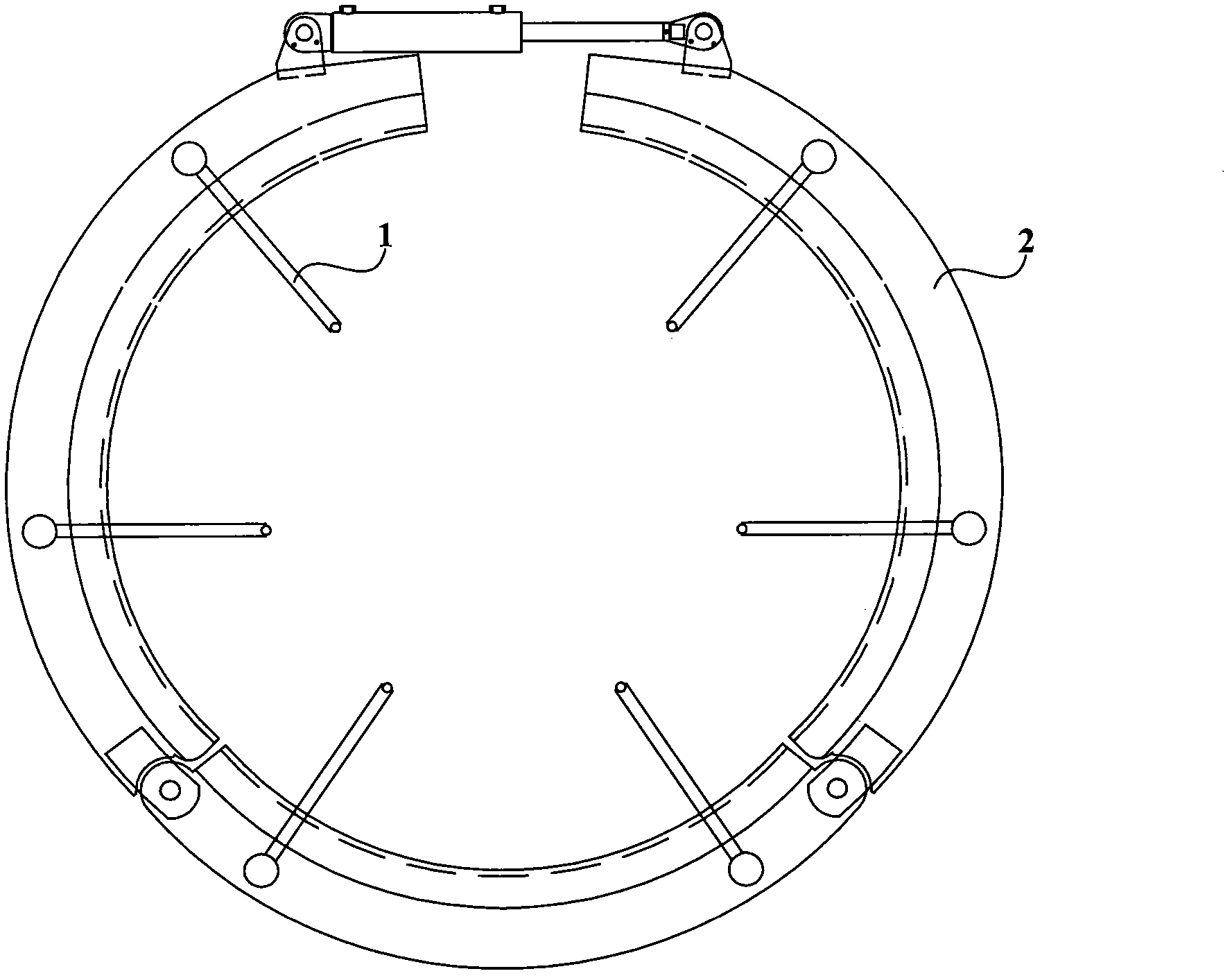

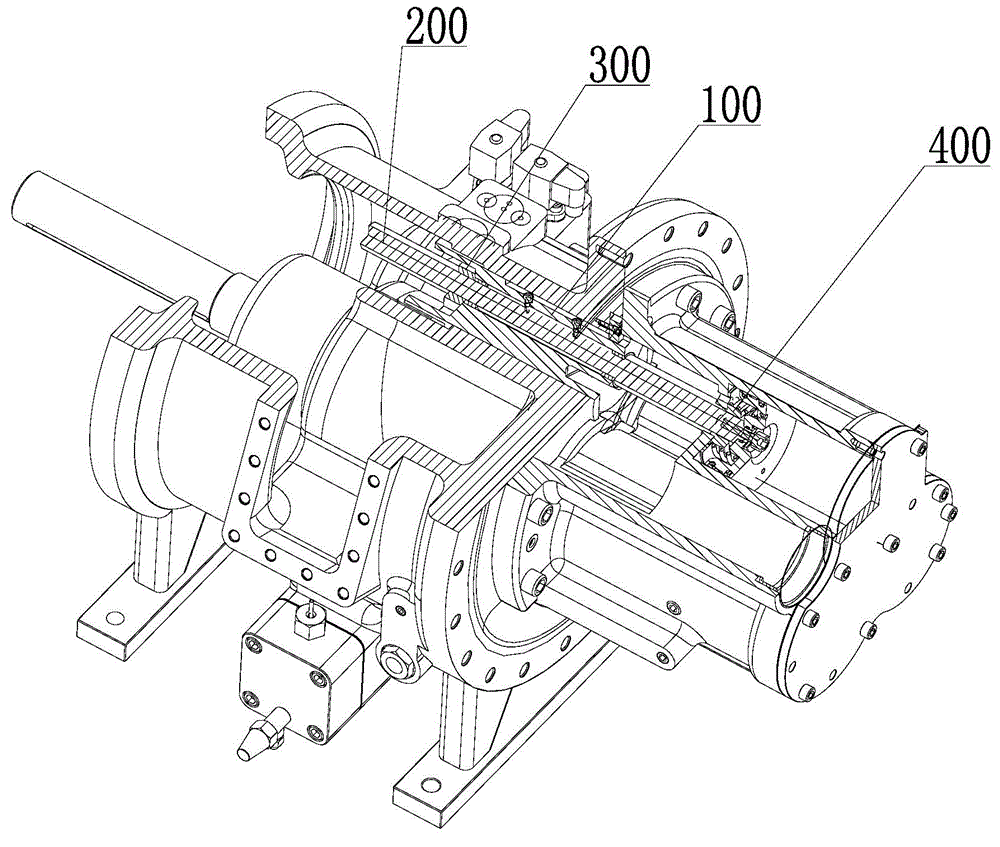

Tank car end socket pressing device, tank car end socket assembling equipment and assembling method thereof

InactiveCN102463430ASolve automatic controlFix scratchesWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlElectrical control

The invention discloses a tank car end socket pressing device, a tank car end socket assembling equipment and an assembling method thereof. The pressing device comprises a power device, a clamping and fixing plate, a header, a connecting rod, a rotating arm and a contact, wherein the tank car end socket pressing device can automatically open and close under the control of an electrical control cabinet by the power device, the clamping and fixing plate, the header, the connecting rod and the rotating arm to press the header to be assembled; therefore, the problem of big operation difficulty because an arc-shaped arm in the prior art needs to be manually rotated can be solved; the tank car end socket can be automatically controlled to be pressed; and the operation convenience for pressing the tank car end socket is improved. In addition, the rotating arm needs to be opened and closed under the driving of the power device, the potential safety hazard caused by uncontrollable arc-shaped arms in the prior art is avoided, and the operation safety is improved.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Method for uniformly mixing lithium titanate slurry containing carbon nanotubes

ActiveCN110165157ASolve dry powderFix scratchesMaterial nanotechnologyCell electrodesHigh rateCarbon nanotube

The invention discloses a method for uniformly mixing lithium titanate slurry containing carbon nanotubes, and belongs to the technical field of preparation of high-rate lithium ion battery mixed slurry. According to the invention, the main points of the technical scheme is that the method comprises the following steps: preparing a glue solution by taking a binder and a solvent as raw materials, adding the carbon nanotubes to prepare a conductive glue solution, and mixing a mixed dry material formed by the conductive agent and a main material with the conductive glue solution according to a specific process to obtain the lithium titanate slurry containing the carbon nanotubes. The preparation method effectively solves the problems that slurry cannot be uniformly mixed due to the application of high-specific-surface-area lithium titanate and carbon nanotubes, so that more dry powder and scratches appear in the coating process, the pole piece peeling phenomenon occurs in the baking process, the battery performance is influenced and the like.

