Cavity mechanism

A cavity and forming mold technology, which is applied in the field of automatic box making machines, can solve the problems of inability to meet the needs of customers, and can not process and form unequal-sided carton boxes, and achieves good spraying and sticking effect. Wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

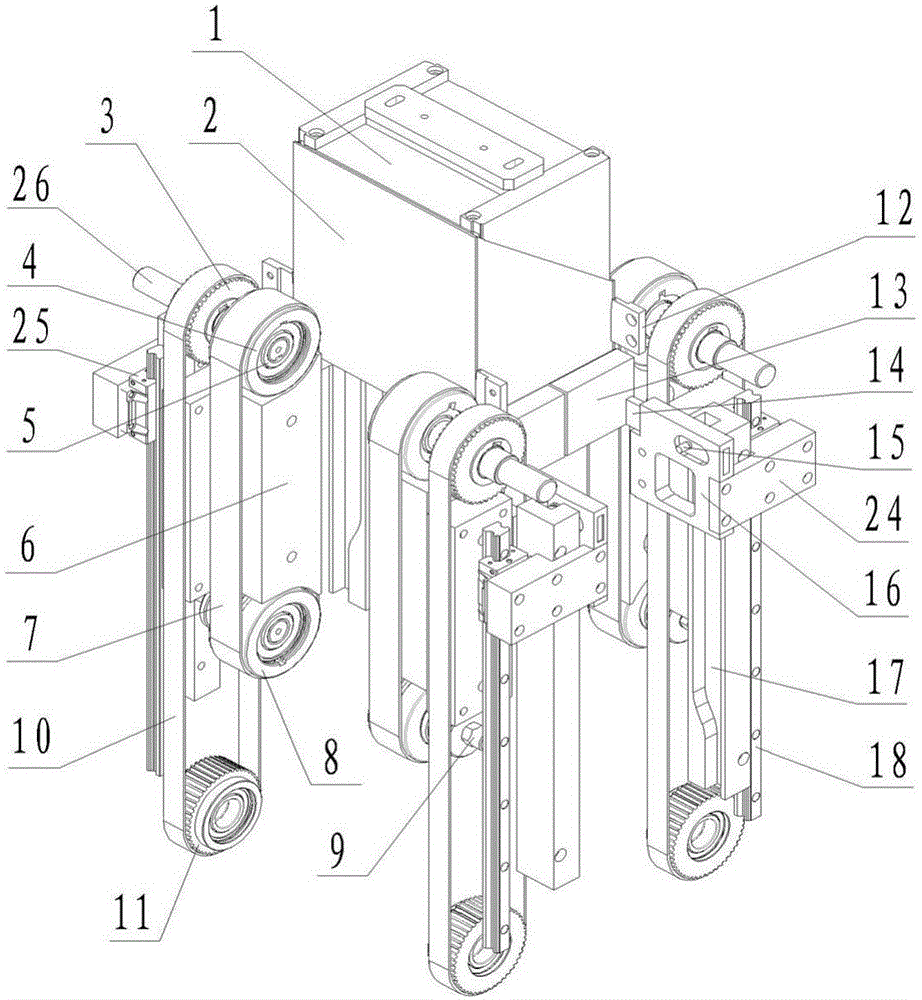

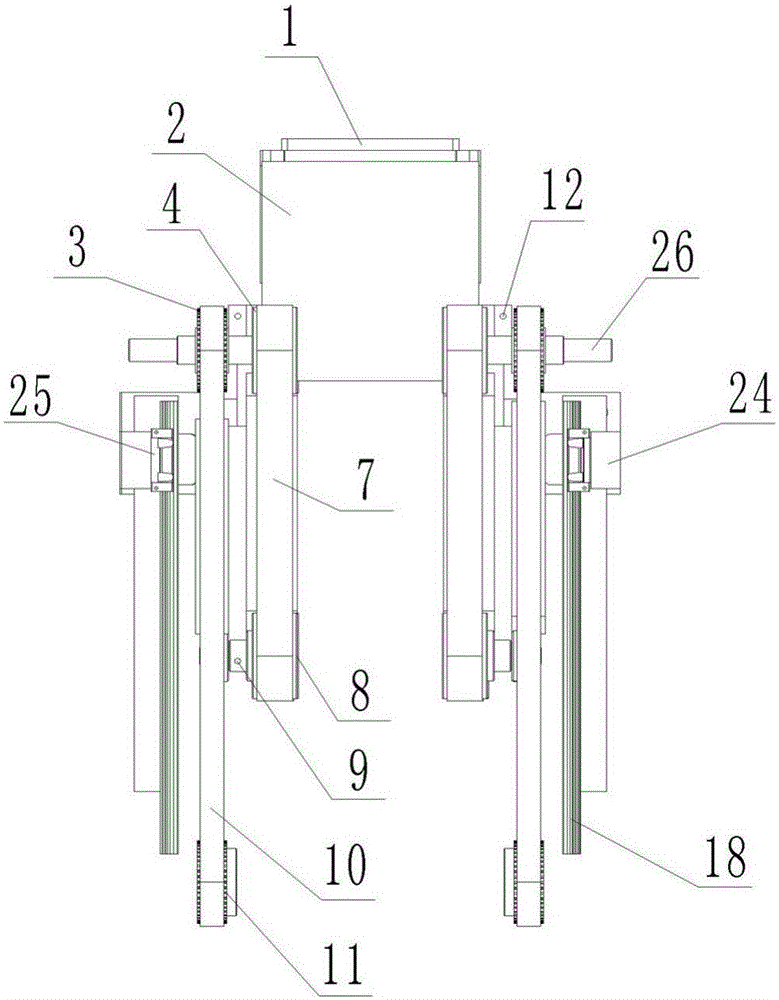

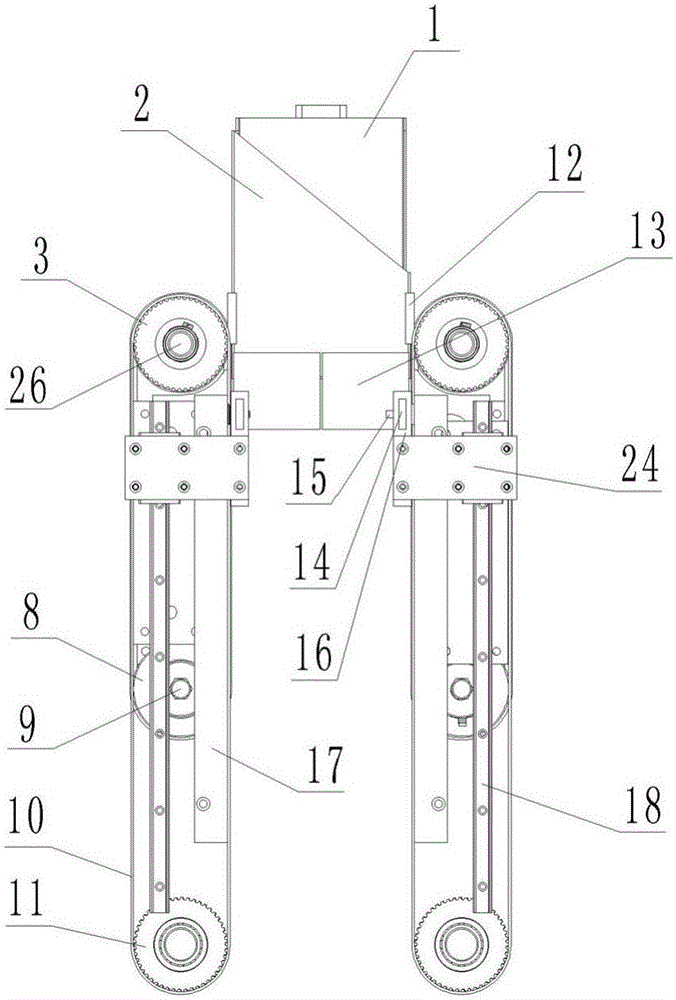

[0108] Such as Figure 1-38 As shown, the cavity mechanism includes a carton forming mold and a carton, the carton includes a main board and side plates, the main board includes a bottom plate 28 and a bending plate, and the bending plate includes a front bending plate 29 and a rear The bending plate 30, the side plate includes a left side plate 31 and a right side plate 32, and also includes four sets of belt drive assemblies and four sets of synchronous belt drive assemblies, and the four sets of belt drive assemblies are respectively connected to the front bending plate 29 and the rear bending plate 30 are bent and formed, each group of the synchronous belt transmission assembly is connected with each group of the belt transmission assembly through the main transmission shaft 26, and the synchronous belt transmission assembly includes Synchronous belt 10 and side plate support moving assembly, described side plate supporting moving assembly comprises two groups of left side...

Embodiment 2

[0113] The cavity mechanism is similar to that of Embodiment 1, except that the cylindrical surface guide rail adopts a concave guide rail.

Embodiment 3

[0115] The cavity mechanism is similar to Embodiment 1, except that the sliding friction guide rail adopts a prismatic guide rail, the prismatic surface guide rail adopts a triangular guide rail, and the triangular guide rail adopts a convex guide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com