Glass window dual-face cleaner

A technology for cleaners and glass windows, applied in cleaning equipment, window cleaning, household appliances, etc., can solve problems such as the inability to clean the glass outside the fully enclosed window, the difficulty in cleaning the window of the guardrail, and the difficulty in cleaning the glass, etc. The effect of saving labor cost and time cost, saving cleaning time and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

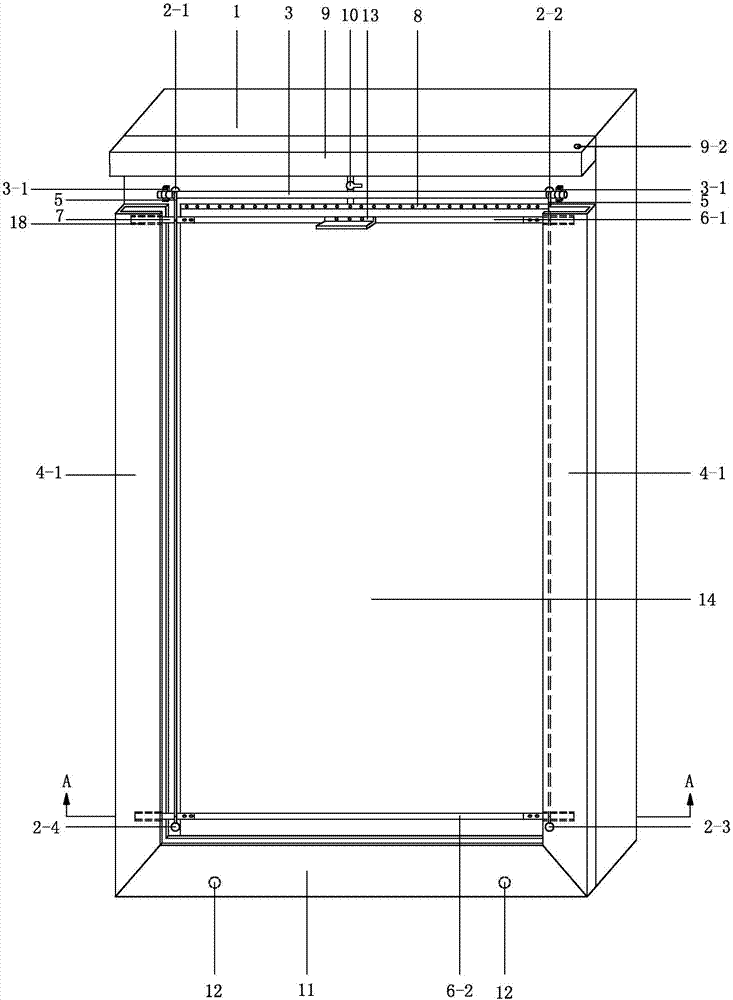

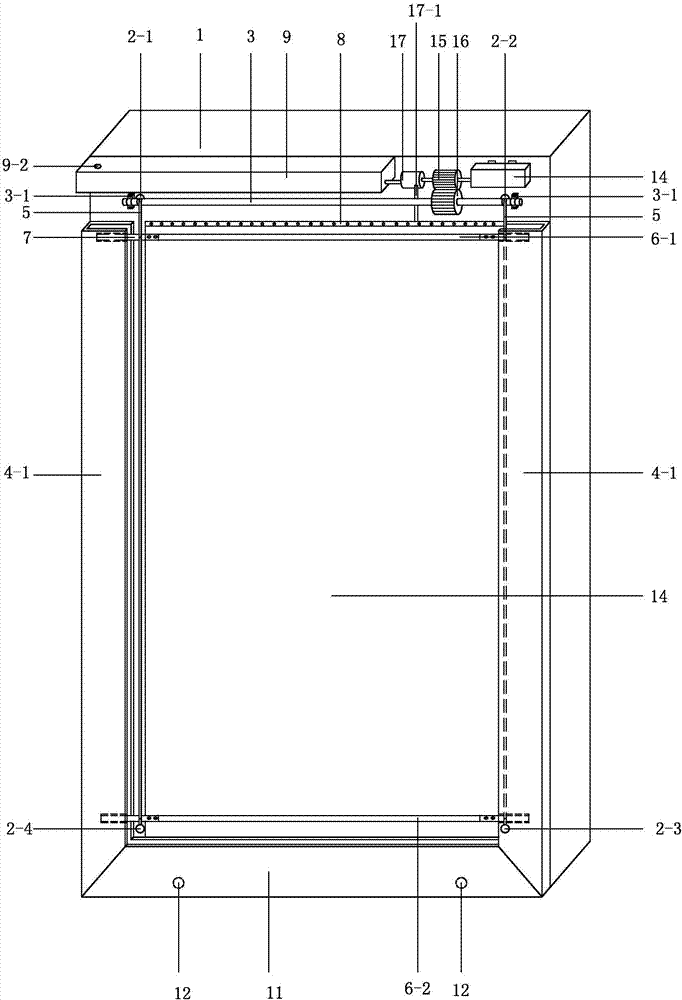

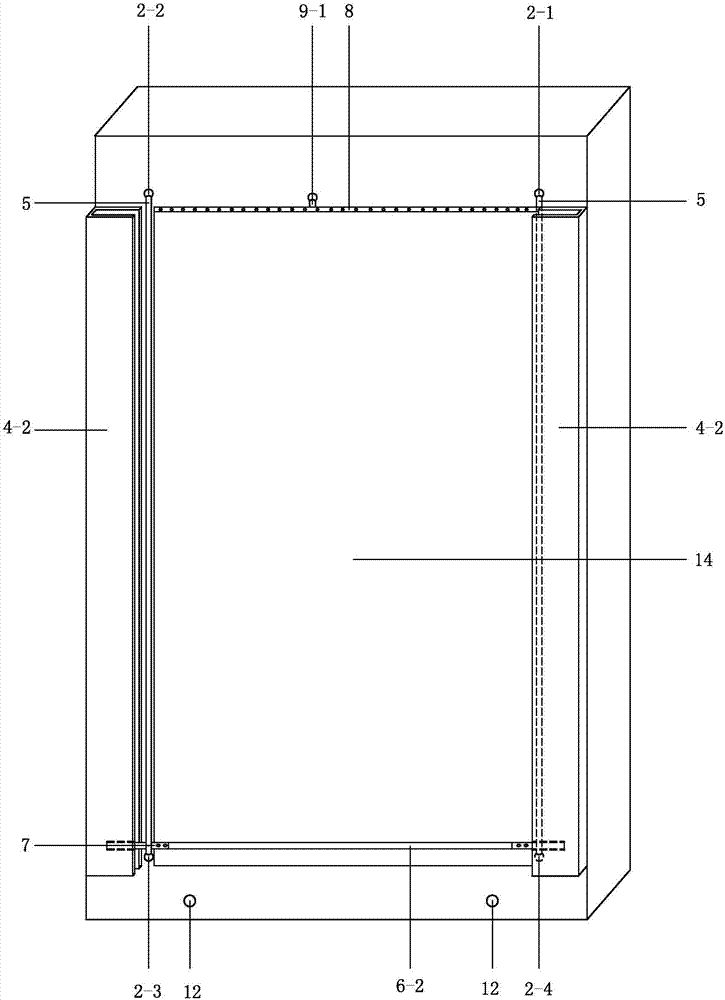

[0036] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a glass window double-sided cleaner in this embodiment, the cleaner is installed on the window frame 1, it includes a transmission shaft 3, a first wiper strip 6-1, a second wiper strip 6 -2, water tank 9, water spray switch 10, water tank water supply pipe 9-1, operating handle 13, two bearing blocks 3-1, two first U-shaped slideways 4-1, two second U-shaped slideways 4-2. Two transmission ropes 5, two shower pipes 8 and four elastic slides 7;

[0037]The four corners of the window frame 1 are sequentially provided with a first through hole 2-1, a second through hole 2-2, a third through hole 2-3 and a fourth through hole 2-4 in a clockwise direction. The hole 2-1 and the second through hole 2-2 lower edge are provided with a transmission shaft 3, and the two ends of the transmission shaft 3 are installed on the window frame 1 through two bearing seats 3-1, and the transmission...

specific Embodiment approach 2

[0042] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment also comprises sump 11, and sump 11 is installed in the inner lower part of window frame 1, and the bottom of window frame 1 offers two sewage discharge ports 12, and sump 11 communicates with two sewage discharge ports 12 . Set in this way, the function of the sump 11 is to collect the sewage flowing down from the cleaning glass and discharge it out of the window through the sewage discharge port 12 at the bottom of the window frame 1 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Specific implementation mode three: combination figure 1 , Figure 4 and Figure 5 Describe this embodiment, this embodiment also comprises a plurality of nylon sliders 18, and each side of one end that each elastic slider 7 is connected with the U-shaped slideway is affixed with a nylon slider 18, and the first wiper strip 6-1 and the second wiper strip 6-2 are slidably connected between the two first U-shaped slideways 4-1 and the two second U-shaped slideways 4-2 through a plurality of nylon sliders 18, respectively. In this way, a plurality of nylon sliders 18 can ensure that the first wiper strip 6-1 and the second wiper strip 6-2 move along the two first U-shaped slideways 4-1 and the two second U-shaped slideways. 4-2 Move up and down smoothly. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com