Owner:河南电池研究院有限公司 +1

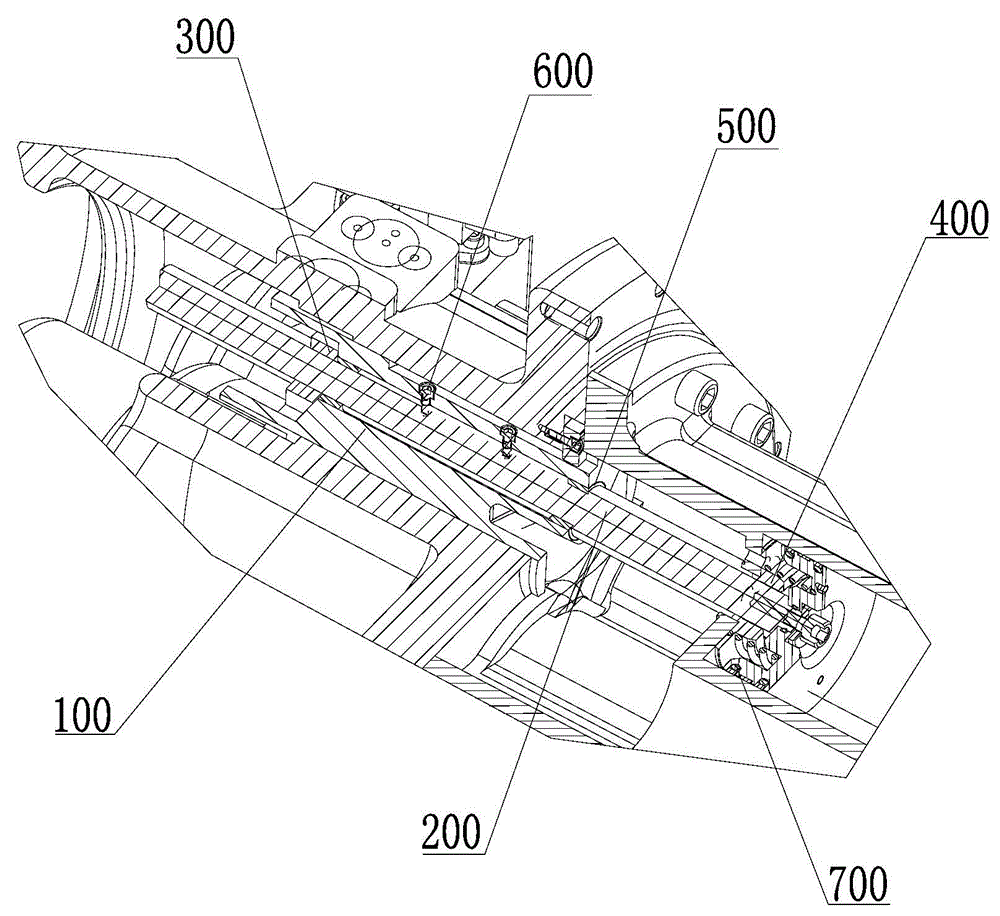

Compressor slide valve assembly and refrigeration screw compressor

InactiveCN104314811ASolve support problemsFix scratchesRotary piston pumpsRotary piston liquid enginesRefrigerationFriction force

The invention discloses a compressor slide valve assembly and a refrigeration screw compressor. The compressor slide valve assembly includes a slide valve, a slide valve rod, a support plate and a connecting rod; the support plate is arranged on the compressor body, in clearance fit with the rear end of the slide valve rod and used for supporting the rear end of the slide valve rod; the connecting rod is arranged on the compressor body, in clearance fit with the front end of the slide valve rod, and for supporting the front end of the sliding valve rod; and the slide valve is connected with the slide valve rod, and keeps a preset distance with the compressor body. The refrigeration screw compressor comprises the compressor slide valve assembly. The compressor slide valve assembly and refrigeration screw compressor of the invention reduce the contact area and friction between the slide valve and the compressor body, and can effectively solve the problems of compressor slide valve cavity abrasion and noise.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com